Content Menu

● Preparation and Setup

>> Workspace and Tools

>> PCB Preparation

>> Component Preparation

● Solder Paste Application

>> Stencil Printing

>> Manual Application

● Component Placement

>> Automated Placement

>> Manual Placement

● Reflow Soldering

>> Reflow Profile

>> Reflow Methods

● Post-Reflow Inspection and Testing

>> Visual Inspection

>> Automated Optical Inspection (AOI)

>> X-ray Inspection

● Common SMT Soldering Defects and Prevention

>> Tombstoning

>> Solder Bridging

>> Cold Solder Joints

>> Component Shifting

● Advanced Techniques and Considerations

>> Fine-Pitch and Ultra-Fine-Pitch Soldering

>> Lead-Free Soldering

>> Nitrogen Atmosphere Soldering

● Process Control and Quality Assurance

>> Solder Paste Inspection (SPI)

>> Statistical Process Control (SPC)

>> Continuous Improvement

● Conclusion

● FAQ

>> 1. What temperature should I use for SMT soldering?

>> 2. How can I prevent solder bridges in fine-pitch components?

>> 3. What are the advantages of using a nitrogen atmosphere for SMT soldering?

>> 4. How often should I clean or replace my soldering iron tip?

>> 5. What are the key differences between hand soldering and reflow soldering for SMT components?

● Citations:

Surface Mount Technology (SMT) soldering is a crucial process in modern electronics manufacturing. It allows for the efficient and precise attachment of components to printed circuit boards (PCBs), enabling the creation of compact and high-performance electronic devices. To ensure successful SMT soldering, it's essential to follow best practices that optimize the process and minimize defects. This article will explore the key techniques, tips, and considerations for achieving high-quality PCB SMT soldering results.

Preparation and Setup

Workspace and Tools

Before beginning the SMT soldering process, it's crucial to prepare a clean and well-organized workspace. Ensure that you have all the necessary tools and equipment readily available, including:

- A temperature-controlled soldering iron

- SMT-specific soldering tips

- High-quality solder paste

- Flux

- Tweezers

- Magnifying glass or microscope

- Cleaning supplies

A clutter-free environment helps prevent contamination and allows for better focus on the delicate soldering tasks.

