Content Menu

● Introduction

● What is a Dual Facing SMT Production Line Layout?

● Key Benefits of Dual Facing SMT Production Line Layout

>> Increased Production Efficiency

>> Enhanced Flexibility

>> Optimized Space Utilization

>> Cost-Effectiveness

>> Improved Quality Control

>> Advanced Technology Integration

● Challenges and Considerations

● Case Studies Illustrating Success

● Future Trends in Dual Facing SMT Layouts

● Conclusion

● FAQ

>> 1. What is the primary purpose of a dual facing SMT production line layout?

>> 2. How does a dual facing layout optimize space utilization?

>> 3. What industries benefit the most from dual facing SMT layouts?

>> 4. Are there any specific equipment requirements for dual facing SMT layouts?

>> 5. What are the cost implications of adopting a dual facing SMT layout?

● Citations:

Introduction

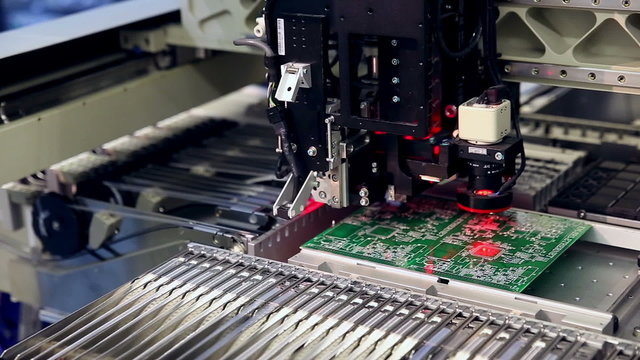

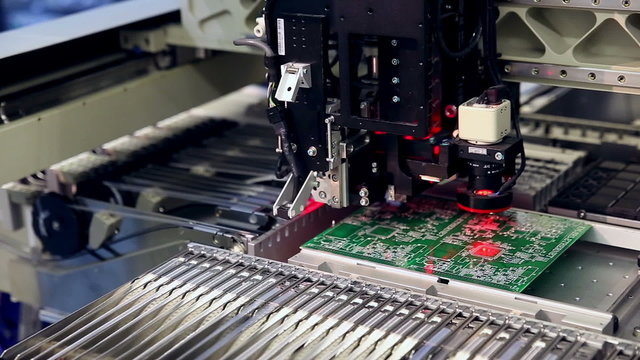

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, allowing for more compact and efficient assembly of electronic components. Among various layouts used in SMT production, the dual facing SMT production line layout stands out due to its unique advantages in enhancing productivity and flexibility. This article delves into the specifics of dual facing layouts, their benefits, challenges, and considerations for implementation.

What is a Dual Facing SMT Production Line Layout?

A dual facing SMT production line layout refers to a manufacturing setup where two lines operate parallel to each other, allowing simultaneous processing of different products or variants. This configuration is particularly beneficial in environments where high-mix, low-volume production is necessary. Each line can be configured independently, enabling manufacturers to respond swiftly to varying production demands without significant downtime.

Key Benefits of Dual Facing SMT Production Line Layout

Increased Production Efficiency

One of the primary advantages of a dual facing layout is its ability to significantly boost production efficiency. By operating two lines concurrently, manufacturers can:

- Enhance throughput: Dual lanes can process more printed circuit boards (PCBs) within the same timeframe compared to single-lane systems.

- Reduce downtime: The independent operation of each lane allows for maintenance or changeovers on one lane without halting production on the other.

This increase in efficiency translates directly into higher output and improved overall productivity.

Enhanced Flexibility

The flexibility offered by dual facing layouts is crucial in today's fast-paced manufacturing environment. Key aspects include:

- Handling diverse product types: Each lane can be tailored to accommodate different products or configurations, allowing manufacturers to switch between product lines quickly and efficiently.

- Rapid response to market changes: As consumer demands fluctuate, dual facing layouts enable manufacturers to pivot swiftly without extensive retooling or downtime.

This adaptability is particularly beneficial for industries that require frequent changes in production runs.

Optimized Space Utilization

In manufacturing, space is often at a premium. A dual facing SMT production line layout optimizes space utilization by:

- Maximizing throughput: Two lanes can achieve higher production volumes without necessitating additional floor space.

- Minimizing equipment footprint: By consolidating operations into a dual lane system, manufacturers can reduce the overall size of their production area while maintaining high output levels.

This efficient use of space can lead to significant cost savings in facility management and operations.

Cost-Effectiveness

While the initial setup costs for a dual facing SMT layout may be higher than traditional single-lane systems, the long-term benefits often outweigh these expenses. Key financial advantages include:

- Reduction in operational costs: Increased efficiency and reduced downtime lead to lower labor and maintenance costs over time.

- Better return on investment (ROI): The ability to produce more products in less time enhances profitability and justifies the initial investment in dual lane technology.

