Content Menu

● Understanding SMT Stencils for PCB Assembly

>> Importance of SMT Stencils

● Common Mistakes in SMT Stencil Usage for PCB Assembly

>> 1. Incorrect Stencil Aperture Design

>> 2. Misalignment of Stencil to PCB Pads

>> 3. Using the Wrong Stencil Thickness

>> 4. Poor Stencil Cleaning and Maintenance

>> 5. Improper Stencil Handling and Storage

>> 6. Excessive or Insufficient Squeegee Pressure

>> 7. Using Inappropriate Solder Paste

● Best Practices for SMT Stencil Usage in PCB Assembly

● Conclusion

● FAQ

>> 1. What is the ideal stencil thickness for fine-pitch SMT components?

>> 2. How does stencil aperture size affect solder paste application?

>> 3. How often should SMT stencils be cleaned?

>> 4. What causes solder bridging when using SMT stencils?

>> 5. How can stencil misalignment be prevented?

● Citations:

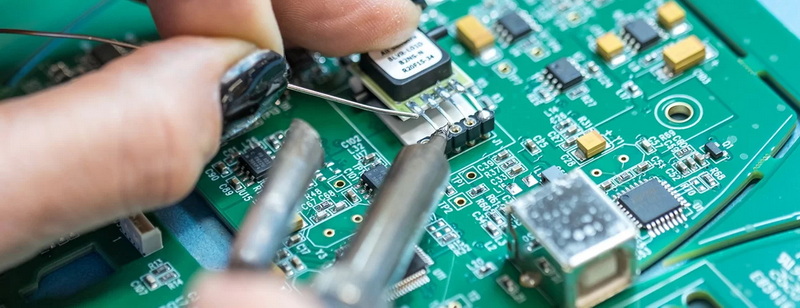

Surface Mount Technology (SMT) stencils play a critical role in the PCB assembly process by enabling precise application of solder paste onto PCB pads. Proper use of SMT stencils ensures high-quality solder joints, reliable electrical connections, and efficient production. However, common mistakes in SMT stencil usage can lead to defects such as solder bridging, insufficient solder, and misalignment, which ultimately affect the functionality and yield of the assembled boards. This article explores the frequent errors encountered with SMT stencils for PCB assembly, their causes, and practical solutions to avoid them.

Understanding SMT Stencils for PCB Assembly

An SMT stencil is a thin metal sheet, typically stainless steel, with apertures precisely cut to match the PCB pads where solder paste needs to be deposited. The stencil is aligned over the PCB, and solder paste is applied through the apertures using a squeegee. This process ensures consistent and repeatable solder paste deposition, which is critical for surface mount device (SMD) placement and reflow soldering.

Importance of SMT Stencils

- Precision and repeatability: Stencils allow simultaneous application of solder paste to multiple pads, improving throughput and consistency.

- Solder volume control: Proper stencil design controls the volume of solder paste deposited, preventing defects.

- Cost and efficiency: Using SMT stencils reduces labor and material waste compared to manual solder paste application methods.

