Content Menu

● Introduction

● What is an SMT Line AOI Factory?

● Key Benefits of SMT Line AOI Factories

>> Enhanced Quality Control

>> Increased Production Efficiency

>> Cost Reduction

>> Real-Time Monitoring and Feedback

>> Data-Driven Process Optimization

● Applications of AOI in SMT Lines

● Challenges and Future Trends

● Detailed Case Studies

>> Case Study 1: Telecommunications Equipment Manufacturer

>> Case Study 2: Automotive Electronics Supplier

● Types of Defects Detected by Modern Systems

● Traditional Manual Inspection vs Automated Solutions

● Continuous Improvement Methodologies

● Regulatory Compliance Challenges

● Emerging Technologies Enhancing Functionality

● Conclusion

● FAQ

>> 1. What is the role of AOI in SMT production?

>> 2. How does AOI improve production efficiency?

>> 3. What are the cost benefits of using AOI?

>> 4. Can AOI systems provide real-time feedback?

>> 5. What are the future trends in AOI technology?

Introduction

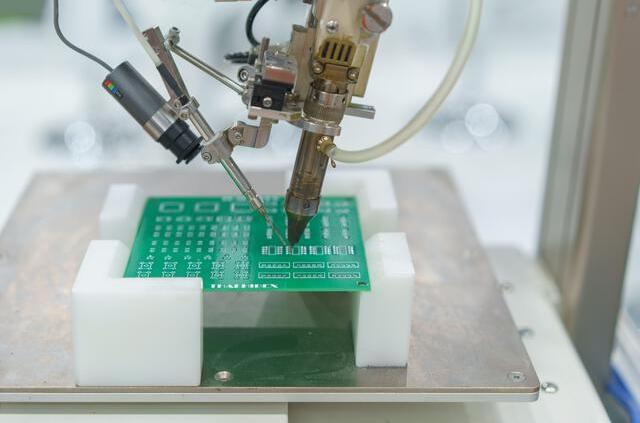

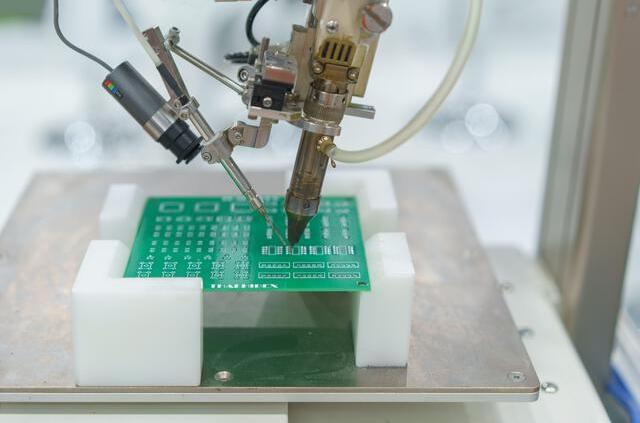

In the fast-evolving world of electronics manufacturing, the need for precision and efficiency has never been more critical. Surface Mount Technology (SMT) has become the standard for assembling electronic components onto printed circuit boards (PCBs). However, as the complexity of these assemblies increases, so does the demand for effective quality control measures. Automated Optical Inspection (AOI) systems have emerged as essential tools in SMT factories, providing a robust solution for ensuring product quality and enhancing production efficiency. This article explores the key benefits of integrating AOI systems into SMT production lines.

What is an SMT Line AOI Factory?

An SMT Line AOI Factory refers to a manufacturing facility that utilizes Surface Mount Technology for assembling electronic components and incorporates Automated Optical Inspection systems to monitor and ensure the quality of the assembly process.

- Surface Mount Technology (SMT) is a method where electronic components are mounted directly onto the surface of PCBs. This technology allows for higher component density and improved performance in electronic devices.

- Automated Optical Inspection (AOI) is a non-contact inspection method that uses high-resolution cameras and sophisticated image processing algorithms to detect defects in soldering and component placement on PCBs. By comparing captured images against predefined templates, AOI systems can identify issues such as misaligned components, insufficient solder, or other anomalies.

Key Benefits of SMT Line AOI Factories

Enhanced Quality Control

One of the primary advantages of implementing AOI in SMT factories is its ability to enhance quality control.

- Early Detection of Defects: AOI systems can swiftly identify defects early in the production process, reducing the likelihood of faulty products reaching customers. This proactive approach minimizes rework and scrap rates.

- Consistency: Unlike manual inspections, which can be prone to human error, AOI provides consistent and objective assessments, ensuring that each PCB meets quality standards.

- Comprehensive Inspection Capabilities: AOI systems can detect a wide range of defects, including missing components, incorrect polarity, solder bridges, and insufficient solder. This comprehensive inspection capability ensures that even minor defects are caught before they escalate into significant issues.

- Statistical Process Control: By integrating AOI data into statistical process control systems, manufacturers can monitor production trends over time. This allows for adjustments to be made proactively rather than reactively, further enhancing overall quality control.

Increased Production Efficiency

AOI systems significantly improve production efficiency by streamlining inspection processes.

