Content Menu

● Understanding SMT Line Balancing

>> Key Concepts of Line Balancing

● Best Techniques for SMT Machine Line Balancing

>> 1. Component Sequencing

>> 2. Machine Placement Strategies

>> 3. Feeder Management

>> 4. Workflow Design

>> 5. Continuous Monitoring and Data Analytics

● Line Balancing Methods

>> 1. Kilbridge and Wester Method

>> 2. Ranked Positional Weights

>> 3. Computerized Methods

● Automation and Technology Integration

● Training and Skill Development

● Lean Production Principles

● Takt Time Analysis

● Total Productive Maintenance (TPM)

● Supplier Management

● Process Monitoring

● Maintenance Practices

● Conclusion

● FAQ

>> 1. What is SMT line balancing?

>> 2. Why is cycle time important in SMT manufacturing?

>> 3. How can automation improve SMT efficiency?

>> 4. What role does training play in SMT line balancing?

>> 5. What are lean manufacturing principles?

● Citations:

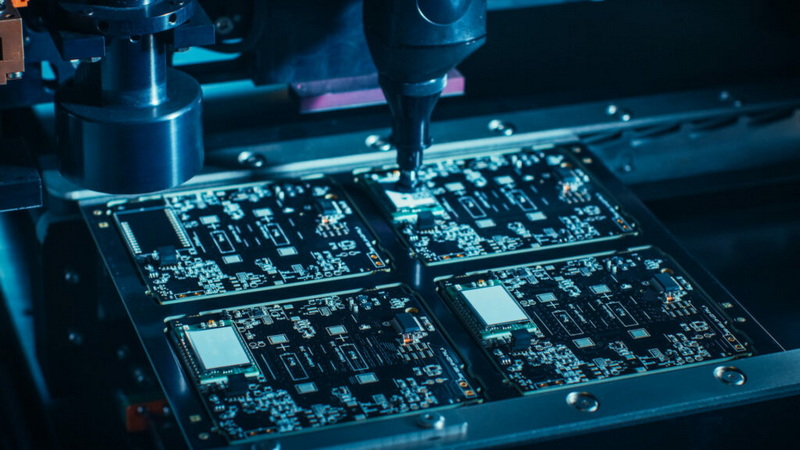

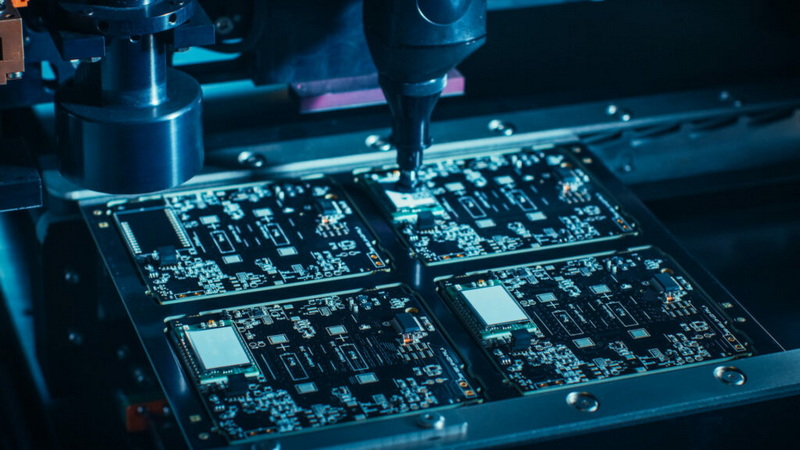

Surface Mount Technology (SMT) is a critical process in electronics manufacturing, particularly in the assembly of printed circuit boards (PCBs). Efficient SMT line balancing is essential for maximizing productivity, reducing waste, and ensuring high-quality output. This article explores the best techniques for SMT machine line balancing, including practical strategies, methodologies, and tools that can enhance production efficiency.

Understanding SMT Line Balancing

SMT line balancing involves distributing tasks evenly across various machines and workstations to minimize idle time and maximize throughput. The primary goal is to ensure that each machine operates at optimal efficiency without causing bottlenecks in the production line.

Key Concepts of Line Balancing

- Cycle Time: The total time required to complete one cycle of production. It is crucial to align the cycle times of different machines to avoid delays.

- Throughput: The rate at which products are produced. Higher throughput indicates a more efficient production line.

- Idle Time: This refers to periods when machines or operators are not actively engaged in production. Minimizing idle time is essential for maintaining efficiency.

Best Techniques for SMT Machine Line Balancing

1. Component Sequencing

Proper sequencing of components can significantly reduce machine setup time and improve overall throughput. By arranging components in the order they will be placed on the PCB, manufacturers can streamline the assembly process and minimize delays caused by searching for components.

2. Machine Placement Strategies

The layout of machines on the production floor plays a vital role in line balancing. Implementing strategies such as:

- Group Technology: Group similar machines together to reduce transportation time between processes.

