Content Menu

● The Role of Ovens in SMT PCB Assembly

>> The SMT Assembly Process

● Key Benefits of Using an Oven for SMT PCB Assembly

>> 1. Precise Temperature Control

>> 2. Consistent and Repeatable Results

>> 3. Increased Throughput and Efficiency

>> 4. Handling Complex and Dense PCB Designs

>> 5. Enhanced Solder Joint Quality

● Advanced Features of Modern SMT Reflow Ovens

>> Nitrogen Atmosphere Capability

>> Vacuum Reflow Technology

>> Smart Controls and Data Logging

● Environmental and Cost Considerations

>> Energy Efficiency

>> Initial Investment vs. Long-term Savings

● Challenges and Considerations

>> Profile Development and Optimization

>> Maintenance and Calibration

>> Training and Expertise

● Future Trends in SMT Oven Technology

>> AI and Machine Learning Integration

>> Enhanced Connectivity and Industry 4.0 Integration

>> Eco-friendly Innovations

● Conclusion

● FAQ

>> 1. What is the difference between SMT and through-hole technology?

>> 2. How does a reflow oven work in SMT PCB assembly?

>> 3. What are the key factors to consider when selecting a reflow oven for SMT assembly?

>> 4. How does nitrogen atmosphere in a reflow oven benefit SMT assembly?

>> 5. What are some common challenges in using reflow ovens for SMT PCB assembly?

● Citations:

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, offering numerous advantages over traditional through-hole assembly methods. At the heart of the SMT process lies a crucial piece of equipment: the reflow oven. This article explores the significant benefits of using an oven for SMT PCB assembly, highlighting how this technology enhances efficiency, precision, and overall product quality.

