Content Menu

● Introduction to Pick and Place SMD LED Machines

>> Key Features of Pick and Place SMD LED Machines

● Common Issues with Pick and Place SMD LED Machines

>> 1. Component Placement Errors

>> 2. Component Damage

>> 3. Inaccurate Fiducial Recognition

>> 4. Component Pick-Up and Release Issues

>> 5. Software and Hardware Compatibility Issues

● Troubleshooting and Maintenance

>> Advanced Troubleshooting Techniques

● Choosing the Right Pick and Place SMD LED Machine

>> Evaluating Cost-Effectiveness

● Future Developments in Pick and Place Technology

>> Integration of AI and Machine Learning

>> Increased Use of Robotics

● Conclusion

● FAQ

>> 1. What are the most common issues with pick and place SMD LED machines?

>> 2. How can I improve the placement accuracy of my pick and place SMD LED machine?

>> 3. What factors should I consider when choosing a pick and place SMD LED machine?

>> 4. How often should I perform maintenance on my pick and place SMD LED machine?

>> 5. Can used or refurbished pick and place SMD LED machines be a viable option?

● Citations:

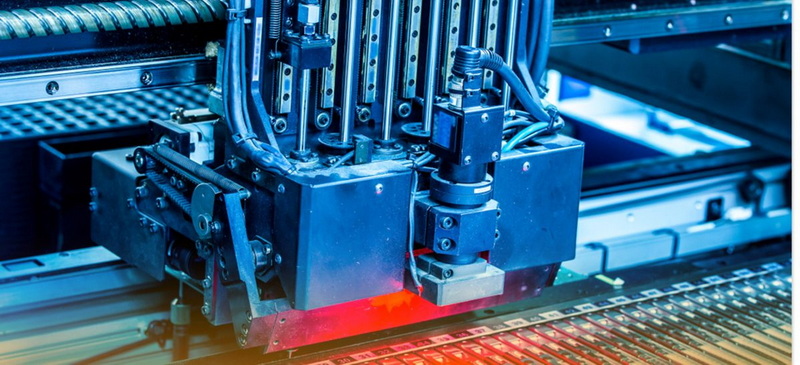

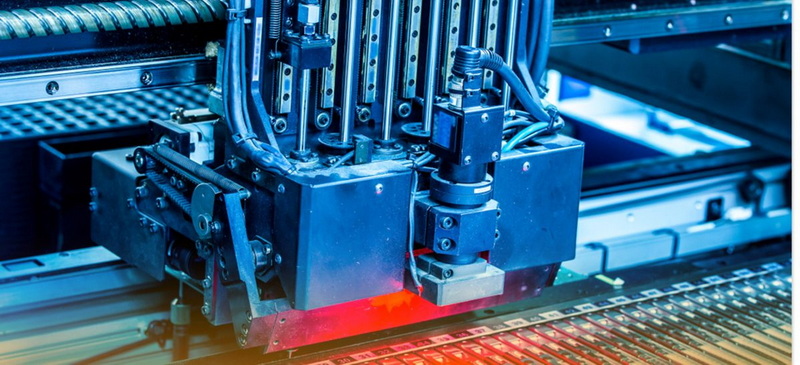

The pick and place SMD LED machine is a crucial component in the electronics manufacturing industry, particularly in the production of LED-based products. These machines are designed to efficiently place Surface Mount Devices (SMDs), including LEDs, onto printed circuit boards (PCBs) with high precision and speed. However, like any complex machinery, they can encounter various issues that affect their performance and productivity. This article will delve into the common problems faced by pick and place SMD LED machines, discuss troubleshooting methods, and explore how these issues can be mitigated to ensure optimal operation.

Introduction to Pick and Place SMD LED Machines

Pick and place SMD LED machines are sophisticated devices that automate the process of placing components onto PCBs. They are essential for high-volume production, offering advantages such as increased speed, reduced labor costs, and improved component placement accuracy compared to manual assembly methods. These machines are widely used in the manufacturing of LED lighting products, consumer electronics, and automotive electronics, among others.

Key Features of Pick and Place SMD LED Machines

1. High-Speed Placement: These machines can place components at speeds that significantly enhance production efficiency, making them ideal for high-volume manufacturing environments.

2. Precision Placement: They offer high placement accuracy, ensuring that components are positioned correctly on the PCB, which is critical for the reliability and functionality of the final product.

3. Component Handling: They can handle a wide range of SMD components, including LEDs, resistors, capacitors, and ICs, making them versatile for various electronic assemblies.

4. Automation and Control: Modern pick and place SMD LED machines are typically controlled by computer software, allowing for precise programming and monitoring of the placement process.

