Content Menu

● Understanding SMT Feeder Parts

>> Types of SMT Feeder Parts

>> The Role of SMT Feeder Parts in the Manufacturing Process

● Advantages of High-Quality SMT Feeder Parts

>> Increase Productivity

>> Improve Product Quality

>> Extend Equipment Life

>> Cost Efficiency

● Innovations in SMT Feeder Technology

>> Automated Feeder Systems

>> Smart Feeder Technology

>> Integration with Industry 4.0

● Key Considerations When Choosing SMT Feeder Parts

>> Compatibility with Existing Equipment

>> Supplier Reputation and Reliability

>> Cost vs. Value

>> Maintenance and Support

>> Scalability

● Future Trends in SMT Feeder Parts

>> Miniaturization of Components

>> Increased Automation

>> Enhanced Connectivity

>> Sustainable Manufacturing Practices

● Conclusion

● FAQ

>> 1. What are SMT feeder parts?

>> 2. Why are high-quality SMT feeder parts important?

>> 3. What types of SMT feeder parts are available?

>> 4. How do SMT feeder parts affect equipment lifespan?

>> 5. How can companies ensure they are using the best SMT feeder parts?

In the rapidly evolving realm of electronics manufacturing, efficiency is paramount. At the core of Surface Mount Technology (SMT) are feeder parts, which play a critical role in ensuring that production lines operate smoothly and effectively. This article delves into the best SMT feeder parts that can significantly enhance efficiency, improve product quality, and prolong the lifespan of equipment.

Understanding SMT Feeder Parts

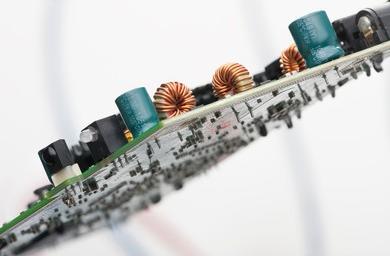

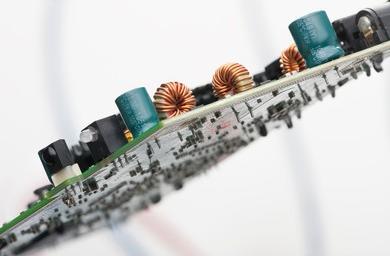

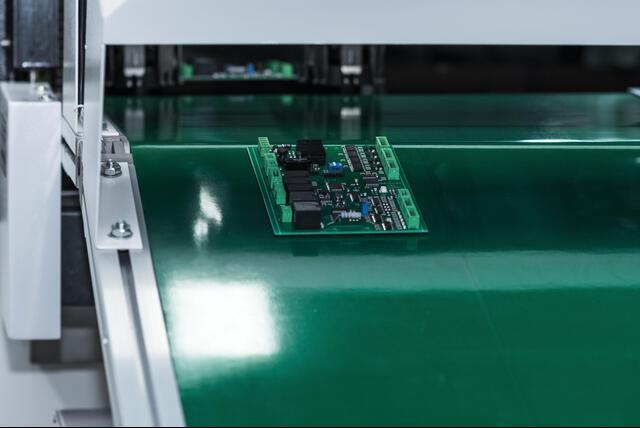

SMT feeder parts are essential components of SMT machines, responsible for delivering electronic components to placement machines with precision and speed. The quality of these feeder parts directly impacts the overall performance of SMT equipment. High-quality feeders ensure a stable supply of components, thereby minimizing downtime and maximizing production efficiency.

Types of SMT Feeder Parts

There are several types of SMT feeder parts, each designed for specific applications:

- Tape and Reel Feeders: The most common type, ideal for placing large quantities of identical small components. These feeders have evolved into high-precision electric types that provide faster feeding speeds and higher accuracy.

- Stick Feeders: Designed for components packed in linear sticks, suitable for small integrated circuits (ICs) issued in low volumes. They can adapt to various component types.

- Matrix Tray Feeders: Used for larger or more delicate components, these feeders provide secure handling without damaging fragile leads.

- Bulk Feeders: Handle chip-style components in large quantities. While cost-effective, they may face performance issues due to debris during the feeding process.

- Direct Die Feeders: Utilized for flip-chip or chip-on-board applications, these feeders offer higher speed and flexibility, reducing costs per placement.