The Role of Ovens in SMT PCB Assembly

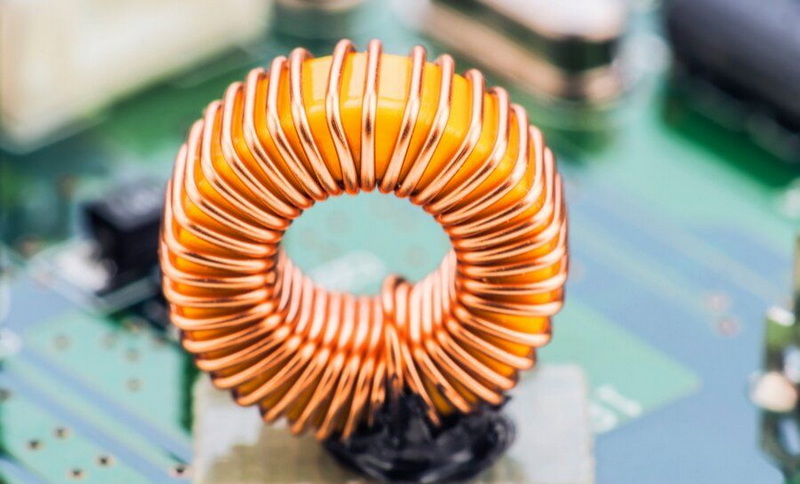

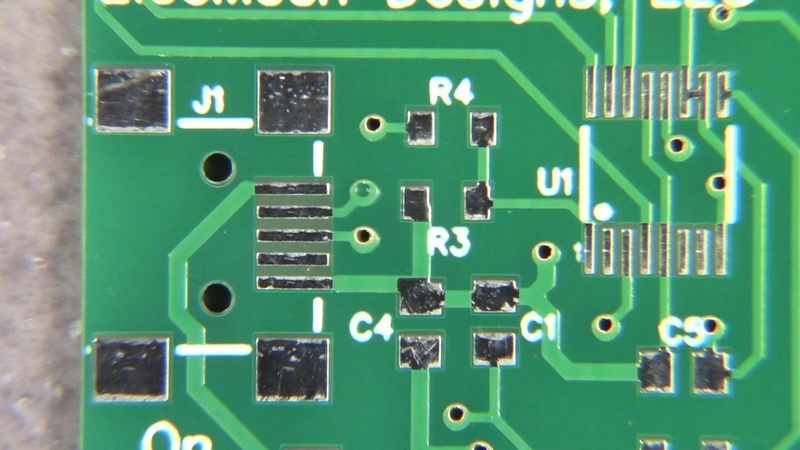

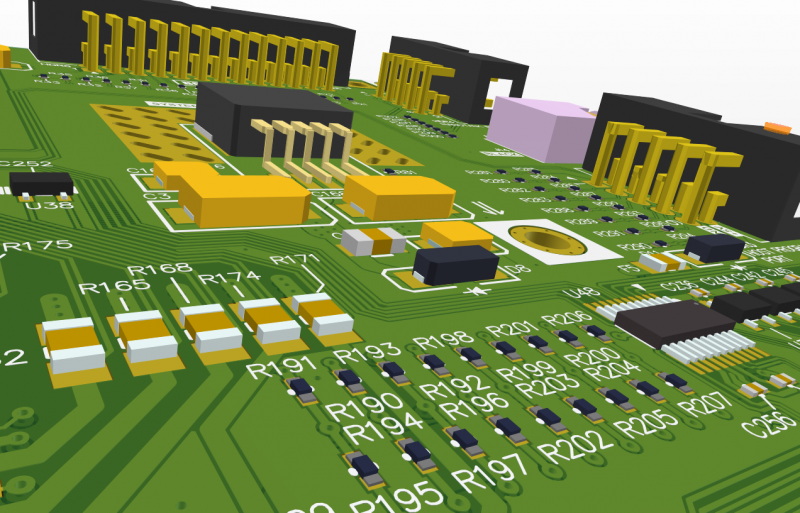

SMT ovens, also known as reflow ovens, play a pivotal role in the assembly process of surface mount devices (SMDs) onto printed circuit boards (PCBs). These specialized ovens are designed to heat PCBs to specific temperatures, melting solder paste and creating reliable connections between components and the board[1][2].

The SMT Assembly Process

Before delving into the benefits of using an oven, it's essential to understand the SMT assembly process:

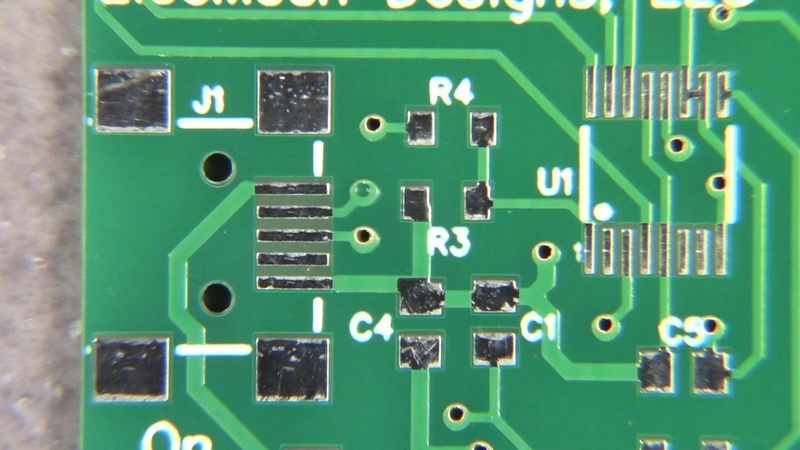

1. Solder Paste Application: A stencil is used to apply solder paste precisely onto the PCB pads.

2. Component Placement: SMD components are placed onto the PCB using automated pick-and-place machines.

3. Reflow Soldering: The PCB with placed components enters the reflow oven, where controlled heating melts the solder paste, creating permanent connections.

Key Benefits of Using an Oven for SMT PCB Assembly

1. Precise Temperature Control

One of the most significant advantages of using an oven for SMT PCB assembly is the ability to maintain precise temperature control throughout the soldering process[4]. Modern reflow ovens feature multiple heating zones, each with independent temperature settings. This zonal heating approach allows for:

- Gradual preheating of components and PCB

- Controlled soak periods for flux activation

- Precise peak temperatures for optimal solder melting

- Controlled cooling to prevent thermal shock

The ability to fine-tune temperature profiles ensures that each component on the PCB receives the ideal amount of heat, regardless of its size or thermal mass. This precision is crucial for achieving high-quality solder joints and minimizing the risk of component damage due to thermal stress[2].

2. Consistent and Repeatable Results

SMT ovens provide a level of consistency and repeatability that is unmatched by manual soldering methods. Once a reflow profile is optimized for a particular PCB design, it can be replicated with high accuracy across multiple production runs[1]. This consistency leads to:

- Reduced defect rates

- Improved product reliability

- Easier quality control and troubleshooting

The automated nature of reflow ovens eliminates variations that can occur with manual soldering, ensuring that each PCB undergoes the same carefully controlled thermal process.

3. Increased Throughput and Efficiency

Reflow ovens significantly boost production efficiency in SMT PCB assembly. These machines can process multiple boards simultaneously, dramatically increasing throughput compared to manual or semi-automated soldering methods[2]. The continuous flow of PCBs through the oven allows for:

- Higher production volumes

- Reduced labor costs

- Faster turnaround times for orders

Moreover, the efficiency of reflow ovens extends beyond just soldering speed. The precise control over the thermal profile minimizes the need for rework, further enhancing overall production efficiency.