- Parallel Placement: Use multiple machines to perform similar tasks concurrently, thereby increasing overall capacity and reducing bottlenecks.

3. Feeder Management

Efficient feeder management is crucial for maintaining a smooth workflow. Key practices include:

- Organization: Keep feeders well-organized and stocked to prevent component shortages.

- Changeover Minimization: Reduce the frequency of feeder changes by optimizing component placement and using similar components together.

4. Workflow Design

Optimizing the workflow layout can minimize material handling and reduce operator movement. Considerations include:

- Minimizing Distances: Arrange workstations to minimize the distance operators must travel between tasks.

- Ergonomic Design: Ensure that workstations are designed for ease of use, allowing operators to perform tasks efficiently without unnecessary strain.

5. Continuous Monitoring and Data Analytics

Implement real-time monitoring systems to track machine performance and identify bottlenecks as they occur. Utilizing data analytics can help manufacturers make informed decisions about process improvements based on actual performance metrics.

Line Balancing Methods

Several methodologies can be employed for effective SMT line balancing:

1. Kilbridge and Wester Method

This iterative method focuses on adjusting cycle times across different operations to achieve a balanced line where all stations have equal cycle times. The steps include:

- Identifying the sequence of operations.

- Determining the ideal cycle time based on the critical path.

- Assigning cycle times iteratively until balance is achieved.

2. Ranked Positional Weights

This method assigns weights to different positions in the manufacturing line based on their importance, helping prioritize tasks effectively to optimize performance.

3. Computerized Methods

With advancements in technology, computerized methods have emerged as effective tools for balancing manufacturing lines. These methods use software algorithms to analyze production processes and optimize task assignments based on real-time data.

Automation and Technology Integration

Incorporating automation into SMT processes can significantly enhance efficiency and quality:

- Automated Equipment: Invest in advanced pick-and-place machines that offer higher speeds and precision.

- Machine Learning Algorithms: Utilize predictive maintenance tools that leverage machine learning to anticipate equipment failures before they occur, thus minimizing downtime.

Training and Skill Development

A well-trained workforce is essential for successful SMT line balancing. Implementing continuous training programs ensures that operators are skilled in equipment operation, troubleshooting, and maintenance practices.

Lean Production Principles

Adopting lean manufacturing principles can further enhance efficiency by minimizing waste and optimizing workflows through practices such as:

- Kaizen: Encourage continuous improvement initiatives within teams.

- Value Stream Mapping: Analyze current processes to identify areas for improvement.

Takt Time Analysis

Takt time is a crucial metric in SMT production that dictates the pace at which products must be completed to meet customer demand. By analyzing takt time, manufacturers can adjust their processes accordingly, ensuring that each station operates efficiently within its designated cycle time.

Total Productive Maintenance (TPM)

Total Productive Maintenance (TPM) involves engaging all employees in maintaining equipment to improve uptime and meet cycle time targets. TPM fosters a culture of ownership among workers, leading to better-maintained machinery and reduced downtime due to unexpected failures.

Supplier Management

Strong relationships with suppliers are vital for ensuring timely delivery of high-quality materials necessary for SMT processes. Effective supplier management includes:

- Regular communication regarding material needs.

- Establishing quality standards for incoming components.

- Collaborating with suppliers on improving lead times and reliability.

Process Monitoring

Continuous monitoring of manufacturing processes is crucial for early error detection and correction. Employing state-of-the-art tools ensures product quality while maintaining production speed. Techniques such as Automated Optical Inspection (AOI) can catch defects early in the process, reducing rework costs significantly.

