Content Menu

● Introduction to Surface Mount Device Resistors

>> Advantages of Surface Mount Resistors

● Common Applications of Surface Mount Device Resistors

>> Consumer Electronics

>> Automotive Electronics

>> Telecommunications

>> Industrial Equipment

>> Medical Devices

>> LED Lighting

>> Power Supply Circuits

>> Audio Equipment

>> Robotics

>> IoT Devices

● Conclusion

● Related Questions

>> 1. What is the difference between surface mount resistors and through-hole resistors?

>> 2. How do you choose the right surface mount resistor for your application?

>> 3. What are the common types of surface mount resistors?

>> 4. Can surface mount resistors be used in high-frequency applications?

>> 5. What are the best practices for soldering surface mount resistors?

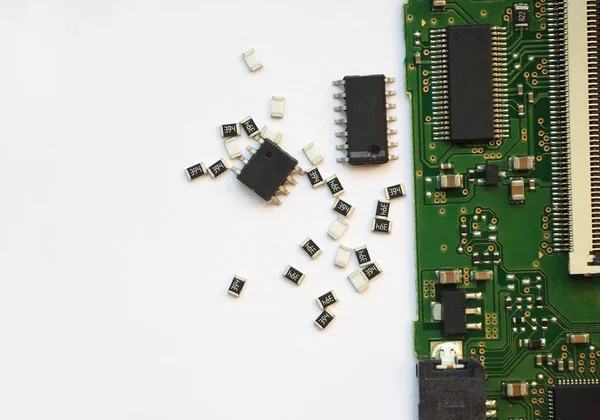

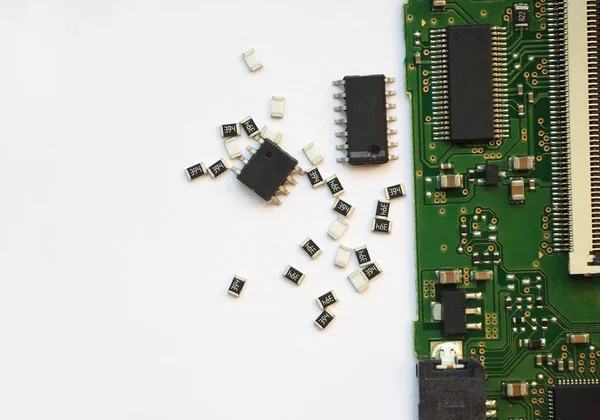

Surface mount device (SMD) resistors are essential components in modern electronic circuits, playing a crucial role in various applications. Their compact size, reliability, and efficiency make them a preferred choice in many designs. This article explores the common applications of surface mount device resistors, highlighting their significance in different fields of electronics.

