Content Menu

● Understanding SMD Paste Printers

● Advantages of Using an SMD Paste Printer

>> Precision and Accuracy

>> Increased Production Speed

>> Reduced Material Waste

>> Consistency in Quality

>> Flexibility and Versatility

>> Enhanced Workflow Integration

>> Improved Operator Safety

>> Cost-Effectiveness

>> Capability for Complex Designs

>> Support for Advanced Technologies

● Conclusion

● FAQ

>> 1. What is an SMD paste printer?

>> 2. How does an SMD paste printer improve production speed?

>> 3. Can SMD paste printers handle different PCB sizes?

>> 4. What are the safety features of SMD paste printers?

>> 5. Are SMD paste printers cost-effective?

In the world of electronics, the manufacturing of printed circuit boards (PCBs) is a critical process that determines the quality and reliability of electronic devices. One of the key components in PCB manufacturing is the application of solder paste, which is essential for the soldering of surface mount devices (SMDs) onto the PCB. The SMD paste machine, also known as an SMD paste printer, plays a vital role in this process. This article will explore the advantages of using an SMD paste printer in PCB manufacturing, highlighting its importance and the benefits it brings to the production line.

Understanding SMD Paste Printers

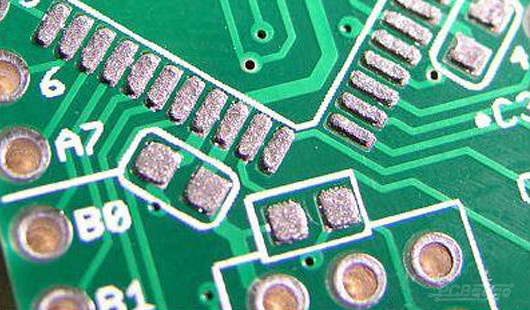

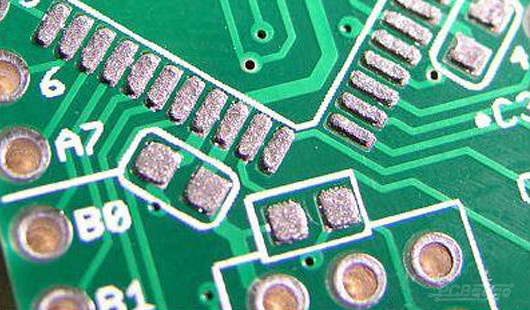

Before delving into the advantages, it is essential to understand what an SMD paste printer is. An SMD paste printer is a specialized machine designed to apply solder paste onto the pads of a PCB. The solder paste is a mixture of tiny solder balls and flux, which helps in the soldering process when heat is applied. The printer uses a stencil to accurately deposit the solder paste onto the designated areas of the PCB, ensuring that the right amount of paste is applied for each component.

Advantages of Using an SMD Paste Printer

Precision and Accuracy

One of the primary advantages of using an SMD paste printer is the precision and accuracy it offers. The machine is designed to apply solder paste in a controlled manner, ensuring that the paste is deposited exactly where it is needed. This level of accuracy is crucial for modern PCBs, which often have very small components and tight spacing. By using an SMD paste printer, manufacturers can achieve consistent results, reducing the risk of defects and improving the overall quality of the PCB.

