Content Menu

● Understanding SMT Manufacturing

>> Key Features of SMT

● Benefits of SMT Manufacturing in Appleton

>> Economic Growth

>> Enhanced Product Quality

>> Flexibility and Scalability

>> Shorter Time-to-Market

>> Environmental Benefits

● The Role of Local Companies

>> Notable SMT Manufacturers in Appleton

● Challenges in SMT Manufacturing

>> Addressing Supply Chain Issues

>> Investing in Technology and Training

● Conclusion

● FAQ

>> 1. What is SMT manufacturing?

>> 2. How does SMT manufacturing benefit local economies?

>> 3. What industries benefit from SMT manufacturing?

>> 4. What challenges do SMT manufacturers face?

>> 5. How can companies in Appleton stay competitive in SMT manufacturing?

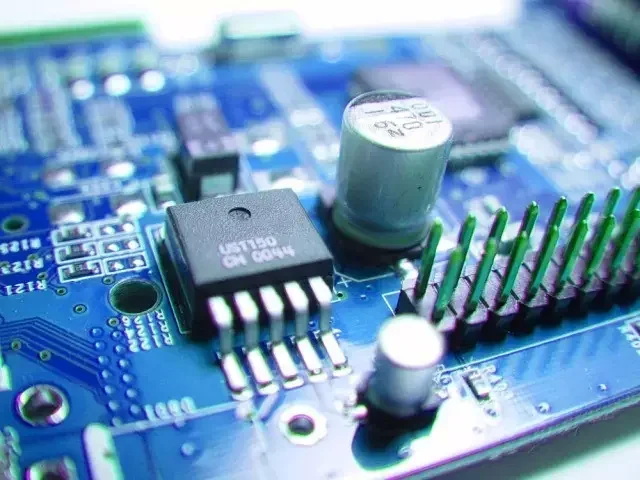

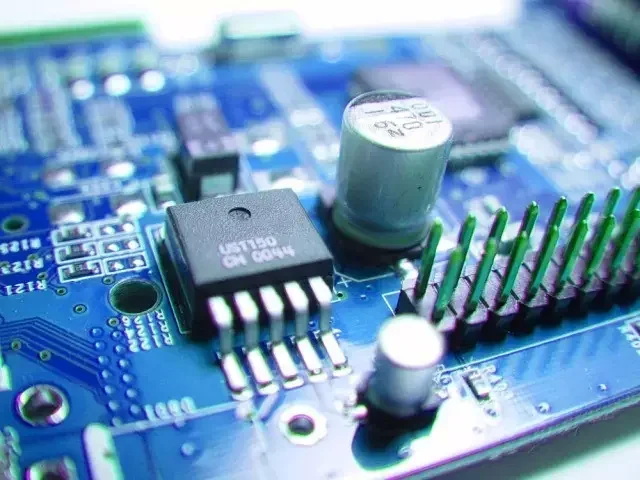

Surface Mount Technology (SMT) manufacturing has become a cornerstone of the electronics industry, particularly in regions like Appleton, Wisconsin. This method of assembling electronic components onto printed circuit boards (PCBs) offers numerous advantages that enhance production efficiency, reduce costs, and improve product quality. In this article, we will explore the benefits of SMT manufacturing in Appleton, delving into its impact on local businesses, the economy, and the technological landscape.

