Content Menu

● Understanding Turnkey SMT Assembly Lines

● Key Benefits of Turnkey SMT Assembly Lines

>> 1. Cost Reduction

>> 2. Streamlined Project Management

>> 3. Enhanced Quality Control

>> 4. Faster Time-to-Market

>> 5. Flexibility and Scalability

● The Role of Surface Mount Technology (SMT)

● Challenges Addressed by Turnkey Solutions

● Innovation Through Technology Integration

● Sustainability Considerations

● Conclusion

● FAQs

>> 1. What is a turnkey SMT assembly line?

>> 2. How does using a turnkey solution save costs?

>> 3. Can I customize my order with a turnkey supplier?

>> 4. What are the advantages of Surface Mount Technology (SMT)?

>> 5. How does a turnkey solution improve quality control?

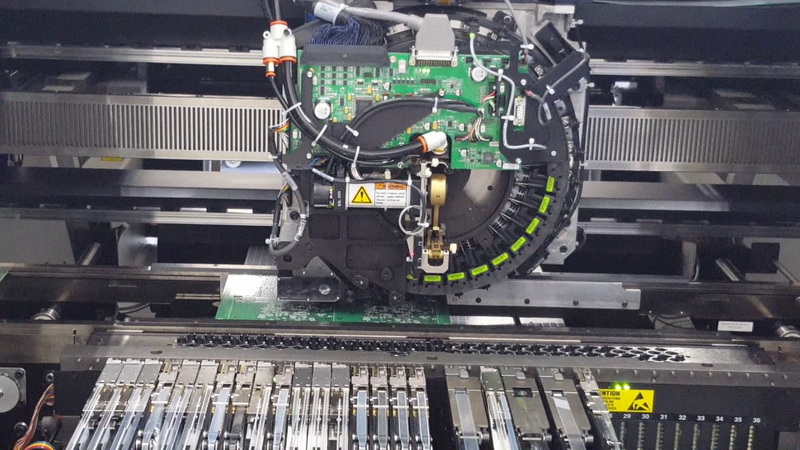

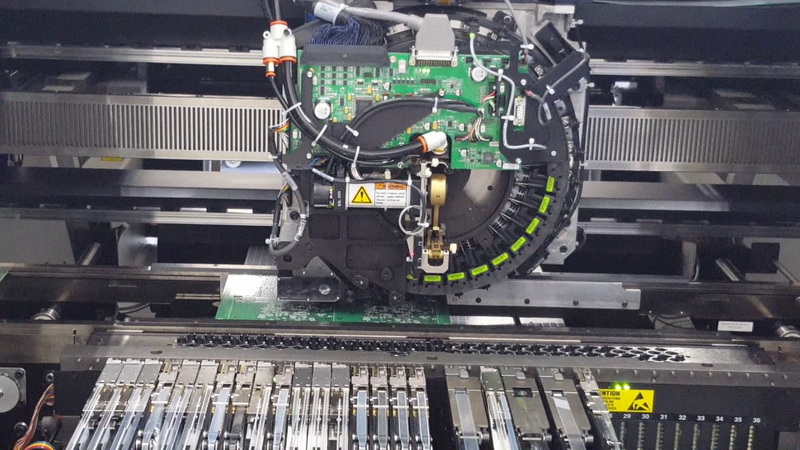

In the fast-paced world of electronics manufacturing, the demand for efficiency, quality, and cost-effectiveness is ever-increasing. One solution that has gained significant traction in recent years is the turnkey SMT (Surface Mount Technology) assembly line. This approach offers a comprehensive solution for the assembly of printed circuit boards (PCBs), allowing businesses to streamline their production processes while ensuring high-quality outputs. In this article, we will delve into the numerous benefits of utilizing a turnkey SMT assembly line, exploring how it can enhance operational efficiency, reduce costs, and improve product quality.

Understanding Turnkey SMT Assembly Lines

A turnkey SMT assembly line refers to a manufacturing process where a single supplier manages all aspects of PCB assembly—from design and component sourcing to assembly and testing. This method contrasts with traditional approaches that often involve multiple vendors, leading to complexities in communication and coordination. By opting for a turnkey solution, businesses can focus on their core competencies while leaving the intricacies of assembly to specialized providers.

Key Benefits of Turnkey SMT Assembly Lines

The advantages of using a turnkey SMT assembly line are manifold. Below are some of the most significant benefits:

1. Cost Reduction

One of the primary advantages of turnkey SMT assembly is its potential for cost savings. By consolidating services under one provider, companies can avoid the additional costs associated with managing multiple suppliers. This includes:

- Reduced Shipping Costs: With a single point of contact, shipping logistics become simpler and more cost-effective.