Introduction to Surface Mount Device Resistors

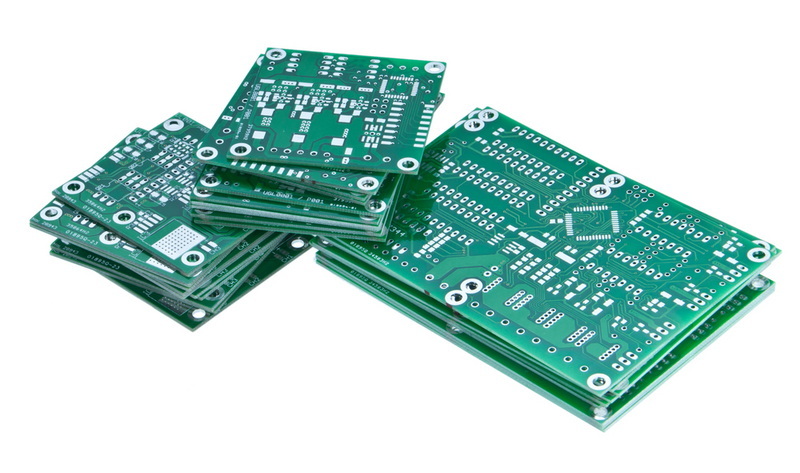

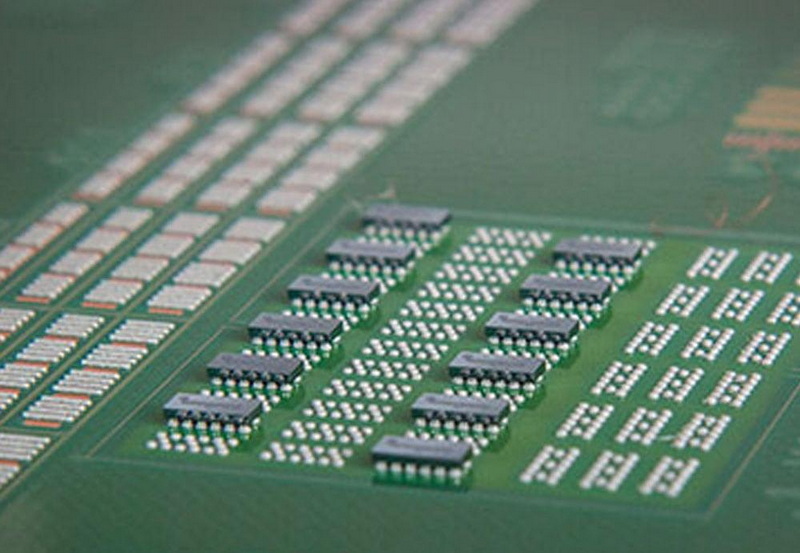

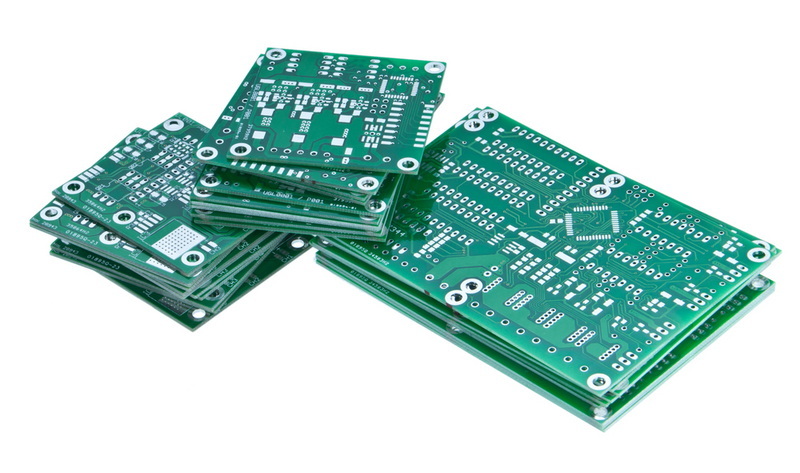

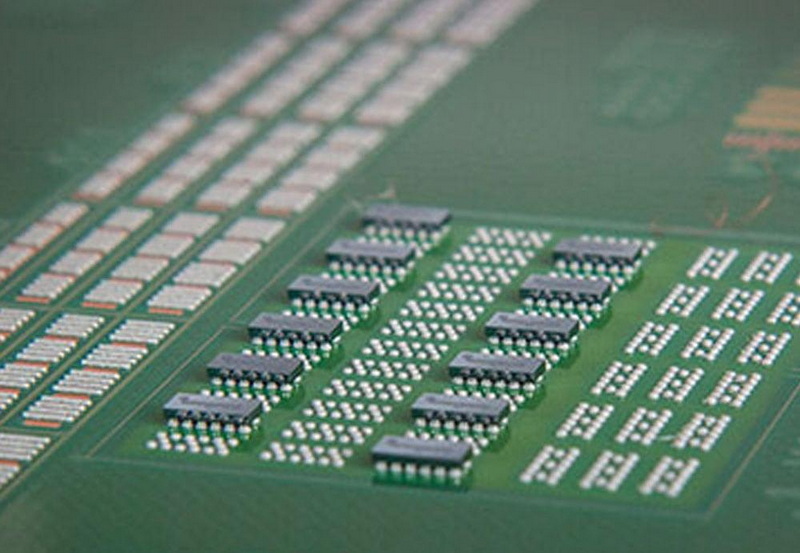

Surface mount resistors are designed to be mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole resistors, which require holes to be drilled into the PCB, SMD resistors are soldered onto pads on the board's surface. This design allows for a more compact layout, enabling manufacturers to create smaller and more efficient electronic devices.

Advantages of Surface Mount Resistors

1. Space Efficiency: SMD resistors occupy less space on PCBs, allowing for more components to be placed in a smaller area.

2. Improved Performance: They typically have better performance characteristics, such as lower parasitic inductance and capacitance, which is crucial for high-frequency applications.

3. Automated Assembly: SMD resistors can be easily integrated into automated assembly processes, reducing manufacturing costs and time.