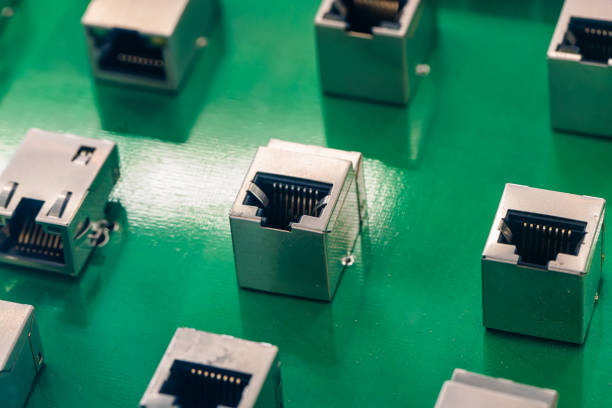

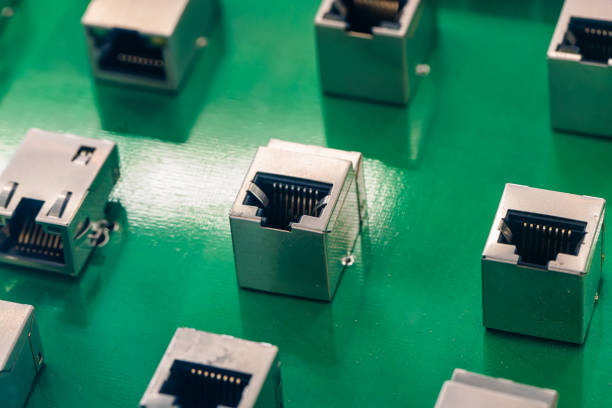

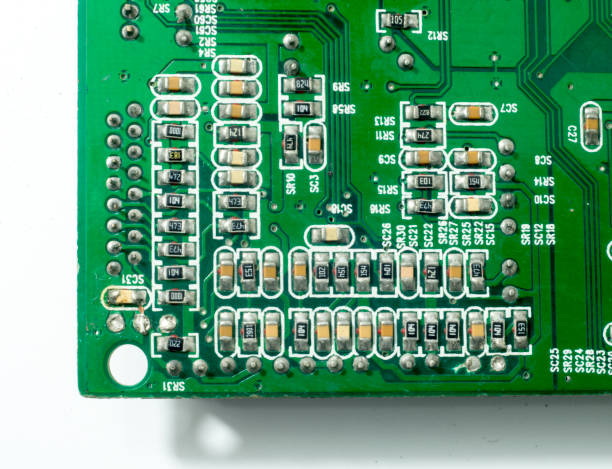

PCB Preparation

Proper PCB preparation is essential for successful SMT soldering. Follow these steps:

1. Inspect the PCB for any defects or damage.

2. Clean the PCB surface thoroughly to remove any dirt, oils, or residues.

3. Bake the PCB to remove moisture, especially for moisture-sensitive boards like FR-1 paper PCBs[8].

4. Apply solder resist dams of at least 0.003 inches, particularly for fine-pitch SMT devices, to prevent short circuits[5].

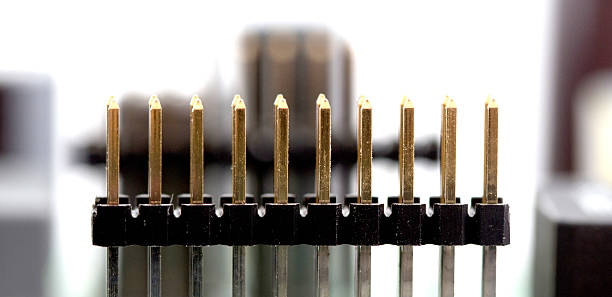

Component Preparation

Ensure that all SMT components are properly stored and handled to prevent damage or contamination. Before soldering:

1. Verify that the components are correct and match the PCB design.

2. Inspect components for any visible defects.

3. If necessary, clean the component leads to ensure good solder adhesion.

Solder Paste Application

Stencil Printing

For high-volume production or complex PCBs, stencil printing is the preferred method for applying solder paste. This process involves:

1. Aligning a metal stencil with the PCB pads.

2. Applying solder paste to the stencil.

3. Using a squeegee to spread the paste evenly across the stencil openings.

4. Carefully removing the stencil to leave precise deposits of solder paste on the PCB pads[2].

Key parameters to consider during stencil printing include:

- Print speed

- Squeegee pressure and angle

- Stencil wipe frequency

- Print gap

Manual Application

For smaller production runs or prototype work, manual application of solder paste can be done using a syringe or dispensing tool. While this method is less precise than stencil printing, it can be effective for simpler PCB designs.

Component Placement

Automated Placement

In a production environment, high-speed pick and place machines are used to accurately position SMT components on the PCB. These machines use advanced vision systems for alignment and can place components with split-second precision[2].

To optimize automated component placement:

- Group components by package size

- Minimize tool changes

- Design an optimal board flow path

Manual Placement

For smaller projects or when working with specialized components, manual placement may be necessary. Use fine-tipped tweezers and a magnifying glass or microscope to carefully position components on the solder paste deposits.

Reflow Soldering

Reflow Profile

The reflow soldering process is critical for forming permanent solder joints. A typical reflow profile consists of four stages:

1. Ramp up: Gradually increase temperature to activate the flux.

2. Soak zone: Maintain temperature to allow for uniform heating of components.

3. Reflow peak: Reach the peak temperature to melt the solder and form joints.

4. Cool down: Gradually decrease temperature to allow solder joints to solidify[2].

It's crucial to develop a reflow profile that suits the specific components and PCB materials being used.

Reflow Methods

Common reflow soldering methods include:

- Convection reflow oven: Uses forced hot air to heat the PCB and components.

- Vapor phase reflow: Utilizes the latent heat of vaporization of a special liquid to provide uniform heating.

