Content Menu

● Introduction

● Understanding SMT Line Equipment

>> What is SMT?

>> Components of an SMT Line

● Benefits of Wholesale SMT Line Equipment

>> 1. Cost Efficiency

>> 2. Enhanced Production Speed

>> 3. Improved Quality Control

>> 4. Scalability

>> 5. Reduced Labor Costs

>> 6. Streamlined Processes

>> 7. Access to Advanced Technology

>> 8. Better Resource Management

>> 9. Enhanced Data Management

>> 10. Competitive Advantage

● Additional Considerations for Implementing Wholesale SMT Lines

>> Training and Support

>> Maintenance and Upkeep

>> Customization Options

>> Environmental Considerations

>> Future-Proofing Your Production

● Conclusion

● FAQ

>> 1. What is the main advantage of using wholesale SMT line equipment?

>> 2. How does SMT technology improve production speed?

>> 3. What role does quality control play in SMT lines?

>> 4. Can wholesale SMT lines be scaled according to production needs?

>> 5. How does automation in SMT lines affect labor costs?

Introduction

In the fast-paced world of electronics manufacturing, the demand for efficient and high-quality production processes is ever-increasing. Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). For manufacturers looking to enhance their production capabilities, investing in wholesale SMT line equipment offers numerous benefits. This article explores these advantages in detail, providing insights into how wholesale SMT lines can optimize production efficiency, reduce costs, and improve product quality.

Understanding SMT Line Equipment

What is SMT?

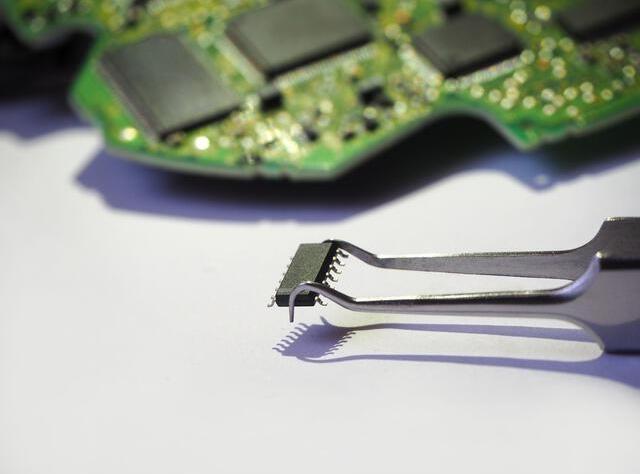

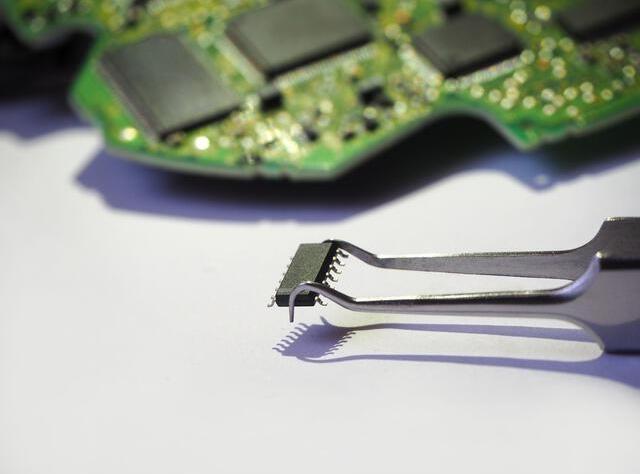

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of PCBs. This technology has largely replaced traditional through-hole mounting due to its ability to accommodate smaller components and higher component densities. SMT allows for automated assembly processes, which significantly enhance production speed and efficiency.

Components of an SMT Line

A typical SMT line consists of several key components, including:

- Pick and Place Machines: These machines are responsible for accurately placing components onto the PCB.

- Solder Paste Printers: They apply solder paste to the PCB pads where components will be placed.

- Reflow Ovens: These ovens heat the assembled boards to melt the solder, creating electrical connections.

- Inspection Systems: Automated Optical Inspection (AOI) systems check for defects in the assembly process.

Benefits of Wholesale SMT Line Equipment

1. Cost Efficiency

One of the primary advantages of purchasing wholesale SMT line equipment is the cost savings associated with bulk buying. Manufacturers can negotiate better prices when purchasing multiple machines or an entire production line. This reduction in capital expenditure allows companies to allocate resources to other critical areas of their business.

2. Enhanced Production Speed

Wholesale SMT lines are designed for high-speed production. With advanced automation, these lines can significantly reduce the time required to assemble PCBs. For instance, a well-optimized SMT line can produce thousands of boards per day, meeting the demands of high-volume production runs.

