Content Menu

● Enhanced Precision in Component Placement

● Increased Production Speed

● Cost-Effectiveness

● Flexibility in Design and Production

● Improved Mechanical Performance

● Case Studies Demonstrating Benefits

● Future Trends in Custom SMT Nozzle Development

● Conclusion

● FAQ

>> 1. What are SMT nozzles used for?

>> 2. How do I know if a nozzle is compatible with my machine?

>> 3. What materials are best for SMT nozzles?

>> 4. Can I get custom nozzles made?

>> 5. How does nozzle quality affect production?

● Citations:

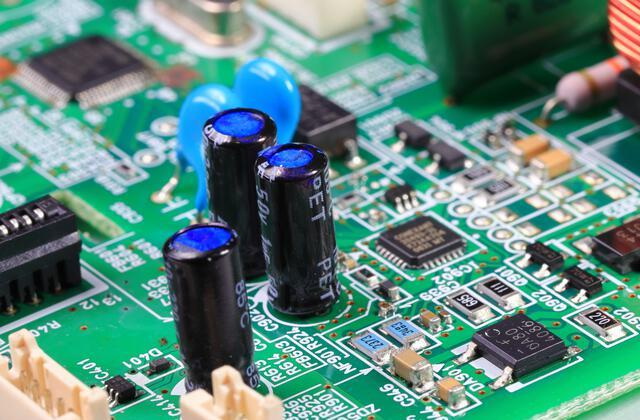

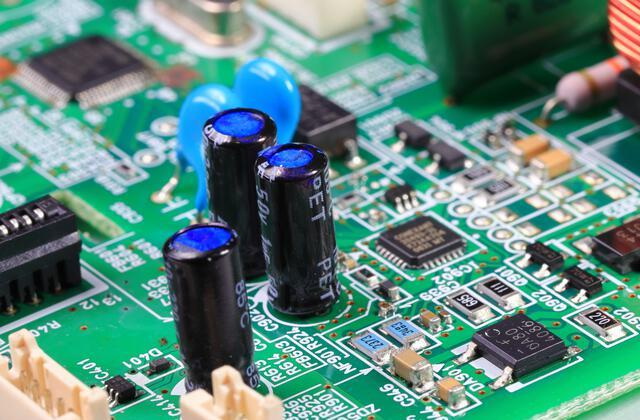

Surface Mount Technology (SMT) has transformed the landscape of printed circuit board (PCB) assembly, enabling manufacturers to produce smaller, more complex electronic devices with greater efficiency. A key element in this process is the SMT nozzle, responsible for picking and placing components onto PCBs with precision. Custom SMT nozzles, designed for specific applications, offer a range of benefits that enhance the overall assembly process. This article delves into the advantages of using custom SMT nozzles in PCB assembly, emphasizing their impact on precision, speed, cost-effectiveness, flexibility, and mechanical performance.

Enhanced Precision in Component Placement

Precision is crucial in PCB assembly, particularly as electronic devices become smaller and more intricate. Custom SMT nozzles are engineered to provide high levels of accuracy in component placement.

- Accurate Alignment: Custom nozzles ensure that components align correctly with PCB pads, minimizing the risk of misplacement that can lead to defects in the final product. This alignment is especially critical for high-density boards where components are closely packed together.

- Reduced Defect Rates: By maintaining high accuracy during placement, manufacturers can significantly lower rework costs and improve product reliability. Inaccurate placements can lead to issues such as poor electrical performance and increased failure rates.

- Adaptability to Component Size: Different components require different handling techniques; custom nozzles can be tailored to accommodate specific sizes and shapes. This adaptability ensures optimal placement for each type of component, which is vital for maintaining quality standards.