- Bulk Purchasing Discounts: Turnkey suppliers often have established relationships with component manufacturers, allowing them to secure better pricing on parts.

- Lower Labor Costs: Automation in SMT processes reduces the need for manual labor, leading to decreased overhead costs.

- Minimized Overhead Expenses: By reducing the number of suppliers and streamlining processes, companies can lower their administrative and operational overhead.

2. Streamlined Project Management

Managing multiple vendors can be a logistical nightmare, leading to miscommunication and delays. A turnkey SMT assembly line simplifies project management by providing:

- Single Point of Contact: Having one supplier means all communications go through one channel, reducing the risk of errors and misunderstandings.

- Integrated Processes: The seamless integration of design, sourcing, and assembly ensures that any changes or issues are addressed promptly without affecting timelines.

- Efficient Workflow Coordination: A unified approach allows for better coordination among different stages of production, leading to smoother transitions between design, manufacturing, and testing phases.

3. Enhanced Quality Control

Quality assurance is critical in electronics manufacturing. Turnkey SMT assembly lines offer improved quality control through:

- Consistent Standards: A single supplier ensures that all components meet the same quality standards throughout the production process.

- Early Issue Identification: With integrated design and manufacturing processes, potential problems can be identified early in the production cycle, allowing for timely corrections.

- Comprehensive Testing Procedures: Turnkey providers often implement rigorous testing protocols at various stages of production to ensure that each component meets quality benchmarks before final assembly.

4. Faster Time-to-Market

In today's competitive landscape, speed is crucial. Turnkey SMT assembly lines facilitate quicker product launches by:

- Accelerated Production Cycles: The automation inherent in SMT allows for rapid assembly without compromising quality.

- Efficient Prototyping: Quick turnaround times for prototypes enable businesses to test and refine their products faster than ever before.

- Rapid Response to Market Demands: With streamlined processes and efficient supply chains, companies can quickly adapt to changing market conditions or customer needs.

5. Flexibility and Scalability

Turnkey solutions provide flexibility that can adapt to changing business needs:

- Custom Solutions: Providers can tailor their services to meet specific project requirements, whether it's low-volume runs or large-scale production.

- Scalable Operations: As businesses grow, turnkey suppliers can easily scale operations up or down based on demand without significant reconfiguration.

- Adaptability to Technological Changes: Turnkey suppliers often stay abreast of technological advancements in SMT processes, allowing them to integrate new technologies into production swiftly.

The Role of Surface Mount Technology (SMT)