- IR/radiant heat: Uses infrared radiation to heat the PCB and components[2].

For lead-free soldering, which is increasingly common due to environmental regulations, higher temperatures are typically required. This can present challenges, especially for temperature-sensitive components or substrates.

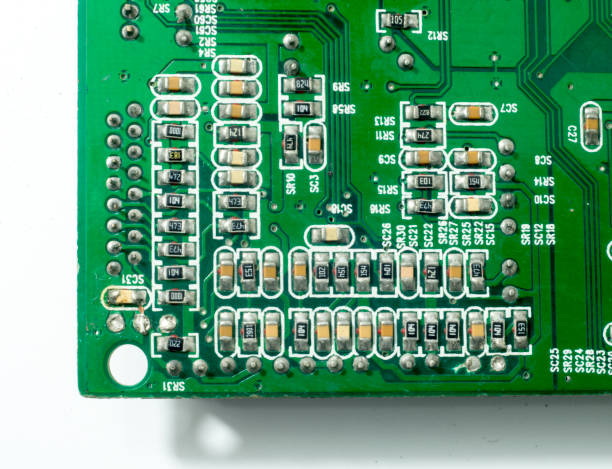

Post-Reflow Inspection and Testing

Visual Inspection

After reflow soldering, a thorough visual inspection should be performed to identify any obvious defects. Look for:

- Solder bridges between adjacent pads

- Insufficient solder joints

- Component misalignment

- Signs of overheating or component damage

Automated Optical Inspection (AOI)

For more comprehensive and efficient inspection, Automated Optical Inspection (AOI) systems can be used. These systems use cameras and image processing software to detect a wide range of soldering defects quickly and accurately[3].

X-ray Inspection

X-ray inspection is particularly useful for examining hidden solder joints, such as those under Ball Grid Array (BGA) components. This non-destructive testing method can reveal voids, insufficient solder, and other internal defects that are not visible from the surface[3].

Common SMT Soldering Defects and Prevention

Tombstoning

Tombstoning occurs when a component stands up on one end due to uneven solder melting. To prevent this:

- Ensure uniform solder paste application

- Use proper pad designs

- Optimize the reflow profile to achieve even heating

Solder Bridging

Solder bridges are unwanted connections between adjacent pads. To minimize this issue:

- Use the correct amount of solder paste

- Ensure proper component placement

- Maintain appropriate reflow temperatures

Cold Solder Joints

Cold solder joints occur when the solder doesn't fully melt or wet the component leads and pads. Prevention measures include:

- Using the correct reflow profile

- Ensuring clean PCB and component surfaces

- Applying sufficient flux

Component Shifting

Component shifting during reflow can lead to misalignment. To prevent this:

- Use proper solder paste volume

- Optimize the reflow profile to minimize solder paste liquefaction time

- Consider using adhesives for larger or heavier components

Advanced Techniques and Considerations

Fine-Pitch and Ultra-Fine-Pitch Soldering

As component sizes continue to shrink, soldering fine-pitch and ultra-fine-pitch devices becomes increasingly challenging. Best practices for these components include:

- Using high-precision stencils

- Employing advanced placement equipment

- Implementing strict process controls

- Utilizing specialized inspection techniques

Lead-Free Soldering

With the widespread adoption of RoHS (Restriction of Hazardous Substances) standards, lead-free soldering has become the norm in many industries. Key considerations for lead-free SMT soldering include:

- Higher melting temperatures (typically around 217°C for SAC305 alloy)

- Increased potential for component damage due to higher temperatures

- Different flux chemistries optimized for lead-free solders

- Potential changes in solder joint appearance and reliability

Nitrogen Atmosphere Soldering

For critical applications or when working with challenging materials, soldering in a nitrogen atmosphere can provide benefits such as:

- Improved wetting and spread of solder

- Reduced oxidation of solder joints

- Enhanced solder joint reliability

- Potential for using lower temperatures or shorter reflow times

When implementing nitrogen atmosphere soldering, it's important to maintain oxygen levels below 4% for optimal results[3].

