Content Menu

● Increased Production Efficiency

● Improved Quality Control

● Cost-Effectiveness

● Enhanced Flexibility and Scalability

● Better Working Conditions

● Continuous Improvement Opportunities

● Enhanced Safety Measures

● Conclusion

● FAQ

>> 1. What is an automated SMT manufacturing line?

>> 2. How does automation improve quality control in SMT manufacturing?

>> 3. What are the initial costs associated with setting up an automated SMT line?

>> 4. Can automated SMT lines handle different types of products?

>> 5. How does automation affect employee working conditions?

● Citations:

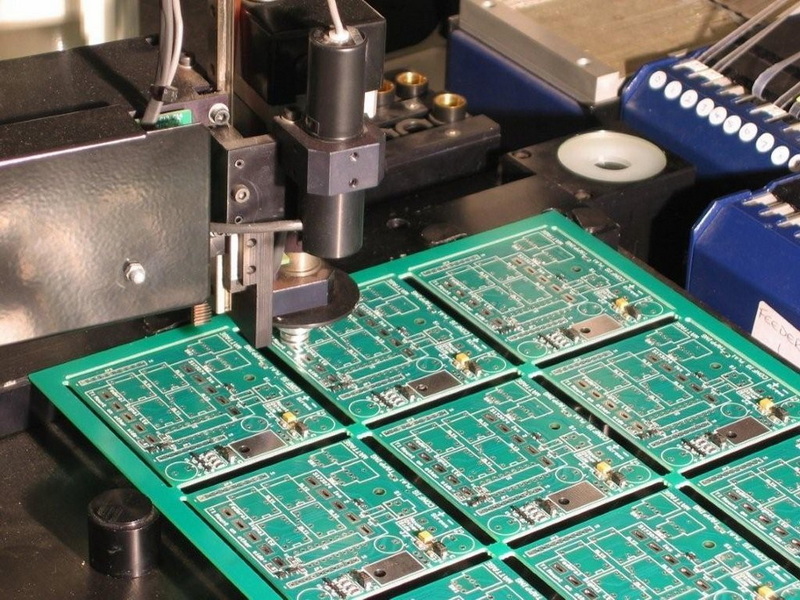

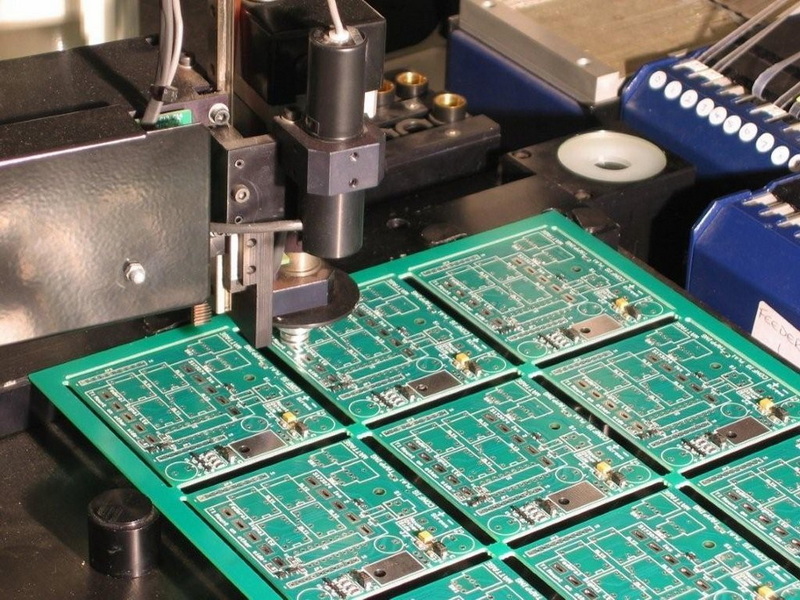

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, allowing for the efficient assembly of electronic components on printed circuit boards (PCBs). As technology evolves, so does the need for automation in SMT manufacturing lines. This article explores the numerous benefits of utilizing an automated SMT manufacturing line, discussing its impact on efficiency, quality, cost-effectiveness, flexibility, and the overall working environment.

Increased Production Efficiency

One of the most significant advantages of automated SMT manufacturing lines is the enhancement of production efficiency. Automation reduces the time required for assembly processes, enabling manufacturers to produce more units in a shorter timeframe.

- Speed: Automated systems can operate at higher speeds than manual processes. Machines can place components on PCBs rapidly and with precision, significantly increasing throughput. For instance, SMT lines can assemble thousands of components per hour, making them ideal for high-volume production[1].

- Reduced Downtime: Automated systems are designed to minimize downtime. With features like quick changeover capabilities and real-time monitoring, production lines can operate continuously without long interruptions. This is crucial in maintaining a steady workflow and meeting production deadlines.

- Consistent Output: Automation ensures that each unit produced meets the same quality standards. This consistency is crucial for maintaining product reliability and customer satisfaction. Automated machines are less prone to fatigue and distraction compared to human operators, resulting in fewer errors during production[6].

Improved Quality Control

Quality control is paramount in electronics manufacturing. Automated SMT lines incorporate advanced technologies that enhance quality assurance processes.

- Precision Placement: Automated pick-and-place machines are capable of placing components with high accuracy. This precision reduces the likelihood of defects caused by human error during assembly. The integration of advanced sensors and robotics ensures that components are placed exactly where they need to be.

