Content Menu

● Introduction

● Understanding Surface Mount Technology (SMT)

>> Key Components of SMD Machines

● Best Surface Mount Device Machines for Beginners

>> Mini SMD Pick and Place Machine

>> Reflow Oven for SMD

>> Solder Paste Printer

>> Desktop SMD Assembly Kit

>> Entry-Level Automated SMD Machine

● Factors to Consider When Choosing an SMD Machine

>> Budget

>> Project Requirements

>> Ease of Use

>> Space Availability

>> Future Scalability

● Conclusion

● Related Questions

>> 1. What is the difference between SMD and through-hole technology?

>> 2. How do I maintain my SMD machine?

>> 3. Can I use SMD machines for prototyping?

>> 4. What types of components can I use with SMD machines?

>> 5. Are there any safety precautions I should take when using SMD machines?

Introduction

Surface Mount Device (SMD) machines are essential tools in modern electronics manufacturing, particularly for assembling printed circuit boards (PCBs). For beginners, selecting the right SMD machine can be daunting due to the variety of options available. This article will explore the best surface mount device machines for beginners, detailing their features, benefits, and considerations to help you make an informed decision.

Understanding Surface Mount Technology (SMT)

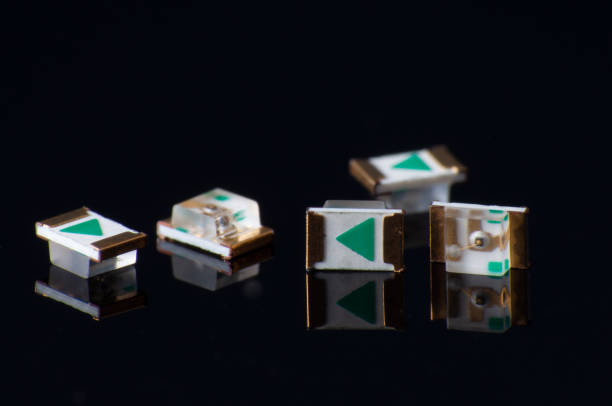

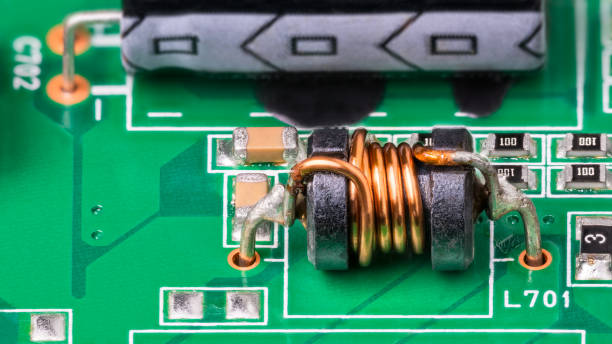

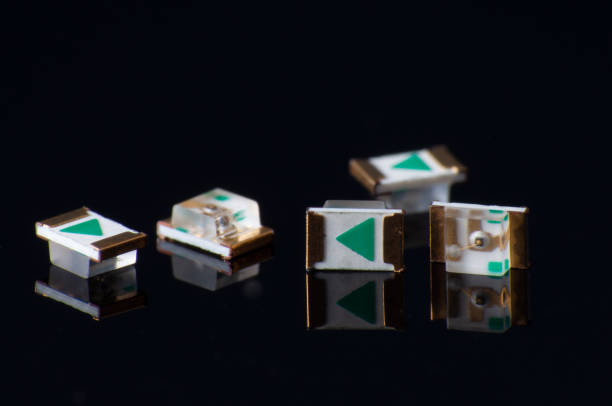

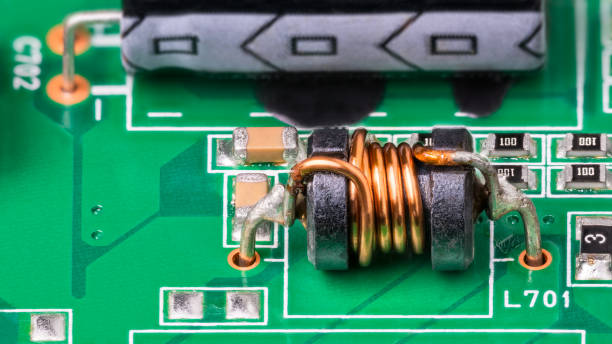

Surface Mount Technology (SMT) refers to the method of mounting electronic components directly onto the surface of PCBs. This technique has largely replaced traditional through-hole technology due to its efficiency and compactness. SMD machines automate the process of placing these components on PCBs, significantly speeding up production and improving accuracy.

