Content Menu

● Why Consider Buying Used PCB SMT Manufacturing Equipment?

● Best Sources to Buy Used PCB SMT Manufacturing Equipment

>> 1. Specialized Dealers

>> 2. Online Marketplaces

>> 3. Global Manufacturers and Distributors

>> 4. Industrial Auctions

>> 5. SMT Sales Group

● Key Considerations When Buying Used PCB SMT Machines

>> 1. Machine Condition

>> 2. Compatibility

>> 3. Brand Reputation

>> 4. After-Sales Support

>> 5. Cost vs. Value

● Tips for a Successful Purchase

● Conclusion

● FAQs

>> 1. What are the most reliable brands for used PCB SMT machines?

>> 2. Where can I find affordable yet high-quality used SMT equipment?

>> 3. How do I verify the quality of a used SMT machine?

>> 4. Are there any risks associated with buying used PCB SMT manufacturing equipment?

>> 5. Can I upgrade my existing production line with used SMT machines?

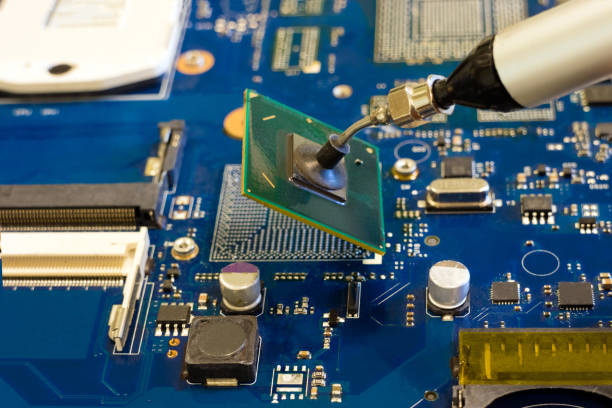

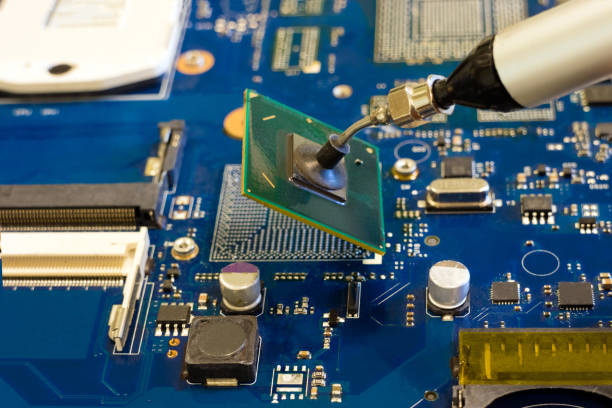

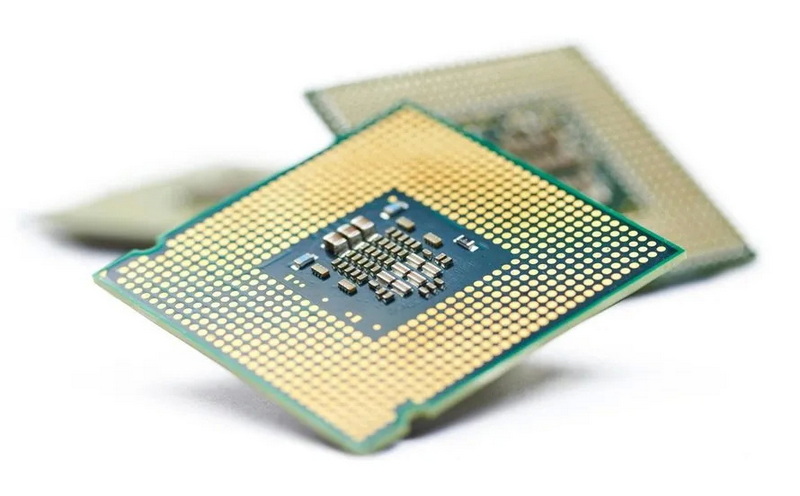

When it comes to scaling or upgrading your electronics manufacturing capabilities, purchasing used PCB Surface Mount Technology (SMT) machines can be a cost-effective and efficient solution. These machines are vital for automating the assembly of printed circuit boards (PCBs), and opting for pre-owned equipment allows businesses to reduce capital investment while maintaining production quality. This article explores the best sources to buy used PCB SMT manufacturing equipment, key considerations, and tips for making informed purchasing decisions.

Why Consider Buying Used PCB SMT Manufacturing Equipment?

Investing in used SMT machines offers several advantages:

- Cost Efficiency: Used equipment is significantly cheaper than new models, which is ideal for startups or businesses with limited budgets.

- Quick Availability: Pre-owned machines are often readily available, avoiding long lead times associated with new equipment.

- Tested Performance: Many used machines have a proven track record of reliability and performance.

- Sustainability: Purchasing used equipment supports a circular economy by extending the lifecycle of industrial machinery.

- Scalability: For small-scale manufacturers or those entering new markets, used SMT machines provide an affordable way to scale operations without overcommitting resources.

However, it's crucial to source these machines from reputable dealers to ensure quality and support.

Best Sources to Buy Used PCB SMT Manufacturing Equipment

1. Specialized Dealers

Specialized dealers often refurbish and test the equipment before resale, ensuring reliability. Here are some trusted names in the industry:

- Lewis & Clark: Offers a wide range of SMT equipment, including test systems. Known for its extensive inventory and customer service.

- Thinking Productivity: Focuses on high-quality used SMT machines and offers services like calibration and maintenance.

- Precision Placement Machines (PPM): Specializes in brands like Quad/Tyco, MPM, and Heller. They also provide consultation services to match buyers with suitable equipment.

