Content Menu

● Understanding Wholesale PCB SMT Production Lines

● Key Benefits of Wholesale PCB SMT Production Lines

>> Enhanced Efficiency

>> Improved Quality Control

>> Scalability and Flexibility

>> Cost-Effectiveness

● Applications of Wholesale PCB SMT Production Lines

>> Consumer Electronics

>> Industrial Equipment

>> Automotive Electronics

>> Medical Devices

● Innovations Driving Future Developments

>> AI and Machine Learning

>> Advanced Robotics

>> Smart Manufacturing Integration

● Case Studies: Success Stories with Wholesale PCB SMT Production Lines

>> Case Study 1: Electronix Solutions Inc.

>> Case Study 2: Automatech Technologies Ltd.

● Conclusion

● FAQ

>> 1. What is a wholesale PCB SMT production machine line?

>> 2. What are the main components of an SMT line?

>> 3. How does using an SMT line improve product quality?

>> 4. Can wholesale PCB SMT production lines handle different types of PCBs?

>> 5. What are some cost benefits associated with using an SMT line?

● Citations:

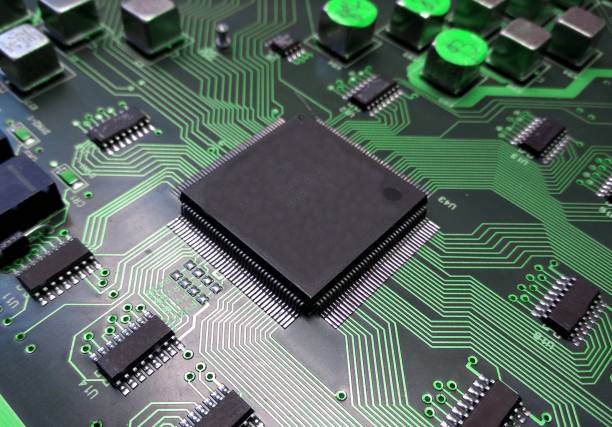

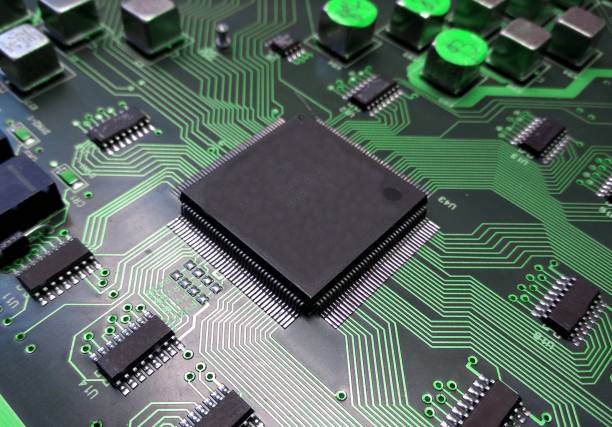

In the rapidly evolving world of electronics manufacturing, the demand for efficient, high-quality production processes has never been greater. One of the key innovations that have revolutionized this industry is the Wholesale PCB SMT (Surface Mount Technology) Production Machine Line. This article explores the numerous benefits of utilizing such production lines, detailing their components, applications, and the transformative impact they have on manufacturing.

Understanding Wholesale PCB SMT Production Lines

A wholesale PCB SMT production machine line is a sophisticated assembly system designed to automate the process of mounting electronic components onto printed circuit boards (PCBs). These lines typically include various machines such as:

- Pick-and-Place Machines: These automated systems accurately position surface-mount components onto PCBs.

- Solder Paste Printers: They apply solder paste to the PCB pads, preparing them for component placement.

- Reflow Ovens: These ovens melt and reflow the solder paste, creating permanent connections between components and PCBs.

- Inspection Systems: Vision-based systems that detect defects in assembled PCBs to ensure quality.

- Conveyors: Automated systems that transport PCBs between different stages of assembly.

Key Benefits of Wholesale PCB SMT Production Lines

Enhanced Efficiency

One of the primary advantages of wholesale PCB SMT production lines is their ability to significantly enhance manufacturing efficiency. By automating various stages of the assembly process, manufacturers can achieve:

- Reduced Cycle Times: Automated processes minimize delays associated with manual labor.