3. Improved Quality Control

Quality is paramount in electronics manufacturing. Wholesale SMT line equipment often comes with integrated inspection systems that ensure each board meets strict quality standards. Automated Optical Inspection (AOI) systems can detect defects in real-time, reducing the likelihood of faulty products reaching the market.

4. Scalability

As production demands fluctuate, manufacturers need equipment that can scale accordingly. Wholesale SMT lines offer flexibility, allowing companies to adjust their production capacity without significant additional investment. This scalability is crucial for businesses that experience seasonal spikes in demand.

5. Reduced Labor Costs

Automation in SMT lines minimizes the need for manual labor, which can lead to significant cost savings. With fewer workers required for assembly, companies can reduce labor costs while also decreasing the risk of human error. This shift not only enhances efficiency but also improves overall product quality.

6. Streamlined Processes

Wholesale SMT line equipment is designed to work seamlessly together, creating a streamlined production process. This integration reduces the time spent on setup and changeovers, allowing manufacturers to switch between different products quickly and efficiently.

7. Access to Advanced Technology

Investing in wholesale SMT line equipment often means gaining access to the latest technology in electronics manufacturing. This includes advanced features such as real-time monitoring, data analytics, and improved machine learning capabilities, which can further enhance production efficiency and quality.

8. Better Resource Management

With the automation provided by wholesale SMT lines, manufacturers can better manage their resources. This includes optimizing material usage, reducing waste, and improving inventory management. Efficient resource management not only lowers costs but also contributes to more sustainable manufacturing practices.

9. Enhanced Data Management

Modern SMT lines come equipped with data management systems that track production metrics in real-time. This data can be invaluable for identifying bottlenecks, improving processes, and making informed decisions about production strategies.

10. Competitive Advantage

In a competitive market, having the latest and most efficient production technology can set a manufacturer apart from its competitors. By investing in wholesale SMT line equipment, companies can improve their production capabilities, leading to faster turnaround times and higher-quality products.

Additional Considerations for Implementing Wholesale SMT Lines

Training and Support

When investing in wholesale SMT line equipment, it is essential to consider the training and support provided by the supplier. Comprehensive training programs ensure that operators are well-versed in the equipment's operation, maintenance, and troubleshooting. This knowledge is crucial for maximizing the efficiency and longevity of the equipment.

Maintenance and Upkeep

Regular maintenance of SMT line equipment is vital for ensuring optimal performance. Suppliers often provide maintenance packages that include routine checks, repairs, and upgrades. By investing in these services, manufacturers can prevent costly downtime and extend the lifespan of their equipment.

Customization Options

Wholesale SMT line equipment can often be customized to meet specific production needs. This flexibility allows manufacturers to tailor their production lines to accommodate unique products or processes, enhancing overall efficiency and effectiveness.

Environmental Considerations

As sustainability becomes increasingly important in manufacturing, many wholesale SMT line equipment suppliers are focusing on eco-friendly practices. This includes energy-efficient machines and processes that minimize waste. By choosing environmentally responsible equipment, manufacturers can reduce their carbon footprint and appeal to eco-conscious consumers.

Future-Proofing Your Production

Investing in wholesale SMT line equipment is not just about meeting current production demands; it is also about future-proofing your operations. As technology continues to evolve, having a modern and adaptable production line will enable manufacturers to stay ahead of industry trends and customer expectations.

Conclusion

Investing in wholesale SMT line equipment offers numerous benefits that can significantly enhance production efficiency, reduce costs, and improve product quality. From cost savings and scalability to advanced technology and better resource management, the advantages are clear. As the electronics manufacturing industry continues to evolve, companies that embrace these innovations will be better positioned to meet the demands of the market and achieve long-term success.

FAQ

1. What is the main advantage of using wholesale SMT line equipment?

The main advantage is cost efficiency, as manufacturers can negotiate better prices when purchasing in bulk, leading to significant savings.

2. How does SMT technology improve production speed?

SMT technology allows for automated assembly processes, which can produce thousands of PCBs per day, significantly reducing production time.

3. What role does quality control play in SMT lines?

Quality control is crucial in SMT lines, with integrated inspection systems like AOI ensuring that each board meets strict quality standards, reducing defects.

4. Can wholesale SMT lines be scaled according to production needs?

Yes, wholesale SMT lines offer scalability, allowing manufacturers to adjust their production capacity based on demand fluctuations without significant additional investment.

5. How does automation in SMT lines affect labor costs?

Automation reduces the need for manual labor, leading to lower labor costs and minimizing the risk of human error, which enhances overall product quality.