Content Menu

● Introduction to SMT Reel X-Ray Counters

>> Operational Principle

● Common Problems Solved by SMT Reel X-Ray Counters

>> Inaccuracy in Manual Counting

>> Efficiency and Time Savings

>> Component Damage

>> Inventory Management Challenges

>> Quality Control

● Benefits of SMT Reel X-Ray Counters

● Applications of SMT Reel X-Ray Counters

● Integration with Advanced Technologies

● Maintenance and Calibration

● Challenges and Future Developments

● Case Studies and Applications

● Conclusion

● FAQs

>> 1. What is the primary advantage of using an SMT reel X-ray counter over manual counting methods?

>> 2. Can SMT reel X-ray counters handle different types of components?

>> 3. How does an SMT reel X-ray counter improve quality control in SMT production?

>> 4. What is the typical accuracy rate of an SMT reel X-ray counter?

>> 5. Can SMT reel X-ray counters integrate with inventory management systems?

● Citations:

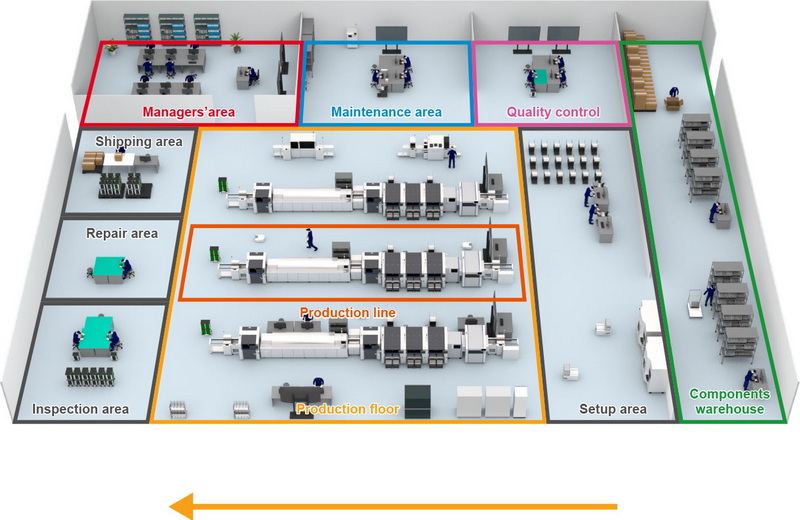

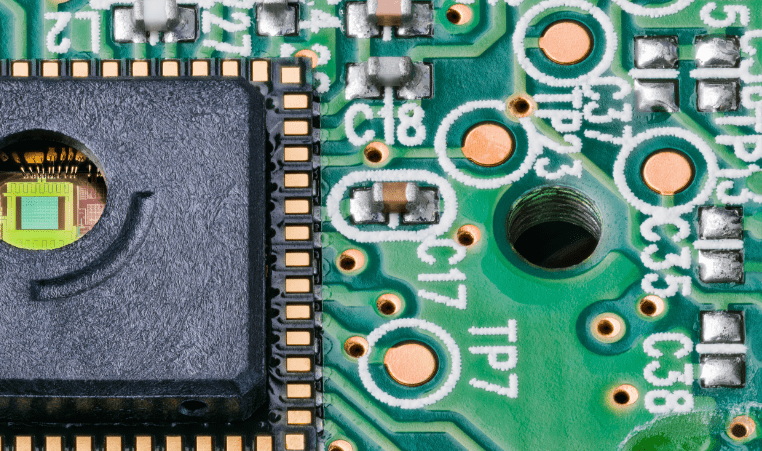

The SMT reel X-ray counter is a revolutionary tool in the electronics manufacturing industry, particularly in the realm of Surface Mount Technology (SMT). This device utilizes X-ray technology to accurately count electronic components on reels, addressing several critical challenges faced by manufacturers. In this article, we will delve into the common problems solved by an SMT reel X-ray counter and explore its applications, benefits, and operational principles.

Introduction to SMT Reel X-Ray Counters

SMT reel X-ray counters are designed to overcome the inefficiencies and inaccuracies associated with traditional component counting methods. These counters leverage X-ray imaging to non-destructively analyze the contents of a reel, providing precise counts without damaging the components. This technology is especially valuable in high-volume production environments where accuracy and speed are paramount.