- Real-Time Inspection: Many automated systems include integrated inspection technologies such as Automated Optical Inspection (AOI). These systems can detect defects in real-time, allowing for immediate corrective actions. By minimizing defects and rework, automation contributes to higher yield rates and improved product reliability[2].

- Traceability: Automation enables better traceability of components and processes. Manufacturers can track each step of production, ensuring compliance with industry standards and facilitating recalls if necessary. This traceability enhances accountability and transparency within the manufacturing process.

Cost-Effectiveness

While the initial investment in automated SMT manufacturing lines may be substantial, the long-term savings can be significant.

- Labor Costs: Automation reduces the reliance on manual labor, leading to lower labor costs over time. Fewer workers are needed to operate machines, and those who remain can focus on more complex tasks that require human intervention. This shift allows companies to allocate resources more efficiently.

- Material Waste Reduction: Automated systems are designed to optimize material usage. Precise placement and real-time monitoring help minimize waste from defective components or incorrect placements. The reduction in waste not only lowers costs but also contributes to more sustainable manufacturing practices[9].

- Lower Operational Costs: Automation often leads to lower operational costs due to increased efficiency and reduced errors. This translates into savings on energy consumption and maintenance over time. Additionally, the ability to quickly adapt production lines for different products enhances overall profitability.

Enhanced Flexibility and Scalability

In today's fast-paced market, flexibility is essential for manufacturers to adapt to changing demands.

- Product Variety: Automated SMT lines can be programmed to handle a wide variety of products without significant reconfiguration. This adaptability allows manufacturers to diversify their offerings quickly without incurring substantial downtime or retooling costs.

- Scalability: As demand increases, automated systems can be scaled up easily by adding more machines or integrating additional production lines. This scalability ensures that manufacturers can meet market demands without extensive downtime or retooling[3].

Better Working Conditions

Automation not only benefits production but also improves working conditions for employees.

- Reduced Physical Strain: By automating repetitive tasks, workers are less prone to injuries associated with manual assembly processes. This reduction in physical strain leads to a healthier workforce and lower absenteeism rates.

- Focus on Value-Added Tasks: With automation handling routine tasks, employees can concentrate on higher-value activities such as quality control, maintenance, and process improvement. This shift enhances job satisfaction and productivity as workers engage in more meaningful work[4].

Continuous Improvement Opportunities

Automated SMT manufacturing lines facilitate continuous improvement through data collection and analysis.

- Data Analytics: Automated systems generate vast amounts of data that can be analyzed to identify bottlenecks or inefficiencies in the production process. Manufacturers can use this information to make informed decisions about improvements.

- Lean Manufacturing Principles: Automation aligns well with lean manufacturing principles by reducing waste and optimizing processes. Manufacturers can implement strategies that enhance productivity while minimizing resource consumption[5].

Enhanced Safety Measures

Automation contributes significantly to workplace safety by reducing human involvement in hazardous tasks.

- Reduction of Workplace Accidents: By entrusting repeatable operations to machines, manufacturers reduce the risk of workplace accidents associated with manual handling of heavy components or exposure to harmful substances used in soldering processes[6].

- Improved Occupational Health: Automation minimizes exposure to hazardous materials (like lead solder) by automating processes that traditionally required human intervention, thus enhancing overall occupational health standards within manufacturing environments[9].

Conclusion

The benefits of using an automated SMT manufacturing line are multifaceted, impacting efficiency, quality, cost-effectiveness, flexibility, working conditions, continuous improvement opportunities, and safety measures. As technology continues to advance, embracing automation becomes increasingly essential for electronics manufacturers seeking to remain competitive in a rapidly evolving market. By investing in automated systems, companies can enhance their production capabilities while ensuring high-quality outputs that meet customer demands.

FAQ

1. What is an automated SMT manufacturing line?

An automated SMT manufacturing line is a production system that uses machines and technology to assemble electronic components onto printed circuit boards (PCBs) without manual intervention.

2. How does automation improve quality control in SMT manufacturing?

Automation improves quality control by ensuring precision placement of components and incorporating real-time inspection technologies like Automated Optical Inspection (AOI) to detect defects immediately during production.

3. What are the initial costs associated with setting up an automated SMT line?

The initial costs of setting up an automated SMT line can be high due to the investment in machinery and technology; however, long-term savings from reduced labor costs and improved efficiency often offset these expenses.

4. Can automated SMT lines handle different types of products?

Yes, automated SMT lines offer flexibility and can be programmed to handle various products without extensive reconfiguration, allowing manufacturers to adapt quickly to market demands.

5. How does automation affect employee working conditions?

Automation improves employee working conditions by reducing physical strain from repetitive tasks and allowing workers to focus on higher-value activities that enhance job satisfaction and productivity.

Citations:

[1] https://www.smtfactory.com/what-is-an-smt-line-and-how-can-it-improve-your-pcb-assembly-process.html

[2] https://www.smtfactory.com/Streamlining-Operations-How-Automation-Enhances-SMT-Line-Productivity-id47973586.html

[3] https://eitplems.com/top-5-benefits-of-industrial-automation-in-electronic-manufacturing/

[4] https://www.wevolver.com/article/smt-process

[5] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[6] https://asselems.com/en/benefits-of-process-automation-in-electronics-production

[7] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[8] https://motionindexdrives.com/blog/how-automation-increases-manufacturing-efficiency/

[9] https://www.technotronix.us/pcbblog/top-benefits-of-automation-in-electronics-manufacturing/

[10] https://www.atmwa.com.au/the-top-10-benefits-of-electronics-automation/