4. Handling Complex and Dense PCB Designs

Modern electronics often require increasingly complex and densely populated PCB designs. Reflow ovens excel at handling these challenging assemblies[7]. The controlled heating environment ensures that:

- Fine-pitch components are soldered correctly

- BGAs and other advanced package types are properly attached

- Heat is distributed evenly across large or multilayer PCBs

This capability allows manufacturers to produce sophisticated electronic devices with high component density and intricate designs, which would be extremely difficult or impossible with manual soldering techniques.

5. Enhanced Solder Joint Quality

The controlled heating and cooling cycles in a reflow oven contribute to superior solder joint quality. The carefully managed thermal profile allows for:

- Proper flux activation and cleaning

- Optimal solder flow and wetting

- Minimized solder defects such as bridging or tombstoning

The result is stronger, more reliable solder connections that can withstand the rigors of use in various electronic devices[1]. This improved joint quality translates directly into enhanced product reliability and longevity.

Advanced Features of Modern SMT Reflow Ovens

As technology advances, SMT reflow ovens continue to evolve, offering new features that further enhance the PCB assembly process:

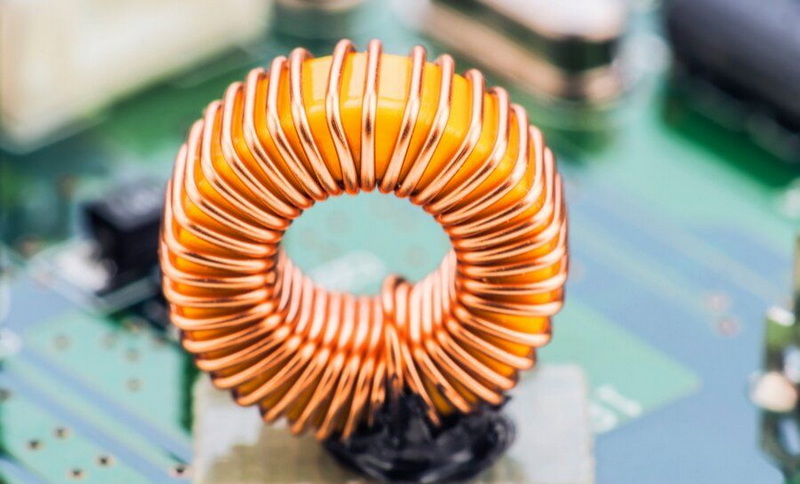

Nitrogen Atmosphere Capability

Some advanced reflow ovens offer the option to create a nitrogen-rich atmosphere during the soldering process. This feature:

- Reduces oxidation of solder and components

- Improves solder wetting and flow

- Enhances the overall quality of solder joints, especially for fine-pitch and challenging components[4]

Vacuum Reflow Technology

Vacuum reflow ovens represent the cutting edge of SMT assembly technology. These ovens apply a vacuum during the peak temperature phase, which:

- Eliminates voids in solder joints

- Improves the reliability of BGA and other complex package types

- Enhances the overall integrity of the solder connections[4]

Smart Controls and Data Logging

Modern reflow ovens often come equipped with advanced control systems and data logging capabilities. These features allow for:

- Real-time monitoring of the reflow process

- Automatic adjustments to maintain optimal thermal profiles

- Comprehensive data collection for quality control and process improvement[4]

Environmental and Cost Considerations

While the benefits of using an oven for SMT PCB assembly are numerous, it's also important to consider the environmental and cost implications:

Energy Efficiency

Modern reflow ovens are designed with energy efficiency in mind. Many models feature:

- Improved insulation to reduce heat loss

- Energy-saving modes during idle periods

- Optimized heating elements for better power utilization

These energy-efficient designs not only reduce operating costs but also minimize the environmental impact of the manufacturing process.

Initial Investment vs. Long-term Savings

While the initial cost of a reflow oven can be significant, the long-term benefits often outweigh this investment:

- Increased production capacity leads to higher revenue potential

- Reduced labor costs due to automation

- Lower defect rates and rework expenses

- Ability to handle more complex and higher-value PCB assemblies

For many electronics manufacturers, the return on investment for a quality reflow oven can be realized relatively quickly, especially when factoring in the improved product quality and expanded capabilities.

Challenges and Considerations

Despite the numerous benefits, using an oven for SMT PCB assembly does come with some challenges that manufacturers need to address:

Profile Development and Optimization

Creating the ideal reflow profile for each PCB design can be a complex process. Factors to consider include:

- Component types and their thermal characteristics

- PCB material and thickness

- Component placement and density

Developing and optimizing these profiles requires expertise and may involve some trial and error. However, once established, these profiles contribute significantly to the consistency and quality of the assembly process.

Maintenance and Calibration

To ensure consistent performance, reflow ovens require regular maintenance and calibration. This includes:

- Cleaning of conveyor systems and heating elements

- Calibration of temperature sensors

- Verification of thermal profiles

While these maintenance tasks represent an ongoing commitment, they are essential for maintaining the oven's performance and the quality of the assembled PCBs.

