Content Menu

● Understanding Prototype SMT Nozzles

● The Importance of Precision in PCB Assembly

● Benefits of Using Prototype SMT Nozzles

>> 1. Increased Precision in Component Placement

>> 2. Higher Packing Density

>> 3. Improved Production Speed

>> 4. Cost-Effectiveness

>> 5. Flexibility in Design

>> 6. Enhanced Quality Control

>> 7. Reduction of Human Error

>> 8. Support for Advanced Technologies

● Challenges Addressed by Prototype SMT Nozzles

>> 1. Handling Fragile Components

>> 2. Compatibility with Various Materials

>> 3. Adaptation to Rapid Prototyping Needs

>> 4. Integration with Automated Systems

● Future Trends in SMT Nozzle Technology

>> 1. Smart Nozzle Technology

>> 2. Sustainability Initiatives

>> 3. Miniaturization Trends

>> 4. Customization Options

● Case Studies: Successful Implementations

>> 1. Company A: High-Density PCB Production

>> 2. Company B: Medical Device Manufacturing

>> 3. Company C: Rapid Prototyping Services

● Conclusion

● FAQ

>> 1. What is a prototype SMT nozzle?

>> 2. How do prototype SMT nozzles improve production speed?

>> 3. Can prototype SMT nozzles handle different component sizes?

>> 4. What role do prototype SMT nozzles play in quality control?

>> 5. Are there cost savings associated with using prototype SMT nozzles?

● Citations:

Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). Among the critical tools in this process are prototype SMT nozzles, which play a significant role in enhancing the efficiency and accuracy of PCB assembly. This article delves into the benefits of using prototype SMT nozzles, exploring their impact on manufacturing processes, cost efficiency, and overall product quality.

