Content Menu

● Understanding SMT Stencils and Their Role in PCB Assembly

● Common Mistakes When Using SMT Stencils

>> 1. Improper Alignment of the Stencil to the PCB

>> 2. Incorrect Tensioning of the Stencil Foil

>> 3. Using the Wrong Stencil Thickness or Aperture Design

>> 4. Neglecting Regular Cleaning and Maintenance

>> 5. Ignoring Environmental and Handling Conditions

>> 6. Using Incorrect Squeegee Pressure and Printing Parameters

>> 7. Reusing Damaged or Worn-Out Stencils

● Best Practices for Using SMT Stencils

● Conclusion

● FAQ

>> 1. What is the difference between framed and frameless SMT stencil frames?

>> 2. How often should SMT stencil frames be cleaned?

>> 3. What is the importance of stencil foil tension in the frame?

>> 4. How does stencil aperture design affect solder paste printing?

>> 5. What environmental conditions should be controlled when using SMT stencil frames?

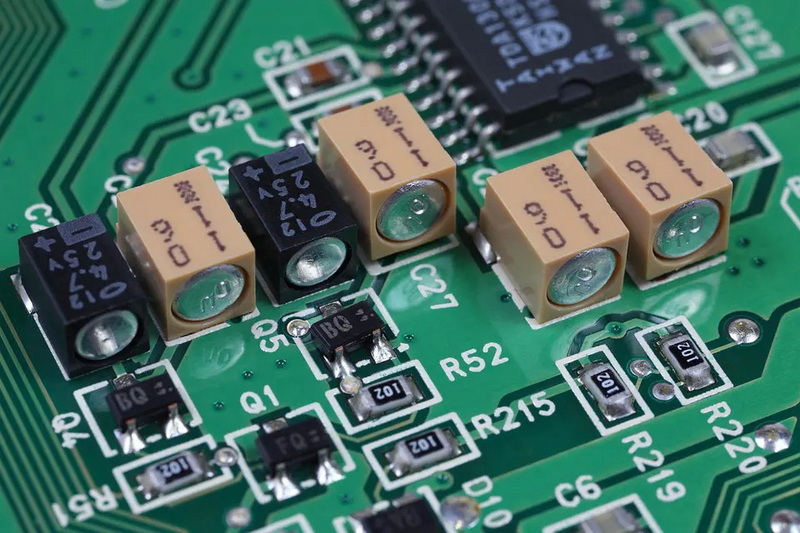

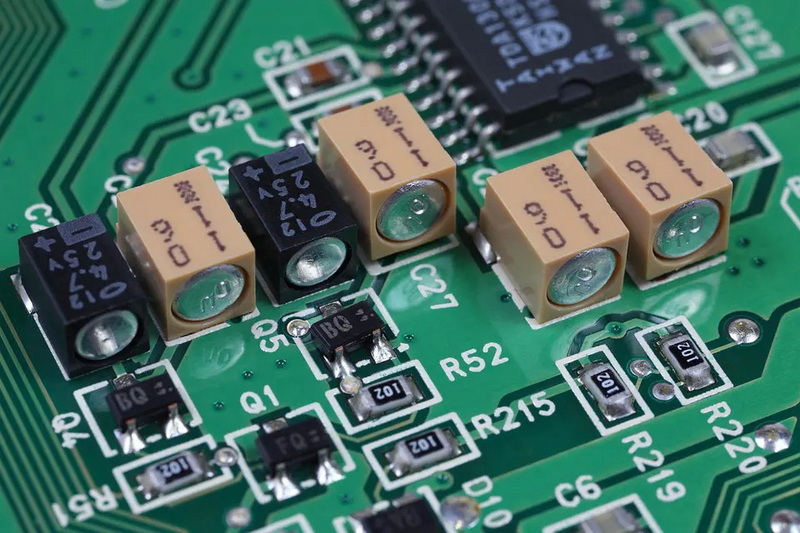

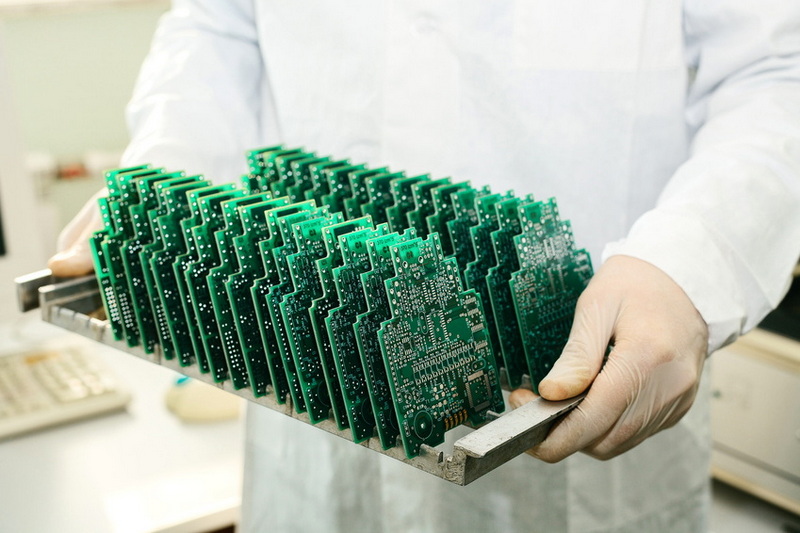

Surface Mount Technology (SMT) stencils are indispensable tools in the SMT PCB assembly process, enabling precise and consistent solder paste application onto PCB pads. The quality of solder paste deposition directly influences solder joint integrity, assembly yield, and the overall reliability of electronic devices. However, improper use of a stencil for SMT PCB assembly can lead to a variety of defects such as solder bridging, insufficient solder joints, misalignment, and even complete assembly failure. This comprehensive article delves into the common mistakes encountered when using SMT stencils, explains their causes and consequences, and provides actionable best practices to avoid these pitfalls and optimize your SMT printing process.

Understanding SMT Stencils and Their Role in PCB Assembly

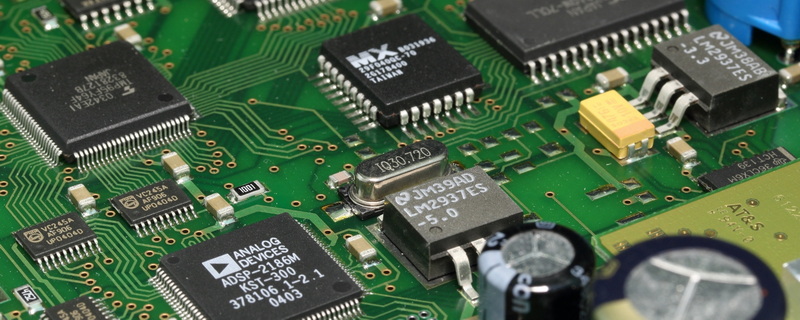

Before exploring common mistakes, it is important to understand what an SMT stencil is and why it is critical in PCB assembly. An SMT stencil is a thin metal sheet-usually stainless steel or nickel-with precisely laser-cut apertures that correspond exactly to the solder pads on a printed circuit board (PCB). The stencil is mounted on a frame, either framed or frameless, and aligned over the PCB during the solder paste printing stage.