The Role of SMT Feeder Parts in the Manufacturing Process

SMT feeder parts are integral to the manufacturing process as they directly influence the speed and accuracy of component placement. A well-functioning feeder ensures that components are delivered to the pick-and-place machine at the right time and in the correct orientation. This precision is crucial because any misalignment can lead to defects in the final product, resulting in increased rework costs and potential delays in production schedules.

Moreover, feeders must be capable of handling various component sizes and types without compromising performance. This adaptability is essential in today's fast-paced manufacturing environments where product lines frequently change.

Advantages of High-Quality SMT Feeder Parts

Investing in premium SMT feeder parts yields numerous benefits:

Increase Productivity

High-quality SMT feeder parts ensure a consistent supply of components, reducing equipment downtime and enhancing production efficiency. Poor-quality feeders can lead to frequent adjustments and shutdowns, significantly hampering productivity. By minimizing these interruptions, manufacturers can achieve higher output rates and meet tight deadlines more effectively.

Improve Product Quality

Premium feeder parts minimize issues such as misplacement and component leakage, thereby enhancing overall product quality. Accurate delivery ensures that products meet stringent standards. In industries where precision is critical—such as aerospace or medical device manufacturing—this quality assurance can be a significant competitive advantage.

Extend Equipment Life

Durable SMT feeder parts reduce the frequency of repairs, extending the lifespan of equipment. This longevity translates into cost savings and uninterrupted production. Regular maintenance combined with high-quality components ensures that machines operate at peak performance levels throughout their operational life.

Cost Efficiency

While high-quality SMT feeder parts may come with a higher initial investment, they often lead to lower overall costs due to reduced downtime, fewer defects, and longer equipment life. Companies that prioritize quality over cost tend to see better returns on their investments in the long run.

Innovations in SMT Feeder Technology

The field of SMT feeder technology is continually advancing to meet the growing demands of modern electronics manufacturing.

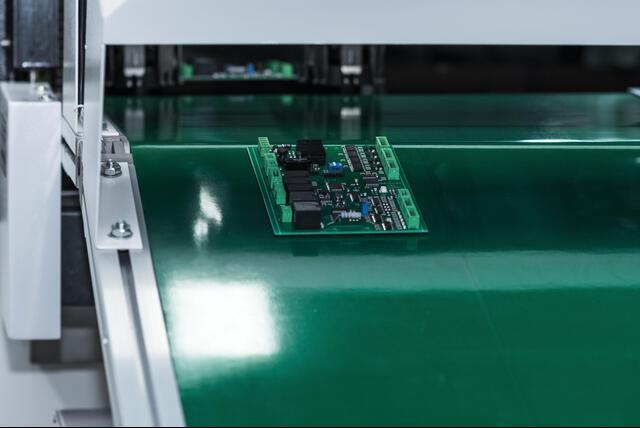

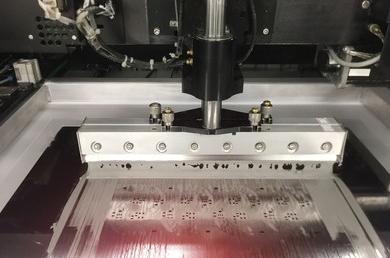

Automated Feeder Systems

Automated feeder systems have emerged as one of the most significant innovations in this field. These systems reduce manual intervention, minimizing human error while increasing production speed. They can quickly adapt to different component sizes and types, making them ideal for high-mix, low-volume production environments.

The automation process not only speeds up operations but also enhances safety by reducing the need for operators to handle potentially hazardous materials directly. Additionally, automated systems often come equipped with diagnostic tools that allow for real-time monitoring and troubleshooting.

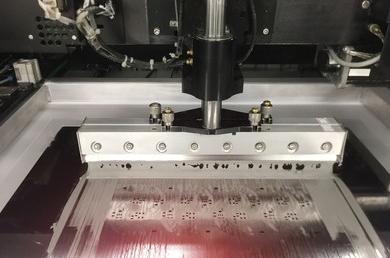

Smart Feeder Technology

Smart feeders incorporate advanced sensors and software to monitor and optimize the feeding process. They can detect issues such as misfeeds or jams in real-time, allowing for immediate corrective actions. This capability not only enhances efficiency but also maintains high product quality by ensuring accurate component placement.