- Higher Throughput: Machines can operate at speeds that far exceed human capabilities, allowing for greater production volumes.

Improved Quality Control

Quality control is crucial in electronics manufacturing. Wholesale PCB SMT production lines offer several features that enhance product quality:

- Integrated Inspection Systems: Automated Optical Inspection (AOI) systems check for defects at multiple stages, ensuring that only high-quality products move forward in the production process.

- Consistent Soldering Quality: The precision of automated soldering processes reduces the likelihood of defects compared to manual methods.

Scalability and Flexibility

Wholesale PCB SMT production lines are designed to be highly scalable and adaptable to changing market demands:

- Modular Design: Manufacturers can easily add or remove machines from the line based on production needs, allowing for quick adjustments in capacity.

- Support for Diverse Designs: These lines can accommodate a wide range of PCB designs and component types, making them suitable for various applications.

Cost-Effectiveness

While the initial investment in a wholesale PCB SMT production line may be substantial, the long-term cost savings are significant:

- Reduced Labor Costs: Automation decreases reliance on manual labor, leading to lower operational costs over time.

- Improved Material Utilization: Efficient processes minimize waste, further enhancing profitability.

Applications of Wholesale PCB SMT Production Lines

Wholesale PCB SMT production lines are utilized across various industries due to their versatility and efficiency. Key applications include:

Consumer Electronics

From smartphones and tablets to home appliances, wholesale PCB SMT production lines are integral to producing a wide array of consumer electronics. Their ability to handle high volumes with precision makes them ideal for this fast-paced market.

Industrial Equipment

Industrial machinery relies heavily on reliable electronic components for control systems and sensors. Wholesale PCB SMT production lines enable manufacturers to produce robust PCBs that meet stringent industrial standards.

Automotive Electronics

The automotive sector demands high reliability in electronic components used in vehicle control systems and infotainment. Wholesale PCB SMT production lines ensure consistent quality and performance in automotive applications.

Medical Devices

Medical devices require strict adherence to quality standards to ensure patient safety. The precision and reliability offered by wholesale PCB SMT production lines are essential for producing high-quality medical device PCBs.

Innovations Driving Future Developments

The landscape of wholesale PCB SMT production is continuously evolving due to technological advancements. Key innovations include:

AI and Machine Learning

The integration of artificial intelligence (AI) into manufacturing processes allows for predictive maintenance and real-time optimization, enhancing overall efficiency.

Advanced Robotics

Robotic automation technologies improve handling and assembly processes, increasing throughput while minimizing human error.

Smart Manufacturing Integration

Connecting production lines with smart manufacturing systems enables real-time monitoring and data analytics, optimizing both efficiency and quality control.

Case Studies: Success Stories with Wholesale PCB SMT Production Lines

Case Study 1: Electronix Solutions Inc.

Electronix Solutions Inc., a prominent electronics manufacturer, faced challenges such as low throughput and high labor costs due to manual assembly processes. By investing in a wholesale PCB SMT production line from Techtronics Manufacturing Systems, they achieved remarkable improvements in productivity and product quality. This transition enabled them to meet customer demands more effectively while gaining a competitive edge in the market.

Case Study 2: Automatech Technologies Ltd.

Automatech Technologies Ltd., a startup focused on IoT devices, required a scalable solution for rapid production volume increases. Partnering with SMT Solutions Co., they implemented a customized wholesale PCB SMT production line tailored to their specific needs. This investment allowed them to scale their operations seamlessly, significantly reducing time-to-market for their innovative products.

Conclusion

Wholesale PCB SMT production machine lines represent a significant advancement in electronics manufacturing. By offering enhanced efficiency, improved quality control, scalability, and cost-effectiveness, these lines are essential tools for manufacturers aiming to thrive in an increasingly competitive landscape. As technology continues to evolve, embracing these advanced production capabilities will be crucial for staying ahead in the market.

FAQ

1. What is a wholesale PCB SMT production machine line?

A wholesale PCB SMT production machine line is an automated system designed for assembling surface-mounted electronic components onto printed circuit boards efficiently and accurately.

