Content Menu

● Understanding SMT Lines

● Initial Setup Costs

● Operational Costs

● Factors Influencing SMT Line Costs

● Cost-Saving Strategies

● Advantages of Using SMT Lines

● Conclusion

● FAQ

>> 1. What is an SMT line?

>> 2. How much does a pick-and-place machine cost?

>> 3. What are the main components of an SMT line?

>> 4. Are there ongoing costs associated with operating an SMT line?

>> 5. How can factories reduce costs associated with SMT lines?

● Citations:

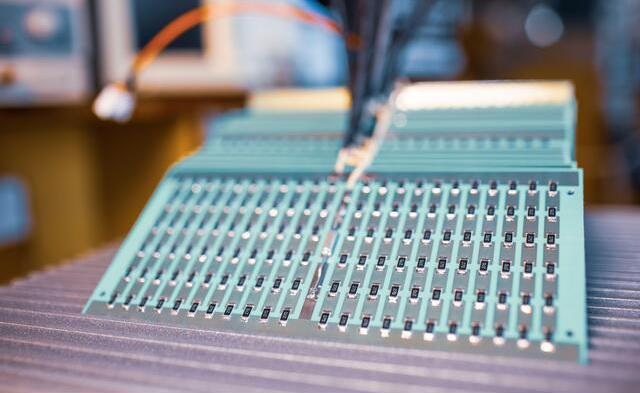

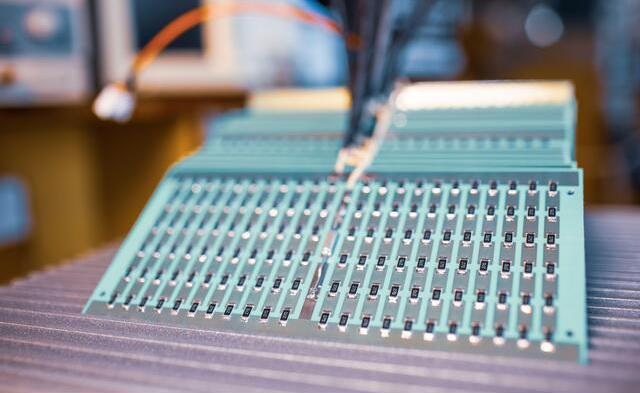

Surface Mount Technology (SMT) lines are essential for modern electronics manufacturing, allowing for the efficient and precise assembly of electronic components onto printed circuit boards (PCBs). Understanding the costs associated with setting up and maintaining an SMT line is crucial for factories aiming to optimize their production processes. This article explores the various costs involved in SMT line machines, including equipment, installation, training, and ongoing operational expenses.

Understanding SMT Lines

SMT lines consist of several key machines that work together to assemble electronic components onto PCBs. The primary machines in an SMT line include:

- Pick and Place Machines: These are responsible for placing surface mount devices (SMDs) onto the PCB with high precision.

- Solder Paste Printers: These machines apply solder paste to designated areas on the PCB where components will be placed.

- Reflow Ovens: After components are placed, reflow ovens melt the solder paste to create electrical connections.

- Inspection Systems: Automated Optical Inspection (AOI) systems check for defects in the assembly process.

The costs associated with these machines can vary significantly based on their capabilities, brand, and whether they are new or used.

Initial Setup Costs

Setting up an SMT line involves substantial initial investment. Here are the primary cost components:

- Equipment Costs: The price of individual machines can range widely. For instance:

- Entry-level pick and place machines may cost between $20,000 and $50,000.

- Mid-range machines can range from $50,000 to $150,000.

- High-end machines designed for high-volume production can exceed $150,000.

- Complete SMT Line Costs: A fully equipped SMT line can cost anywhere from $100,000 to over $8 million depending on the complexity and capability of the equipment. For example, a high-volume production line might be priced around $607,995 plus additional costs for feeders and setup.

- Installation Costs: Setting up the facility to accommodate SMT equipment may require modifications such as enhanced ventilation systems, power supply upgrades, and cleanliness standards compliance. These costs can add thousands to the overall budget.

Operational Costs

Once an SMT line is established, ongoing operational costs must be considered:

- Material Costs: This includes the price of electronic components, solder paste, and other consumables. Fluctuations in market prices can significantly impact these expenses.