These smart systems can also collect data on feeding patterns and performance metrics over time. Manufacturers can analyze this data to identify trends and make informed decisions about future investments or operational changes.

Integration with Industry 4.0

As manufacturing transitions towards Industry 4.0, SMT feeder technology is evolving to integrate with smart factory systems. This integration facilitates better data collection and analysis, enabling manufacturers to optimize their production processes further. By connecting feeders to a central data system, manufacturers can gain insights into performance metrics and identify areas for improvement.

For instance, if a particular type of feeder consistently experiences jams or misfeeds during operation, manufacturers can investigate potential causes—whether it be component design flaws or improper setup—and implement corrective measures swiftly.

Key Considerations When Choosing SMT Feeder Parts

Selecting the right SMT feeder parts involves several crucial considerations:

Compatibility with Existing Equipment

Ensuring that feeder parts are compatible with existing SMT equipment is essential. Incompatible parts can lead to inefficiencies and potential damage to machinery. Manufacturers should consult with equipment suppliers or conduct thorough research before making purchases.

Supplier Reputation and Reliability

Choosing reputable suppliers is vital for ensuring the quality and reliability of feeder parts. Manufacturers should seek suppliers with proven track records in delivering high-quality components backed by solid customer support.

Cost vs. Value

While cost is an important factor, manufacturers should focus on the overall value that feeder parts provide. High-quality parts may have higher upfront costs but offer greater long-term savings through improved efficiency and reduced operational costs.

Maintenance and Support

Regular maintenance is crucial for ensuring the longevity and performance of SMT feeder parts. Manufacturers should opt for parts that are easy to maintain and come with reliable support from suppliers. A good supplier will offer training resources or technical support to help manufacturers troubleshoot issues as they arise.

Scalability

As production demands fluctuate, manufacturers may need to scale their operations up or down quickly. Choosing flexible SMT feeder solutions that can accommodate varying production volumes without requiring extensive modifications is essential for maintaining efficiency during transitions.

Future Trends in SMT Feeder Parts

Looking ahead, several trends are poised to shape the future of SMT feeder technology:

Miniaturization of Components

As electronic devices become smaller and more complex, SMT feeder parts will need to be designed to handle these miniaturized components efficiently. This will require precision engineering to ensure accurate placement while minimizing damage risks during handling.

Increased Automation

The trend towards greater automation will continue to grow, with fully automated systems becoming more prevalent in the industry. This shift will further reduce human intervention and increase production speeds while enhancing safety protocols within manufacturing environments.

Enhanced Connectivity

Future SMT feeder parts will likely feature enhanced connectivity capabilities, allowing them to integrate seamlessly with other smart manufacturing systems. This connectivity will enable real-time data sharing and process optimization across various stages of production.

Sustainable Manufacturing Practices

Sustainability will remain a key focus in the design of SMT feeder parts. Manufacturers will increasingly seek eco-friendly materials and processes that minimize waste and energy consumption while meeting regulatory requirements related to environmental impact.

Conclusion

In conclusion, high-quality SMT feeder parts are essential for improving efficiency in electronics manufacturing. By investing in premium components and staying abreast of technological advancements such as automation and smart technology integration, manufacturers can enhance productivity while maintaining high standards of product quality. As the industry continues to evolve towards greater complexity in electronic devices coupled with increased demand for rapid production cycles, selecting the right SMT feeder parts will be crucial for maintaining a competitive edge in this dynamic landscape.

FAQ

1. What are SMT feeder parts?

SMT feeder parts are components within surface mount technology machines that deliver electronic components accurately to placement machines.

2. Why are high-quality SMT feeder parts important?

They ensure a stable supply of components, reduce downtime, improve production efficiency, and enhance product quality.

3. What types of SMT feeder parts are available?

Common types include tape and reel feeders, stick feeders, matrix tray feeders, bulk feeders, and direct die feeders.

4. How do SMT feeder parts affect equipment lifespan?

Durable feeder parts minimize repair needs while extending equipment life by ensuring consistent operation without frequent breakdowns.

5. How can companies ensure they are using the best SMT feeder parts?

Companies should choose reputable suppliers, maintain their equipment regularly, replace worn-out parts as needed for optimal performance.