Content Menu

● Introduction

● Why Are SMT Rework Tools Important?

● Top SMT Rework Tools for Precision Soldering

>> 1. Soldering Stations

>> 2. Hot Air Rework Stations

>> 3. Desoldering Tools

>> 4. Tweezers and Magnification Tools

>> 5. ESD Protection

● Additional Considerations When Choosing SMT Rework Tools

● Step-by-Step Guide to Using SMT Rework Tools

>> 1. Removing Components

>> 2. Cleaning the Pads

>> 3. Replacing Components

>> 4. Inspecting Your Work

>> 5. Testing Functionality

● Conclusion

● FAQ

>> 1. What are the essential SMT rework tools?

>> 2. How do I choose the right soldering station?

>> 3. What is the role of flux in SMT rework?

>> 4. Can I use a regular soldering iron for SMT rework?

>> 5. How do I prevent ESD damage during rework?

Introduction

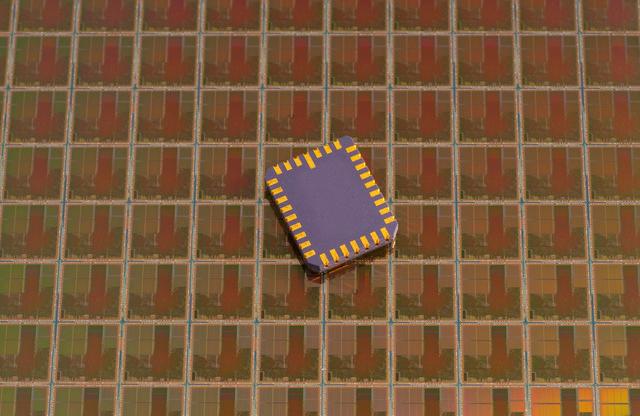

Surface Mount Technology (SMT) rework tools are indispensable for precision soldering tasks in today's electronics landscape, where components are becoming increasingly miniaturized. Whether you are a professional technician or a hobbyist, having the right SMT rework tools can significantly impact the quality and efficiency of your work. This article delves into the best SMT rework tools available on the market, their features, and how they can enhance your soldering experience.

Why Are SMT Rework Tools Important?

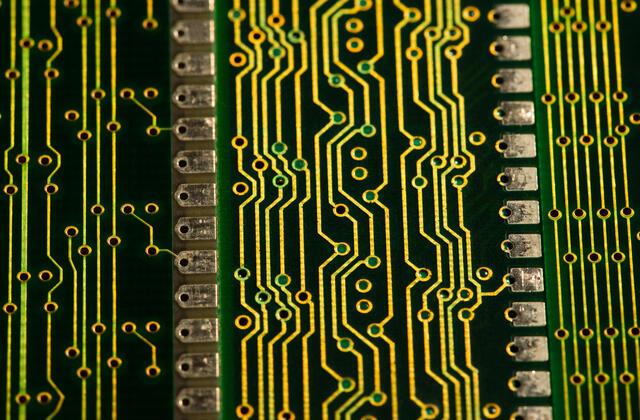

SMT rework tools are specifically designed to handle the delicate and precise nature of surface mount components. These tools ensure that components are soldered or desoldered without damaging the printed circuit board (PCB) or surrounding parts. With advancements in technology, modern SMT rework tools now offer features such as:

- Temperature Control: Allows for precise heating, essential for sensitive components.

- ESD Protection: Safeguards against electrostatic discharge that can damage electronic parts.

- Ergonomic Designs: Enhances user comfort during prolonged use.

Investing in high-quality SMT rework tools not only improves the reliability of solder joints but also enhances overall workflow efficiency.

Top SMT Rework Tools for Precision Soldering

1. Soldering Stations

Soldering stations are fundamental in any rework setup. They provide precise temperature control, which is crucial for working with sensitive components. Some notable options include:

- AiXun T420D 200W Dual Channel Electronics Soldering Station: Ideal for professionals, this station offers rapid heating and dual-handle functionality. It features a digital display for easy temperature adjustments and comes with a variety of interchangeable tips for different applications.

- AiXun T3B 96W Micro Soldering Station: A favorite among hobbyists, known for its advanced temperature control and compact design. This station is particularly effective for micro soldering tasks, making it suitable for intricate work on small components.

The choice of soldering station should align with the specific requirements of your projects. For instance, if you frequently work on high-density boards with tiny components, a station with fine-tipped soldering irons will be beneficial.

2. Hot Air Rework Stations

Hot air rework stations are essential for tasks like reballing and desoldering. They allow controlled heating, making them suitable for removing and replacing components without causing thermal damage. Weller's range of hot-air stations is highly regarded for their reliability and precision.

- Quick 861DW Hot Air Rework Station: This model is known for its fast heat-up time and adjustable airflow settings, allowing users to customize the heat application based on the component size and type.

- Hakko FR-301 Desoldering Tool: While primarily a desoldering tool, it can also function effectively in conjunction with hot air stations to remove surface-mounted components safely.