Increased Production Speed

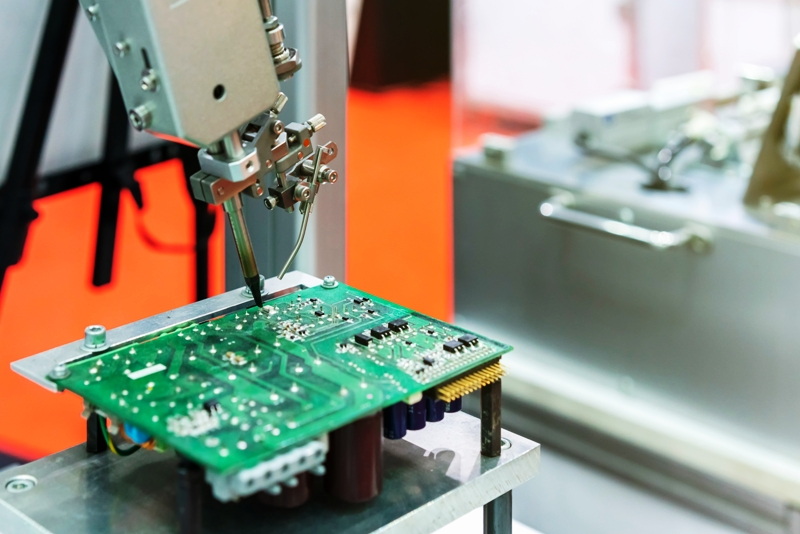

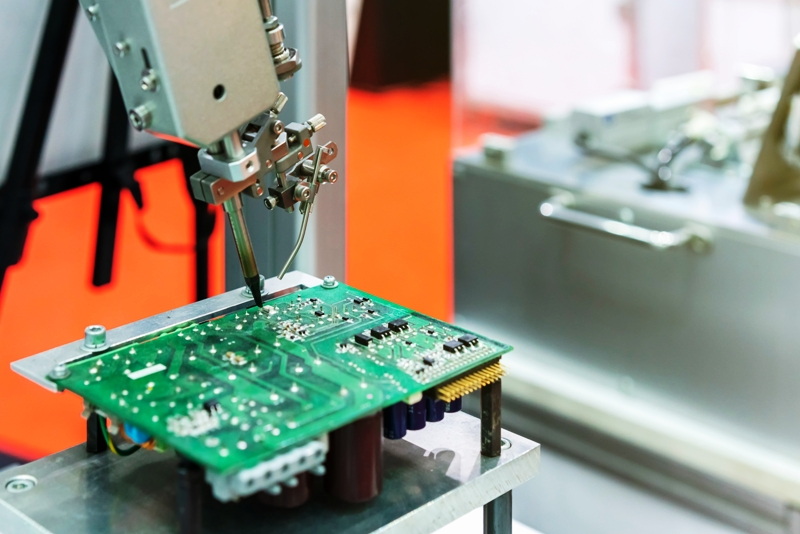

In the fast-paced world of electronics manufacturing, speed is of the essence. SMD paste printers are designed for high-speed operation, allowing manufacturers to apply solder paste quickly and efficiently. This increased production speed can significantly reduce the time it takes to assemble a PCB, enabling manufacturers to meet tight deadlines and increase their output. The automation provided by the SMD paste printer also minimizes the need for manual labor, further enhancing production efficiency.

Reduced Material Waste

Another significant advantage of using an SMD paste printer is the reduction of material waste. Traditional methods of applying solder paste, such as manual application, can lead to excess paste being used, resulting in waste. SMD paste printers are designed to apply the exact amount of paste needed for each component, minimizing waste and reducing costs. This not only benefits the manufacturer's bottom line but also contributes to more sustainable manufacturing practices.

Consistency in Quality

Quality control is a critical aspect of PCB manufacturing. SMD paste printers provide a level of consistency that is difficult to achieve with manual methods. The machine operates under controlled conditions, ensuring that each PCB receives the same amount of solder paste. This consistency helps to reduce variations in the soldering process, leading to higher quality products. Manufacturers can rely on SMD paste printers to deliver uniform results, which is essential for maintaining high standards in electronic devices.

Flexibility and Versatility

SMD paste printers are designed to handle a wide range of PCB sizes and configurations. This flexibility allows manufacturers to adapt to different production requirements without the need for extensive retooling. Whether producing small batches of custom PCBs or large volumes of standard designs, an SMD paste printer can accommodate various needs. This versatility makes it an invaluable asset in any PCB manufacturing facility.

Enhanced Workflow Integration

Modern SMD paste printers are often equipped with advanced features that allow for seamless integration into existing manufacturing workflows. Many machines can be connected to other equipment, such as pick-and-place machines and reflow ovens, creating a fully automated production line. This integration streamlines the manufacturing process, reducing the need for manual intervention and minimizing the risk of errors. By enhancing workflow integration, SMD paste printers contribute to a more efficient and effective manufacturing environment.

Improved Operator Safety

Safety is a paramount concern in any manufacturing setting. SMD paste printers are designed with safety features that protect operators from potential hazards associated with solder paste application. Automated processes reduce the need for manual handling of materials, minimizing the risk of accidents. Additionally, many machines are equipped with safety guards and emergency stop functions, ensuring a safer working environment for operators.

Cost-Effectiveness

While the initial investment in an SMD paste printer may be significant, the long-term cost savings can be substantial. The increased efficiency, reduced material waste, and improved quality all contribute to lower production costs over time. Manufacturers can achieve a higher return on investment by utilizing an SMD paste printer, making it a cost-effective solution for PCB manufacturing.

Capability for Complex Designs

As electronic devices become more sophisticated, the complexity of PCB designs has also increased. SMD paste printers are capable of handling intricate designs with multiple layers and various component types. The precision and accuracy of these machines allow manufacturers to produce complex PCBs that meet the demands of modern electronics. This capability is essential for staying competitive in the rapidly evolving electronics market.

Support for Advanced Technologies

The electronics industry is constantly evolving, with new technologies emerging regularly. SMD paste printers are designed to support these advancements, including the use of new materials and components. As manufacturers adopt new technologies, having a reliable SMD paste printer ensures that they can keep pace with industry changes and continue to produce high-quality PCBs.

Conclusion

In conclusion, the advantages of using an SMD paste printer in PCB manufacturing are numerous and significant. From precision and accuracy to increased production speed and reduced material waste, these machines play a crucial role in the modern manufacturing process. The ability to produce high-quality, complex PCBs efficiently and cost-effectively makes SMD paste printers an essential investment for any electronics manufacturer. As the industry continues to evolve, the importance of these machines will only grow, solidifying their place in the future of PCB manufacturing.

FAQ

1. What is an SMD paste printer?

An SMD paste printer is a specialized machine used in PCB manufacturing to apply solder paste onto the pads of a printed circuit board. It ensures precise and accurate deposition of solder paste, which is essential for soldering surface mount devices.

2. How does an SMD paste printer improve production speed?

SMD paste printers are designed for high-speed operation, allowing for quick and efficient application of solder paste. This automation reduces the time required for manual application, significantly increasing overall production speed.

3. Can SMD paste printers handle different PCB sizes?

Yes, SMD paste printers are versatile and can accommodate a wide range of PCB sizes and configurations. This flexibility allows manufacturers to adapt to various production requirements without extensive retooling.

4. What are the safety features of SMD paste printers?

SMD paste printers are equipped with safety features such as safety guards, emergency stop functions, and automated processes that minimize manual handling of materials, ensuring a safer working environment for operators.

5. Are SMD paste printers cost-effective?

While the initial investment may be high, SMD paste printers can lead to significant long-term cost savings through increased efficiency, reduced material waste, and improved quality, making them a cost-effective solution for PCB manufacturing.