Content Menu

● What Is a Manual Pick and Place Machine for SMD Components?

● Key Cost Considerations

>> 1. Initial Purchase Price

>> 2. Features and Specifications

>> 3. Operational Costs

>> 4. Training and Labor Efficiency

>> 5. Accessories and Customization

● Advantages of Manual Pick and Place Machines

>> 1. Cost-Effectiveness for Small Batches

>> 2. Precision and Error Reduction

>> 3. Scalability

● Factors Influencing the Total Cost of Ownership (TCO)

>> 1. Durability and Lifespan

>> 2. Resale Value

>> 3. Support and Community

● How to Choose the Right Machine

>> Step 1: Assess Your Needs

>> Step 2: Compare Brands

>> Step 3: Calculate ROI

● Case Study: Reducing Prototyping Costs with a Manual Pick and Place Machine

● Conclusion

● FAQs

>> 1. What Are the Typical Costs of a Manual Pick and Place Machine?

>> 2. Is a Manual Pick and Place Machine Suitable for Prototyping?

>> 3. How Do Vision Systems Impact Costs?

>> 4. What Maintenance Is Required?

>> 5. Can Manual Machines Handle Fine-Pitch Components?

Investing in a manual pick and place machine for SMD components can be a strategic decision for small-scale manufacturers, prototyping labs, and businesses looking to optimize their assembly processes. However, understanding the cost considerations is critical to ensure the investment aligns with your operational and financial goals. This article explores the key factors influencing the cost of manual pick and place machines, their advantages, and how to make an informed purchasing decision.

What Is a Manual Pick and Place Machine for SMD Components?