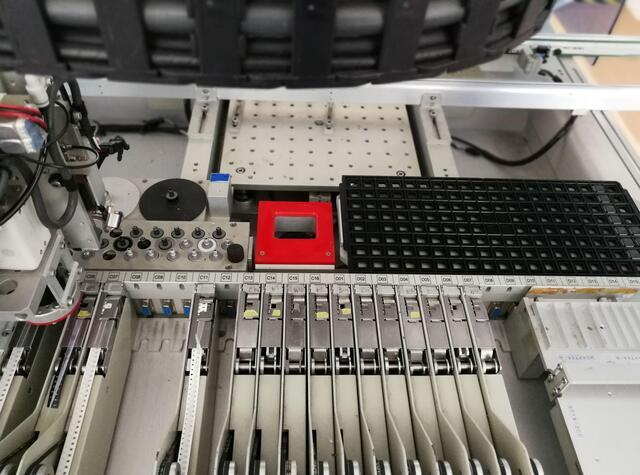

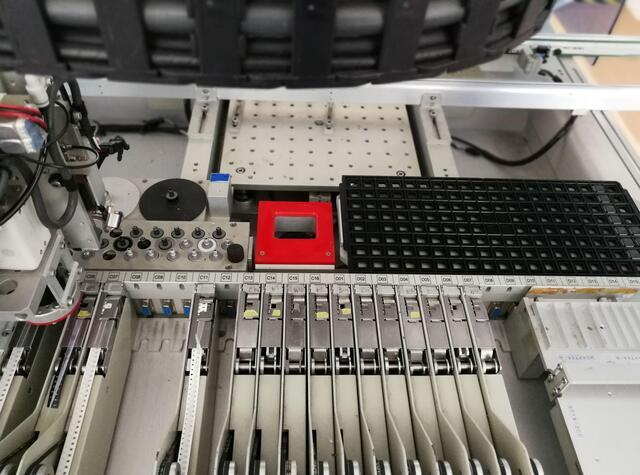

Increased Production Speed

The automation capabilities offered by custom SMT nozzles significantly improve production speed. In high-volume production environments, time-to-market is critical.

- Faster Component Placement: Automated pick-and-place machines equipped with custom nozzles can place components at a much higher rate than manual methods. For instance, some machines can exceed 136,000 components per hour, drastically reducing assembly time.

- Minimized Downtime: High-quality custom nozzles reduce machine downtime due to fewer failures or replacements needed. This efficiency is particularly beneficial during peak production times when demand is high.

- Streamlined Processes: The ability to quickly switch between different nozzle types allows manufacturers to adapt to varying production needs without significant downtime. This flexibility in operations enhances overall productivity.

Cost-Effectiveness

While the initial investment in custom SMT nozzles may be higher than traditional tools, they ultimately lead to substantial cost savings in the long run.

- Reduced Labor Costs: Increased automation minimizes the need for manual labor, which can be costly and prone to errors. By relying on machines for component placement, manufacturers can achieve consistent quality across batches while reducing variability caused by human factors.

- Lower Waste Rates: With improved accuracy and speed, manufacturers experience less waste from defective products, translating into lower material costs. The efficiency gained from using custom nozzles means fewer resources are wasted on rework or scrapped boards.

- Higher Profit Margins: The ability to produce high-quality PCBs more quickly can lead to greater profitability for manufacturers as they meet market demands efficiently. Investing in custom nozzles can yield a favorable return on investment over time.

Flexibility in Design and Production

Custom SMT nozzles provide unparalleled flexibility in design by accommodating various component types and sizes.

- Support for Innovation: Engineers can experiment with different layouts during the prototyping phase without being limited by tooling constraints. This freedom fosters innovation in product design and allows for rapid development cycles.

- Adaptation to Market Changes: As market demands evolve, manufacturers can quickly adjust their production processes by utilizing custom nozzles tailored to new components or configurations. This adaptability ensures that companies remain competitive in a fast-paced industry.

- Enhanced Quality Control: The precision of custom nozzles ensures that components are placed correctly, reducing the risk of solder joint failures or electrical issues later on. Automated inspection systems can easily integrate with nozzle technology for real-time monitoring during production.

Improved Mechanical Performance

Custom SMT nozzles contribute to better mechanical performance under various conditions.

- Resistance to Vibration: The design of custom nozzles often incorporates features that enhance their resistance to shock and vibration. This reliability is crucial for applications where PCBs are subject to movement or stress during operation.

- Lower Inductance and Resistance: By allowing for closer component placement without compromising electrical performance, custom nozzles help reduce unwanted RF signal effects and improve overall circuit functionality. This enhancement is particularly important for high-frequency applications where signal integrity is paramount.

