Content Menu

● Understanding the Role of SMD Chip Counter Machines

● Common Issues Faced with SMD Chip Counter Machines

>> 1. Counting Inaccuracies

>>> Causes:

>>> Solutions:

>> 2. Mechanical Wear and Tear

>>> Causes:

>>> Solutions:

>> 3. Sensor Malfunction

>>> Causes:

>>> Solutions:

>> 4. Software and Calibration Errors

>>> Causes:

>>> Solutions:

>> 5. Component Damage During Counting

>>> Causes:

>>> Solutions:

>> 6. Power and Electrical Issues

>>> Causes:

>>> Solutions:

● Additional Challenges in Using SMD Chip Counter Machines

>> Tape Compatibility Problems

>> Environmental Factors

>> Operator Errors

● Best Practices to Mitigate Common Issues

● Conclusion

● FAQ

>> 1. What causes counting errors in SMD chip counter machines?

>> 2. How often should an SMD chip counter machine be calibrated?

>> 3. Can SMD chip counter machines damage components?

>> 4. What maintenance is required for SMD chip counter machines?

>> 5. How can sensor malfunctions be prevented?

● Citations:

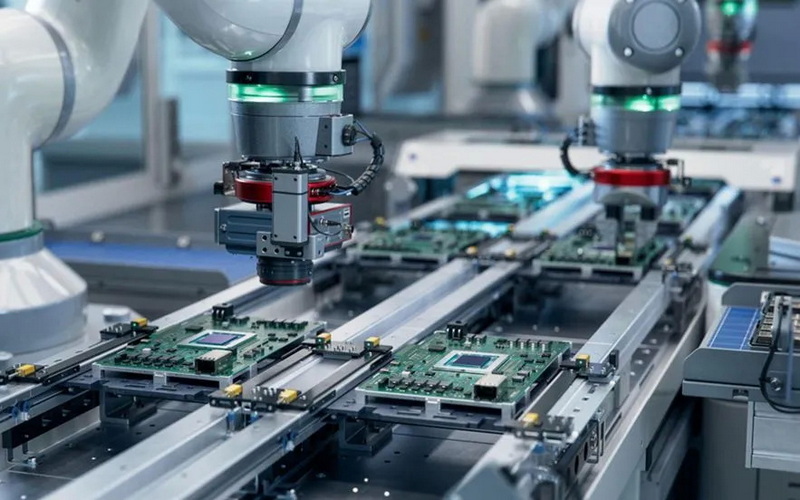

Surface Mount Device (SMD) chip counter machines have become indispensable tools in the electronics manufacturing industry, especially in managing the inventory and assembly processes of small electronic components like resistors, capacitors, diodes, and integrated circuits. These machines automate the counting of SMD components on reels or tapes, significantly improving accuracy and efficiency compared to manual counting. However, despite their advanced technology, SMD chip counter machines face several common issues that can affect their performance, accuracy, and longevity. This article explores these challenges in detail, providing insights into their causes and practical solutions.

Understanding the Role of SMD Chip Counter Machines

Before delving into the issues, it is important to understand the core functions and importance of SMD chip counter machines in Surface Mount Technology (SMT) manufacturing:

- Accurate Counting: These machines count components on reels or tapes automatically, reducing human error.

- Inventory Management: They help maintain precise inventory levels, preventing shortages or overstocking.

- Quality Control: By detecting missing or damaged components, they ensure the integrity of production batches.

- Efficiency Boost: Automating counting speeds up the material preparation process, supporting faster assembly lines.

SMD chip counter machines have become a cornerstone in modern electronics manufacturing facilities where thousands of small components are used daily. The ability to quickly and accurately count these components helps manufacturers reduce waste, avoid production delays, and maintain high-quality standards.

Common Issues Faced with SMD Chip Counter Machines

Despite their advantages, SMD chip counter machines are not without challenges. Below are the most frequently encountered issues that users face:

1. Counting Inaccuracies

One of the most critical problems is inaccurate counting, which can lead to production delays, material wastage, and increased costs.

Causes:

- Dust, debris, and static electricity: These can interfere with the optical sensors that detect components, causing false counts or missed components.

- Misalignment of the component tape or reel: If the tape is not fed properly, the machine may count empty spaces or double-count components.

