Content Menu

● Understanding SMT Assembly Lines

● Cost Savings Breakdown

>> 1. Labor Cost Reduction

>> 2. Increased Production Efficiency

>> 3. Improved Quality Control

>> 4. Material Waste Reduction

>> 5. Long-Term Financial Benefits

● Additional Considerations

>> 1. Initial Investment vs. Long-Term Savings

>> 2. Training and Adaptation

>> 3. Maintenance Costs

>> 4. Flexibility and Adaptability

>> 5. Environmental Impact

● Conclusion

● FAQs

>> 1. What is an SMT assembly line?

>> 2. How does automation reduce labor costs in SMT?

>> 3. What are the key components of an automatic SMT assembly line?

>> 4. How does automation improve product quality?

>> 5. What is the typical return on investment (ROI) for an automated SMT line?

In the rapidly evolving landscape of electronics manufacturing, Surface Mount Technology (SMT) has emerged as a game-changer. The shift towards fully automated SMT assembly lines has not only transformed production processes but also brought significant cost savings to manufacturers. This article explores the various dimensions of cost savings associated with using a full automatic SMT assembly line, including labor reduction, increased efficiency, improved quality control, and long-term financial benefits.

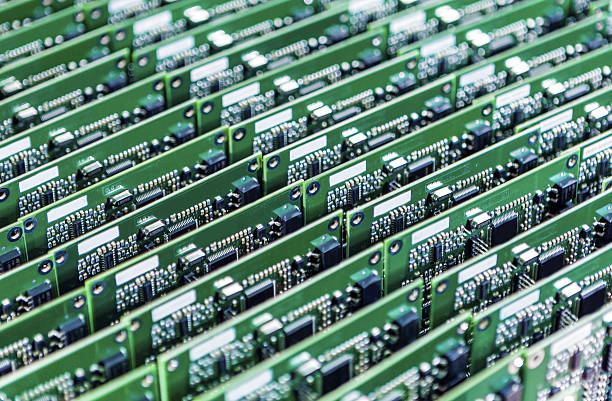

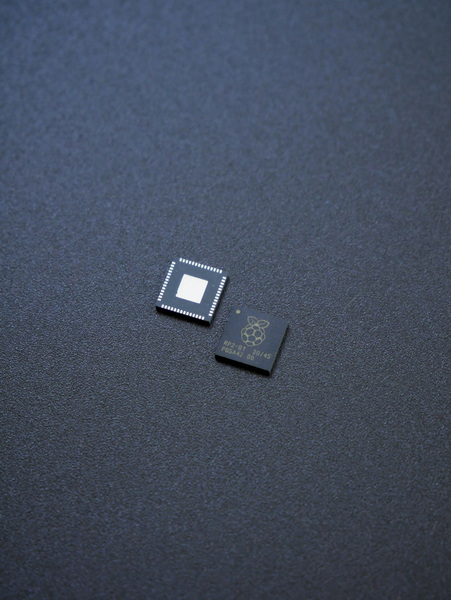

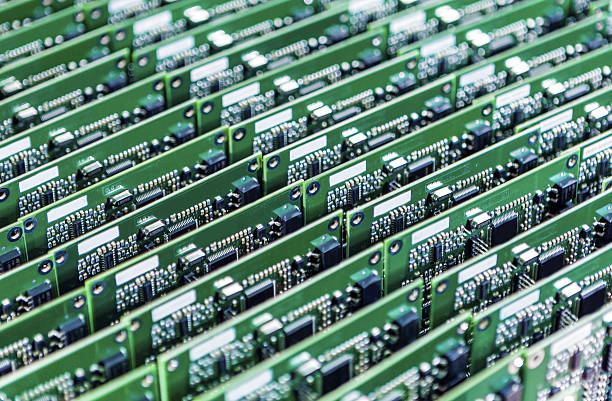

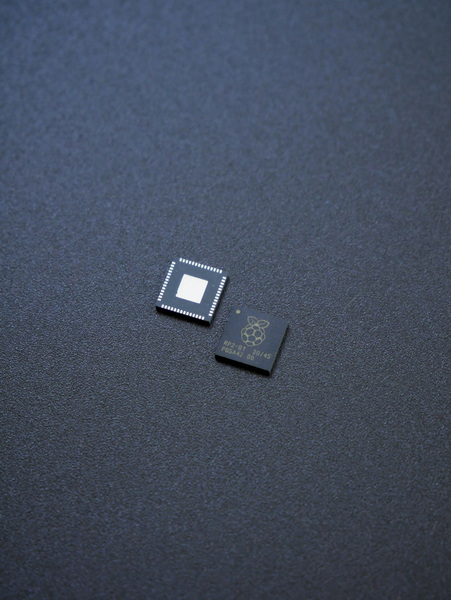

Understanding SMT Assembly Lines

SMT is a method for producing electronic circuits in which the components are mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, which requires drilling holes in the PCB, SMT allows for higher component density and smaller board sizes. This technology is particularly suited for mass production due to its speed and efficiency.

A full automatic SMT assembly line typically consists of several interconnected machines that work seamlessly to automate the entire assembly process. Key components of an SMT line include:

- Stencil Printer: Applies solder paste to the PCB.

- Pick and Place Machine: Accurately places components on the PCB.

- Reflow Oven: Melts solder paste to create electrical connections.

- Automated Optical Inspection (AOI): Inspects the assembled boards for defects.

Cost Savings Breakdown

The cost savings associated with a full automatic SMT assembly line can be categorized into several key areas:

1. Labor Cost Reduction

One of the most significant advantages of automating the SMT assembly process is the reduction in labor costs. Traditional manual assembly processes require a considerable workforce, which can be expensive due to wages, benefits, and training costs. In contrast:

- Automation minimizes human intervention, allowing machines to perform repetitive tasks continuously without breaks.

