Content Menu

● Common SMT PCB Assembly Defects

>> Solder Joint Defects

>> Component Placement Defects

>> Other Defects

● Causes and Solutions for SMT Assembly Defects

>> Insufficient Solder Joints or Electrical Opens

>> Solder Bridges

>> Component Misalignment

>> Tombstoning

>> Solder Ball Residues

>> Cold Joints

>> Lifted Pads

>> Rework

● The Role of Design for Manufacturability (DFM) in Defect Prevention

● Minimizing SMT PCB Assembly Defects

● Conclusion

● FAQ

>> 1. What are the most common defects in SMT PCB assembly?

>> 2. What causes open solder joints?

>> 3. How can solder bridging be prevented?

>> 4. What is tombstoning and how can it be avoided?

>> 5. Why is quality control important in SMT PCB assembly?

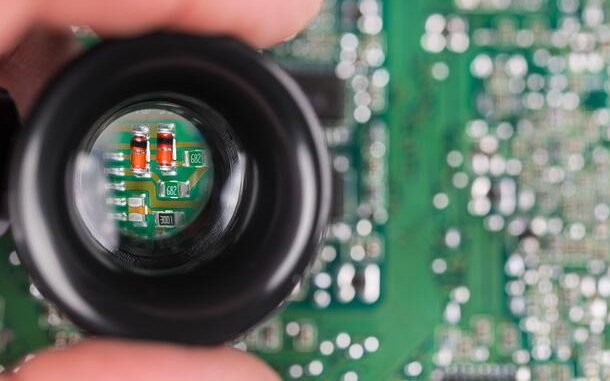

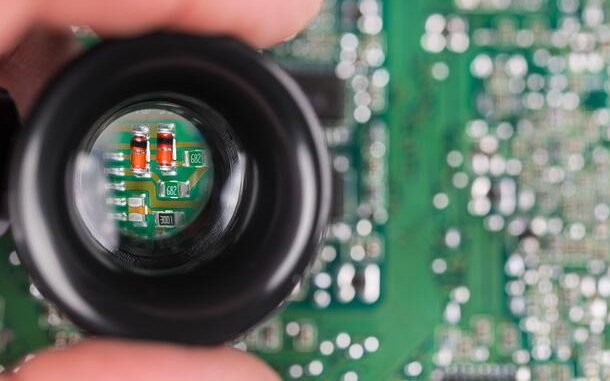

Surface Mount Technology (SMT) has become the predominant method for assembling electronic components on printed circuit boards (PCBs) due to the increasing complexity and miniaturization of these boards. However, the SMT assembly process presents several challenges that can lead to defects and inefficiencies if not properly addressed. Achieving the highest product quality requires a thorough understanding of the common defects encountered in SMT assembly. By understanding these defects, their root causes, and how to prevent them, the quality of manufactured assemblies can be greatly improved. The goal of every China SMT PCB assembly line should be to minimize these common defects.

Common SMT PCB Assembly Defects

Solder Joint Defects

Solder joint defects are a significant concern in SMT PCB assembly. Industry statistics indicate that 60% to 90% of quality defects in SMT PCB assembly are related to solder paste printing, with 75% of soldering defects manifesting in three main areas: open solder joints, solder shorts, and component misalignment. Effective China SMT PCB assembly must address these critical areas.

- Open Solder Joints: An open solder joint occurs when there is no electrical connection between the component lead and the PCB pad. This can happen if insufficient solder is applied, or if the solder fails to contact both the lead and the pad during reflow. According to industry statistics, open solder joints account for 35% of soldering defects. Causes can include insufficient solder paste deposition, improper stencil design, component lead coplanarity issues, and poor PCB surface finish. In China SMT PCB assembly, addressing these causes is paramount.

- Solder Shorts (Solder Bridges): Solder bridging, also known as solder shorts, occurs when solder connects two or more conductive features, causing a short circuit. This is often due to improper solder mask application, excessive solder paste, or issues with the reflow profile. Solder shorts account for approximately 20% of soldering defects. Precise solder paste application and effective reflow profiling are essential in China SMT PCB assembly to mitigate this defect.

- Insufficient Solder Fillets: Solder fillets that do not adequately form around component leads or pads result in weak connections. This can be caused by inadequate solder paste volume, poor wetting of solder to the pads or leads, or excessively rapid cooling during reflow. Consistent solder paste volume control is vital for achieving proper solder fillets in China SMT PCB assembly.

