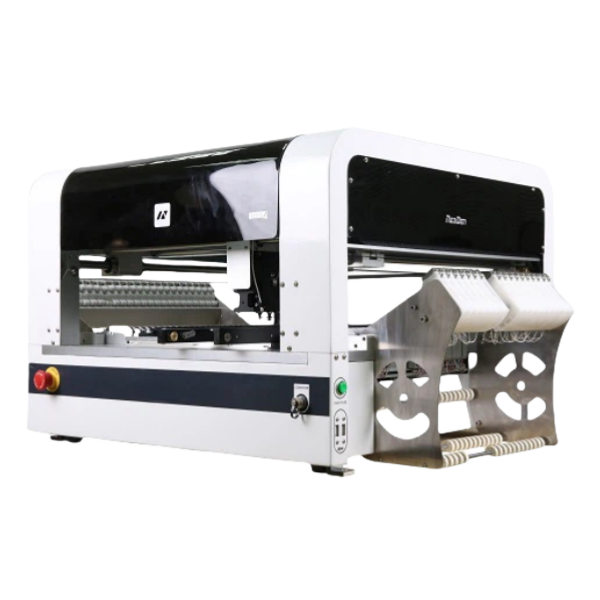

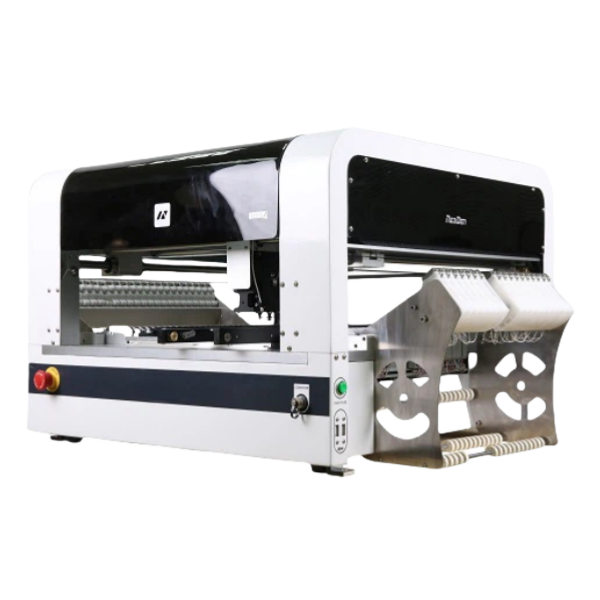

Understanding Automatic SMD Machines

Automatic SMD machines are specialized devices designed to automate the placement of surface mount devices (SMDs) onto printed circuit boards (PCBs). These machines utilize advanced technologies such as vision systems, robotics, and software algorithms to ensure precise placement and efficient assembly processes. The key components of an automatic SMD machine include:

- Pick-and-Place Mechanism: This component is responsible for picking SMDs from their packaging and placing them onto the PCB.

- Vision System: Used for alignment and verification, ensuring that components are placed accurately.

- Control Software: Manages the entire operation, including programming for different PCB layouts and component types.

Benefits of Automatic SMD Machines

1. Increased Production Speed

- Automatic SMD machines significantly increase the speed of the assembly process compared to manual methods. They can place thousands of components per hour, drastically reducing production time. For instance, a high-speed machine can place up to 60,000 components in just one hour, making it ideal for high-volume production runs.

2. Improved Accuracy and Consistency

- The precision of automatic SMD machines minimizes errors associated with manual placement. This accuracy leads to higher quality assemblies with fewer defects. The use of advanced vision systems allows these machines to detect misalignments and adjust placements in real time, ensuring that every component is correctly positioned.

3. Cost Efficiency

- By automating the assembly process, manufacturers can reduce labor costs and minimize material waste. The initial investment in an automatic SMD machine is often offset by long-term savings. For example, companies can see a return on investment within a year due to reduced labor expenses and increased throughput.

4. Flexibility in Production

- Modern automatic SMD machines can be programmed to handle various component sizes and types, allowing manufacturers to adapt quickly to changing market demands without significant downtime. This flexibility is particularly beneficial for companies that produce a diverse range of products or need to switch between different designs frequently.