- Reduced reliance on skilled labor: Automated systems can be programmed easily, reducing the need for highly skilled operators.

This shift not only lowers direct labor costs but also mitigates expenses related to employee turnover and training.

Furthermore, companies can allocate their human resources more effectively by focusing on higher-value tasks such as design, engineering, and strategic planning rather than manual assembly processes. This leads to a more skilled workforce that can contribute to innovation and improvement in other areas of the business.

2. Increased Production Efficiency

Automated SMT lines enhance production efficiency in several ways:

- Higher Throughput: Automated machines can operate at much faster speeds than manual laborers. For instance, pick-and-place machines can place thousands of components per hour.

- Shorter Lead Times: Automation reduces cycle times, enabling manufacturers to meet tight deadlines and respond quickly to market demands.

- Continuous Operation: Unlike human workers who require breaks and downtime, automated systems can run 24/7, significantly increasing output.

These efficiencies translate into lower per-unit costs as production scales up. Moreover, automated systems often include advanced features such as real-time monitoring and data analytics that help identify bottlenecks in production processes. This enables manufacturers to make immediate adjustments to optimize performance further.

3. Improved Quality Control

Quality assurance is critical in electronics manufacturing. Automated systems enhance quality control through:

- Precision Placement: Automated pick-and-place machines ensure that components are placed accurately, reducing defects caused by human error.

- Real-Time Inspection: Automated Optical Inspection (AOI) systems can detect defects during production, allowing for immediate corrections before products move forward in the assembly line.

The result is a higher yield rate and fewer defective products, which can lead to substantial cost savings associated with rework and returns. Additionally, many automated systems come equipped with machine learning capabilities that allow them to learn from past errors and improve their accuracy over time.

4. Material Waste Reduction

Automation helps minimize material waste in several ways:

- Accurate Solder Paste Application: Stencil printers apply solder paste precisely where needed, reducing excess material usage.

- Efficient Component Usage: Automated systems optimize component placement on PCBs, maximizing space utilization and minimizing scrap.

By reducing waste, manufacturers can significantly lower material costs over time. Furthermore, many modern SMT lines incorporate features like predictive maintenance that help avoid equipment failures that could lead to material loss during production.

5. Long-Term Financial Benefits

While the initial investment in a full automatic SMT assembly line can be substantial—often ranging from hundreds of thousands to millions of dollars—the long-term financial benefits are compelling:

- Return on Investment (ROI): Many companies report achieving ROI within a few years due to reduced operational costs and increased production capacity.

- Scalability: Automated lines are highly scalable; as demand increases, manufacturers can ramp up production without proportionally increasing labor costs.

- Competitive Advantage: Companies that adopt automation often gain a competitive edge through lower prices and faster delivery times, attracting more customers and increasing market share.

Moreover, as technology continues to advance, automated systems are becoming more affordable and accessible for small and medium-sized enterprises (SMEs). This democratization of technology allows more companies to benefit from automation without prohibitive upfront investments.

Additional Considerations

While the advantages of full automatic SMT assembly lines are clear, there are additional considerations that manufacturers should keep in mind when evaluating this transition:

1. Initial Investment vs. Long-Term Savings

The transition to an automated system requires careful financial planning. While initial costs may be high, manufacturers must weigh these against long-term savings from reduced labor costs, increased efficiency, and improved quality control. A detailed cost-benefit analysis can help organizations understand their potential ROI better.

2. Training and Adaptation

Transitioning from manual processes to automation may require training for existing staff or hiring new employees with specialized skills. It's essential to invest in training programs that will help staff adapt to new technologies effectively while ensuring smooth integration into existing workflows.

3. Maintenance Costs

Automated systems require regular maintenance to ensure optimal performance. Manufacturers should factor in these ongoing costs when planning their budgets. Predictive maintenance technologies can help mitigate unexpected downtime by alerting operators about potential issues before they become critical failures.

4. Flexibility and Adaptability

As market demands change rapidly, manufacturers need flexible solutions that allow them to adapt quickly without extensive reconfiguration or downtime. Modern automated SMT lines often feature modular designs that enable manufacturers to switch between different product types with relative ease.

5. Environmental Impact

Finally, organizations should consider the environmental implications of their manufacturing processes. Automation can lead to reduced energy consumption due to optimized operations and minimized waste generation through precise material usage. Sustainable practices not only benefit the environment but also enhance brand reputation among increasingly eco-conscious consumers.

Conclusion

The transition to a full automatic SMT assembly line represents a significant opportunity for manufacturers seeking to reduce costs while enhancing efficiency and quality. By minimizing labor expenses, increasing production throughput, improving quality control, reducing material waste, and realizing long-term financial benefits, companies can position themselves favorably in a competitive marketplace. As technology continues to advance and become more accessible, embracing automation will likely become essential for success in electronics manufacturing.

FAQs

1. What is an SMT assembly line?

An SMT assembly line is an automated system used for assembling electronic components onto printed circuit boards (PCBs) using surface mount technology.

2. How does automation reduce labor costs in SMT?

Automation reduces labor costs by minimizing the need for manual intervention in repetitive tasks, allowing machines to operate continuously without breaks or downtime.

3. What are the key components of an automatic SMT assembly line?

Key components include stencil printers for solder paste application, pick-and-place machines for component placement, reflow ovens for soldering, and automated optical inspection systems for quality control.

4. How does automation improve product quality?

Automation improves product quality by ensuring precise placement of components and enabling real-time inspection during production to catch defects early.

5. What is the typical return on investment (ROI) for an automated SMT line?

While ROI varies by company and market conditions, many manufacturers report achieving ROI within two to three years due to reduced operational costs and increased production capacity.