Training and Expertise

Operating a reflow oven effectively requires trained personnel who understand the intricacies of the SMT process. Investing in staff training and development is crucial for maximizing the benefits of this technology.

Future Trends in SMT Oven Technology

As the electronics industry continues to evolve, so too does the technology behind SMT reflow ovens. Some emerging trends include:

AI and Machine Learning Integration

Future reflow ovens may incorporate artificial intelligence and machine learning algorithms to:

- Automatically optimize reflow profiles based on PCB characteristics

- Predict and prevent potential defects

- Self-adjust parameters in real-time for optimal performance

Enhanced Connectivity and Industry 4.0 Integration

As part of the broader Industry 4.0 movement, reflow ovens are likely to become more connected, offering:

- Seamless integration with other production line equipment

- Real-time data sharing and analysis

- Remote monitoring and control capabilities

Eco-friendly Innovations

With increasing focus on environmental sustainability, future reflow ovens may feature:

- Even more energy-efficient designs

- Use of environmentally friendly materials in construction

- Integration with renewable energy sources

Conclusion

The use of ovens in SMT PCB assembly offers a multitude of benefits that have transformed the electronics manufacturing landscape. From precise temperature control and consistent results to increased throughput and the ability to handle complex designs, reflow ovens have become indispensable tools in modern PCB production.

As technology continues to advance, we can expect even more innovative features and capabilities from SMT reflow ovens, further enhancing their role in producing high-quality, reliable electronic devices. For manufacturers looking to stay competitive in the fast-paced world of electronics, investing in quality reflow oven technology is not just beneficial—it's essential.

The combination of improved product quality, increased efficiency, and the ability to tackle complex designs makes the use of ovens in SMT PCB assembly a cornerstone of modern electronics manufacturing. As the industry continues to push the boundaries of what's possible in electronic devices, the role of advanced reflow ovens will undoubtedly remain crucial in turning innovative designs into reality.

FAQ

1. What is the difference between SMT and through-hole technology?

SMT (Surface Mount Technology) involves mounting components directly onto the surface of a PCB, while through-hole technology requires components to be inserted through holes in the board. SMT allows for more compact designs, higher component density, and is generally more suitable for automated assembly processes[7].

2. How does a reflow oven work in SMT PCB assembly?

A reflow oven works by heating PCBs with placed components through a series of temperature zones. The process typically includes preheating, soaking, reflow (peak temperature), and cooling stages. This controlled heating profile melts the solder paste, creating electrical connections between components and the PCB[2][4].

3. What are the key factors to consider when selecting a reflow oven for SMT assembly?

When selecting a reflow oven, consider factors such as:

- Production volume requirements

- Types of components and PCBs to be assembled

- Temperature control precision and stability

- Number of heating zones

- Energy efficiency

- Maintenance requirements and ease of use

- Additional features like nitrogen atmosphere or vacuum capability[4]

4. How does nitrogen atmosphere in a reflow oven benefit SMT assembly?

A nitrogen atmosphere in a reflow oven offers several benefits:

- Reduces oxidation of solder and component leads

- Improves solder wetting and flow characteristics

- Enhances the quality of solder joints, especially for fine-pitch components

- Allows for better control of the reflow process

- Can result in brighter, shinier solder joints[4]

5. What are some common challenges in using reflow ovens for SMT PCB assembly?

Common challenges include:

- Developing and optimizing reflow profiles for different PCB designs

- Ensuring even heating across the entire PCB, especially for large or complex boards

- Managing the thermal sensitivity of certain components

- Maintaining consistent performance through regular calibration and maintenance

- Balancing energy efficiency with performance requirements

- Training operators to effectively use and troubleshoot the equipment[2][4]

Citations:

[1] https://www.zetwerk.com/resources/knowledge-base/electronics-manufacturing-services-ems/smt-pcb-assembly-processes-benefits-and-applications/

[2] https://www.pcbonline.com/blog/smt-manufacturing-process.html

[3] https://www.wevolver.com/article/smt-process

[4] https://www.smtfactory.com/Precision-Perfected-Unveiling-The-Advantages-of-Reflow-Ovens-in-PCB-Assembly-id45063497.html

[5] https://www.ablcircuits.co.uk/blog/what-is-the-smt-process-and-why-should-oems-care/

[6] https://www.made-in-china.com/products-search/hot-china-products/Smt_Oven.html

[7] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[8] https://www.protoexpress.com/kb/pcb-assembly-process-overview/

[9] https://www.pcbway.com/pcb_prototype/SMT_Assembly_Capabilities.html

[10] https://www.pcbgogo.com/Article/Why_SMT_Technology_Benefit_PCB_Assembly_.html