During the printing process, solder paste is applied over the stencil using a squeegee blade. The paste passes through the stencil apertures and deposits onto the PCB pads beneath. This step must be highly accurate and repeatable because the volume and placement of solder paste determine the quality of the solder joints formed during reflow soldering. Too much solder paste can cause bridging or tombstoning, while too little can result in weak or open joints.

Therefore, the stencil for SMT PCB assembly is a key enabler of high-quality solder paste printing, and any mistakes in stencil design, handling, or usage can significantly compromise assembly quality.

Common Mistakes When Using SMT Stencils

1. Improper Alignment of the Stencil to the PCB

One of the most common and critical mistakes is failing to achieve precise alignment between the stencil apertures and the PCB pads. Misalignment can occur due to manual placement errors, inaccurate fiducial recognition, or mechanical issues in automated stencil printers.

When the stencil is misaligned, solder paste may be deposited partially or entirely off the intended pads. This leads to insufficient solder volume on some pads or solder bridging between adjacent pads, causing open circuits or short circuits after reflow. In high-density PCBs with fine-pitch components, even a slight misalignment can cause catastrophic assembly defects.

To avoid this, it is essential to use automated stencil printers equipped with optical alignment systems that detect fiducials on the PCB and stencil, ensuring micron-level accuracy. For manual printing, operators must carefully align the stencil using fiducial marks and alignment pins, though this method is less precise and more prone to human error.

2. Incorrect Tensioning of the Stencil Foil

The stencil foil must be stretched to an optimal tension within its frame to maintain flatness and stability during printing. Over-tensioning the foil can cause it to warp, deform, or even tear, damaging the stencil and resulting in inconsistent paste deposition. Under-tensioning, on the other hand, causes the foil to sag or flutter, leading to smudging, uneven paste thickness, and print defects.

Maintaining correct tension is especially important for frameless stencils, which rely on external tensioning systems. Framed stencils generally come pre-tensioned and provide more consistent results. Operators should regularly check stencil tension and adjust or replace foil as needed to ensure stable printing conditions.