Specialized dealers often work closely with manufacturers to ensure that the refurbished machines meet industry standards. They may also offer training programs for operators, which can be invaluable for companies adopting SMT technology for the first time.

2. Online Marketplaces

Websites dedicated to buying and selling industrial equipment provide a vast selection of used SMT machines:

- SMTnet.com: Lists over 700 marketplace items, including pick-and-place machines, reflow ovens, and conveyors. It also connects buyers with global sellers.

- BuySMT.com: Offers refurbished SMT equipment from top brands like Yamaha, Panasonic, and JUKI. They also provide after-sales support.

- eBay Industrial Equipment Section: While not exclusively focused on SMT machines, eBay often features listings from both private sellers and companies looking to offload surplus equipment.

These platforms allow buyers to compare prices across multiple vendors, read reviews, and even contact sellers directly for additional details. However, due diligence is essential when using online marketplaces since not all listings guarantee quality or authenticity.

3. Global Manufacturers and Distributors

Some manufacturers sell their refurbished or demo units at discounted prices:

- Dongguan Kingsun Automation Technology Co., Ltd.: Based in China, this company specializes in both new and used SMT equipment along with repair services.

- Global Soul Limited: Offers pre-owned chip shooters and other high-performance SMT machines directly from their inventory.

- Mycronic Pre-Owned Equipment Program: Mycronic provides certified pre-owned solutions with warranties and technical support.

Buying directly from manufacturers ensures that the equipment has been inspected and maintained according to factory standards. This option is particularly appealing for businesses that require high-end machinery with minimal risk.

4. Industrial Auctions

Auctions are excellent for finding high-quality used equipment at competitive prices:

- Companies like HongCheng Import & Export Co., Ltd. frequently host auctions for surplus or decommissioned industrial machinery.

- Platforms such as GoIndustry DoveBid specialize in online auctions for manufacturing equipment.

While auctions can offer significant savings, they require careful planning. Buyers should research the auctioneer's reputation, understand bidding rules, and inspect items whenever possible before placing bids.

5. SMT Sales Group

This international supplier provides fully functional pre-owned PCB assembly and SMT equipment. Their expertise in rigging, preparation, and shipping makes them a reliable partner for global buyers.

SMT Sales Group also offers consultation services to help businesses identify the right equipment based on their production needs. Their global reach ensures access to a diverse inventory of machines across various price points.

Key Considerations When Buying Used PCB SMT Machines

1. Machine Condition

Inspect the machine's condition thoroughly or request detailed documentation about its usage history, maintenance records, and refurbishment status. Machines that have undergone professional refurbishment are generally more reliable than those sold "as-is."

2. Compatibility

Ensure that the machine is compatible with your existing production line in terms of size, speed, software integration, and power requirements. For example:

- A pick-and-place machine must handle your specific component sizes.

- Reflow ovens should match your soldering process requirements.

3. Brand Reputation

Opt for trusted brands like Yamaha, JUKI, Panasonic, Universal Instruments, or Mycronic as they offer robust performance and easier access to spare parts.

4. After-Sales Support

Choose suppliers that provide technical support, training programs, or warranties for their used equipment. Support services can significantly reduce downtime during installation or troubleshooting.

5. Cost vs. Value

While price is important, prioritize value by considering factors like machine lifespan, efficiency gains, potential downtime savings, and overall return on investment (ROI).

Tips for a Successful Purchase

1. Set a Budget: Define your financial limits but remain flexible to accommodate high-value deals.

2. Research Extensively: Compare multiple sources to find the best combination of price and quality.

3. Request Demonstrations: Whenever possible, see the machine in action before committing to a purchase.

4. Negotiate Terms: Discuss payment options (e.g., leasing vs outright purchase), shipping costs, and warranty terms with the seller.

5. Plan Installation: Ensure you have the required infrastructure (e.g., power supply) before delivery.

Additionally, consider hiring an independent technician or consultant to inspect the machine before finalizing your purchase if you lack in-house expertise.

Conclusion

Buying used PCB SMT manufacturing equipment can be a strategic move for businesses looking to enhance their production capabilities without overspending. By sourcing from reputable dealers like Lewis & Clark or platforms such as BuySMT.com or SMTnet.com, you can secure reliable machinery tailored to your needs while saving significantly on costs compared to new models.

Always prioritize quality over cost by thoroughly inspecting equipment and ensuring compatibility with your production line. Whether you're purchasing from specialized dealers or participating in industrial auctions, taking time to evaluate your options will ensure you make an informed decision that benefits your business in the long run.

FAQs

1. What are the most reliable brands for used PCB SMT machines?

Trusted brands include Yamaha, JUKI, Panasonic, Universal Instruments, Mycronic, Fuji Electric Systems Co., Ltd., and Assembleon due to their proven performance and availability of spare parts.

2. Where can I find affordable yet high-quality used SMT equipment?

Platforms like SMTnet.com and BuySMT.com offer extensive inventories of affordable pre-owned SMT machines from reputable sellers worldwide.

3. How do I verify the quality of a used SMT machine?

Request maintenance records from the seller or dealer; inspect its physical condition (if possible); ask for a live demonstration; or hire an independent technician to evaluate its performance before purchase.

4. Are there any risks associated with buying used PCB SMT manufacturing equipment?

Risks include potential hidden defects or compatibility issues with your production line. Mitigate these risks by purchasing from trusted dealers who offer warranties or after-sales support services.

5. Can I upgrade my existing production line with used SMT machines?

Yes! Many used machines are compatible with modern production lines provided they meet your technical requirements such as software integration capability or throughput speed.