Key Components of SMD Machines

1. Pick and Place Mechanism: This is the heart of any SMD machine. It uses a vacuum system to pick up components and place them accurately on the PCB.

2. Solder Paste Printer: This component applies solder paste to the PCB before components are placed. It ensures that the right amount of solder is used, which is crucial for a reliable connection.

3. Reflow Oven: After components are placed, the PCB goes through a reflow oven where the solder paste is melted to create permanent connections.

4. Inspection Systems: Many modern SMD machines include automated optical inspection (AOI) systems to check for placement accuracy and solder quality.

Best Surface Mount Device Machines for Beginners

When choosing an SMD machine, beginners should consider factors such as ease of use, cost, and the types of projects they plan to undertake. Here are some of the best options available:

Mini SMD Pick and Place Machine

Mini SMD pick and place machines are ideal for hobbyists and small-scale production. They are compact, affordable, and easy to operate. Many models come with user-friendly software that simplifies the programming process.

- Pros: Affordable, compact, easy to use.

- Cons: Limited speed and capacity compared to larger machines.

Reflow Oven for SMD

A reflow oven is essential for any SMD assembly process. For beginners, a small, benchtop reflow oven is a great choice. These ovens are designed to handle small batches and are often equipped with programmable temperature profiles.

- Pros: Essential for soldering, programmable settings.

- Cons: Requires some learning to optimize settings.

Solder Paste Printer

A solder paste printer is crucial for applying solder paste accurately. For beginners, a manual or semi-automatic printer can be a good starting point. These printers are generally more affordable and easier to use than fully automatic models.

- Pros: Affordable, easy to learn.

- Cons: Slower than automatic printers.

Desktop SMD Assembly Kit

For those just starting, a desktop SMD assembly kit can be an excellent choice. These kits often include a pick and place machine, a reflow oven, and a solder paste printer, providing a complete solution for beginners.

- Pros: All-in-one solution, cost-effective.

- Cons: May lack advanced features.

Entry-Level Automated SMD Machine

For those looking to invest in a more advanced machine, entry-level automated SMD machines offer a good balance between cost and functionality. These machines typically feature automated pick and place capabilities and can handle a wider range of components.

- Pros: Faster, more versatile.

- Cons: Higher initial investment.

Factors to Consider When Choosing an SMD Machine

When selecting an SMD machine, consider the following factors:

Budget

Determine how much you are willing to spend. Entry-level machines can range from a few hundred to several thousand dollars.

Project Requirements

Consider the types of projects you will be working on. If you plan to work with small batches or prototypes, a mini machine may suffice. For larger projects, consider a more robust solution.

Ease of Use

Look for machines with user-friendly interfaces and good customer support. This is especially important for beginners who may need assistance during setup and operation.

Space Availability

Ensure you have enough space for the machine and any additional equipment, such as a reflow oven or solder paste printer.

Future Scalability

Consider whether the machine can grow with your needs. Some entry-level machines can be upgraded with additional features or capabilities.

Conclusion

Choosing the right surface mount device machine is crucial for beginners looking to dive into electronics assembly. By understanding the different types of machines available and considering your specific needs, you can select a machine that will help you succeed in your projects. Whether you opt for a mini pick and place machine or a more advanced automated system, investing in quality equipment will enhance your productivity and the quality of your work.

Related Questions

1. What is the difference between SMD and through-hole technology?

SMD technology mounts components directly on the surface of PCBs, while through-hole technology involves inserting leads through holes in the board. SMD is generally more compact and allows for higher component density.

2. How do I maintain my SMD machine?

Regular maintenance includes cleaning the pick and place head, checking for software updates, and ensuring that all mechanical parts are functioning correctly.

3. Can I use SMD machines for prototyping?

Yes, many SMD machines are suitable for prototyping, especially those designed for small batch production.

4. What types of components can I use with SMD machines?

SMD machines can handle a wide variety of components, including resistors, capacitors, integrated circuits, and more.

5. Are there any safety precautions I should take when using SMD machines?

Always follow the manufacturer's safety guidelines, wear appropriate personal protective equipment, and ensure proper ventilation when using soldering equipment.