Common Mistakes in SMT Stencil Usage for PCB Assembly

1. Incorrect Stencil Aperture Design

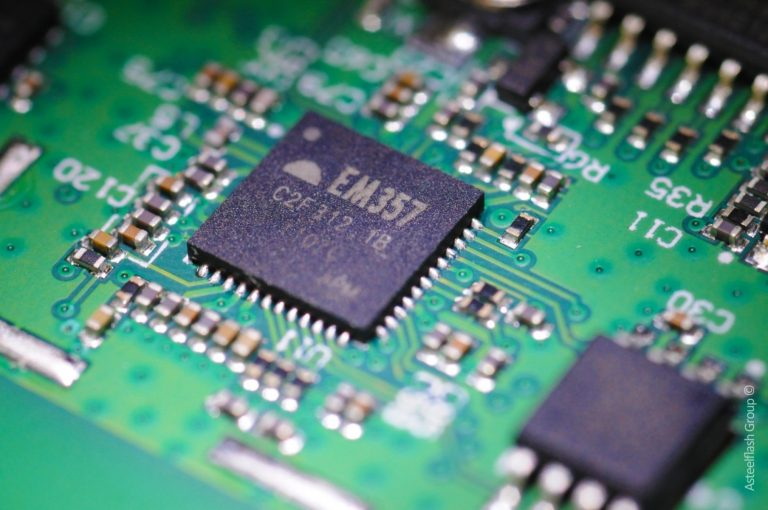

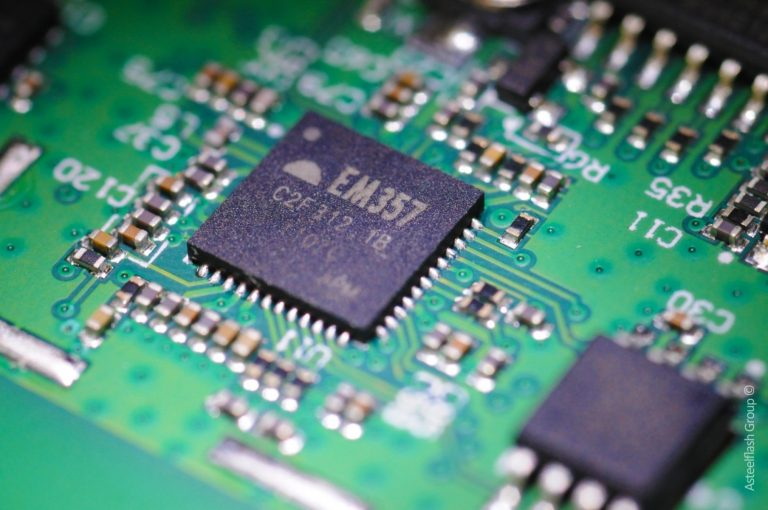

One of the most prevalent mistakes is improper aperture sizing and shape in the stencil file. Apertures that are too large or too small can cause excessive or insufficient solder paste deposition.

- Oversized apertures lead to solder bridging between adjacent pads, especially in fine-pitch components like microcontrollers with many pins.

- Undersized apertures result in insufficient solder, causing electrical opens or weak joints.

- Aperture shape issues, such as sharp corners, can hinder solder paste release and cause clogging.

How to avoid:

Use design guidelines to optimize aperture size and shape. For example, reducing aperture size by about 10% can help prevent bridging. Rounded corners on apertures improve paste release. Maintain an appropriate aspect ratio (aperture width to stencil thickness) and area ratio (aperture opening area to wall area) to ensure proper paste transfer[2][6][5].

2. Misalignment of Stencil to PCB Pads

Misalignment between the stencil apertures and PCB pads causes solder paste to be applied off-target, leading to insufficient solder on pads or bridging.

- Manual alignment errors or warped/stretching stencils contribute to misalignment.

- Inaccurate fiducial marks or poor registration in the printing machine exacerbate the problem.

How to avoid:

Use fiducial marks on both stencil and PCB for precise alignment. Employ automated stencil printers with vision systems to ensure accurate placement. Regularly inspect stencils for warping or stretching and replace if necessary[2][3][7].

3. Using the Wrong Stencil Thickness

Stencil thickness directly influences the volume of solder paste deposited. Using a stencil that is too thick for the component pitch can cause excessive solder paste, leading to bridging.

- For fine-pitch components (e.g., 0.5mm pitch), thinner stencils (around 0.1mm) are recommended.

- Thicker stencils (e.g., 0.15mm or more) are suitable for larger components like 0805 or 0603 packages.

How to avoid:

Select stencil thickness based on component size, pad design, and required solder volume. The stencil thickness can be calculated using the formula:

Stencil thickness=Stencil aspect ratioAperture width

Maintaining the correct aspect ratio ensures good paste release without clogging[2][5][6].

4. Poor Stencil Cleaning and Maintenance

Residue buildup on stencil apertures from solder paste can clog apertures, causing insufficient solder deposition and print defects.

- Frequent dry wiping with abrasive materials damages stencil coatings.

- Infrequent cleaning leads to paste buildup and inconsistent printing.

How to avoid:

Implement a regular cleaning schedule using wet solvents, ultrasonic cleaning, or automated stencil cleaners. Use soft wipes to preserve stencil nanocoatings. Inspect apertures under magnification to detect clogging or damage early[6][9][11].

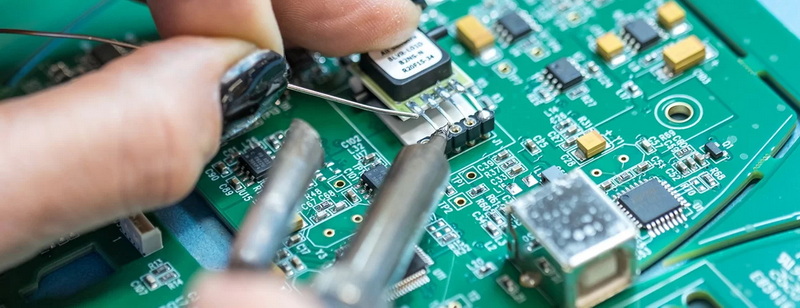

5. Improper Stencil Handling and Storage

SMT stencils are delicate, often only 4-5 mils thick. Mishandling can cause bending, scratching, or damage to the stencil foil, affecting print quality.