Case Studies Demonstrating Benefits

To illustrate the benefits discussed above, let's explore a few case studies where companies have successfully implemented custom SMT nozzles:

- Company A, specializing in high-density PCBs for consumer electronics, integrated custom SMT nozzles into their assembly line and achieved a 30% increase in production speed while maintaining a defect rate below 0.5%. The flexibility offered by these nozzles allowed them to switch between different component types quickly without significant downtime.

- Company B, operating in the medical device sector where precision is critical due to regulatory requirements and safety standards, adopted custom SMT nozzles designed specifically for fragile components used in their devices. This resulted in a 40% reduction in component damage during assembly and improved overall product reliability.

- Company C, providing rapid prototyping services for startups developing new electronic products, utilized custom SMT nozzles enabling them to offer quick turnaround times on prototypes while accommodating various SMD configurations requested by clients—enhancing customer satisfaction significantly.

Future Trends in Custom SMT Nozzle Development

As technology continues to advance, the demand for customized solutions tailored to specific manufacturing needs will likely drive innovations in nozzle design and functionality.

- Additive Manufacturing: New production methods using additive manufacturing (3D printing) allow for rapid prototyping of nozzle designs that meet specific requirements without lengthy lead times or significant costs associated with traditional manufacturing methods.

- Smart Nozzle Technologies: Incorporating sensors into nozzle designs could enable real-time feedback during the assembly process, allowing adjustments based on component characteristics or environmental conditions—further enhancing precision and efficiency.

- Sustainability Considerations: As industries move towards more sustainable practices, future nozzle designs may focus on materials that reduce environmental impact while maintaining performance standards.

Conclusion

The adoption of custom SMT nozzles in PCB assembly offers numerous advantages that enhance precision, speed, cost-effectiveness, flexibility, and mechanical performance. As manufacturers continue to seek ways to improve their processes and meet evolving market demands, investing in high-quality custom SMT nozzles will be crucial for maintaining a competitive advantage. These specialized tools not only streamline PCB assembly but also support innovation within the electronics industry by enabling more compact designs and advanced functionalities.

FAQ

1. What are SMT nozzles used for?

SMT nozzles are specialized tools used in pick-and-place machines to accurately position electronic components onto printed circuit boards (PCBs).

2. How do I know if a nozzle is compatible with my machine?

To determine compatibility, check the specifications provided by your machine's manufacturer or consult with your nozzle supplier regarding compatibility details.

3. What materials are best for SMT nozzles?

High-quality plastics or metals that resist wear are ideal materials for durability and performance in SMT nozzles.

4. Can I get custom nozzles made?

Yes, many suppliers offer custom nozzle solutions tailored to specific component needs, allowing manufacturers greater flexibility in their assembly processes.

5. How does nozzle quality affect production?

Higher quality nozzles lead to improved placement accuracy and reduced downtime due to fewer failures or maintenance issues during production.

Citations:

[1] https://www.gssmt-parts.com/what-are-the-benefits-of-using-prototype-smt-nozzles-in-pcb-assembly.html

[2] https://www.wellpcb.com/blog/pcb-assembly/smt-vs-tht-pcb-assembly/

[3] https://pubs.aip.org/aip/acp/article/2607/1/120004/2892462/Design-of-nozzles-for-surface-mount-technologies

[4] https://es.hayawin.com/resources/how-to-optimize-pcb-design-for-smt-assembly-process-flow.html

[5] https://www.gssmt-parts.com/how-to-choose-the-right-smt-nozzle-for-different-pcb-designs.html

[6] https://pmc.ncbi.nlm.nih.gov/articles/PMC11342301/

[7] https://www.viasion.com/blog/smt-assembly-explained-an-introductory-guide-for-beginners/

[8] https://www.gssmt-parts.com/what-are-the-top-features-to-look-for-in-an-smt-nozzle-manufacturer.html

[9] https://autoinsertion.com/what-is-smt-advantages-disadvantages-and-applications/

[10] https://www.raypcb.com/smt-assembly-process-optimization-by-multi-head-gantry-type-chip-mounter/