Improved Quality Control

Quality control is paramount in electronics manufacturing. A dual facing SMT layout enhances quality assurance through:

- Better monitoring capabilities: With two lanes operating simultaneously, manufacturers can implement rigorous quality checks at multiple points in the production process.

- Reduced errors: The independent operation of lanes allows for specialized quality control processes tailored to specific product types, leading to fewer defects and higher overall quality.

Advanced Technology Integration

Recent advancements in SMT technology have further enhanced the benefits of dual facing layouts. For instance, modern equipment like Yamaha's YRM20DL dual-lane mounter supports various production methods such as parallel mounting and alternate mounting. This flexibility enables manufacturers to optimize their operations based on specific product requirements while minimizing transport losses and maximizing productivity[1][3].

Challenges and Considerations

Despite its numerous benefits, implementing a dual facing SMT production line layout does come with challenges:

- Initial investment costs: The upfront costs associated with acquiring specialized equipment and setting up dual lanes can be significant.

- Complexity in management: Managing two independent lines requires careful planning and coordination to ensure seamless operations.

To address these challenges, manufacturers should conduct thorough feasibility studies and consider phased implementations that allow for incremental investments and adjustments based on operational feedback.

Case Studies Illustrating Success

Several companies have successfully implemented dual facing SMT layouts, showcasing their effectiveness across various applications:

1. High-Mix Low-Volume Production: A leading electronics manufacturer adopted a dual lane setup to cater to its diverse product range. By configuring each lane for different product types, they achieved a 30% increase in throughput while reducing lead times by 25%.

2. Automotive Industry Applications: An automotive parts supplier utilized a dual facing layout to manage varying component sizes and specifications. This flexibility allowed them to respond quickly to changes in customer demand while maintaining high-quality standards.

3. Consumer Electronics Sector: A consumer electronics company implemented a dual lane system equipped with advanced inspection technologies. This integration not only improved quality control but also reduced defect rates by 15%, significantly enhancing customer satisfaction.

These case studies highlight how adopting a dual facing SMT production line layout can lead to substantial improvements in efficiency, flexibility, and quality across different industries.

Future Trends in Dual Facing SMT Layouts

As technology continues to evolve, several trends are likely to shape the future of dual facing SMT layouts:

- Increased Automation: The integration of AI and machine learning will enhance operational efficiency by optimizing workflows and predictive maintenance schedules.

- Smart Manufacturing: IoT-enabled devices will facilitate real-time monitoring and data collection, allowing manufacturers to make informed decisions quickly.

- Sustainability Practices: As environmental concerns grow, manufacturers will increasingly focus on sustainable practices within their dual lane operations, such as reducing waste and energy consumption.

These trends indicate that the future of dual facing SMT layouts will be characterized by greater efficiency, adaptability, and sustainability.

Conclusion

The adoption of a dual facing SMT production line layout presents numerous advantages for manufacturers seeking to enhance productivity, flexibility, and quality control while optimizing space utilization. While challenges exist, careful planning and strategic implementation can lead to significant long-term benefits. As industries increasingly demand high-mix, low-volume production capabilities, the relevance of dual facing layouts will continue to grow. The ongoing advancements in technology will further bolster these systems' effectiveness, ensuring they remain at the forefront of modern manufacturing practices.

FAQ

1. What is the primary purpose of a dual facing SMT production line layout?

The primary purpose is to enhance production efficiency and flexibility by allowing simultaneous processing of different products.

2. How does a dual facing layout optimize space utilization?

It enables higher throughput without requiring additional floor space, maximizing the use of existing manufacturing areas.

3. What industries benefit the most from dual facing SMT layouts?

Industries such as electronics, automotive, and aerospace benefit significantly due to their need for high-mix, high-volume production.

4. Are there any specific equipment requirements for dual facing SMT layouts?

Yes, specialized dual-lane machines and conveyors are often required to facilitate independent operation of each lane.

5. What are the cost implications of adopting a dual facing SMT layout?

While initial setup costs may be higher, long-term savings in operational costs and increased ROI make it a cost-effective solution over time.

Citations:

[1] https://core-emt.com/blog/smt-news-1/dual-lane-smt-manufacturing-innovations-boost-output-and-flexibility-105

[2] https://www.pnconline.com/blog/layouts-of-smt-assembly-line/

[3] https://smttoday.com/2023/02/13/yamaha-motor-launches-premium-high-efficiency-dual-lane-modular-yrm20dl/

[4] https://smt.yamaha-motor-robotics.de/boosting-smt-throughput-with-single-and-dual-lane-upgrades/

[5] https://www.ipcb.com/pcba-tech/8280.html

[6] https://core-emt.com/blog/smt-news-1/yamaha-smt-launches-premium-dual-lane-modular-yrm20dl-97

[7] https://www.ocmmanufacturing.com/resources/resource/dfm-tip-best-practices-for-double-sided-mixed-technology-board-design/

[8] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[9] https://www.pcbasic.com/blog/smt_production_line.html

[10] https://global.yamaha-motor.com/business/smt/mounter/yrm20dl/