- Labor Costs: While automation reduces labor needs, skilled operators are still required. Training costs for staff can be significant but are necessary for efficient operation.

- Maintenance Costs: Regular maintenance is crucial for preventing breakdowns that can lead to costly downtime. Maintenance expenses may include routine inspections and parts replacements.

- Energy Costs: SMT lines consume substantial energy, particularly during reflow soldering. Implementing energy-efficient practices can help mitigate these costs over time.

Factors Influencing SMT Line Costs

Several factors influence the overall cost of setting up and operating an SMT line:

- Component Complexity: The complexity of the PCB design directly affects costs. More intricate designs require advanced machinery and skilled technicians, increasing assembly costs.

- Production Volume: Larger production volumes benefit from economies of scale, reducing per-unit costs. Conversely, smaller batches face higher prices due to inefficiencies in lower production volumes.

- Geographic Location: The location of the manufacturing facility can impact labor rates and material availability, influencing overall costs.

- Type of Components Used: The choice between surface mount and through-hole components also affects cost dynamics. Generally, SMT components are more cost-effective due to lower labor requirements during assembly.

Cost-Saving Strategies

To manage and reduce costs associated with SMT lines effectively, factories can adopt several strategies:

- Optimize Production Processes: Streamlining workflows and reducing setup times can enhance efficiency and reduce waste. Implementing lean manufacturing principles is beneficial.

- Invest in Advanced Technology: Modern SMT equipment often features automation and advanced software that improve precision and throughput. Although these technologies may have a higher upfront cost, they can lead to long-term savings through increased productivity.

- Negotiate with Suppliers: Building strong relationships with suppliers can lead to better pricing on materials through bulk purchasing agreements or negotiated discounts.

Advantages of Using SMT Lines

The adoption of SMT lines brings numerous advantages that contribute to their popularity in electronics manufacturing:

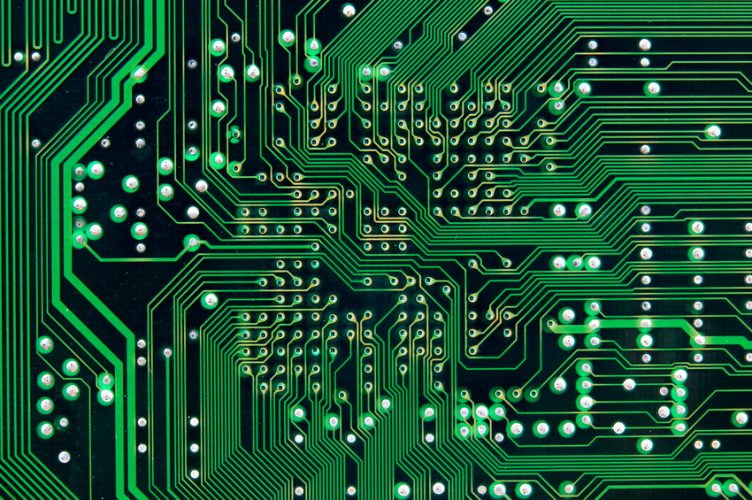

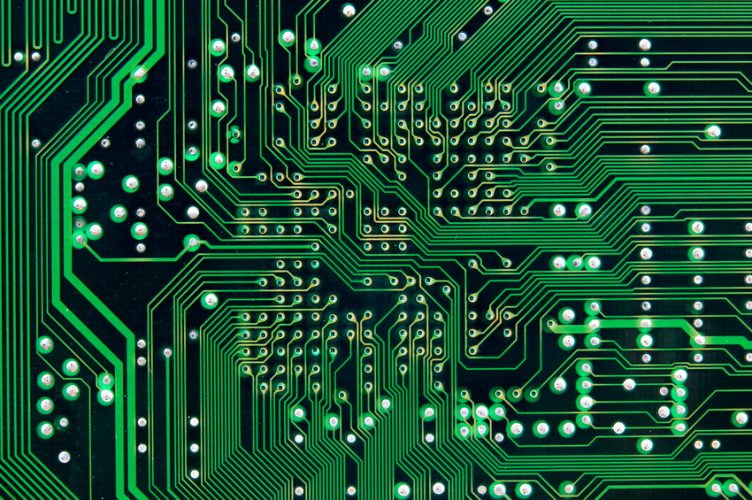

- Increased Component Density: SMT allows for a higher density of components on PCBs due to smaller sizes compared to traditional through-hole technology. This results in more compact devices that are essential in modern electronics like smartphones and wearables.