- Wear and tear of sensors or mechanical parts: Over time, sensors can degrade, and mechanical parts can loosen or malfunction.

- Improper calibration: Incorrect calibration settings can cause the machine to misinterpret component sizes or spacing.

Solutions:

- Regular cleaning of sensors and feed mechanisms using soft cloths and mild cleaning agents to remove dust and debris.

- Frequent calibration as per manufacturer guidelines to ensure sensor accuracy.

- Inspection and replacement of worn parts to maintain mechanical integrity.

- Storing the machine in a dust-free, dry environment to prevent sensor contamination.

2. Mechanical Wear and Tear

Mechanical components such as motors, sprockets, and feed rollers are subject to wear due to continuous operation.

Causes:

- Continuous operation without proper maintenance leads to lubrication loss and part degradation.

- Exposure to dust, moisture, or corrosive environments accelerates wear.

- Overloading or improper handling of reels causes mechanical stress.

Solutions:

- Scheduled maintenance checks focusing on lubrication and part replacement.

- Using the machine within recommended operational limits to avoid excessive strain.

- Keeping the machine in controlled environments to prevent corrosion and dust accumulation.

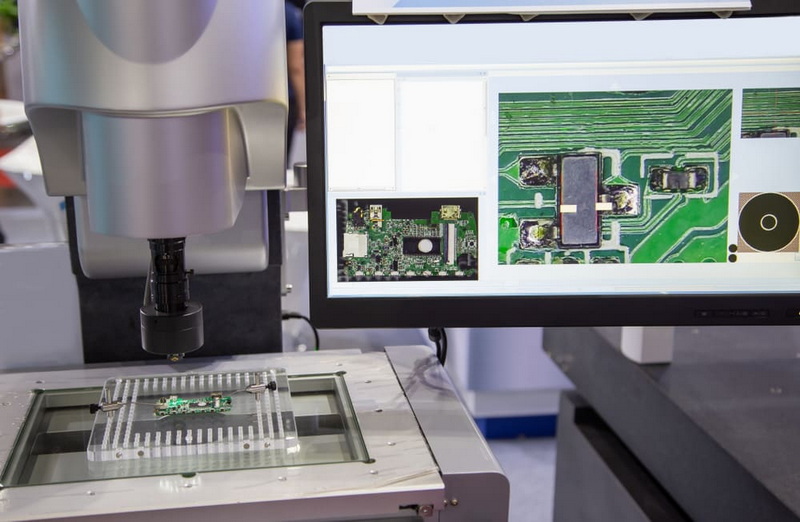

3. Sensor Malfunction

Optical sensors are vital for detecting and counting components accurately. Their malfunction can severely affect counting precision.

Causes:

- Dirty or scratched sensor lenses reduce the sensor's ability to detect components.

- Sensor misalignment during setup or after maintenance.

- Electrical issues such as static discharge or faulty wiring can disrupt sensor signals.

Solutions:

- Regular cleaning and inspection of sensors to ensure clear lenses.

- Proper calibration and alignment during setup and after maintenance.

- Using anti-static measures and ensuring electrical connections are secure and shielded.

4. Software and Calibration Errors

The internal software controls counting logic and calibration, and errors here can cause inconsistent or wrong counts.

Causes:

- Outdated or corrupted firmware can introduce bugs or incorrect counting algorithms.

- Incorrect calibration parameters set by operators.

- User errors during setup or operation.

Solutions:

- Updating firmware regularly to benefit from bug fixes and improvements.

- Following manufacturer calibration procedures strictly.

- Providing thorough training to operators to minimize setup errors.

5. Component Damage During Counting

While not common in all counters, some machines can cause damage to delicate components, leading to quality issues.

Causes:

- Excessive mechanical pressure applied during feeding.

- Improper tape handling causing components to jam or get crushed.

- Faulty or worn-out parts causing jams or snags.

Solutions:

- Adjusting machine settings to handle components gently.

- Regular inspection and replacement of parts that contact components.

- Using high-quality tapes and reels compatible with the machine.

6. Power and Electrical Issues

Unstable power supply or electrical faults can cause machine stoppages or erratic behavior.

Causes:

- Voltage fluctuations causing resets or sensor errors.

- Loose wiring or connectors leading to intermittent connections.

- Faulty power supply units causing inconsistent power delivery.