Operational Principle

The operational principle of an SMT reel X-ray counter involves several key steps:

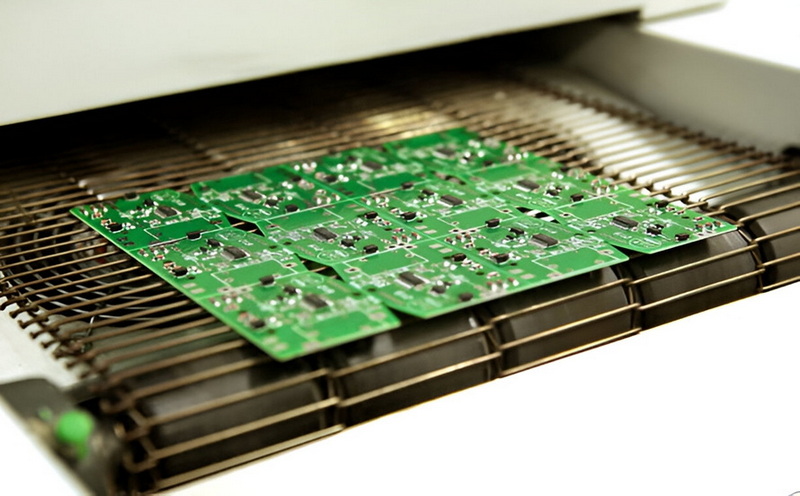

1. Reel Loading: The reel containing the components is placed into the counter.

2. X-ray Imaging: An X-ray beam is emitted through the reel, creating an image of the components.

3. Image Analysis: Advanced algorithms analyze the X-ray image to identify and count individual components based on their shapes, sizes, and densities.

4. Data Output: The counted results are displayed and can be integrated into inventory management systems.

Common Problems Solved by SMT Reel X-Ray Counters

Inaccuracy in Manual Counting

Manual counting of components is time-consuming and prone to human error. The SMT reel X-ray counter solves this problem by providing accurate counts, reducing the likelihood of miscounts and ensuring that inventory levels are precise.

Efficiency and Time Savings

Traditional counting methods are labor-intensive and slow. The X-ray counter automates the counting process, significantly reducing the time required to count components and allowing for faster inventory management and production planning.

Component Damage

Manual handling of components can lead to damage, especially when components are fragile or sensitive. The non-destructive nature of X-ray counting ensures that components remain undamaged, preserving their integrity for use in production.

Inventory Management Challenges

Accurate inventory management is crucial for efficient production. The SMT reel X-ray counter helps by providing precise counts, which can be directly integrated into inventory systems, reducing errors in stock levels and improving supply chain management.

Quality Control

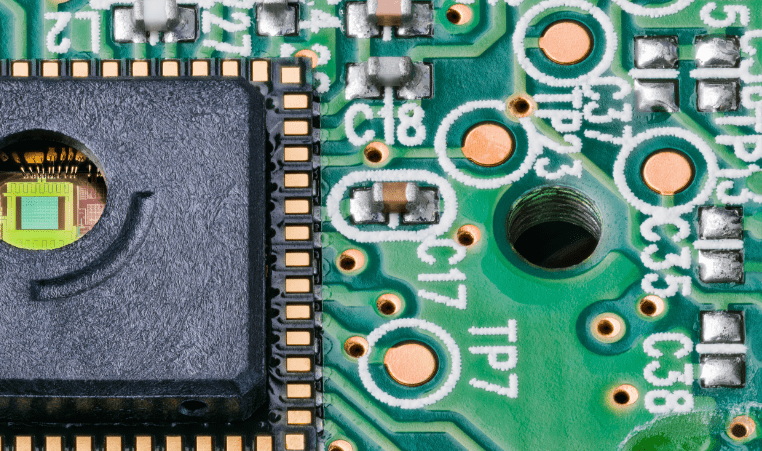

In addition to counting, X-ray technology can inspect the internal structure of components, identifying defects such as soldering issues. This enhances quality control by ensuring that only high-quality components are used in production.

Benefits of SMT Reel X-Ray Counters

The benefits of using an SMT reel X-ray counter are multifaceted:

- Accuracy: Provides highly accurate counts, reducing errors and improving inventory management.

- Efficiency: Automates the counting process, saving time and labor costs.

