Content Menu

● Introduction to PCBA Challenges

>> Common PCBA Issues

● Solutions to Common PCBA Issues

>> Soldering Defects

>> Thermal Management

>> Component Placement Errors

>> Manufacturing Defects

● PCBA Design Errors and Their Impact

● Advanced Assembly Techniques for Enhanced Efficiency

>> Role of Automation

>> Importance of Advanced Materials

>> Real-Time Monitoring and Data Analytics

● PCBA Troubleshooting and Repair

● Conclusion

● FAQs

>> 1. What are the most common soldering defects in PCBA?

>> 2. How can thermal management issues be mitigated in PCBA?

>> 3. What role does component placement play in PCBA quality?

>> 4. How can manufacturing defects like plating voids and acid traps be prevented?

>> 5. What methods are used for troubleshooting faulty PCBs?

● Citations:

Printed Circuit Board Assembly (PCBA) is a critical process in electronics manufacturing, involving the assembly of components onto a printed circuit board (PCB). Despite advancements in technology, PCBA still faces numerous challenges that can affect product quality, reliability, and production efficiency. This article will delve into common issues encountered during PCBA and provide solutions to address these challenges.

Introduction to PCBA Challenges

PCBA involves both Surface Mount Technology (SMT) and Dual In-Line Package (DIP) assembly methods. SMT is widely used due to its efficiency and compactness, while DIP is preferred for certain components requiring manual assembly. Common challenges in PCBA include soldering defects, thermal management issues, component placement errors, and manufacturing defects like plating voids and acid traps.

Common PCBA Issues

1. Soldering Defects: These are among the most prevalent issues in PCBA. Defects such as cold solder joints, solder bridges, and voids can compromise the performance and reliability of the final product. Soldering defects often result from improper soldering techniques, inadequate solder paste quality, or incorrect reflow oven settings.

2. Thermal Management: Electronic components generate heat during operation, which can lead to performance issues or component failure if not managed properly. Thermal management involves using heat sinks, thermal vias, and conductive materials to dissipate heat effectively.

3. Component Placement Errors: Incorrect placement of components can lead to signal interference, reduced board reliability, and increased production difficulty. Advanced design tools and precision assembly equipment are essential for ensuring accurate component placement.

4. Manufacturing Defects: Issues like plating voids and acid traps can occur during PCB fabrication. Plating voids are gaps in the copper plating of through-holes, while acid traps are areas where etching solutions can accumulate, causing uneven copper traces.

Solutions to Common PCBA Issues

Soldering Defects

- Automated Soldering Processes: Utilize advanced soldering equipment like reflow ovens and wave soldering machines to ensure precision and consistency.

- Quality Materials: Invest in high-quality solder paste and flux to reduce defects.

- Inspection Systems: Implement Automated Optical Inspection (AOI) and X-ray inspection systems to detect soldering issues during production[2][5].

Thermal Management

- Thermal Simulation: Use thermal analysis tools during the design phase to predict heat distribution and identify potential hot spots.

- Heat Dissipation Strategies: Incorporate heat sinks, thermal vias, and conductive materials to improve heat dissipation.

- Proper Component Placement: Position heat-sensitive components away from high-heat-generating components to minimize thermal stress[2][4].

Component Placement Errors

- Advanced Design Tools: Use PCB design software that supports high-density interconnects (HDI) and multilayer boards.

- Precision Equipment: Invest in high-precision assembly equipment capable of handling microcomponents.

- Skilled Workforce: Train personnel to manage the intricacies of miniaturized PCBAs[2][3].

Manufacturing Defects

- Proper Cleaning and Inspection: Ensure thorough cleaning of PCBs after drilling to prevent debris accumulation and inspect for defects before assembly.

- Quality Control Processes: Implement effective rinsing and quality control processes during PCB fabrication to mitigate acid traps and plating voids[4].

PCBA Design Errors and Their Impact

In addition to manufacturing issues, PCBA design errors can significantly impact the quality and reliability of the final product. Common design errors include:

- Component Placement Errors: Misaligned components can result in functionality and reliability problems. As PCBAs become smaller and denser, optimizing board space while maintaining proper alignment is crucial[1].

- Routing Errors: Incorrect routing can lead to signal interference and noise issues. Ground routing is particularly important for preventing these errors, and simulation software can help identify potential problems[1].

- Power Distribution Errors: Overloaded power supplies and inconsistent voltage levels can cause overheating and component failure. Proper power plane design and component spacing are essential for preventing these issues[1].

Advanced Assembly Techniques for Enhanced Efficiency

The integration of advanced assembly techniques in PCB design has significantly improved the efficiency and performance of PCBA. Techniques such as automation in assembly lines, improved soldering methods, and precise component placement are instrumental in achieving high-performance printed circuit board assemblies (PCBAs)[3].