3. Using the Wrong Stencil Thickness or Aperture Design

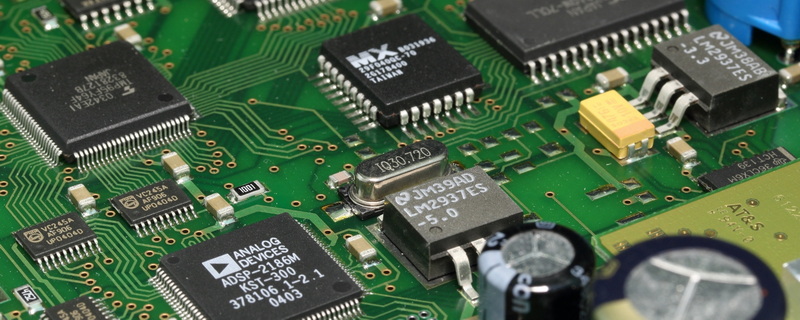

Stencil thickness and aperture geometry directly control the volume of solder paste deposited on each pad. A thicker stencil deposits more solder paste, while a thinner stencil deposits less. Similarly, aperture size, shape, and aspect ratio influence paste release and volume.

Using a stencil that is too thick or apertures that are too large can cause excessive solder paste, which increases the risk of solder bridging, tombstoning, and solder balls. Conversely, a stencil that is too thin or apertures that are undersized may not deposit enough paste, resulting in weak or open solder joints.

A widely accepted guideline is to maintain an aperture area ratio (the ratio of aperture opening area to stencil thickness) of at least 0.66 to ensure reliable paste release. Aperture shapes should also be optimized-rounded corners and trapezoidal shapes reduce paste smearing and improve release compared to sharp rectangular apertures.

Designers should collaborate closely with stencil manufacturers and assembly engineers to select the appropriate stencil thickness and aperture design based on component type, pad size, and PCB layout.

4. Neglecting Regular Cleaning and Maintenance

Solder paste is sticky and tends to accumulate in stencil apertures and on the foil surface after multiple printing cycles. If not cleaned regularly, this residue clogs apertures, impedes paste release, and causes inconsistent solder paste deposition.

Neglecting stencil cleaning leads to insufficient paste volume, open joints, and increased rework or scrap rates. Cleaning methods vary from manual wiping with solvents to ultrasonic cleaning and automated stencil cleaning machines. The choice depends on production volume and cleanliness requirements.

Best practice is to clean stencils frequently-often after every few printing cycles or at least once per shift-to maintain aperture integrity and print quality. Additionally, inspecting stencils for damage or wear during cleaning helps prevent defects caused by physical stencil degradation.

5. Ignoring Environmental and Handling Conditions

Environmental factors such as humidity, temperature, and dust contamination significantly impact solder paste behavior and stencil condition. High humidity can cause solder paste to slump or become too fluid, leading to bridging and poor print definition. Excessive heat can dry out paste, reducing its tackiness and printability.

Dust and particles settling on the stencil foil or PCB surface can block apertures or contaminate solder paste, causing printing defects and solder joint failures.

Moreover, rough or careless handling of stencils can cause physical damage such as bent apertures, scratches, or frame distortion. Damaged stencils produce inconsistent paste deposition and increase defect rates.

To mitigate these issues, stencils should be stored in clean, climate-controlled environments and handled with care using gloves and protective covers. Operators should be trained in proper stencil handling and storage procedures.

6. Using Incorrect Squeegee Pressure and Printing Parameters

The squeegee blade applies pressure to push solder paste through stencil apertures onto the PCB. Incorrect squeegee pressure, speed, or angle can cause printing defects such as insufficient paste transfer, smearing, or bridging.

Too much pressure may scrape paste off the stencil or cause paste to flood adjacent pads, while too little pressure leads to incomplete paste deposition. Similarly, printing speed that is too fast can cause paste to smear or skip pads, whereas too slow printing reduces throughput and may cause paste drying.

Printing parameters must be carefully calibrated and optimized based on stencil thickness, solder paste type, PCB layout, and production requirements. Many modern stencil printers allow programmable control of squeegee pressure, speed, and angle to ensure consistent results.

7. Reusing Damaged or Worn-Out Stencils

Over time, stencil apertures can become distorted, bent, or clogged beyond cleaning due to repeated use, improper cleaning, or mechanical damage. Continuing to use such damaged stencils leads to poor solder paste printing quality, increased defects, and rework costs.

Regular inspection of stencil condition is essential. Apertures should be checked under magnification for deformation or clogging. If damage or excessive wear is detected, the stencil should be repaired or replaced promptly.

Using high-quality stencils and adhering to proper cleaning and handling procedures prolong stencil life and maintain assembly quality.

