Content Menu

● Understanding SMT Line Icons

>> The Importance of SMT Line Icons

● Types of SMT Line Icons

>> 1. Component Icons

>> 2. Equipment Icons

>> 3. Process Icons

>> 4. Safety Icons

● How SMT Line Icons Are Used

>> 1. Workflow Diagrams

>> 2. Work Instructions

>> 3. Training Materials

>> 4. Control Panels

● Creating Effective SMT Line Icons

>> 1. Simplicity

>> 2. Consistency

>> 3. Intuitive Design

>> 4. User Feedback

● Challenges in Using SMT Line Icons

>> 1. Cultural Differences

>> 2. Technological Changes

>> 3. Training Requirements

● The Role of Stencils in SMT

● The Importance of PCB Design for Assembly

● Trends Influencing SMT Production Lines

>> 1. Automation Integration

>> 2. Environmental Considerations

>> 3. Advanced Inspection Technologies

● Conclusion

● FAQ

>> 1. What is the primary purpose of SMT line icons?

>> 2. How do component icons differ from equipment icons?

>> 3. Why is consistency important in designing SMT line icons?

>> 4. What challenges might arise from using SMT line icons?

>> 5. How can manufacturers improve their use of SMT line icons?

● Citations:

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for the assembly of components directly onto the surface of printed circuit boards (PCBs). Within this context, SMT line icons play a crucial role in conveying information about the manufacturing process. This article will explore what SMT line icons are, their significance, and how they are utilized in the SMT assembly process.

Understanding SMT Line Icons

SMT line icons are graphical symbols used to represent various components, processes, and equipment within an SMT production line. These icons serve as a universal language that helps operators, engineers, and technicians communicate effectively about the manufacturing process.

The Importance of SMT Line Icons

1. Standardization: Icons provide a standardized way to represent complex processes and components, making it easier for personnel to understand and follow procedures.

2. Efficiency: By using icons, operators can quickly identify equipment and processes without needing extensive training or detailed explanations.

3. Error Reduction: Clear visual representations help reduce misunderstandings that could lead to errors in assembly, ultimately improving product quality.

4. Training Tool: SMT line icons can be used as teaching aids for new employees, helping them learn the layout and processes of the SMT line more effectively.

Types of SMT Line Icons

SMT line icons can be categorized into several types based on their function:

1. Component Icons

These icons represent various electronic components used in SMT assembly, such as resistors, capacitors, integrated circuits (ICs), and connectors. Each icon is designed to visually depict the component's shape and function.