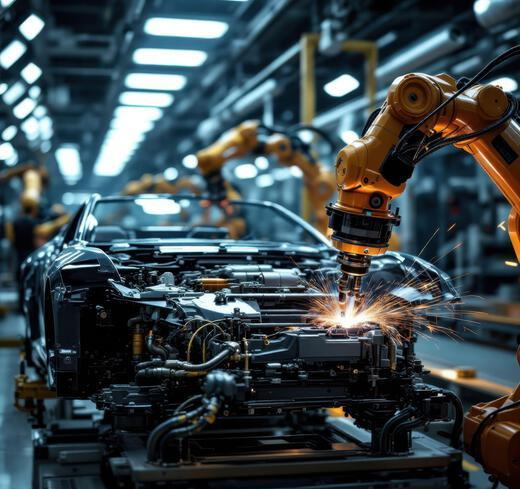

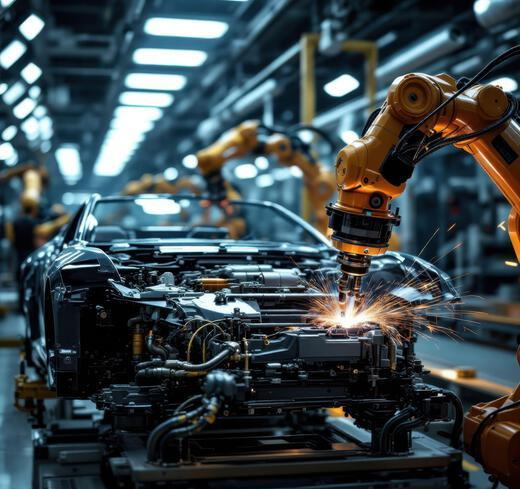

Role of Automation

Automation in PCBA assembly reduces human error and increases production speed, making it possible to meet high demand without sacrificing quality. Automated assembly systems utilize robotics and machine vision technologies to optimize placement accuracy and speed during the PCBA process[3].

Importance of Advanced Materials

Employing advanced materials can result in lighter, more durable boards that are better suited for modern technology. Continuous training and development of personnel involved in PCB assembly ensure they are equipped with the latest insights and skills relevant to these advanced methods[3].

Real-Time Monitoring and Data Analytics

Real-time monitoring and data analytics play a crucial role in identifying bottlenecks in the PCB assembly workflow. By utilizing Internet of Things (IoT) devices, manufacturers can gather data on production metrics to refine processes continuously[3].

PCBA Troubleshooting and Repair

Troubleshooting a faulty PCB involves several methods, including visual inspection, comparative analysis, and principle analysis. Repairing PCBs often requires removing damaged components, cleaning tracks, and replacing faulty parts. For complex circuits without available schematics, engineers must use their experience to draw diagrams and repair the board.

Conclusion

PCBA is a complex process fraught with challenges that can impact product quality and manufacturing efficiency. Understanding these issues and implementing effective solutions is crucial for maintaining high standards in electronics manufacturing. By leveraging advanced technologies, quality materials, and skilled personnel, manufacturers can reduce defects, improve thermal management, and enhance overall PCBA quality.

FAQs

1. What are the most common soldering defects in PCBA?

- Common soldering defects include cold solder joints, solder bridges, and voids. These issues can be addressed by using automated soldering processes, high-quality materials, and inspection systems.

2. How can thermal management issues be mitigated in PCBA?

- Thermal management can be improved by using thermal simulation tools, incorporating heat dissipation strategies like heat sinks and thermal vias, and ensuring proper component placement.

3. What role does component placement play in PCBA quality?

- Accurate component placement is crucial for preventing signal interference and ensuring board reliability. Advanced design tools and precision assembly equipment are essential for achieving this.

4. How can manufacturing defects like plating voids and acid traps be prevented?

- These defects can be minimized by ensuring proper cleaning and inspection of PCBs, following quality control processes during fabrication, and using effective rinsing techniques.

5. What methods are used for troubleshooting faulty PCBs?

- Troubleshooting involves visual inspection, comparative analysis, principle analysis, and sometimes replacing components to identify and repair faults.

Citations:

[1] https://www.macrofab.com/blog/avoid-common-pcba-design-errors/

[2] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/common-challenges-in-pcba-manufacturing-and-how-to-overcome-them/

[3] https://www.andwinpcb.com/unlocking-efficiency-advanced-assembly-techniques-for-pcb-design/

[4] https://www.mclpcb.com/pcb-guide/

[5] https://www.fcpcba.com/tips/pcb-assembly-defects-and-solutions/

[6] https://www.rigiflex.com/blog/get-to-know-about-the-advanced-pcb-assembly-techniques-for-complex-circuits/

[7] https://www.oem-pcb.com/news/common-issues-in-pcb-pcba-production-and-how-t-78064589.html

[8] https://www.bestproto.net/news/common-challenges-in-pcb-assembly-and-how-to-overcome-them/

[9] https://camptechii.com/next-level-advanced-pcb-fabrication-techniques/

[10] https://novaenginc.com/common-pcb-manufacturing-challenges-and-their-solutions/

[11] https://www.electronicdesign.com/technologies/eda/printed-circuit-boards/article/55041417/viasion-technology-top-5-miniaturization-challenges-in-pcb-assembly-and-their-solutions

[12] https://www.twistedtraces.com/blog/know-the-advancements-in-pcb-manufacturing-processes

[13] https://sierraconnect.protoexpress.com/t/5-typical-pcb-design-challenges-with-solutions-for-engineers/2782

[14] https://www.ablcircuits.co.uk/blog/common-pcb-production-challenge/

[15] https://summitinterconnect.com/article/8-trends-pcb-fabrication/

[16] https://www.marctech2.com/news/common-pcb-manufacturing-problems-solutions

[17] https://www.linkedin.com/pulse/exploring-advanced-techniques-pcbs-rushpcb

[18] https://resources.altium.com/p/common-pcb-assembly-defects-you-should-know

[19] https://www.pcbway.com/high-quality-pcb.html

[20] https://www.ourpcb.com/pcba-manufacturing.html