5. Enhanced Quality Control

- With integrated inspection systems, these machines can perform real-time quality checks during the assembly process, ensuring that any defects are identified and corrected immediately. This capability not only improves product quality but also reduces the likelihood of costly recalls or rework later in the production cycle.

6. Reduced Labor Dependency

- Automation reduces reliance on manual labor, which can be particularly beneficial in regions facing labor shortages or high wage demands. By investing in automatic SMD machines, companies can maintain production levels even when skilled labor is scarce.

Key Features of Automatic SMD Machines

To fully appreciate the benefits of automatic SMD machines, it's essential to understand their key features:

- Multi-Functionality: Many modern machines can perform multiple tasks beyond just placing components; they can also handle solder paste application and inspection.

- User-Friendly Interfaces: Advanced control software often comes with intuitive interfaces that allow operators to program jobs quickly and efficiently.

- Modular Design: Some machines are designed with modular components that can be upgraded or replaced easily, extending their lifespan and adaptability.

- Data Collection Capabilities: Automatic SMD machines often include features for collecting production data that can be analyzed to optimize processes further.

Choosing an Automatic SMD Machine Supplier

When selecting an automatic SMD machine supplier, several factors should be considered:

- Reputation and Experience: Look for suppliers with a proven track record in the SMT industry. Research customer reviews and case studies to gauge their reliability.

- Technical Support: Ensure that the supplier offers comprehensive support services, including installation, training, and maintenance. A responsive support team can significantly reduce downtime in case of equipment failure.

- Customization Options: Suppliers should provide machines that can be tailored to specific production needs. Customization may include software modifications or hardware upgrades.

- Warranty and Service Agreements: Check for warranty terms and service agreements that provide peace of mind regarding equipment longevity.

Case Studies: Successful Implementations

Case Study 1: Electronics Manufacturer X

Electronics Manufacturer X faced challenges with manual assembly processes that resulted in high labor costs and inconsistent quality. After investing in an automatic SMD machine from a reputable supplier, they reported a 40% increase in production speed and a 30% reduction in defects within six months. The machine's flexibility allowed them to switch between different product lines without extensive reconfiguration.

Case Study 2: Start-Up Y

Start-Up Y was struggling to meet growing demand for their innovative electronic products. By implementing an automatic SMD machine early in their operations, they were able to scale production rapidly while maintaining quality standards. The machine's data collection capabilities provided insights into their manufacturing processes, enabling continuous improvement strategies that further enhanced efficiency.

Future Trends in Automatic SMD Machines

As technology continues to advance, several trends are emerging in the field of automatic SMD machines:

1. Integration with Industry 4.0

- The rise of Industry 4.0 emphasizes smart manufacturing through connectivity and data exchange between machines. Automatic SMD machines will increasingly incorporate IoT capabilities for better monitoring and control.

2. Artificial Intelligence (AI)

- AI algorithms are being developed to optimize placement strategies based on real-time data analysis, further enhancing efficiency and accuracy.

3. Sustainability Initiatives

- Manufacturers are focusing on sustainability by developing more energy-efficient machines and reducing waste during production processes.

4. Advanced Materials Handling

- Future automatic SMD machines may include sophisticated materials handling systems that streamline the supply chain from component delivery to assembly.

Conclusion

The adoption of automatic SMD machines represents a significant advancement in electronics manufacturing. Their ability to enhance speed, accuracy, and cost-effectiveness makes them indispensable tools for modern manufacturers. As technology continues to evolve, these machines will play an even more critical role in shaping the future of electronics assembly.

Frequently Asked Questions

1. What is an automatic SMD machine?

- An automatic SMD machine is a device used for placing surface mount devices onto printed circuit boards automatically.

2. How does an automatic SMD machine improve production efficiency?

- It increases speed by placing components much faster than manual methods while ensuring accuracy and reducing defects.

3. What should I consider when choosing an automatic SMD machine supplier?

- Consider their reputation, technical support offerings, customization options, and warranty terms.

4. Can automatic SMD machines handle different types of components?

- Yes, modern machines are designed to accommodate various component sizes and types through programmable settings.

5. What are the long-term benefits of investing in an automatic SMD machine?

- Long-term benefits include reduced labor costs, improved product quality, increased production capacity, and greater flexibility in manufacturing processes.