Using hot air rework stations requires some skill; it's important to maintain a steady hand while directing the airflow to avoid overheating adjacent components.

3. Desoldering Tools

Desoldering tools such as vacuum pumps and solder wicks are vital for cleaning up excess solder. They ensure that pads are clean and ready for new components. Using flux can further enhance the effectiveness of these tools by improving solder flow and adhesion.

- Solder Wick: This copper braid is used to absorb molten solder when placed over it and heated with a soldering iron. It's an essential tool for cleaning up after removing components.

- Vacuum Desoldering Pump: This tool provides an efficient way to remove excess solder from PCB pads quickly. When used correctly, it can help prevent damage to the pads during desoldering.

When selecting desoldering tools, consider their compatibility with various PCB types and component sizes to ensure optimal performance during rework tasks.

4. Tweezers and Magnification Tools

Handling tiny SMT components requires precision tools like tweezers and magnification aids. High-quality tweezers provide a firm grip, while magnifying glasses or microscopes offer the clarity needed for accurate placement and inspection.

- Precision Tweezers: Look for tweezers made from stainless steel with anti-magnetic properties to avoid any interference with electronic components. Different tip shapes (like pointed or flat) serve various purposes depending on component size and type.

- Magnifying Glasses or Microscopes: A good magnification tool is crucial when working with small parts. LED-lit magnifiers enhance visibility, allowing you to see fine details clearly while working on intricate tasks.

Using these tools effectively can significantly reduce errors during assembly or repair processes, leading to higher-quality results.

5. ESD Protection

Electrostatic discharge (ESD) can severely damage sensitive electronic components. Tools like ESD wrist straps and mats are crucial for protecting your work from static electricity, ensuring that your components remain intact during the rework process.

- ESD Wrist Straps: These straps ground the user to prevent static buildup while handling sensitive parts. They should be worn at all times when working on electronic assemblies to minimize ESD risks.

- ESD Mats: Placing your workspace on an ESD mat helps dissipate static charges safely away from sensitive components. These mats are particularly useful in environments where multiple technicians may be working simultaneously.

Additional Considerations When Choosing SMT Rework Tools

When selecting SMT rework tools, consider the following factors:

- Quality vs. Cost: While it might be tempting to opt for cheaper alternatives, investing in high-quality tools often pays off in terms of durability and performance.

- User Reviews: Research user feedback on specific models before purchasing. Reviews provide insights into real-world performance and reliability that specifications alone may not reveal.

- Brand Reputation: Established brands typically offer better customer support and warranties, which can be crucial if you encounter issues with your tools down the line.

Step-by-Step Guide to Using SMT Rework Tools

1. Removing Components

Start by securing the PCB on a stable surface and ensuring ESD protection is in place. Use a hot air rework station to heat the component evenly until the solder melts. Carefully lift the component with tweezers to avoid damaging the PCB.

2. Cleaning the Pads

After removing the component, clean the pads using a desoldering braid or solder wick to remove any residual solder. Applying flux can make this process easier and ensure that the pads are flat and clean.

3. Replacing Components

Position the new component on the cleaned pads using tweezers. Apply heat with a soldering iron or hot air station to reflow the solder, securing the component in place. Ensure that all connections are solid and free from defects.

4. Inspecting Your Work

After completing your soldering task, inspect all connections closely using magnification tools. Look for any signs of bridging between pads or cold joints that may compromise functionality.

5. Testing Functionality

Once inspection is complete, power up your device to test functionality before finalizing your work area. This step ensures that everything is functioning as intended before closing up any enclosures or casings.

Conclusion

Investing in high-quality SMT rework tools is essential for achieving precision and reliability in soldering tasks. Whether you are a beginner or an experienced technician, having the right tools at your disposal can significantly enhance your efficiency and improve the quality of your work. By understanding which tools best suit your needs, you can tackle any SMT project with confidence.

FAQ

1. What are the essential SMT rework tools?

Essential tools include soldering stations, hot air rework stations, desoldering tools (like vacuum pumps and solder wicks), tweezers, magnification aids, and ESD protection equipment.

2. How do I choose the right soldering station?

When selecting a soldering station, consider factors such as temperature control, power output, compatibility with different soldering tips, and whether it meets your specific needs (professional vs. hobbyist).

3. What is the role of flux in SMT rework?

Flux plays a critical role in cleaning and preparing pads before soldering or desoldering tasks. It helps remove oxidation from surfaces, improves heat transfer during soldering, and ensures strong solder joints by preventing bridging between pads.

4. Can I use a regular soldering iron for SMT rework?

While it is possible to use a regular soldering iron for some SMT tasks, specialized SMT rework tools provide better precision and temperature control necessary for handling small components effectively.

5. How do I prevent ESD damage during rework?

To prevent ESD damage during rework, use ESD wrist straps, mats, and other protective equipment designed to safeguard sensitive components from static electricity.