- Speed: Automated inspections can occur at high speeds, allowing manufacturers to maintain fast production rates without sacrificing quality. AOI systems can inspect thousands of PCBs per hour, far surpassing manual inspection capabilities.

- Reduced Downtime: By integrating AOI into production lines, manufacturers can quickly identify issues that may cause downtime, enabling immediate corrective actions and minimizing disruptions.

- Inline Inspection Integration: Many modern AOI systems are designed to be integrated directly into the production line. This allows for real-time inspections immediately after critical processes like soldering, ensuring that defective products do not progress further down the line.

- Optimized Workflow: The integration of AOI allows for a smoother workflow by reducing bottlenecks associated with manual inspections. This leads to faster turnaround times from assembly to final product testing.

Cost Reduction

Implementing AOI technology leads to substantial cost savings for SMT factories.

- Labor Savings: With automated inspections reducing the need for manual checks, labor costs decrease significantly. This allows skilled workers to focus on more complex tasks rather than routine inspections.

- Minimized Rework Costs: Early detection of defects through AOI reduces the need for costly rework or scrapping of defective products. This not only saves money but also enhances overall productivity.

- Long-Term Investment Returns: Although the initial investment in AOI technology may be significant, the long-term savings from reduced defects and improved efficiency often justify this expenditure. Manufacturers can expect a return on investment through enhanced product quality and reduced operational costs over time.

- Lower Warranty Costs: By improving product quality through effective inspection processes, manufacturers may experience lower warranty claims from customers due to fewer defective products being shipped.

Real-Time Monitoring and Feedback

AOI systems provide real-time monitoring capabilities that are invaluable in modern manufacturing environments.

- Instant Feedback: By continuously analyzing production data, AOI systems can provide immediate feedback to operators about defects or process inefficiencies. This allows for timely adjustments to be made during production runs.

- Process Improvement Insights: The data collected by AOI systems can be analyzed to identify trends and recurring issues in the manufacturing process. This leads to long-term improvements in efficiency and quality by enabling manufacturers to address root causes rather than just symptoms.

- Integration with Manufacturing Execution Systems (MES): Many factories integrate AOI data with their MES platforms to create a comprehensive view of production performance. This integration helps managers make informed decisions based on real-time data.

Data-Driven Process Optimization

The integration of AOI technology facilitates data-driven decision-making in SMT factories.

- Historical Data Analysis: AOI systems collect vast amounts of data during inspections, which can be utilized for analyzing past performance. This information helps engineers identify bottlenecks and optimize production processes over time.

- Predictive Maintenance: By monitoring equipment performance through AOI data, manufacturers can anticipate maintenance needs before failures occur, thereby reducing unexpected downtime and maintenance costs.

- Enhanced Traceability: With detailed records generated by AOI systems regarding defect types and frequencies, manufacturers can improve traceability throughout their production processes—facilitating compliance with industry regulations and standards.

Applications of AOI in SMT Lines

The applications of AOI in SMT lines are diverse and critical to maintaining high-quality standards:

- Solder Joint Inspection: AOI systems are used to inspect solder joints for defects such as cold solder joints or bridging that could lead to circuit failures.

- Component Placement Verification: They ensure that components are placed correctly on PCBs by checking their alignment and orientation against specified parameters.

- Solder Paste Inspection: Before components are placed on PCBs, AOI can inspect solder paste application to ensure it meets required specifications for volume and placement accuracy.

- Final Assembly Inspection: In addition to inspecting individual components during assembly, some factories use AOI at final assembly stages to ensure complete assemblies meet quality standards before shipping out products.

Challenges and Future Trends

While the benefits of AOI are clear, there are challenges associated with its implementation:

- Initial Investment Costs: The upfront costs associated with purchasing and integrating advanced AOI systems can be significant. However, these costs are often offset by long-term savings in labor and rework.

- Complexity of Setup: Setting up AOI systems requires careful calibration and programming to ensure accurate inspections. Manufacturers must invest time in training personnel to operate these systems effectively.

Looking ahead, several trends are shaping the future of AOI technology:

- Integration with AI: The incorporation of artificial intelligence into AOI systems promises enhanced defect detection capabilities through machine learning algorithms that adapt over time. AI can help reduce false rejects by learning from historical data patterns.

- 3D Inspection Technologies: The development of 3D AOI systems enables more comprehensive inspections by providing volumetric information about components and solder joints. This advancement improves accuracy by allowing inspectors to evaluate height variations that could indicate potential issues not detectable with 2D imaging alone.

Detailed Case Studies

To illustrate the effectiveness of AOI in PCB and SMT production lines further:

Case Study 1: Telecommunications Equipment Manufacturer

A telecommunications equipment manufacturer implemented 3D AOI systems in their SMT production line to improve product quality significantly. The system effectively detected defects such as insufficient solder joints—previously challenging to identify through manual inspections—leading to a marked reduction in rework costs from approximately $100k annually down to $20k post-AOI implementation due to improved defect detection rates.

| Defect Type | Before Implementation | After Implementation |

| Insufficient Solder | 2.5% | 0.8% |

| Lifted Leads | 1.8% | 0.5% |

| Tombstoning | 1.2% | 0.3% |

By reducing these defect rates significantly through early detection capabilities offered by their new system configuration—combined with operator training—the manufacturer was able to enhance overall customer satisfaction while simultaneously reducing operational costs associated with defective product returns.

