Content Menu

● Understanding SMT Components and Their Packaging

● Benefits of Using Reels for SMT Components

>> 1. Enhanced Efficiency in Assembly Processes

>> 2. Cost-Effectiveness

>> 3. Improved Inventory Management

>> 4. Versatility Across Different Component Types

>> 5. Environmental Benefits

● Additional Considerations When Using Reels

>> 1. Reel Compatibility

>> 2. Initial Investment

>> 3. Training Requirements

● Conclusion

● FAQ

>> 1. What types of SMT components can be packaged in reels?

>> 2. How do reels improve efficiency in assembly processes?

>> 3. Are there cost savings associated with using reels?

>> 4. Can reels help with inventory management?

>> 5. What environmental benefits do reels offer?

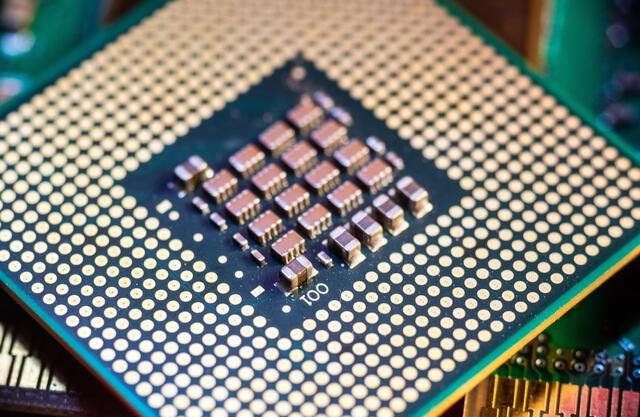

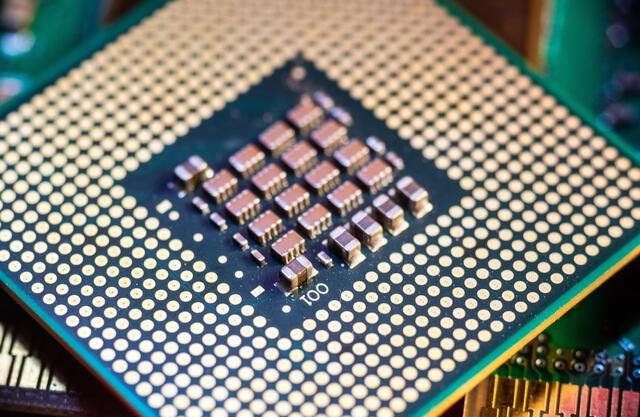

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, allowing for smaller, more efficient components to be used in a variety of devices. One of the key aspects of SMT is the packaging of components, and reels are among the most popular methods for this purpose. In this article, we will explore the benefits of using reels for SMT components, examining their advantages in terms of efficiency, cost-effectiveness, and overall impact on production processes.

Understanding SMT Components and Their Packaging

Before diving into the benefits of reels, it's essential to understand what SMT components are and how they are packaged. SMT components are electronic parts that are mounted directly onto the surface of printed circuit boards (PCBs). These components come in various shapes and sizes, including resistors, capacitors, integrated circuits (ICs), and more.

The packaging of these components is crucial for several reasons:

- Protection: Proper packaging protects components from physical damage during transport and handling.

- Organization: Packaging helps in organizing components for easy access during assembly.

- Efficiency: Efficient packaging methods can significantly speed up the assembly process.

Reels have emerged as a preferred choice for packaging SMT components due to their numerous benefits.

Benefits of Using Reels for SMT Components

1. Enhanced Efficiency in Assembly Processes

One of the primary benefits of using reels for SMT components is the enhanced efficiency they bring to assembly processes. Reels allow for:

- Automated Feeding: Reels can be easily integrated into automated pick-and-place machines. This automation minimizes manual handling and speeds up the assembly line.

- Continuous Supply: Reels provide a continuous supply of components, reducing downtime caused by frequent reloading or searching for parts.

- Consistent Orientation: Components on reels are typically oriented uniformly, which simplifies the placement process and reduces errors.

In addition to these points, using reels can also streamline workflow processes. With a consistent supply and orientation of components, operators can focus on other critical tasks rather than spending time on component management. This leads to an overall increase in productivity on the assembly line.

2. Cost-Effectiveness

Using reels for SMT components can lead to significant cost savings in several ways:

- Reduced Labor Costs: With automation, fewer workers are needed to handle component placement, which lowers labor costs.

