Content Menu

● Understanding Surface Mount Devices

● Importance of Automation in SMD Assembly

● Key Components of SMD Automation

>> 1. Pick and Place Machines

>> 2. Soldering Techniques

>> 3. Inspection Systems

>> 4. Conveyor Systems

>> 5. Software Solutions

● Best Practices for Implementing SMD Automation

>> 1. Conduct a Thorough Assessment

>> 2. Invest in Training

>> 3. Focus on Flexibility

>> 4. Maintain Regular Maintenance

>> 5. Implement Continuous Improvement Practices

● Challenges in SMD Automation

● Future Trends in SMD Automation

● Conclusion

● FAQ

>> 1. What is Surface Mount Device (SMD) automation?*

>> 2. What are the benefits of automating SMD assembly?*

>> 3. What types of machines are used in SMD automation?*

>> 4. How does quality control work in automated SMD assembly?*

>> 5. What trends are shaping the future of SMD automation?*

Surface Mount Device (SMD) automation has become an essential aspect of modern electronics manufacturing. As the demand for high-quality, efficient, and cost-effective production processes continues to grow, companies are increasingly turning to automation solutions for their SMD assembly lines. This article explores the best practices for SMD automation, focusing on technology, process optimization, and quality assurance.

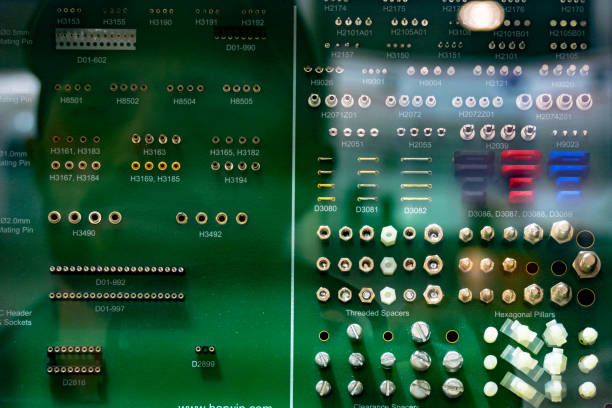

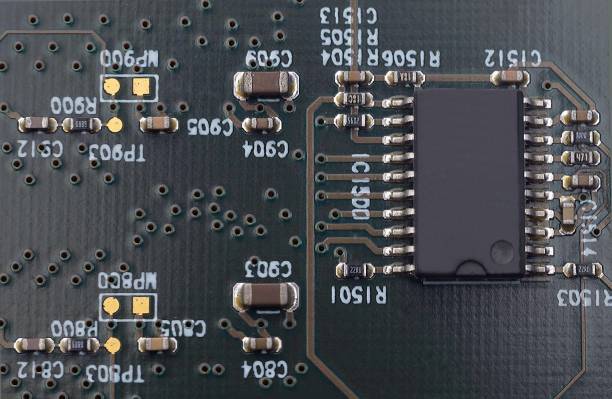

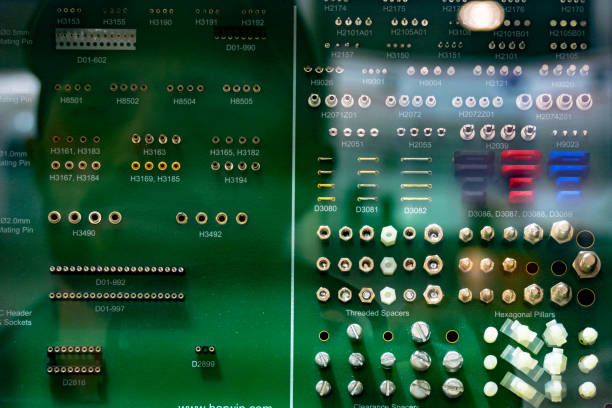

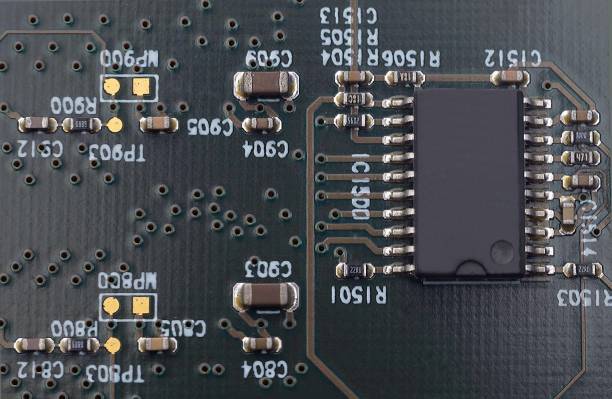

Understanding Surface Mount Devices

Surface Mount Devices are electronic components that are mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole components, SMDs are typically smaller and lighter, allowing for more compact designs and higher circuit density. The automation of SMD assembly processes can significantly enhance production efficiency, reduce labor costs, and improve product quality.

Importance of Automation in SMD Assembly

Automation in SMD assembly offers numerous advantages:

- Increased Speed: Automated systems can place components on PCBs much faster than manual processes.

- Higher Precision: Automation reduces human error, ensuring that components are placed accurately.

- Cost Efficiency: While the initial investment in automated equipment can be high, the long-term savings in labor and increased throughput often justify the expense.