4. Variety of Types: Available in various resistance values and sizes, SMD resistors can be tailored to meet specific circuit requirements.

Common Applications of Surface Mount Device Resistors

Consumer Electronics

Surface mount resistors are widely used in consumer electronics, including smartphones, tablets, and laptops. They help regulate current flow, protect sensitive components, and ensure the overall functionality of devices. For instance, in smartphones, SMD resistors are used in power management circuits to optimize battery performance and efficiency.

Automotive Electronics

In the automotive industry, SMD resistors are crucial for various applications, including engine control units (ECUs), infotainment systems, and safety features. They help manage power distribution, signal processing, and sensor interfacing. The compact size of SMD resistors allows for more efficient use of space in vehicle electronics, which is essential for modern automotive designs.

Telecommunications

Telecommunication devices, such as routers, switches, and base stations, rely heavily on surface mount resistors. These components are used in signal conditioning, impedance matching, and filtering applications. Their ability to handle high frequencies and provide stable performance makes them ideal for telecommunications equipment.

Industrial Equipment

In industrial applications, SMD resistors are used in control systems, automation equipment, and monitoring devices. They play a vital role in ensuring the reliability and accuracy of measurements in various industrial processes. For example, in temperature sensors, SMD resistors are used to create voltage dividers that help in precise temperature readings.

Medical Devices

Medical devices, including diagnostic equipment and monitoring systems, utilize surface mount resistors for their reliability and precision. These resistors are critical in ensuring accurate readings and safe operation of devices such as ECG machines and blood pressure monitors. The compact nature of SMD resistors also allows for the development of smaller, portable medical devices.

LED Lighting

Surface mount resistors are commonly used in LED lighting applications to control current and voltage levels. They help in managing the brightness and efficiency of LED lights, ensuring optimal performance. In LED drivers, SMD resistors are used to set the current flowing through the LEDs, which is crucial for their longevity and performance.

Power Supply Circuits

In power supply circuits, SMD resistors are used for voltage regulation and current limiting. They help maintain stable output voltages and protect against overcurrent conditions. Their small size allows for efficient designs in compact power supply units, which are essential in various electronic devices.

Audio Equipment

Surface mount resistors are also found in audio equipment, where they are used in signal processing and amplification circuits. They help in controlling audio signals, ensuring high-quality sound reproduction. In mixing consoles and amplifiers, SMD resistors are used to set gain levels and manage signal integrity.

Robotics

In robotics, SMD resistors are used in control systems, sensors, and communication modules. They help in managing power distribution and signal processing, which are critical for the operation of robotic systems. The compact size of SMD resistors allows for more efficient designs in robotic applications, where space is often limited.

IoT Devices

The Internet of Things (IoT) has seen a surge in the use of surface mount resistors. These components are integral to smart devices, sensors, and communication modules. SMD resistors help manage power consumption and signal integrity, which are crucial for the performance of IoT devices. Their small size and efficiency make them ideal for the compact designs often required in IoT applications.

Conclusion

Surface mount device resistors are indispensable components in modern electronics, finding applications across various industries, including consumer electronics, automotive, telecommunications, industrial equipment, medical devices, LED lighting, power supply circuits, audio equipment, robotics, and IoT devices. Their compact size, reliability, and efficiency make them a preferred choice for designers and manufacturers. As technology continues to evolve, the demand for surface mount resistors will likely increase, driving innovation and advancements in electronic design.

Related Questions

1. What is the difference between surface mount resistors and through-hole resistors?

Surface mount resistors are soldered directly onto the surface of PCBs, while through-hole resistors require holes to be drilled into the board. SMD resistors are generally smaller and allow for more compact designs.

2. How do you choose the right surface mount resistor for your application?

Choosing the right SMD resistor involves considering factors such as resistance value, power rating, tolerance, and size. It's essential to match these specifications to the requirements of your circuit.

3. What are the common types of surface mount resistors?

Common types of surface mount resistors include thick film, thin film, and metal film resistors. Each type has its unique characteristics and is suited for different applications.

4. Can surface mount resistors be used in high-frequency applications?

Yes, surface mount resistors are suitable for high-frequency applications due to their low parasitic inductance and capacitance, which helps maintain signal integrity.

5. What are the best practices for soldering surface mount resistors?

Best practices for soldering SMD resistors include using the correct soldering technique (e.g., reflow or hand soldering), ensuring proper pad size, and maintaining appropriate temperature settings to avoid damage to the components.