- Stacking stencils horizontally or placing heavy objects on them causes warping.

- Dropping squeegees or tools onto the stencil can create irreparable damage.

How to avoid:

Store stencils vertically in dedicated racks to prevent deformation. Handle stencils carefully, avoiding contact with sharp or heavy objects. Install squeegees before placing stencils in printers to avoid damage[9].

6. Excessive or Insufficient Squeegee Pressure

Applying too much pressure during paste application can squeeze solder paste out of the apertures, causing bridging or smearing. Too little pressure results in incomplete paste transfer.

How to avoid:

Adjust squeegee pressure to an optimal level that ensures complete paste transfer without forcing excess paste through apertures. Use consistent, single-pass squeegee strokes to avoid over-deposition[1][5].

7. Using Inappropriate Solder Paste

The solder paste composition affects its viscosity, slump, and wetting properties. Using solder paste with incorrect metal-to-flux ratios or poor quality can cause bridging, insufficient joints, or paste slump.

How to avoid:

Use solder paste with a metal content suitable for fine-pitch printing (typically 90% metal). Store paste properly to avoid contamination and degradation. Match solder paste properties with stencil design and reflow profile[1][5].

Best Practices for SMT Stencil Usage in PCB Assembly

- Design Optimization: Collaborate with PCB designers to optimize pad size and stencil apertures for reliable solder paste deposition.

- Regular Inspection: Check stencils for wear, damage, and cleanliness before use.

- Controlled Environment: Maintain stable temperature and humidity to prevent solder paste slump and contamination.

- Proper Equipment: Use automated stencil printers with vision alignment and controlled squeegee pressure.

- Training: Ensure operators understand stencil handling, cleaning, and printing procedures.

Conclusion

SMT stencils are indispensable tools in PCB assembly, enabling precise and repeatable solder paste application. However, common mistakes such as incorrect aperture design, misalignment, improper stencil thickness, poor cleaning, and handling errors can severely impact assembly quality. By understanding these pitfalls and implementing best practices—including optimized stencil design, accurate alignment, regular maintenance, and proper handling—manufacturers can significantly reduce defects like solder bridging and opens, enhancing yield and reliability in SMT PCB assembly.

FAQ

1. What is the ideal stencil thickness for fine-pitch SMT components?

For fine-pitch components such as 0.5mm pitch ICs, a stencil thickness of around 0.1mm is recommended to prevent excessive solder paste deposition and bridging[5][6].

2. How does stencil aperture size affect solder paste application?

Aperture size controls the volume of solder paste deposited. Oversized apertures cause solder bridging, while undersized apertures lead to insufficient solder joints. Aperture shape and aspect ratio also influence paste release[2][6].

3. How often should SMT stencils be cleaned?

Stencils should be cleaned regularly during production runs to prevent solder paste buildup and aperture clogging. Cleaning frequency depends on paste type and print volume but typically includes cleaning after every few boards or shifts[6][9].

4. What causes solder bridging when using SMT stencils?

Solder bridging is often caused by excessive solder paste deposition due to oversized apertures, thick stencils, misalignment, or poor solder paste properties. Overpressure during squeegee application can also contribute[1][5].

5. How can stencil misalignment be prevented?

Using fiducial marks on both stencil and PCB, automated vision alignment systems, and regularly inspecting stencils for warping help ensure precise stencil-to-PCB alignment[2][3][7].

Citations:

[1] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[2] https://www.protoexpress.com/blog/design-mistakes-that-lead-to-pcb-assembly-errors/

[3] https://scancad.net/common-solder-paste-stencil-defects/

[4] https://www.viasion.com/blog/smt-assembly-introduction-applications-steps-common-errors/

[5] https://www.reddit.com/r/AskElectronics/comments/ivrx72/details_about_stencils_and_solder_paste/

[6] https://pcbpit.com/smt-stencil-a-comprehensive-guide/

[7] https://www.youtube.com/watch?v=YiEIYUo_JpI

[8] https://www.creativehitech.com/blog/must-know-things-about-solder-paste-stencils-part-1/

[9] https://www.linkedin.com/pulse/best-worst-practices-stencil-care-maintenance-vslpc

[10] https://www.instructables.com/How-to-Order-a-SMT-Stencil/

[11] https://rigidflexpcb.org/comprehensive-guide-to-smt-stencils/

[12] https://www.pcbonline.com/blog/guide-to-smt-stencils.html