Understanding SMT Manufacturing

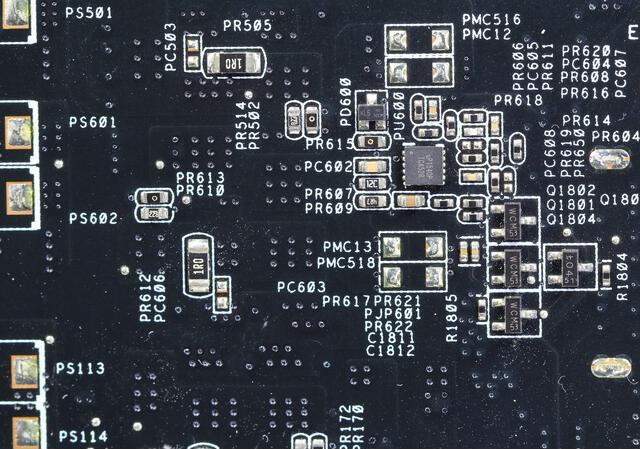

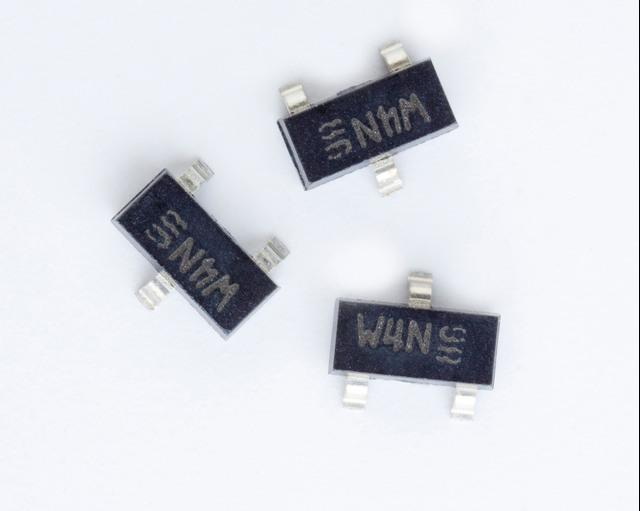

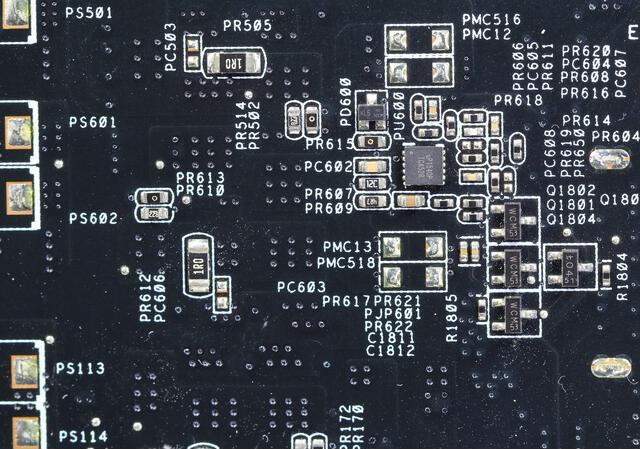

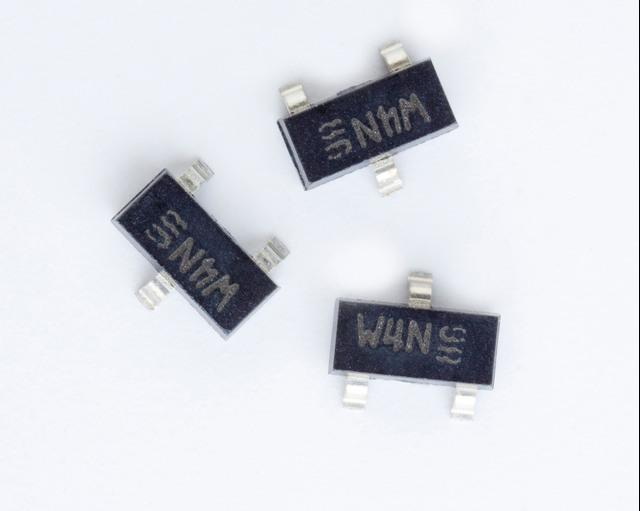

SMT manufacturing involves placing electronic components directly onto the surface of PCBs. This technique contrasts with traditional through-hole technology, where components are inserted into holes drilled in the board. SMT allows for a more compact design, enabling manufacturers to produce smaller and more efficient electronic devices.

Key Features of SMT

- High Density: SMT allows for a higher density of components on a PCB, which is essential for modern electronic devices that require miniaturization.

- Automated Processes: The use of automated pick-and-place machines in SMT manufacturing increases speed and accuracy, reducing the likelihood of human error.

- Cost Efficiency: By minimizing the number of components and optimizing the assembly process, SMT can significantly lower production costs.