Common Issues with Pick and Place SMD LED Machines

Despite their advanced technology, pick and place SMD LED machines can experience several common issues that impact their performance:

1. Component Placement Errors

- Incorrect Component Calibration: If the machine is not properly calibrated for the specific components being placed, it can lead to misplacement or incorrect orientation of components on the PCB.

- Damaged Feeders: Feeders that are damaged or not functioning correctly can cause components to be picked up incorrectly or not at all.

- Inadequate Maintenance: Failure to regularly maintain the machine can result in mechanical issues that affect placement accuracy.

2. Component Damage

- Malfunction or Incorrect Operation: If the machine is not operated correctly or malfunctions, it can cause physical damage to components during the placement process.

- Overworked Machine: Running the machine beyond its capacity can lead to increased wear and tear, potentially damaging components.

- Poor-Quality Components: Using components that are not suitable for the machine or are of poor quality can increase the likelihood of damage during placement.

3. Inaccurate Fiducial Recognition

- Damaged or Dirty Camera Lens: The camera used for fiducial recognition must be clean and undamaged to accurately identify PCB locations.

- Inaccurate Calibration: The machine's fiducial recognition system needs to be calibrated regularly to ensure accurate PCB alignment.

- Malfunction of the Fiducial Recognition Software: Software issues can prevent the machine from correctly identifying PCB fiducials.

4. Component Pick-Up and Release Issues

- Inadequate or Inaccurate Vacuum or Nozzle Pressure: Incorrect pressure settings can prevent components from being picked up or released properly.

- Worn-Out or Damaged Nozzles: Nozzles that are worn out or damaged can cause components to stick or be dropped during placement.

- Inadequate or Ineffective Vibration: Some machines use vibration to help release components; if this function is not working correctly, it can lead to placement issues.

5. Software and Hardware Compatibility Issues

- Outdated Software: Using outdated software can lead to compatibility issues with newer components or hardware upgrades.

- Incompatible Hardware Upgrades: Adding new hardware components that are not compatible with the existing system can cause operational issues.

Troubleshooting and Maintenance

To mitigate these issues, regular maintenance and troubleshooting are essential:

- Regular Calibration: Ensure that the machine is calibrated correctly for the components being placed.

- Feeder Inspection: Regularly inspect and replace damaged feeders.

- Nozzle Maintenance: Check and replace nozzles as needed to prevent sticking or dropping components.

- Software Updates: Keep software up to date to fix any bugs or issues with fiducial recognition.

- Operator Training: Ensure operators are well-trained to avoid incorrect operation.

Advanced Troubleshooting Techniques

1. Use of Diagnostic Tools: Many modern machines come with built-in diagnostic tools that can help identify specific issues.

2. Consulting Manufacturer Support: Reaching out to the manufacturer's support team can provide valuable insights and solutions for complex problems.

3. Implementing Predictive Maintenance: Regularly monitoring machine performance can help predict potential issues before they occur.