- Cold Solder Joints: These are weak, brittle connections that occur when the solder does not flow properly during reflow, often due to insufficient heat or improper flux activation. They are also known as grainy joints and are difficult to clean due to impurities. Low preheating and insufficient dwell time can be the reasons. In China SMT PCB assembly, maintaining the recommended preheating and dwell time are also important in mitigating cold joints.

Component Placement Defects

- Component Misalignment: Surface mount components may be misaligned or skewed during placement, leading to solder joint defects or open connections. Component shift, the misalignment of a component to its target, can occur during reflow as components float on molten solder. Misalignment can occur due to inaccurate pick-and-place machine calibration, incorrect component orientation in the pick-and-place machine database, or vibration during placement. Accurate equipment calibration is crucial for preventing component misalignment in China SMT PCB assembly.

- Missing Components: Components may be missed during the placement process due to equipment or operator errors. This can happen due to pick-and-place machine programming errors, component shortages, or pick-and-place machine vacuum system failures. Regular checks of pick-and-place machine programming and maintenance are necessary for minimizing missing components in China SMT PCB assembly.

- Tombstoning: This occurs when a surface mount component stands on one end due to imbalanced solder reflow. It is often caused by temperature differences during reflow, where one side of the component heats up faster than the other. Tombstoning is a major defect, especially in MLCC components, and is challenging to rework. This can be caused by uneven heating during reflow, differences in pad size, or differences in component termination metallization. Ensuring uniform heating during reflow is vital for preventing tombstoning in China SMT PCB assembly.

- Warped or Bent Components: SMT components can become warped or bent during reflow, affecting their placement and solder joint quality. High warpage in the PCB can also result in SMT package warpage. Causes can include moisture absorption, improper storage, or excessively high temperatures during reflow. Proper component storage and controlled reflow profiles are essential to prevent component warpage in China SMT PCB assembly.

- Wrong Parts: Misalignment of parts on the PCB is a significant challenge in SMT assembly. This error can occur when the reflow process and alignment are not accurately provided in the pick and place file, or due to a polarity mismatch in the silkscreen on the PCB. Incorrect component reels, pick-and-place machine programming errors, or inadequate verification procedures can cause this issue. Accurate component verification and pick-and-place machine programming are critical for minimizing wrong parts placement in China SMT PCB assembly.

Other Defects

- Solder Ball Residues: Solder balls left on the PCB surface after reflow can cause short circuits and other issues. Causes can include excessive solder paste volume, solder paste oxidation, or improper reflow profiles. Controlling solder paste volume and reflow profiles is critical for preventing solder ball residues in China SMT PCB assembly.

- Lifted or Missing Pads: Pads can become detached during assembly, resulting in non-functional components. This can be caused by excessive heat or mechanical stress during soldering. Excessive soldering temperatures, mechanical stress during component placement, or poor PCB material quality can lead to lifted or missing pads. Careful soldering techniques and high-quality PCB materials are essential for minimizing lifted pads in China SMT PCB assembly.

- Solder Beading: This defect can arise from various factors, including oxidized paste or running an improper reflow profile. Solder beading occurs when small solder balls form and adhere to the solder mask. Oxidized solder paste, excessive flux, or an improper reflow profile can cause this defect. Using fresh solder paste and optimizing the reflow profile are crucial for preventing solder beading in China SMT PCB assembly.

- Rework: Rework, the process of repairing and replacing faulty parts during quality inspection, is a challenging part of PCB manufacturing. It requires careful removal and replacement of components in the same location. Incorrect rework procedures, inadequate equipment, or inexperienced operators can result in damage to the PCB or adjacent components. Training and proper rework procedures are critical for effective rework processes in China SMT PCB assembly.

Causes and Solutions for SMT Assembly Defects

Insufficient Solder Joints or Electrical Opens

- Causes: Insufficient solder paste, solder paste clogging in stencil apertures, component lead coplanarity issues, or PCB fabrication defects.

- Solutions:

Ensure adequate solder paste volume and proper stencil cleaning.

Verify component lead coplanarity to ensure proper contact with pads.

Implement stringent PCB fabrication quality control measures. Regular maintenance of stencil printing equipment is important.

Solder Bridges

- Causes: Improper solder mask, excessive solder paste, high through-hole component lengths, and inadequate solder reflow profiles.

- Solutions:

Apply solder mask properly.

Use fiducials for accurate alignment.

Optimize through-hole parts length and SMT pad size according to IPC standards.

Ensure accurate stencil printing and proper reflow profiles. Reflow oven optimization is also key.