- Non-Destructive Testing: Ensures components remain undamaged, preserving their usability.

- Quality Control: Enhances product quality by detecting internal defects.

- Integration with Management Systems: Seamlessly integrates with ERP, MES, and WMS systems for real-time inventory updates.

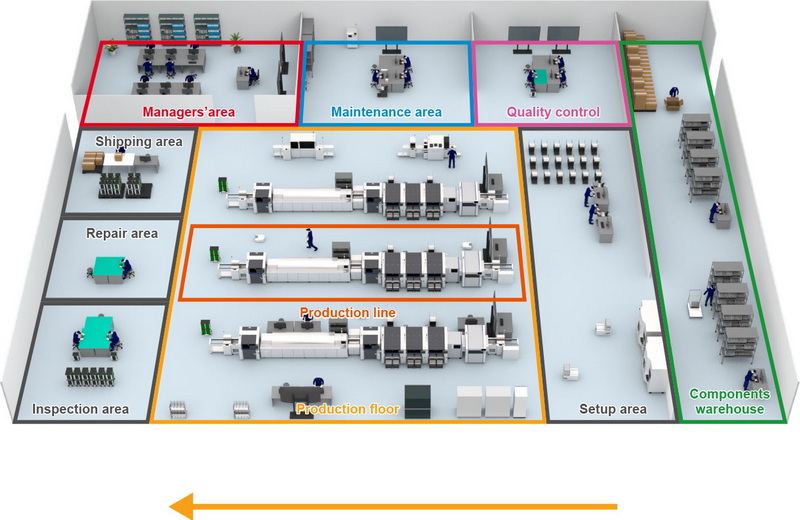

Applications of SMT Reel X-Ray Counters

SMT reel X-ray counters are widely used in various industries, including:

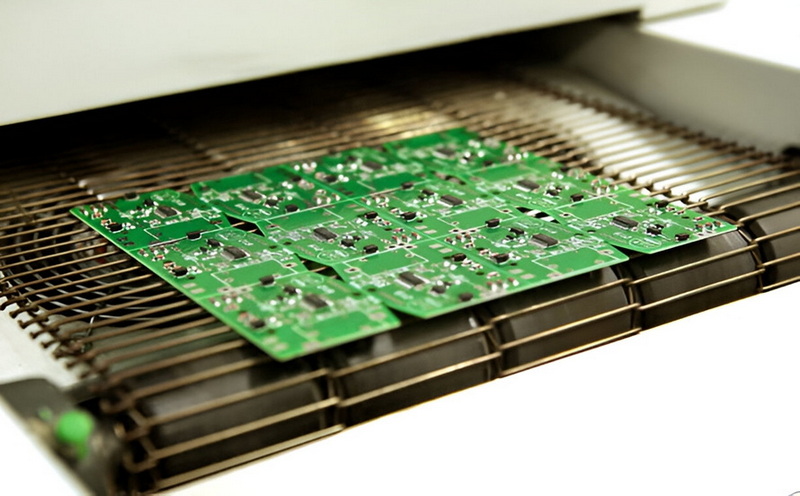

- Electronics Manufacturing: Critical for SMT production lines where component accuracy is vital.

- Automotive Industry: Used for counting and quality control of automotive electronic components.

- Inventory Management: Essential for maintaining accurate stock levels and optimizing supply chains.

Integration with Advanced Technologies

The integration of advanced technologies such as Artificial Intelligence (AI) and Machine Learning (ML) is transforming the capabilities of SMT reel X-ray counters. These technologies enable real-time data analysis, improving the accuracy of defect detection and reducing false positives. AI-driven systems can learn from historical data, adapting their detection criteria based on patterns and anomalies, which significantly enhances the reliability of inspections in manufacturing processes[4].

Moreover, advancements in X-ray imaging techniques, such as phase-contrast X-ray imaging, provide a more detailed view of the internal structures of components, offering superior contrast and resolution compared to traditional X-ray imaging. This allows for the detection of minute defects that would otherwise go unnoticed, ensuring the integrity and reliability of electronic devices[4].

Maintenance and Calibration

To ensure optimal performance, regular maintenance and calibration of the SMT reel X-ray counter are essential. This includes cleaning the machine, inspecting for wear, and following manufacturer guidelines for calibration to maintain accuracy.