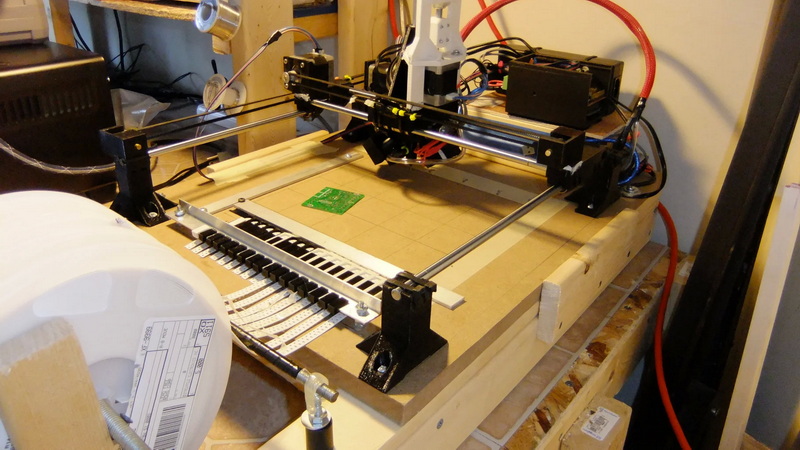

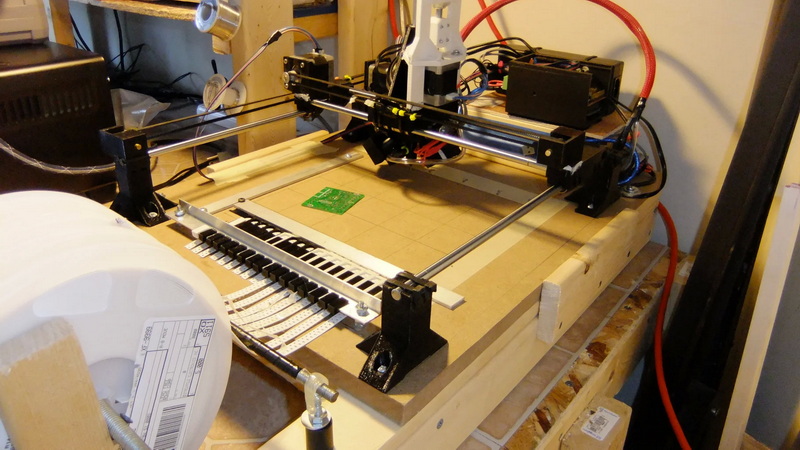

Choosing the Right Pick and Place SMD LED Machine

When selecting a pick and place SMD LED machine, several factors should be considered:

- Precision and Speed: The machine should offer the required level of precision and speed for your production needs.

- Component Handling Capacity: Ensure the machine can handle the types and sizes of components you need to place.

- Automation Level: Consider the level of automation and control needed for your production environment.

- Maintenance and Support: Look for machines with good maintenance support and easy troubleshooting options.

Evaluating Cost-Effectiveness

1. Initial Investment vs. Long-Term Savings: While the initial cost of a pick and place SMD LED machine may be high, it can lead to significant long-term savings through increased efficiency and reduced labor costs.

2. Production Volume: The machine should be capable of handling your current and projected production volumes.

3. Flexibility and Adaptability: Consider whether the machine can adapt to changes in production requirements or new component types.

Future Developments in Pick and Place Technology

The future of pick and place SMD LED machines is promising, with advancements in automation, AI integration, and improved precision. These developments will further enhance production efficiency and reduce errors, making them even more indispensable in modern electronics manufacturing.

Integration of AI and Machine Learning

- Predictive Maintenance: AI can help predict when maintenance is needed, reducing downtime.

- Component Inspection: AI-powered vision systems can inspect components for defects before placement.

- Optimized Production Planning: AI can optimize production schedules and component placement strategies for maximum efficiency.

Increased Use of Robotics

- Robotic Arms: The integration of robotic arms can enhance flexibility and precision in component placement.

- Automated Component Feeding: Robots can automate the feeding process, reducing manual intervention.

Conclusion

Pick and place SMD LED machines are vital for efficient and precise component placement in electronics manufacturing. While they offer numerous benefits, they can encounter issues such as placement errors, component damage, and pick-up/release problems. By understanding these common issues and implementing regular maintenance and troubleshooting practices, manufacturers can optimize the performance of these machines and ensure high-quality production outputs.

FAQ

1. What are the most common issues with pick and place SMD LED machines?

The most common issues include component placement errors, component damage, inaccurate fiducial recognition, and component pick-up and release problems. Regular maintenance and proper operation can help mitigate these issues.

2. How can I improve the placement accuracy of my pick and place SMD LED machine?

Improving placement accuracy involves ensuring proper calibration of the machine, using high-quality components, and maintaining the machine regularly. Additionally, ensuring that the feeders and nozzles are in good condition is crucial.

3. What factors should I consider when choosing a pick and place SMD LED machine?

When choosing a machine, consider factors such as precision, speed, component handling capacity, automation level, and maintenance support. The machine should align with your production needs and offer good reliability and customer support.

4. How often should I perform maintenance on my pick and place SMD LED machine?

Regular maintenance should be performed based on the manufacturer's recommendations, typically after a certain number of production cycles. This includes checking and replacing nozzles, cleaning the camera lens, and updating software.

5. Can used or refurbished pick and place SMD LED machines be a viable option?

Yes, used or refurbished machines can be a cost-effective option. However, ensure that they are properly refurbished, come with updated software, and have good customer support available.

Citations:

[1] https://www.circuitinsight.com/pdf/led_pick_place_challenge_ipc.pdf

[2] http://etasmt.com:9060/te_news_industry/2021-07-08/22561.chtml

[3] https://www.tronstol.com/the-knowledge-and-steps-you-need-to-know-about-smt-pick-and-place-machine-programs.html

[4] https://es.aliexpress.com/w/wholesale-smd-pick-and-place-machine.html

[5] https://www.zjyingxing.com/info/what-are-the-common-smt-pick-and-place-machine-88387624.html

[6] https://www.youtube.com/watch?v=s5Qaxi2uEhw

[7] https://www.smtneoden.com/pick-and-place-smd-led-machine-product/

[8] https://www.alibaba.com/showroom/smd-led-mounting-machine.html

[9] http://www.smt33.com/te_news_news/2021-09-14/33975.chtml