Component Misalignment

- Causes: Inaccurate placement during assembly, components floating on molten solder during reflow.

- Solutions:

Ensure accurate component placement using automated equipment.

Optimize reflow profiles to minimize component movement.

Verify alignment at the earlier DFA (Design for Assembly) stage. Accurate Pick and Place programming ensures consistent placement.

Tombstoning

- Causes: Uneven heating during reflow, thermal imbalances due to different pad sizes.

- Solutions:

Ensure even heating during the reflow process.

Optimize pad sizes to minimize thermal imbalances.

Improve the placement of electronic parts and conduct quality inspections before reflow.

Solder Ball Residues

- Causes: Oxidized solder paste, improper reflow profiles.

- Solutions:

Use fresh solder paste.

Run recommended reflow profiles.

Ensure a slower ramp-up profile to allow volatiles to evaporate. Proper solder paste storage is essential.

Cold Joints

- Causes: Insufficient heat during soldering, impurities in the solder.

- Solutions:

Use proper soldering techniques.

Pay attention to parameters such as temperature, speed, and density. Skilled operators can mitigate this defect.

Lifted Pads

- Causes: Excessive heat or mechanical stress during soldering.

- Solutions:

Control heat exposure during soldering.

Avoid mechanical stress on pads. Proper board handling is very important to avoid such issues.

Rework

- Causes: Inaccurate placement of assembly parts.

- Solutions:

Ensure accurate placement of all assembly parts.

Designers need to check SMT capabilities. Design for manufacturability (DFM) guidelines prevent placement challenges.

The Role of Design for Manufacturability (DFM) in Defect Prevention

DFM guidelines play a crucial role in preventing defects during SMT PCB assembly. By considering manufacturing constraints early in the design process, it's possible to mitigate many common assembly issues. Some key DFM considerations include:

- Component Spacing: Adequate spacing between components is crucial for preventing solder bridging and allowing for proper inspection and rework.

- Pad Design: Consistent pad sizes and shapes help to ensure uniform solder reflow and prevent tombstoning.

- Silkscreen Placement: Clear and accurate silkscreen markings are essential for preventing component misidentification and polarity errors.

- Fiducial Markers: Properly placed fiducial markers are necessary for accurate component alignment by automated placement equipment.

Minimizing SMT PCB Assembly Defects

Minimizing solder joint defects in PCB assembly should be the goal of all China SMT PCB manufacturers. To achieve and maintain high product quality, manufacturers should focus on:

- Understanding Common Defects: Gain a thorough understanding of the common defects encountered in SMT assembly.

- Analyzing Root Causes: Constantly sum up and analyze the causes of these defects.

- Implementing Preventative Measures: Implement solutions and best practices to optimize SMT processes.

- Ensuring Quality Control: Conduct thorough quality inspections at various stages of the assembly process.

- Adhering to Industry Standards: Follow IPC standards for solder pad aspect ratios and other critical parameters.

Conclusion

Defects in SMT PCB assembly can lead to increased costs, delays, and potential damage to the circuit assembly. To minimize these defects, manufacturers must understand the common issues, their causes, and effective solutions. By focusing on proper solder paste application, accurate component placement, optimized reflow profiles, and stringent quality control, it is possible to significantly improve the reliability and performance of SMT assembled PCBs. Continuous improvement and adherence to industry standards are essential for achieving the highest levels of product quality in SMT assembly. China SMT PCB assembly houses can ensure consistently high quality by addressing common defects and implementing rigorous quality controls.

FAQ

1. What are the most common defects in SMT PCB assembly?

The most common defects include open solder joints, solder shorts (bridging), component misalignment, tombstoning, and insufficient solder fillets.

2. What causes open solder joints?

Open solder joints can be caused by insufficient solder paste, solder paste clogging in stencil apertures, component lead coplanarity issues, or PCB fabrication defects.

3. How can solder bridging be prevented?

Solder bridging can be prevented by using proper solder mask application, optimizing solder paste volume, controlling through-hole component lengths, and ensuring accurate solder reflow profiles.

4. What is tombstoning and how can it be avoided?

Tombstoning occurs when a surface mount component stands on one end due to imbalanced solder reflow. It can be avoided by ensuring even heating during reflow, optimizing pad sizes to minimize thermal imbalances, and improving component placement.

5. Why is quality control important in SMT PCB assembly?

Quality control is crucial for identifying and correcting defects early in the assembly process, which helps to prevent latent failures in the field and ensures that every assembly meets the highest quality standards.