Solutions:

- Using voltage stabilizers or UPS systems to ensure stable power.

- Regular electrical inspections and tightening of connections.

- Prompt repair or replacement of faulty power components.

Additional Challenges in Using SMD Chip Counter Machines

Beyond the primary issues listed above, users may also encounter the following challenges:

Tape Compatibility Problems

Not all tapes and reels are created equal. Differences in tape thickness, width, or material can cause feeding issues.

- Causes: Using non-standard or damaged tapes can cause jams or misfeeds.

- Solutions: Always use tapes and reels recommended by the machine manufacturer and inspect tapes before loading.

Environmental Factors

Environmental conditions such as humidity, temperature, and dust levels can impact machine performance.

- Causes: High humidity can cause tape adhesion or sensor fogging; dust can accumulate on sensors and moving parts.

- Solutions: Maintain a clean, climate-controlled environment for the machine.

Operator Errors

Human factors such as improper loading, incorrect settings, or neglecting maintenance can cause many issues.

- Causes: Lack of training or rushing operations.

- Solutions: Provide comprehensive training and enforce standard operating procedures.

Best Practices to Mitigate Common Issues

To ensure optimal performance and longevity of SMD chip counter machines, manufacturers and operators should adopt the following best practices:

- Regular Cleaning: Keep the machine free from dust and debris, especially around sensors and feed mechanisms.

- Routine Calibration: Follow the manufacturer's calibration schedule to maintain counting accuracy.

- Scheduled Maintenance: Perform lubrication, part replacement, and system checks regularly.

- Proper Storage: Store the machine in a clean, dry, and static-free environment when not in use.

- Operator Training: Ensure users are well-trained to operate and maintain the machine correctly.

- Use Quality Materials: Employ high-quality tapes, reels, and components to reduce jams and damage.

- Environmental Control: Maintain stable temperature and humidity levels in the workspace.

- Power Stability: Use voltage stabilizers or UPS systems to protect against electrical fluctuations.

Conclusion

SMD chip counter machines are vital for efficient and accurate management of electronic components in SMT manufacturing. However, they face several common issues such as counting inaccuracies, mechanical wear, sensor malfunctions, calibration errors, component damage, and electrical problems. Addressing these challenges requires a combination of regular maintenance, proper calibration, careful handling, and operator training. By implementing best practices and promptly resolving issues, manufacturers can ensure their SMD chip counter machines deliver reliable performance, reduce downtime, and maintain production quality. Investing time and resources into proper machine care not only extends the lifespan of the equipment but also significantly enhances manufacturing efficiency and product quality.

FAQ

1. What causes counting errors in SMD chip counter machines?

Counting errors are mainly caused by dust and debris on sensors, misalignment of tapes, worn mechanical parts, and improper calibration.

2. How often should an SMD chip counter machine be calibrated?

Calibration frequency depends on usage but generally should be done regularly according to the manufacturer's guidelines to maintain accuracy.

3. Can SMD chip counter machines damage components?

Yes, if the machine applies excessive pressure or has worn parts causing jams, it can damage delicate components. Proper maintenance and settings adjustment help prevent this.

4. What maintenance is required for SMD chip counter machines?

Regular cleaning, lubrication, inspection for wear and tear, sensor checks, and electrical system inspections are essential maintenance tasks.

5. How can sensor malfunctions be prevented?

Sensor malfunctions can be minimized by keeping lenses clean, ensuring proper alignment, protecting against static electricity, and performing regular inspections.

Citations:

1.https://www.seamarkzm.com/maintaining-and-calibrating-an-smd-reel-counter.html

2.https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

3.https://www.zjyingxing.com/info/what-are-the-common-smt-pick-and-place-machine-88387624.html

4.https://www.diverseelectronics.com/upload/documents/COU2000.pdf

5.https://cnsmtline.com/products/smd-counter-machine/

6.https://www.seamarkzm.com/smd-counter-machines-in-surface-mount-technology.html

7.http://www.smtworldwide.com/pf/ch-comp-counter/

8.https://www.indiamart.com/proddetail/smd-chip-counter-machine-23214921588.html

9.https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

10.https://www.alibaba.com/showroom/smd-chip-counter.html

https://www.alibaba.com/showroom/smd-ic-chip-counter.html