Understanding Prototype SMT Nozzles

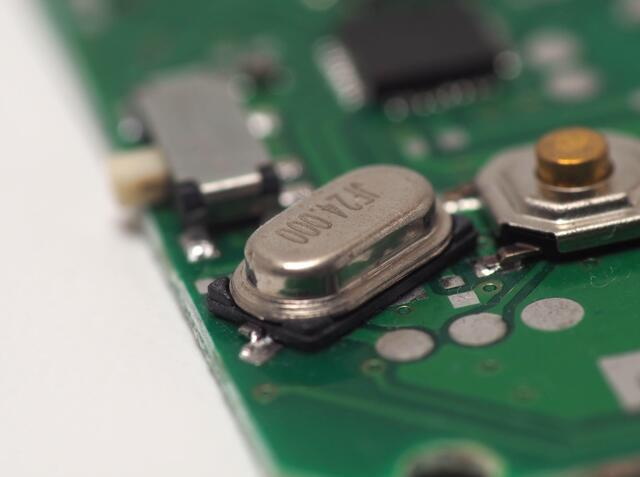

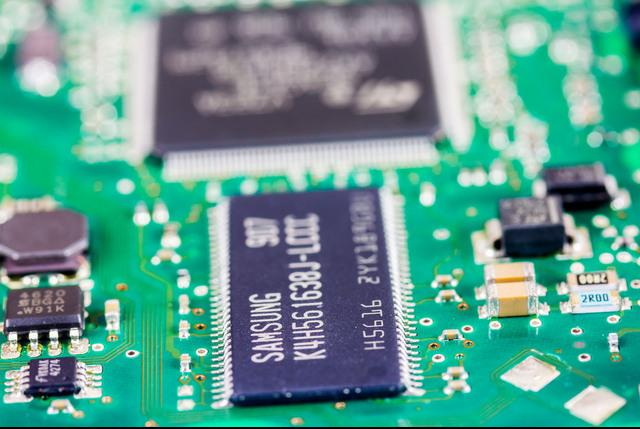

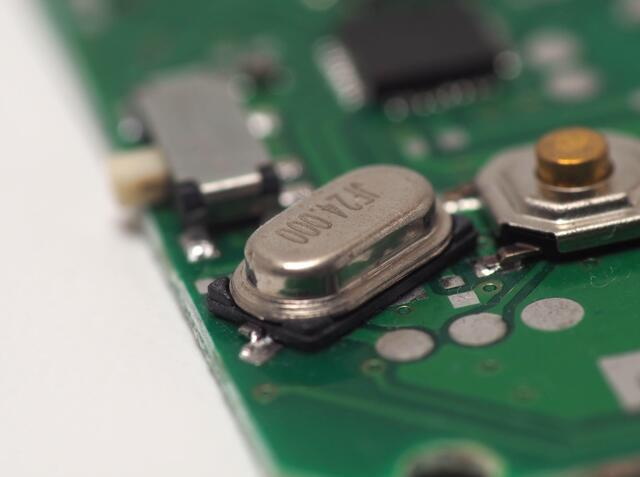

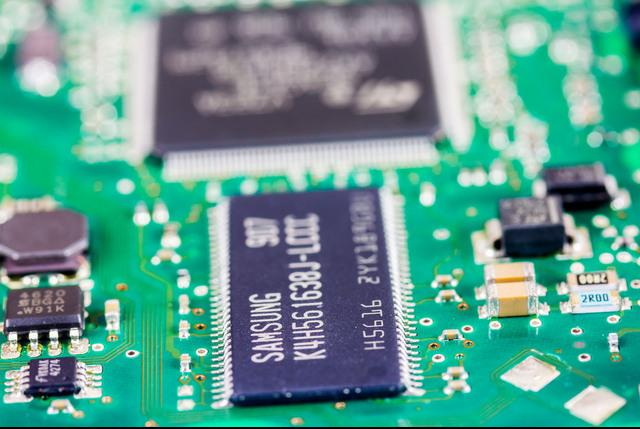

Prototype SMT nozzles are specialized components used in pick-and-place machines during the assembly of PCBs. These nozzles are designed to handle various types of surface mount devices (SMDs), enabling precise placement on the PCB. The use of these nozzles is essential for achieving high packing density and ensuring that components are accurately positioned for soldering.

The Importance of Precision in PCB Assembly

Precision is paramount in PCB assembly, particularly as devices become smaller and more complex. Inaccurate placement can lead to a range of issues, including poor electrical performance, increased failure rates, and higher rework costs. Prototype SMT nozzles are engineered to provide high levels of accuracy, ensuring that each component is placed exactly where it needs to be. This precision is especially critical for high-density boards where components are packed closely together.

Benefits of Using Prototype SMT Nozzles

1. Increased Precision in Component Placement

One of the primary advantages of using prototype SMT nozzles is their ability to enhance precision in component placement. The design of these nozzles allows for accurate alignment with the PCB pads, reducing the likelihood of misplacement that can lead to defects in the final product. This precision is crucial, especially when working with small components that require exact positioning to function correctly.

2. Higher Packing Density

Prototype SMT nozzles facilitate a higher packing density on PCBs. By allowing more components to be placed in a smaller area, manufacturers can create more compact and efficient designs. This is particularly beneficial for modern electronic devices, which often require miniaturization without compromising functionality. The ability to use smaller components also contributes to reduced board size and weight.

3. Improved Production Speed

The automation capabilities offered by prototype SMT nozzles significantly improve production speed. By enabling faster and more efficient component placement, manufacturers can increase their throughput without sacrificing quality. This efficiency is particularly important in high-volume production environments where time-to-market is critical.

4. Cost-Effectiveness

While the initial investment in prototype SMT nozzles may be higher than traditional tools, they ultimately lead to cost savings in the long run. The increased speed and accuracy reduce labor costs and minimize waste from defective products. Additionally, the ability to produce high-quality PCBs more quickly can lead to greater profitability for manufacturers.

5. Flexibility in Design

Prototype SMT nozzles provide flexibility in design by accommodating various component types and sizes. This versatility allows engineers to experiment with different layouts and configurations during the prototyping phase without being limited by tooling constraints. As a result, manufacturers can innovate more freely and adapt to changing market demands.

6. Enhanced Quality Control

Using prototype SMT nozzles contributes to enhanced quality control throughout the assembly process. The precision of these nozzles ensures that components are placed correctly, reducing the risk of solder joint failures or electrical issues later on. Furthermore, automated inspection systems can easily integrate with nozzle technology, allowing for real-time monitoring and adjustments during production.

7. Reduction of Human Error

Automation through prototype SMT nozzles minimizes human intervention, which is often a source of errors in manual assembly processes. By relying on machines for component placement, manufacturers can achieve consistent quality across batches while reducing variability caused by human factors.

8. Support for Advanced Technologies

As electronic devices become increasingly sophisticated, there is a growing need for advanced technologies such as 5G and IoT devices that demand high-performance PCBs. Prototype SMT nozzles are designed to handle complex components required for these technologies, ensuring that manufacturers can keep pace with industry advancements.

Challenges Addressed by Prototype SMT Nozzles

While prototype SMT nozzles offer numerous advantages, they also address several challenges faced by manufacturers:

1. Handling Fragile Components

Many modern electronic components are delicate and can be easily damaged during handling or placement. Prototype SMT nozzles are designed with features that minimize mechanical stress on these fragile parts, ensuring they remain intact throughout the assembly process.

2. Compatibility with Various Materials

Different PCBs may be made from various materials that require specific handling techniques. Prototype SMT nozzles can be customized or selected based on the material properties of the PCB being used, ensuring compatibility and optimal performance.