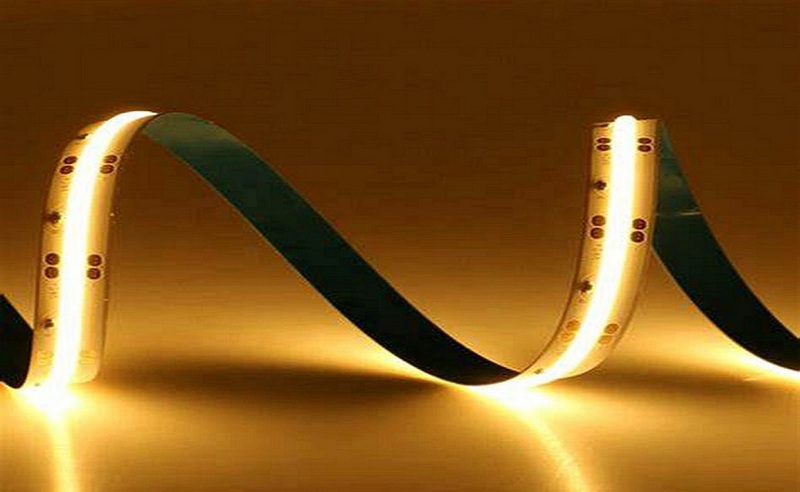

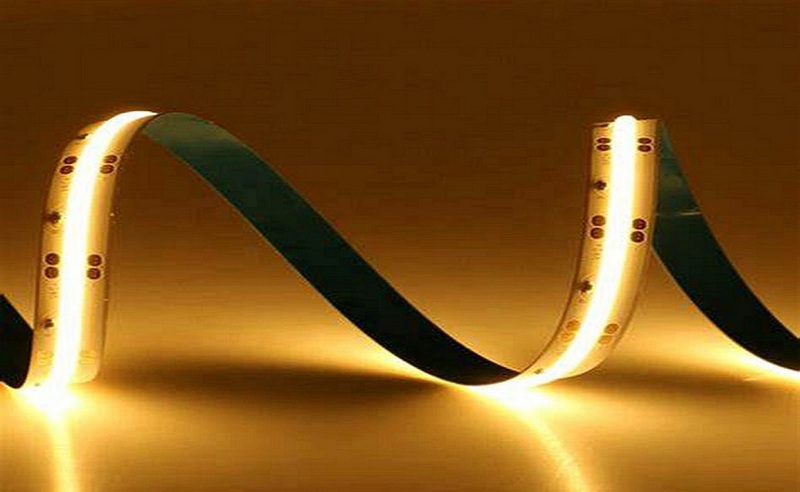

SMT has revolutionized PCB manufacturing by allowing components to be mounted directly onto the surface of PCBs rather than through holes. This technology offers several advantages:

- Higher Component Density: SMT allows for more components to be placed on a board, enabling smaller and more compact electronic devices.

- Improved Performance: Shorter interconnection lengths reduce parasitic capacitance and inductance, enhancing signal integrity and overall performance.

- Automation Potential: The automated nature of SMT processes leads to increased production efficiency and reduced labor costs.

- Versatility in Component Types: SMT accommodates a wide variety of components including resistors, capacitors, integrated circuits (ICs), and more complex devices like system-on-chip (SoC) solutions.

Challenges Addressed by Turnkey Solutions

The complexities associated with traditional PCB assembly methods often lead to challenges such as:

- Supply Chain Disruptions: Managing multiple suppliers increases the risk of delays due to miscommunication or logistical issues.

- Quality Variability: Different suppliers may have varying standards for quality control, leading to inconsistencies in product output.

Turnkey solutions effectively address these challenges by integrating all processes under one roof, ensuring consistency and reliability throughout production.

Innovation Through Technology Integration

The integration of advanced technologies into turnkey SMT assembly lines further enhances their effectiveness. Some key innovations include:

- Industry 4.0 Technologies: The adoption of IoT (Internet of Things) devices allows real-time monitoring and data collection throughout the production process. This data can be analyzed for continuous improvement initiatives.

- Artificial Intelligence (AI): AI algorithms can optimize supply chain logistics by predicting demand patterns and adjusting inventory levels accordingly.

- Robotics Automation: Advanced robotics can perform repetitive tasks with high precision while reducing human error rates significantly.

Sustainability Considerations

As environmental concerns become more prominent in manufacturing practices, turnkey SMT assembly lines also offer opportunities for sustainability:

- Reduced Waste Generation: Streamlined processes minimize material waste during production due to better planning and execution.

- Energy Efficiency: Automated systems often consume less energy compared to traditional methods due to optimized workflows and reduced labor requirements.

- Recycling Initiatives: Many turnkey suppliers are now implementing recycling programs for electronic waste (e-waste), contributing positively towards environmental conservation efforts.

Conclusion

Utilizing a turnkey SMT assembly line presents numerous benefits for businesses looking to optimize their electronics manufacturing processes. From significant cost reductions and streamlined project management to enhanced quality control and faster time-to-market, turnkey solutions provide a comprehensive approach that meets the demands of modern manufacturing. Additionally, innovations in technology integration and sustainability considerations further solidify their relevance in today's industry landscape. As technology continues to evolve, adopting such efficient practices will be crucial for companies aiming to stay competitive in an increasingly crowded marketplace.

FAQs

1. What is a turnkey SMT assembly line?

A turnkey SMT assembly line is a manufacturing process where one supplier manages all aspects of PCB assembly—from design through component sourcing to final testing—streamlining operations and improving efficiency.

2. How does using a turnkey solution save costs?

Turnkey solutions save costs by reducing shipping expenses through consolidated logistics, securing bulk discounts on components due to established supplier relationships, minimizing labor costs through automation, and lowering overhead expenses through streamlined operations.

3. Can I customize my order with a turnkey supplier?

Yes! Turnkey suppliers offer customizable solutions tailored to meet specific project requirements, whether it involves low-volume runs or large-scale production needs.

4. What are the advantages of Surface Mount Technology (SMT)?

SMT allows for higher component density on PCBs, improved performance due to shorter interconnection lengths, greater automation potential which enhances production efficiency, and versatility in accommodating various component types.

5. How does a turnkey solution improve quality control?

A single supplier ensures consistent quality standards throughout production and enables early identification of issues during the design phase while implementing comprehensive testing procedures at various stages of production.