Challenges and Future Developments

Despite the numerous benefits, the adoption of SMT reel X-ray counters faces challenges such as high initial investment costs. However, the long-term benefits often outweigh these costs by preventing costly rework, scrap, and product recalls, ultimately leading to significant cost savings and increased profitability for manufacturers[1][4].

The future of SMT reel X-ray counters is promising, with ongoing advancements in technology expected to enhance their capabilities further. The integration of Industry 4.0 principles, such as IoT connectivity, will enable real-time monitoring and remote diagnostics, enhancing operational efficiency and reducing downtime[4].

Case Studies and Applications

In real-world applications, SMT reel X-ray counters have been instrumental in improving production efficiency and quality control. For instance, in the automotive industry, these counters are used to ensure the accuracy and reliability of electronic components, which is critical for safety and performance. Similarly, in consumer electronics, they help maintain high-quality standards by detecting defects early in the manufacturing process.

Conclusion

In conclusion, the SMT reel X-ray counter is a powerful tool that addresses several common problems in the electronics manufacturing industry. By providing accurate counts, improving efficiency, and enhancing quality control, these counters are indispensable for modern production environments. As technology continues to evolve, the role of SMT reel X-ray counters will only become more critical in ensuring the precision and reliability of electronic component production.

FAQs

1. What is the primary advantage of using an SMT reel X-ray counter over manual counting methods?

The primary advantage is the high accuracy and speed of counting, which significantly reduces labor costs and errors associated with manual counting.

2. Can SMT reel X-ray counters handle different types of components?

Yes, SMT reel X-ray counters can handle a variety of components, including capacitors, diodes, transistors, and more, making them versatile for different production needs.

3. How does an SMT reel X-ray counter improve quality control in SMT production?

It improves quality control by using X-ray imaging to inspect the internal structure of components, detecting defects such as cold solder joints, which ensures only high-quality components are used.

4. What is the typical accuracy rate of an SMT reel X-ray counter?

The typical accuracy rate of an SMT reel X-ray counter is over 99.99%, making it highly reliable for precise inventory management.

5. Can SMT reel X-ray counters integrate with inventory management systems?

Yes, SMT reel X-ray counters can integrate with ERP, MES, and WMS systems, allowing for real-time updates of inventory levels and enhancing supply chain management.

Citations:

[1] https://wellmanxray.com/blog/the-invaluable-role-of-x-ray-in-the-smt-industry/

[2] https://www.seamarkzm.com/application-of-xray-smd-component-counter-in-smt-production.html

[3] https://www.dhsinobgas.com/x-ray-counting-machine/x-ray-smd-component-counter.html

[4] https://pmarketresearch.com/auto/x-ray-smd-counter-market/

[5] https://www.dhsinobgas.com/x-ray-counting-machine/xray-smd-component-counter.html

[6] https://www.seamarkzm.com/the-main-reasons-for-the-inaccurate-material-count-of-the-x-ray-component-counter.html

[7] https://www.seamarkzm.com/can-smt-reel-counters-be-used-for-spot-tray-loose-material.html

[8] https://www.seamarkzm.com/products/xc1000-offline-reel-counter/

[9] https://www.seamarkzm.com/future-development-trends-of-automatic-xray-inspection.html

[10] https://www.seamarkzm.com/why-every-electronics-manufacturer-needs-an-electronic-component-reel-counter.html

[11] https://www.seamarkzm.com/future-development-trends-of-xray-inspection-equipment.html

[12] https://global.neotel.tech/products/neo-counter-series/smt-reel-counter-x800/

[13] https://www.linkedin.com/pulse/inline-x-ray-component-counter-next-step-smt-inventory-automation-

[14] https://wellmanxray.com/blog/how-the-x-ray-parts-counter-calculates-the-number-of-components-in-a-reel/

[15] https://www.seamarkzm.com/maintaining-and-calibrating-an-smd-reel-counter.html

[16] https://global.neotel.tech/2023/01/06/5-benefits-to-use-smd-reel-counter-machine/

[17] https://www.nordson.com/en/products/test-and-inspection-products/cc-assure

[18] https://www.verifiedmarketreports.com/product/x-ray-component-counter-market/

[19] http://blog.inovaxe.com/en/x-ray-counters-and-you

[20] https://www.eevblog.com/forum/manufacture/x-ray-component-reel-counter/