- Scalability: Automated systems can be easily scaled to meet changing production demands.

Key Components of SMD Automation

To effectively implement SMD automation, several key components must be considered:

1. Pick and Place Machines

Pick and place machines are at the heart of SMD automation. These machines use robotic arms to pick components from a feeder and place them accurately on the PCB. When selecting a pick and place machine, consider factors such as:

- Speed: Look for machines that offer high placement rates.

- Flexibility: Choose machines that can handle a variety of component sizes and types.

- Ease of Use: User-friendly interfaces can simplify operation and reduce training time.

2. Soldering Techniques

Effective soldering is crucial for ensuring reliable connections between SMDs and PCBs. There are several soldering techniques used in automated processes:

- Reflow Soldering: This method involves applying solder paste to the PCB, placing the components, and then heating the assembly to melt the solder.

- Wave Soldering: Primarily used for through-hole components but can also be adapted for some SMD applications.

- Selective Soldering: This technique allows for targeted soldering of specific areas on a PCB without affecting other components.

3. Inspection Systems

Quality control is vital in SMD automation. Automated inspection systems help identify defects early in the production process. Common inspection methods include:

- Automated Optical Inspection (AOI): Uses cameras to detect misaligned or missing components.

- X-ray Inspection: Essential for inspecting hidden solder joints, particularly in multi-layered PCBs.

4. Conveyor Systems

Efficient material handling is critical for maintaining workflow in automated environments. Conveyor systems facilitate the smooth movement of PCBs through various stages of assembly, reducing bottlenecks and improving overall efficiency.

5. Software Solutions

Advanced software solutions play a crucial role in managing SMD automation processes. These systems can assist with:

- Production Planning: Optimizing schedules based on demand forecasts.

- Data Analysis: Collecting data from various stages of production to identify trends and areas for improvement.

- Integration: Ensuring seamless communication between different pieces of equipment on the assembly line.

Best Practices for Implementing SMD Automation

To maximize the benefits of SMD automation, manufacturers should adhere to several best practices:

1. Conduct a Thorough Assessment

Before implementing automation solutions, conduct a comprehensive assessment of current processes. Identify areas where automation can provide significant improvements in efficiency or quality.

2. Invest in Training

Proper training is essential for ensuring that staff can effectively operate automated systems. Invest in training programs that cover not only machine operation but also troubleshooting and maintenance.

3. Focus on Flexibility

Choose equipment that offers flexibility to accommodate different product lines or changes in design specifications. This adaptability will help maintain efficiency as market demands evolve.

4. Maintain Regular Maintenance

Automated equipment requires regular maintenance to ensure optimal performance. Establish a maintenance schedule that includes routine checks and servicing to prevent unexpected downtime.

5. Implement Continuous Improvement Practices

Adopt a culture of continuous improvement within your organization. Regularly review processes and seek feedback from operators to identify opportunities for enhancement.

Challenges in SMD Automation

While there are many benefits to automating SMD assembly processes, challenges do exist:

- High Initial Costs: The upfront investment in automated equipment can be significant.

- Complexity of Integration: Integrating new automated systems with existing processes may require careful planning and execution.

- Skill Gaps: A lack of skilled personnel who can operate and maintain advanced automation systems can hinder implementation efforts.

Future Trends in SMD Automation

The future of SMD automation looks promising with several emerging trends:

- Artificial Intelligence (AI): AI technologies are being integrated into manufacturing processes to enhance decision-making and predictive maintenance capabilities.

- Internet of Things (IoT): IoT devices will enable real-time monitoring and data collection from automated systems, allowing for more informed operational decisions.

- Collaborative Robots (Cobots): Cobots are designed to work alongside human operators, enhancing productivity while maintaining safety standards.

Conclusion

Surface Mount Device automation is transforming the electronics manufacturing landscape by improving efficiency, precision, and cost-effectiveness. By understanding key components like pick and place machines, soldering techniques, inspection systems, conveyor systems, and software solutions, manufacturers can implement best practices that drive success in their operations. While challenges exist, staying informed about future trends such as AI integration and IoT will help businesses remain competitive in an ever-evolving market.

In summary, adopting effective strategies for SMD automation not only enhances productivity but also ensures high-quality products that meet consumer demands.

FAQ

1. What is Surface Mount Device (SMD) automation?*

SMD automation refers to the use of automated machinery and technology to assemble surface mount devices onto printed circuit boards efficiently and accurately.

2. What are the benefits of automating SMD assembly?*

The benefits include increased speed, higher precision, cost efficiency over time, improved scalability, and reduced labor costs associated with manual assembly processes.

3. What types of machines are used in SMD automation?*

Key machines include pick and place machines for component placement, soldering machines (reflow or wave), inspection systems like AOI or X-ray inspection units, and conveyor systems for material handling.

4. How does quality control work in automated SMD assembly?*

Quality control is maintained through automated inspection systems that monitor component placement accuracy and solder joint integrity throughout the assembly process.

5. What trends are shaping the future of SMD automation?*

Emerging trends include increased use of artificial intelligence for decision-making support, IoT integration for real-time monitoring, and collaborative robots that work alongside human operators to enhance productivity.