Benefits of SMT Manufacturing in Appleton

Economic Growth

Appleton has seen substantial economic growth due to the rise of SMT manufacturing. The presence of SMT companies has created numerous job opportunities, attracting skilled workers to the area. This influx of talent not only benefits local businesses but also stimulates the economy through increased spending and investment.

Enhanced Product Quality

One of the primary advantages of SMT manufacturing is the improvement in product quality. The precision of automated assembly processes leads to fewer defects and higher reliability in electronic products. This is particularly important in industries such as automotive and medical devices, where product failure can have serious consequences.

Flexibility and Scalability

SMT manufacturing offers significant flexibility, allowing companies in Appleton to quickly adapt to changing market demands. Whether it's a small batch of prototypes or large-scale production runs, SMT processes can be easily scaled to meet the needs of different projects. This adaptability is crucial in today's fast-paced technology landscape.

Shorter Time-to-Market

With the efficiency of SMT manufacturing, companies can significantly reduce their time-to-market. The streamlined processes and automation involved in SMT allow for quicker turnaround times from design to production. This speed is essential for businesses looking to stay competitive in the electronics market.

Environmental Benefits

SMT manufacturing is often more environmentally friendly than traditional methods. The reduction in material waste and the ability to use lead-free solder contribute to a lower environmental impact. Additionally, the compact nature of SMT designs can lead to energy savings in the final products.

The Role of Local Companies

Several companies in Appleton specialize in SMT manufacturing, contributing to the region's reputation as a hub for electronics production. These companies leverage advanced technologies and skilled labor to deliver high-quality products to various industries.

Notable SMT Manufacturers in Appleton

- SMT Corporation: Known for its commitment to quality and innovation, SMT Corporation provides a range of electronic manufacturing services, including PCB assembly and design.

- Fox Valley Tool and Die: This company offers SMT services alongside traditional manufacturing, showcasing the versatility of their operations.

Challenges in SMT Manufacturing

While SMT manufacturing presents numerous benefits, it is not without its challenges. Companies in Appleton must navigate issues such as supply chain disruptions, the need for continuous technological upgrades, and the demand for skilled labor. Addressing these challenges is crucial for maintaining the competitive edge of SMT manufacturing in the region.

Addressing Supply Chain Issues

The global supply chain has faced significant disruptions in recent years, impacting the availability of components necessary for SMT manufacturing. Companies in Appleton are working to establish more resilient supply chains by diversifying their suppliers and investing in local sourcing.

Investing in Technology and Training

To keep pace with advancements in SMT technology, local manufacturers must continually invest in new equipment and training for their workforce. This commitment to innovation ensures that Appleton remains a leader in SMT manufacturing.

Conclusion

In conclusion, SMT manufacturing offers a multitude of benefits for companies in Appleton, from economic growth and enhanced product quality to flexibility and environmental sustainability. As the demand for electronic devices continues to rise, the importance of SMT manufacturing will only increase. By addressing the challenges and leveraging the advantages of this technology, Appleton can solidify its position as a key player in the electronics manufacturing industry.

FAQ

1. What is SMT manufacturing?

Answer: SMT (Surface Mount Technology) manufacturing is a method of assembling electronic components directly onto the surface of printed circuit boards (PCBs), allowing for higher density and more compact designs.

2. How does SMT manufacturing benefit local economies?

Answer: SMT manufacturing creates job opportunities, stimulates local spending, and attracts skilled workers, contributing to overall economic growth in regions like Appleton.

3. What industries benefit from SMT manufacturing?

Answer: Industries such as automotive, medical devices, consumer electronics, and telecommunications benefit significantly from SMT manufacturing due to its efficiency and product quality.

4. What challenges do SMT manufacturers face?

Answer: Challenges include supply chain disruptions, the need for continuous technological upgrades, and the demand for skilled labor to operate advanced manufacturing equipment.

5. How can companies in Appleton stay competitive in SMT manufacturing?

Answer: Companies can stay competitive by investing in new technologies, diversifying their supply chains, and providing ongoing training for their workforce to adapt to industry changes.