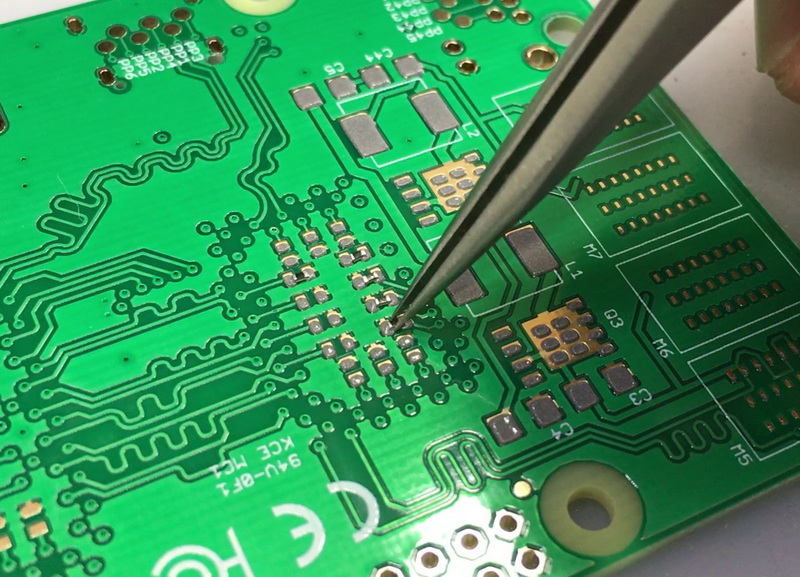

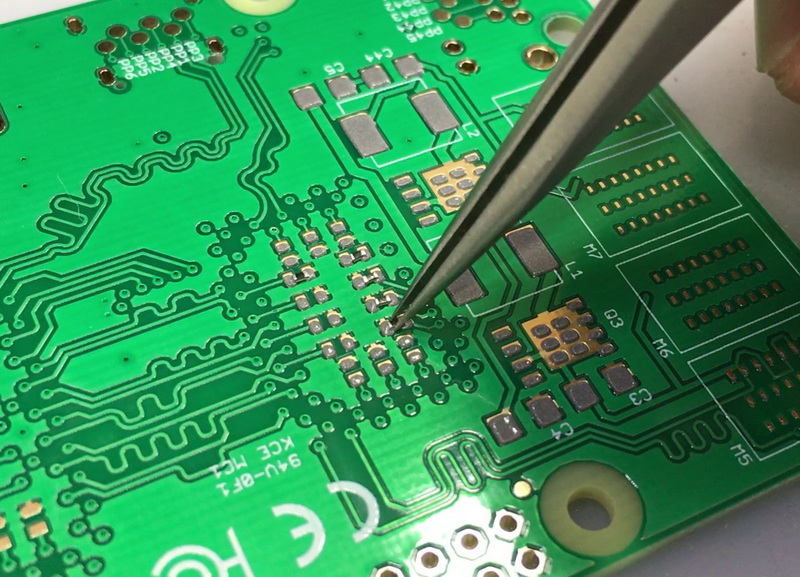

A manual pick and place machine is a device designed to assist operators in placing surface-mount devices (SMD) onto printed circuit boards (PCBs) with precision. Unlike fully automated systems, these machines rely on human input for operation but offer features such as vacuum-assisted placement, X-Y axis movement, and ergonomic designs to improve accuracy and reduce operator fatigue. They are particularly suitable for:

- Prototyping: Ideal for testing new PCB designs without high setup costs.

- Low-volume production: Cost-effective for batches under 1,000 units.

- Custom PCB assembly: Flexibility to handle mixed component types, including resistors, capacitors, and ICs.

These machines bridge the gap between fully manual assembly and expensive automated systems, making them a practical choice for businesses prioritizing affordability and adaptability.

Key Cost Considerations

1. Initial Purchase Price

The price of a manual pick and place machine varies widely based on brand, features, and build quality. Entry-level models like the Neoden S1 start at around $2,000, while premium options such as the LPKF ProtoPlace S can exceed $10,000. Key price drivers include:

- Construction materials: Aluminum frames are lightweight and affordable, while steel frames offer durability at a higher cost.

- Component compatibility: Machines supporting smaller components (e.g., 01005 packages) often command a premium.

- Modularity: Systems allowing upgrades (e.g., adding vision systems later) may have higher upfront costs but long-term savings.

2. Features and Specifications

Advanced features significantly impact costs but enhance functionality:

- Placement Speed: Basic models handle 1,500–2,500 components per hour (CPH), while high-end machines reach 5,000 CPH.

- Vision Systems: Cameras with 5–10x magnification improve accuracy for fine-pitch components but add $1,500–$3,000 to the price.

- Feeder Capacity: Machines with 10–20 feeder slots support diverse SMD components but cost 15–25% more than models with 5 slots.

3. Operational Costs

Manual pick and place machines have lower ongoing expenses than automated systems, but consider:

- Power Consumption: Most consume 160–200W, translating to $10–$15 monthly for 8-hour daily use.

- Consumables: Vacuum nozzles ($20–$50 each) and adhesive tapes ($0.10–$0.30 per meter) add marginal costs.

- Maintenance: Annual costs average $200–$500 for calibration, lubrication, and part replacements.

4. Training and Labor Efficiency

While operators require training, manual systems reduce labor costs compared to hand placement:

- Learning Curve: Most users achieve proficiency in 10–15 hours of practice.

- Throughput Gains: Operators can place components 3–4x faster than manual tweezers, reducing assembly time by 40–60%.

5. Accessories and Customization

Optional add-ons enhance performance but increase initial investment:

- Vacuum Pumps: $300–$800 for models with adjustable suction strength.

- Custom Feeders: $50–$150 per feeder for non-standard component sizes.

- Ergonomic Upgrades: Adjustable workstations ($200–$500) reduce operator fatigue during long shifts.