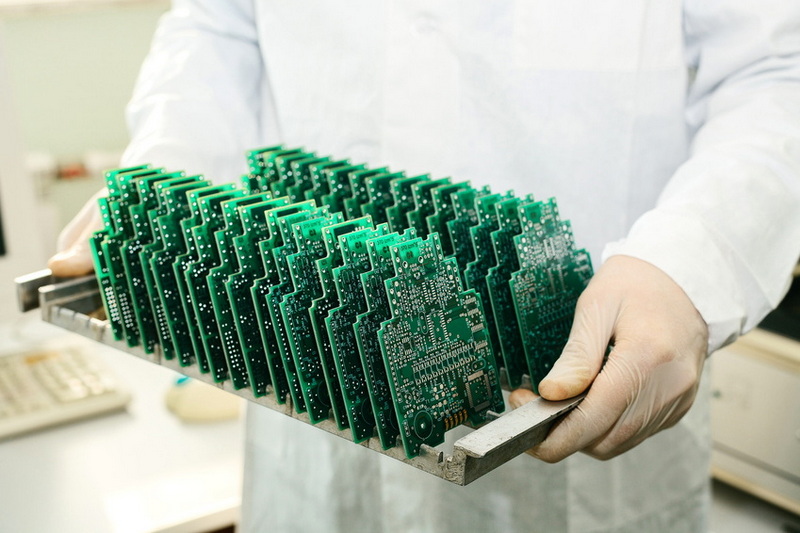

Best Practices for Using SMT Stencils

To avoid the common mistakes outlined above and ensure high-quality solder paste printing, consider the following best practices when using a stencil for SMT PCB assembly:

- Use framed stencils for high-volume production: Framed stencils provide consistent foil tension and easier alignment, reducing printing variability.

- Employ automated stencil printers with optical alignment: Automated systems improve alignment accuracy and repeatability, minimizing human error.

- Maintain proper stencil foil tension: Regularly check and adjust tension to keep the stencil foil flat and stable during printing.

- Clean stencils regularly: Use solvent wiping, ultrasonic cleaning, or automated cleaning systems to prevent aperture clogging and maintain paste release.

- Store stencils properly: Keep stencils in clean, dry, and temperature-controlled environments to prevent damage and contamination.

- Optimize stencil aperture design: Work with stencil manufacturers to design apertures with appropriate size, shape, and aspect ratio for reliable paste deposition.

- Calibrate printing parameters: Adjust squeegee pressure, speed, and angle to match stencil and PCB requirements for consistent paste transfer.

- Inspect stencils routinely: Check for physical damage or wear and replace stencils when necessary to maintain print quality.

- Train operators: Ensure personnel understand stencil handling, cleaning, and printing procedures to reduce errors.

By implementing these measures, manufacturers can significantly improve solder paste printing quality, reduce defects, and enhance overall SMT PCB assembly yield.

Conclusion

The stencil for SMT PCB assembly is a fundamental element in the solder paste printing process, directly influencing the quality and reliability of solder joints. Common mistakes such as improper alignment, incorrect stencil tension, wrong stencil thickness or aperture design, neglecting cleaning, environmental neglect, improper printing parameters, and reusing damaged stencils can cause serious defects including solder bridging, insufficient solder joints, open circuits, and rework.

Understanding these pitfalls and adopting best practices-including precise alignment, correct tensioning, regular cleaning, optimized aperture design, controlled environmental conditions, and calibrated printing parameters-enables manufacturers to achieve consistent, high-quality solder paste deposition. This ultimately leads to improved assembly yields, reduced costs, and higher product reliability in SMT PCB assembly.

FAQ

1. What is the difference between framed and frameless SMT stencil frames?

Framed stencils have the stencil foil permanently mounted on a rigid frame, providing consistent tension and easier alignment, ideal for high-volume production. Frameless stencils consist only of the foil and require external tensioning systems or reusable frames, making them more cost-effective but more challenging to handle and align accurately.

2. How often should SMT stencil frames be cleaned?

Cleaning frequency depends on production volume and paste type but should be regular enough to prevent solder paste residue buildup in apertures. Many manufacturers clean stencils after every few printing cycles or at the end of each production shift using solvent wiping, ultrasonic cleaning, or automated cleaning machines.

3. What is the importance of stencil foil tension in the frame?

Proper tensioning keeps the stencil foil flat and stable during printing. Over-tensioning can warp or tear the foil, while under-tensioning causes sagging. Both conditions lead to inconsistent solder paste deposition and printing defects, so maintaining optimal tension is critical for print quality.

4. How does stencil aperture design affect solder paste printing?

Aperture size, shape, and aspect ratio determine the volume and release of solder paste. Poor aperture design can cause excessive paste leading to bridging or insufficient paste causing open joints. Maintaining an aperture area ratio above 0.66 and using rounded or trapezoidal apertures improves paste release and solder joint reliability.

5. What environmental conditions should be controlled when using SMT stencil frames?

Humidity, temperature, and cleanliness should be controlled to prevent solder paste slump, drying, or contamination. Stencils should be stored in clean, dry, temperature-controlled environments and handled carefully to avoid physical damage and maintain print quality.