Case Study 2: Automotive Electronics Supplier

An automotive electronics supplier implemented inline 2D AOI systems within their PCB assembly line specifically targeting defects early during assembly processes—such as solder bridges or incorrect component placements—to prevent defective products from reaching later stages:

| Defect Type | Before Implementation | After Implementation |

| Solder Bridges | 3.2% | 1.1% |

| Component Absence | 1.5% | 0.4% |

| Incorrect Component Placement | 2.1% | 0.7% |

This proactive approach not only minimized rework costs but also improved overall yield rates across their product lines—demonstrating how strategically integrating advanced inspection technologies like AI-enhanced inline inspection solutions fosters both operational excellence while ensuring compliance with stringent automotive safety standards.

Types of Defects Detected by Modern Systems

Modern Automated Optical Inspection (AOI) technologies have evolved significantly since their inception—now capable of detecting an extensive range of potential defects including but not limited to:

- Misalignment or skewed components

- Missing or misplaced parts

- Insufficient or excessive solder application

- Solder bridges between adjacent pads

- Component polarity errors

- Surface irregularities such as scratches or stains

As electronic devices continue becoming more compact—often featuring intricate designs—the ability for advanced imaging algorithms within both traditional two-dimensional (2D) setups alongside newer three-dimensional (3D) configurations ensures even minute discrepancies do not go unnoticed during routine inspections.

Traditional Manual Inspection vs Automated Solutions

While traditional manual inspection methods have served industries well over decades past—relying heavily upon human operators' visual acuity—the inherent limitations associated with fatigue-induced errors make them less viable within today's fast-paced manufacturing environments where precision remains paramount:

| Criteria | Manual Inspection | Automated Optical Inspection |

| Speed | Slower | High-speed |

| Consistency | Variable | Consistent |

| Error Rate | Higher due to fatigue | Lower due to automation |

| Data Collection | Limited | Extensive |

The transition towards automated optical inspection represents not only an evolution towards increased accuracy but also reflects broader industry trends emphasizing lean manufacturing principles aimed at maximizing throughput while minimizing waste throughout production cycles.

Continuous Improvement Methodologies

Integrating continuous improvement methodologies such as Six Sigma alongside advanced inspection technologies like Automated Optical Inspection enhances overall operational effectiveness across electronic manufacturing environments:

- Utilizing statistical analysis derived from defect data collected via automated inspections enables teams tasked with process improvement initiatives pinpoint specific areas requiring attention—be it adjustments made during assembly procedures or modifications applied at upstream supply chain levels.

- By fostering a culture centered around continuous improvement—where employees actively engage identifying inefficiencies within existing workflows—manufacturers stand better positioned adaptively respond evolving market demands while maintaining high-quality output standards.

Regulatory Compliance Challenges

In an era where regulatory scrutiny surrounding product safety remains heightened across sectors ranging from consumer electronics automotive applications—ensuring compliance becomes paramount:

Automated Optical Inspection provides manufacturers robust mechanisms facilitating adherence regulatory mandates governing product safety requirements through precise detection capabilities ensuring defective items do not inadvertently enter circulation.

Emerging Technologies Enhancing Functionality

As we look towards future advancements shaping landscape surrounding automated optical inspection technologies—emerging innovations such as Internet-of-things (IoT) integration promise further enhancements functionality:

Real-time connectivity between machines allows seamless communication throughout entire production lines enabling rapid identification corrective actions needed if deviations arise during assembly processes resulting ultimately greater efficiencies achieved across operations.

Conclusion

In conclusion, integrating Automated Optical Inspection (AOI) into SMT line factories offers numerous benefits that enhance quality control while increasing production efficiency through cost reductions alongside real-time monitoring capabilities backed by data-driven optimizations—all crucial elements fostering sustainable growth within competitive electronics markets today!

With advancements continuing emerge—from artificial intelligence integration improving defect detection capabilities—to three-dimensional imaging providing unparalleled insights into complex assemblies—the role played by automated optical inspection will undoubtedly expand further ensuring every circuit produced meets towering standards demanded modern technological landscapes!

FAQ

1. What is the role of AOI in SMT production?

AOI ensures quality by detecting defects in soldering and component placement during the assembly process.

2. How does AOI improve production efficiency?

By automating inspection processes, AOI reduces the time spent on manual checks and minimizes errors associated with human inspection.

3. What are the cost benefits of using AOI?

AOI reduces rework and labor costs by identifying issues early in the manufacturing process before they escalate into larger problems.

4. Can AOI systems provide real-time feedback?

Yes, AOI systems monitor production continuously and provide instant feedback for necessary adjustments during assembly operations.

5. What are the future trends in AOI technology?

Future trends include integration with AI for smarter defect detection and advancements in 3D inspection technologies for enhanced accuracy in assessments.