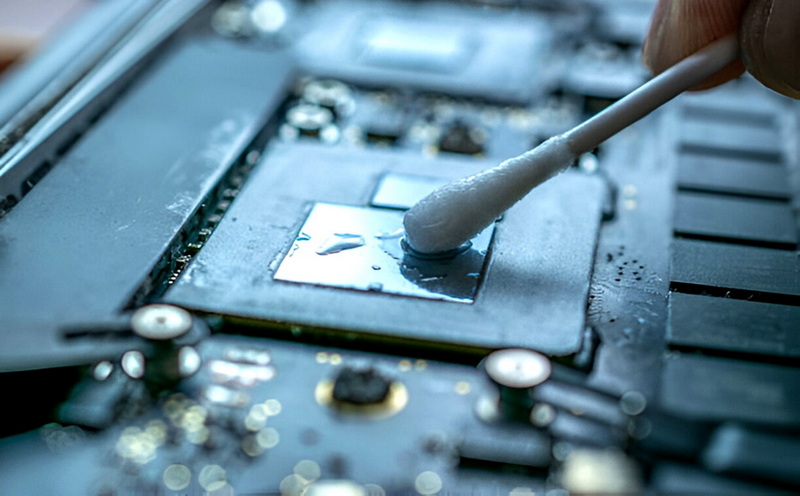

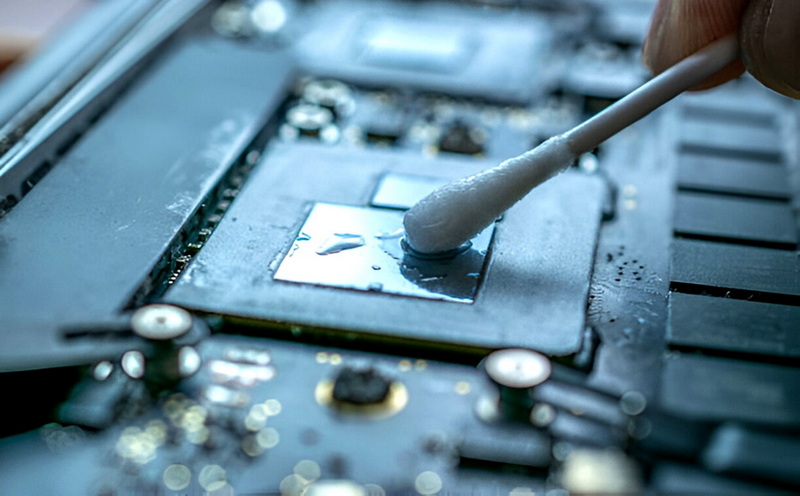

Maintenance Practices

Regular maintenance activities on SMT lines include:

- Cleaning conveyors, nozzles, and filters.

- Lubricating moving parts.

- Replacing worn clamp belts and conveyor belts.

- Checking calibration of pick-and-place accuracy.

- Updating heating elements and thermocouples.

- Testing power supplies and servos.

Such maintenance sustains performance, prevents breakdowns, and reduces unplanned downtime, contributing significantly to overall productivity.

Conclusion

Effective SMT machine line balancing is crucial for optimizing productivity in electronics manufacturing. By employing techniques such as component sequencing, strategic machine placement, feeder management, workflow design, continuous monitoring, automation integration, training programs, lean principles, takt time analysis, TPM practices, supplier management, process monitoring, and regular maintenance routines, manufacturers can significantly enhance their production efficiency. This holistic approach not only improves throughput but also enhances product quality while reducing costs associated with waste and rework.

FAQ

1. What is SMT line balancing?

SMT line balancing refers to the process of distributing tasks evenly across machines in an SMT production line to minimize idle time and maximize throughput.

2. Why is cycle time important in SMT manufacturing?

Cycle time is critical as it determines how quickly products can be produced; aligning cycle times across machines helps prevent bottlenecks.

3. How can automation improve SMT efficiency?

Automation enhances speed and precision while reducing labor costs, leading to improved overall efficiency in production lines.

4. What role does training play in SMT line balancing?

Training ensures that operators possess the necessary skills to operate equipment efficiently, troubleshoot issues quickly, and maintain high-quality standards.

5. What are lean manufacturing principles?

Lean manufacturing principles focus on minimizing waste while maximizing productivity through continuous improvement processes like Kaizen.

Citations:

[1] https://txjpcb.com/the-best-practices-for-smt-line-balancing-and-optimization/

[2] https://prototypepcbassembly.com/optimizing-smt-production-lines-for-maximum-efficiency/

[3] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[4] https://smtnet.com/library/files/upload/line-balance.pdf

[5] https://www.ocmmanufacturing.com/resources/resource/dfm-tip-best-practices-for-surface-mount-technology-smt-design/

[6] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[7] https://iconnect007.com/article/110962/modeling-an-smt-line-to-improve-throughput/110965/smt

[8] https://www.linkedin.com/pulse/rapid-smt-assembly-improving-efficiency-surface-oerzc

[9] https://www.neodensmt.com/news/improve-smt-production-efficiency-48868013.html

[10] https://www.smtneoden.com/news/how-to-effectively-improve-the-production-efficiency-of-pcb-smt-machine/

[11] https://www.circuitinsight.com/pdf/Modeling_SMT_Line_Improve_Throughput_smta.pdf

[12] https://blog.matric.com/smt-production-for-pcbs-matric

[13] https://www.smthelp.com/methods-and-measures-to-improve-the-production-efficiency-of-smt-production-line

[14] https://www.linkedin.com/pulse/how-improve-smt-production-efficiency-

[15] https://www.researchgate.net/publication/245330069_Balancing_and_scheduling_of_surface_mount_technology_lines

[16] https://www.andwinpcb.com/efficient-strategies-for-smt-board-assembly-in-electronics-production/

[17] https://circuitsassembly.com/ca/magazine/25128-line-balancing-1508.html

[18] https://www.linkedin.com/pulse/essential-practices-long-lived-smt-lines-hawker-richardson