Process Control and Quality Assurance

Solder Paste Inspection (SPI)

Implementing Solder Paste Inspection (SPI) before component placement can help identify issues early in the process. SPI systems check for:

- Correct solder paste volume

- Proper paste alignment

- Absence of smears or bridging[3]

Statistical Process Control (SPC)

Implementing Statistical Process Control techniques can help maintain consistent quality in SMT soldering. Key metrics to monitor include:

- Solder paste deposit volume and position

- Component placement accuracy

- Reflow oven temperature profiles

- Defect rates from AOI and functional testing

Continuous Improvement

Regularly review and refine your SMT soldering process to:

- Incorporate new technologies and techniques

- Address recurring issues

- Optimize for new component types or board designs

- Improve efficiency and reduce costs

Conclusion

Mastering PCB SMT soldering requires a combination of proper preparation, precise execution, and rigorous quality control. By following the best practices outlined in this article, you can significantly improve the reliability and quality of your SMT soldering process. Remember that successful SMT soldering is not just about the soldering itself, but also about the entire process from PCB design to final inspection.

As technology continues to advance, staying updated with the latest SMT soldering techniques and equipment is crucial. Regular training, process optimization, and investment in advanced tools can help ensure that your SMT soldering capabilities remain at the cutting edge of electronics manufacturing.

FAQ

1. What temperature should I use for SMT soldering?

The optimal temperature for SMT soldering depends on the type of solder being used. For lead-based solders, temperatures around 315-330°C are typical, while lead-free solders often require higher temperatures, usually in the range of 350-370°C. Always refer to the solder manufacturer's recommendations and adjust based on your specific components and PCB materials.

2. How can I prevent solder bridges in fine-pitch components?

To prevent solder bridges in fine-pitch components:

- Use a properly designed stencil with appropriate aperture sizes

- Ensure correct solder paste volume

- Optimize your reflow profile

- Consider using no-clean flux to reduce residue

- Implement proper PCB pad design with adequate spacing

3. What are the advantages of using a nitrogen atmosphere for SMT soldering?

Using a nitrogen atmosphere for SMT soldering offers several benefits:

- Improved solder wetting and spread

- Reduced oxidation of solder joints

- Enhanced solder joint reliability

- Potential for using lower temperatures or shorter reflow times

- Better results with lead-free solders

4. How often should I clean or replace my soldering iron tip?

For optimal performance, clean your soldering iron tip frequently during use, ideally after every few solder joints. Replace the tip when it shows signs of wear, pitting, or when it no longer accepts solder easily. Regular maintenance can significantly extend the life of your soldering iron tip and improve soldering quality.

5. What are the key differences between hand soldering and reflow soldering for SMT components?

The main differences between hand soldering and reflow soldering for SMT components are:

- Precision: Reflow soldering offers higher precision and consistency, especially for fine-pitch components

- Speed: Reflow soldering is much faster for high-volume production

- Heat control: Reflow ovens provide more uniform heating across the entire PCB

- Solder paste application: Reflow uses stencil-printed solder paste, while hand soldering typically uses wire solder

- Component placement: Reflow allows for simultaneous soldering of all components, while hand soldering is done one component at a time

Citations:

[1] https://ksnpcb.com/mastering-the-art-of-soldering-pcb-techniques-tips-and-best-practices/

[2] https://www.raypcb.com/smt-soldering-process/

[3] https://www.pcbonline.com/blog/pcb-soldering.html

[4] https://resources.pcb.cadence.com/blog/2022-smt-soldering-defects-examples-causes

[5] https://www.ocmmanufacturing.com/resources/resource/dfm-tip-best-practices-for-surface-mount-technology-smt-design/

[6] https://www.youtube.com/watch?v=5uiroWBkdFY

[7] https://versae.com/smt-assembly-faq/

[8] https://patents.google.com/patent/CN102922070B/en

[9] https://www.vse.com/blog/2022/04/28/best-practices-for-pcb-soldering-techniques/

[10] https://www.instructables.com/How-to-Solder-SMD-SMT-Components-With-a-Soldering-/