- Enhanced Production Speed: Automation in SMT lines significantly speeds up production cycles compared to manual assembly methods. This efficiency translates into lower labor costs and faster time-to-market for products.

- Improved Quality Control: Automated systems reduce human error during assembly processes. Additionally, integrated inspection systems ensure that defects are identified early in production.

- Flexibility in Design: SMT accommodates a wide range of component types and sizes, allowing manufacturers to adapt quickly to changing market demands or product designs.

Conclusion

The costs associated with SMT line machines for factories vary widely based on equipment type, installation needs, operational expenses, and maintenance requirements. While initial setup costs can be substantial—ranging from tens of thousands to millions of dollars—factories can achieve significant long-term savings by optimizing production processes and investing in advanced technology. Understanding these costs is essential for making informed decisions that enhance efficiency and profitability in electronics manufacturing. As technology continues to evolve, staying abreast of advancements will be vital for maintaining competitiveness in this dynamic industry.

FAQ

1. What is an SMT line?

An SMT line is a production setup used in electronics manufacturing that employs Surface Mount Technology to assemble electronic components onto printed circuit boards (PCBs).

2. How much does a pick-and-place machine cost?

Pick-and-place machines vary in price from approximately $20,000 for entry-level models to over $150,000 for high-end machines designed for high-volume production.

3. What are the main components of an SMT line?

The main components include pick-and-place machines, solder paste printers, reflow ovens, and inspection systems.

4. Are there ongoing costs associated with operating an SMT line?

Yes, ongoing costs include material expenses (like electronic components), labor costs for skilled operators, maintenance expenses for equipment upkeep, and energy consumption during operation.

5. How can factories reduce costs associated with SMT lines?

Factories can reduce costs by optimizing production processes through lean manufacturing principles, investing in advanced technology that enhances efficiency, and negotiating better terms with suppliers.

Citations:

[1] https://www.hayawin.com/resources/smt-line-an-efficient-and-cost-effective-production-line.html

[2] https://www.smtfactory.com/Essential-Steps-for-SMT-Production-Line-Setup-id49117676.html

[3] https://reprosupplies.co.za/what-factors-influence-the-cost-of-an-smt-assembly-project/

[4] https://www.manncorp.com/pages/smt-assembly-lines

[5] https://www.viasion.com/blog/smt-manufacturing-process-step-by-step-guide/

[6] https://iconnect007.com/index.php/article/46082/cost-of-ownership-considerations/46085?skin=smt

[7] https://www.pcbasic.com/blog/smt_production_line.html

[8] https://ventureoutsource.com/contract-manufacturing/setting-up-electronics-manufacturing-smt-pcb-assembly-lines/

[9] https://www.smtfactory.com/Exploring-SMT-Line-Cost-Factors-and-Savings-id43117676.html

[10] https://faroads.com/start-smt-line-guide-2024/

[11] https://www.itechsmt.com/blogs/news/smt-machine-cost

[12] https://www.smtfactory.com/Perfecting-Your-SMT-Line-Layout-for-Efficiency-id47017676.html

[13] https://pcbandassembly.com/blog/smt-assembly-cost-analysis-and-optimization-strategy/

[14] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[15] https://alimco.in/WriteReadData/UserFiles/file/Specification3MR3.pdf

[16] https://geospacemfg.com/blog/smt-assembly-technology/

[17] https://www.viasion.com/blog/smt-assembly-explained-an-introductory-guide-for-beginners/

[18] https://www.wevolver.com/article/smt-process

[19] https://www.linkedin.com/pulse/ins-outs-setting-up-smt-factory-prototype-pcb-assembly-yljdc

[20] https://www.7pcb.com/blog/factors-affecting-cost-pcb-assembly

[21] https://www.linkedin.com/pulse/what-factors-affect-quality-smt-patch-processing-cost-%E6%81%92-%E6%9D%8E-4ytuc