Advantages of Manual Pick and Place Machines

1. Cost-Effectiveness for Small Batches

Manual pick and place machines eliminate the need for costly programming or re-tooling, making them ideal for:

- Startups with limited capital

- Educational institutions

- R&D departments testing multiple designs

2. Precision and Error Reduction

Features like magnifying lenses and micro-adjustment knobs enable placements with ±0.1mm accuracy, critical for:

- Fine-pitch components (e.g., QFN packages)

- High-density interconnect (HDI) boards

- Mixed-technology assemblies (SMD + through-hole)

3. Scalability

Businesses can start with a basic model and upgrade later. For example:

- Add vision systems for $1,500–$3,000

- Integrate semi-automatic feeders ($800–$1,200)

- Connect to CAD software for $500–$1,000

Factors Influencing the Total Cost of Ownership (TCO)

1. Durability and Lifespan

High-quality manual pick and place machines last 8–12 years with proper maintenance. Compare warranties:

- Entry-level: 1 year

- Mid-range: 2–3 years

- Premium: 5 years

2. Resale Value

Well-maintained machines retain 50–70% of their value after 5 years. Brands like Essemtec and Manix have stronger secondary markets.

3. Support and Community

Manufacturers offering video tutorials, live chat, and local service centers reduce downtime. For example:

- LPKF provides lifetime technical support for its ProtoPlace series.

- Open-source communities like DIY Pick and Place offer free troubleshooting guides.

How to Choose the Right Machine

Step 1: Assess Your Needs

- Component Sizes: Ensure compatibility with your smallest SMD parts (e.g., 0402 vs. 0201).

- Board Sizes: Verify the machine's maximum PCB dimensions.

- Production Volume: Match placement speed to your daily output goals.

Step 2: Compare Brands

| Brand | Price Range | Key Feature | Best For |

| Neoden | $2,000–$4,000 | Modular design | Startups |

| LPKF | $8,000–$12,000 | High-precision vision systems | Aerospace prototyping |

| Manix | $5,000–$7,000 | Rugged steel frame | Educational labs |

Step 3: Calculate ROI

Use this formula to evaluate payback period:

ROI (Months) = (Machine Cost + Training) / [(Labor Savings/Month) – Operational Costs]

Example:

- Machine cost: $5,000

- Monthly labor savings: $1,200

- Operational costs: $100

ROI = $5,000 / ($1,200 – $100) ≈ 4.5 months

Case Study: Reducing Prototyping Costs with a Manual Pick and Place Machine

A Boston-based IoT startup reduced assembly costs by 62% after purchasing a $3,500 manual pick and place machine for SMD components. Key outcomes:

- Prototyping time per board dropped from 8 hours to 2.5 hours.

- Placement errors decreased by 80% compared to hand assembly.

- The machine paid for itself in 3 months through labor savings.

Conclusion

A manual pick and place machine for SMD components offers an optimal balance of affordability and precision for low-to-medium volume PCB assembly. By carefully evaluating factors like upfront costs, feature requirements, and total ownership expenses, businesses can select a system that enhances productivity without straining budgets. As technology advances, these machines continue to evolve, integrating features like AI-assisted error detection and IoT connectivity, further solidifying their role in modern electronics manufacturing.

FAQs

1. What Are the Typical Costs of a Manual Pick and Place Machine?

Manual pick and place machines typically range from $2,000 to $10,000 depending on features like placement speed, vision systems, and feeder capacity.

2. Is a Manual Pick and Place Machine Suitable for Prototyping?

Yes, these machines are ideal for prototyping due to their flexibility in handling various component types and low setup costs.

3. How Do Vision Systems Impact Costs?

Vision systems enhance placement accuracy but increase the machine's cost by approximately 20–30% compared to models without this feature.

4. What Maintenance Is Required?

Routine maintenance includes cleaning nozzles, calibrating settings, and inspecting feeders to ensure optimal performance. Maintenance costs are generally low compared to automated systems.

5. Can Manual Machines Handle Fine-Pitch Components?

Yes, many manual machines are equipped with features like vacuum-assisted heads and vision systems that allow precise handling of fine-pitch components such as 0402 packages.