- Minimized Waste: Reels help reduce waste by ensuring that all components are used efficiently. Any leftover parts can be easily stored and reused.

- Bulk Purchasing: Components packaged in reels are often available in bulk, which can lower per-unit costs when purchasing materials.

Moreover, manufacturers benefit from lower shipping costs as bulk orders reduce the number of shipments required. This not only saves money but also contributes to a more efficient supply chain management system.

3. Improved Inventory Management

Reels facilitate better inventory management practices:

- Standardized Sizes: Reels come in standardized sizes, making it easier to store and organize large quantities of components.

- Easy Tracking: It is simpler to track inventory levels when components are stored on reels. This helps manufacturers maintain optimal stock levels without over-ordering or running out of critical parts.

- Reduced Risk of Damage: The reel packaging protects components from dust and physical damage, preserving their integrity until they are needed.

Additionally, implementing a just-in-time inventory system becomes more feasible with reels. Manufacturers can order supplies based on actual consumption rather than overstocking, leading to better cash flow management.

4. Versatility Across Different Component Types

Reels can accommodate a wide variety of SMT components:

- Diverse Component Types: From resistors to capacitors and ICs, reels can hold many different types of SMT components without compromising their safety or accessibility.

- Customizable Options: Manufacturers can customize reel sizes and specifications based on their specific needs, making them adaptable for various production requirements.

This versatility is particularly beneficial in industries where rapid prototyping is essential. Engineers can quickly switch between different component types without needing to change packaging methods or invest in new storage solutions.

5. Environmental Benefits

Using reels for SMT components also has positive environmental implications:

- Reduced Packaging Waste: Reels minimize the amount of packaging material required compared to individual packaging methods.

- Recyclability: Many reel materials can be recycled after use, contributing to more sustainable manufacturing practices.

Furthermore, manufacturers are increasingly focusing on sustainability as part of their corporate responsibility initiatives. By adopting reel packaging, companies not only reduce waste but also enhance their brand image as environmentally conscious organizations.

Additional Considerations When Using Reels

While there are numerous benefits associated with using reels for SMT components, there are also some considerations that manufacturers should keep in mind:

1. Reel Compatibility

Not all SMT components may be compatible with reel packaging. It is important to ensure that the specific component type being used can be effectively packaged on a reel without compromising its integrity or performance during assembly.

2. Initial Investment

The initial investment in automated pick-and-place equipment that accommodates reel feeding may be significant. However, this cost is often offset by long-term savings achieved through increased efficiency and reduced labor costs.

3. Training Requirements

Employees may require training to effectively operate new automated systems designed for reel handling. Investing in proper training ensures that workers maximize the potential benefits offered by these systems.

Conclusion

In conclusion, utilizing reels for SMT components offers numerous benefits that enhance efficiency, reduce costs, improve inventory management, provide versatility across different component types, and contribute positively to environmental sustainability. As electronics manufacturing continues to evolve, adopting efficient packaging solutions like reels will remain essential in optimizing production processes and maintaining competitiveness in the industry.

The integration of reels not only streamlines operations but also supports manufacturers in meeting increasing demands for high-quality electronic products while minimizing environmental impact. As technology advances and new materials emerge, it will be interesting to see how reel technology adapts further to meet future challenges in electronics manufacturing.

FAQ

1. What types of SMT components can be packaged in reels?

Reels can accommodate a wide range of SMT components including resistors, capacitors, integrated circuits (ICs), diodes, and more. This versatility makes them suitable for various electronic manufacturing needs.

2. How do reels improve efficiency in assembly processes?

Reels enhance efficiency by allowing automated feeding into pick-and-place machines, providing a continuous supply of components with consistent orientation that simplifies placement and reduces errors.

3. Are there cost savings associated with using reels?

Yes, using reels can lead to cost savings through reduced labor costs due to automation, minimized waste from efficient component usage, and lower per-unit costs when purchasing materials in bulk.

4. Can reels help with inventory management?

Absolutely! Reels facilitate better inventory management by providing standardized sizes for easy storage and organization while allowing easier tracking of inventory levels.

5. What environmental benefits do reels offer?

Reels contribute positively to environmental sustainability by reducing packaging waste compared to individual packaging methods and often being made from recyclable materials.