3. Adaptation to Rapid Prototyping Needs

In today's fast-paced market, rapid prototyping has become essential for testing new designs quickly before mass production. Prototype SMT nozzles allow for quick changes between different SMD types and sizes without significant downtime or reconfiguration.

4. Integration with Automated Systems

As manufacturing processes become increasingly automated, prototype SMT nozzles can seamlessly integrate with other automated systems such as vision inspection systems and robotic arms. This integration enhances overall efficiency and accuracy across the entire assembly line.

Future Trends in SMT Nozzle Technology

The landscape of PCB assembly continues to evolve with advancements in technology. Several trends are shaping the future of prototype SMT nozzle technology:

1. Smart Nozzle Technology

Emerging smart nozzle technologies incorporate sensors and artificial intelligence (AI) capabilities that allow for real-time adjustments based on feedback from the assembly process. These smart systems can detect misalignments or defects instantly and make corrections on-the-fly.

2. Sustainability Initiatives

With increasing emphasis on sustainability within manufacturing processes, future prototype SMT nozzles may focus on reducing waste and enhancing energy efficiency during production runs.

3. Miniaturization Trends

As electronics continue to shrink in size while increasing in complexity, prototype SMT nozzles will need to evolve further to accommodate even smaller components without sacrificing performance or reliability.

4. Customization Options

The demand for customized solutions tailored to specific manufacturing needs will likely drive innovations in nozzle design and functionality, allowing manufacturers greater flexibility in their production processes.

Case Studies: Successful Implementations

To illustrate the benefits discussed above, let's explore a few case studies where companies have successfully implemented prototype SMT nozzles:

1. Company A: High-Density PCB Production

Company A specializes in producing high-density PCBs for consumer electronics. By integrating prototype SMT nozzles into their assembly line, they achieved a 30% increase in production speed while maintaining a defect rate below 0.5%. The flexibility offered by these nozzles allowed them to switch between different component types quickly without significant downtime.

2. Company B: Medical Device Manufacturing

In the medical device sector, precision is critical due to regulatory requirements and safety standards. Company B adopted prototype SMT nozzles specifically designed for fragile components used in their devices. This resulted in a 40% reduction in component damage during assembly and improved overall product reliability.

3. Company C: Rapid Prototyping Services

Company C provides rapid prototyping services for startups developing new electronic products. Utilizing prototype SMT nozzles enabled them to offer quick turnaround times on prototypes while accommodating various SMD configurations requested by clients—enhancing customer satisfaction significantly.

Conclusion

The benefits of using prototype SMT nozzles in PCB assembly are manifold, ranging from increased precision and packing density to improved production speed and cost-effectiveness. As manufacturers continue to seek ways to enhance their processes and meet evolving market demands, investing in high-quality prototype SMT nozzles will be crucial for maintaining competitive advantage.

In summary, adopting prototype SMT technology not only streamlines PCB assembly but also supports innovation within the electronics industry by enabling more compact designs and advanced functionalities.

FAQ

1. What is a prototype SMT nozzle?

A prototype SMT nozzle is a specialized tool used in pick-and-place machines for accurately placing surface mount devices onto printed circuit boards during assembly.

2. How do prototype SMT nozzles improve production speed?

Prototype SMT nozzles enhance production speed by automating component placement, allowing for faster assembly compared to manual methods.

3. Can prototype SMT nozzles handle different component sizes?

Yes, prototype SMT nozzles are designed to accommodate various sizes and types of surface mount devices, providing flexibility in PCB design.

4. What role do prototype SMT nozzles play in quality control?

Prototype SMT nozzles contribute to quality control by ensuring precise component placement, reducing defects related to misalignment or improper soldering.

5. Are there cost savings associated with using prototype SMT nozzles?

While initial costs may be higher, using prototype SMT nozzles leads to long-term cost savings through reduced labor costs and minimized waste from defective products.

Citations:

[1] https://jhdpcb.com/pcb-assembly/smt-assembly/

[2] https://swimbi.com/prototype-smt-pcb-assembly/

[3] https://www.viasion.com/blog/smt-assembly-explained-an-introductory-guide-for-beginners/

[4] https://www.viasion.com/smt-assembly/

[5] https://morepcb.com/smt/

[6] https://www.circuits-central.com/blog/a-comprehensive-guide-to-surface-mount-technology-in-pcb-assembly/

[7] https://www.raypcb.com/smt-assembly-process-optimization-by-multi-head-gantry-type-chip-mounter/

[8] https://www.linkedin.com/pulse/smd-pcb-assembly-comprehensive-guide-prototype-pcb-assembly-wctfc