2. What are the main components of an SMT line?

The main components include pick-and-place machines, solder paste printers, reflow ovens, inspection systems (like AOI), and conveyors that facilitate the movement of PCBs through different stages of assembly.

3. How does using an SMT line improve product quality?

SMT lines enhance product quality through integrated inspection systems that detect defects early in the process and by ensuring consistent soldering quality through precise automated methods.

4. Can wholesale PCB SMT production lines handle different types of PCBs?

Yes, these production lines are highly flexible and can accommodate various designs and component types, making them suitable for diverse applications across multiple industries.

5. What are some cost benefits associated with using an SMT line?

Cost benefits include reduced labor costs due to automation, improved material utilization which minimizes waste, and increased throughput leading to higher overall profitability.

Citations:

[1] https://www.hct-smt.com/blog/optimizing-electronics-manufacturing-with-a-wholesale-pcb-smt-production-machine-line

[2] https://www.ourpcb.com/smt-line.html

[3] https://www.hayawin.com/products/wholesale-pcb-smt-machine.html

[4] https://www.quick-pcba.com/the-main-equipment-in-an-smt-line/

[5] https://www.hct-smt.com/blog/comprehensive-guide-to-led-smt-production-line

[6] https://mpe.researchmfg.com/smt-qa/

[7] https://www.hayawin.com/resources/smt-line-an-efficient-and-cost-effective-production-line.html

[8] https://www.hayawin.com/resources/advantages-of-smt-manufacturing.html

[9] https://www.raypcb.com/smt-lines/

[10] https://www.pcbasic.com/blog/smt_production_line.html

[11] https://blog.matric.com/smt-production-for-pcbs-matric

[12] https://www.pcbonline.com/blog/smt-manufacturing-process.html

[13] https://www.pcbasic.com/blog/smt_production_line.html

[14] https://www.pcbgogo.com/Article/How_does_double_sided_SMT_assembly_work_.html

[15] https://blog.matric.com/smt-production-for-pcbs-matric

[16] https://www.wevolver.com/article/smt-process

[17] https://www.hayawin.com/products/what-does-smt-mean.html

[18] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[19] https://m.smt11.com/solution/Consumer-Electronics/Exploring-the-Benefits-of-SMT-Production-Line-and-DIP-Line-in-Power-Supply-PCBA-Manufacturing-56.html

[20] https://shenzhenshengdian.en.made-in-china.com/product/AFDTOZiEhIrY/China-PCB-Machine-Automatic-SMT-Assembly-Line-PCB-Magazine-Loader-for-SMT-Production-Line.html

[21] https://www.electronicdesign.com/markets/automation/article/21259057/ddm-novastar-the-pros-and-cons-of-bringing-pcb-smt-assembly-in-house

[22] https://www.neodensmt.com/other-products/prototype-smt-production-line-pnp-machine.html

[23] https://www.ablcircuits.co.uk/blog/what-is-the-smt-process-and-why-should-oems-care/

[24] https://www.linkedin.com/pulse/advantages-smt-manufacturing-practical-cost-effective-nyn3c

[25] https://www.neodensmt.com/other-products/online-smt-inspection-machine.html

[26] https://www.qhsmt.com/2023/11/29/smt-pick-and-place-most-asked-power-electronics-supply-questions-and-answers/

[27] https://versae.com/smt-assembly-faq/

[28] https://www.nextpcb.com/blog/pcb-assembly--a-comprehensive-guide

[29] https://electronics.stackexchange.com/questions/342068/automatic-smt-line-pcb-soldering

[30] https://www.viasion.com/blog/smt-assembly-introduction-applications-steps-common-errors/

[31] https://www.mktpcb.com/pcb-manufacturing-process/

[32] https://levisonenterprises.com/your-surface-mount-technology-questions-answered/

[33] https://www.pcbcart.com/article/content/qa-about-smt-assembly.html

[34] https://www.technotronix.us/faqs.html

[35] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[36] https://global.yamaha-motor.com/business/smt/faq/

[37] https://www.eevblog.com/forum/manufacture/so-i-want-to-have-my-own-smt-assembly-line/

[38] https://www.pivotint.com/blog/3-benefits-of-choosing-a-manufacturing-partner-with-mirrored-smt-lines/