2. Equipment Icons

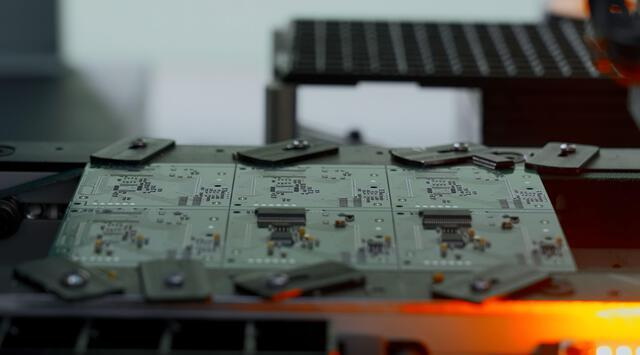

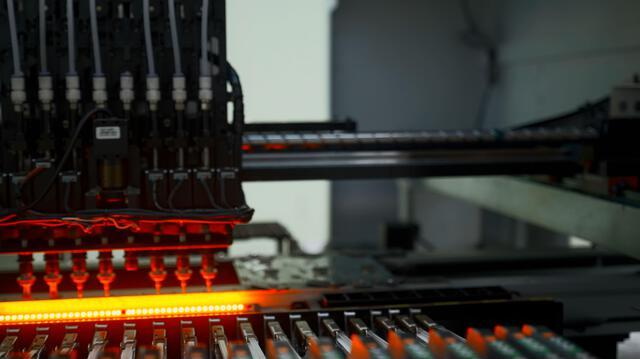

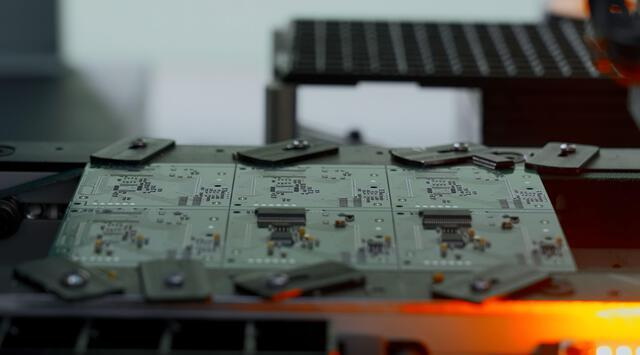

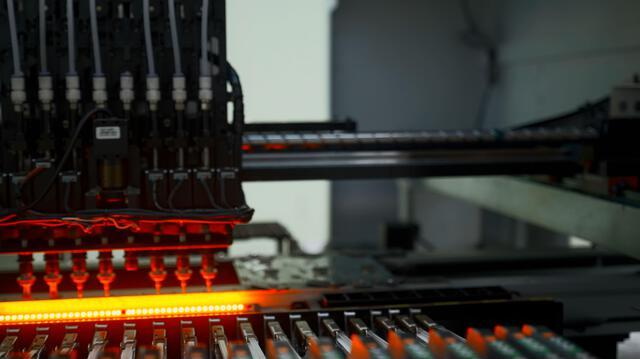

Icons representing machinery and tools used in the SMT process include pick-and-place machines, soldering stations, inspection equipment, and reflow ovens. These icons help operators quickly identify which machines are involved at each stage of production.

3. Process Icons

These icons illustrate specific steps in the manufacturing process, such as loading components onto a PCB, soldering connections, or performing quality checks. Process icons guide operators through the workflow efficiently.

4. Safety Icons

Safety-related icons indicate precautions that must be taken during production to ensure a safe working environment. These may include warnings about high temperatures or the need for personal protective equipment (PPE).

How SMT Line Icons Are Used

SMT line icons are employed in various aspects of the manufacturing process:

1. Workflow Diagrams

In workflow diagrams, SMT line icons are used to visually represent each step in the production process. This helps operators understand their tasks and how they fit into the overall workflow.

2. Work Instructions

Manufacturers often include SMT line icons in work instructions to provide visual cues alongside written instructions. This dual approach enhances comprehension and retention of information.

3. Training Materials

Training programs for new employees frequently utilize SMT line icons to familiarize them with equipment and processes before they start working on the production floor.

4. Control Panels

Control panels on machinery may feature SMT line icons to indicate operational status or settings. Operators can quickly assess whether a machine is functioning correctly or requires attention.

Creating Effective SMT Line Icons

To ensure that SMT line icons serve their intended purpose effectively, manufacturers should consider several best practices when designing these symbols:

1. Simplicity

Icons should be simple and easy to recognize at a glance. Overly complex designs can lead to confusion rather than clarity.

2. Consistency

Using a consistent style across all icons helps reinforce understanding among operators. This includes maintaining uniform colors, shapes, and sizes.

3. Intuitive Design

Icons should intuitively represent their meaning; for instance, a soldering icon might depict a soldering iron or a wave pattern indicating heat application.

4. User Feedback

Gathering feedback from operators during the design process can help ensure that the icons are effective and meet their needs in real-world applications.

Challenges in Using SMT Line Icons

While SMT line icons offer numerous benefits, there are also challenges associated with their use:

1. Cultural Differences

Different cultures may interpret symbols differently; thus, manufacturers operating globally must consider these variations when designing icons.

2. Technological Changes

As technology evolves, so do manufacturing processes; this may necessitate updates or changes to existing icons to keep them relevant.

3. Training Requirements

Despite their simplicity, some operators may still require training to fully understand all aspects of the iconography used in their specific environment.

The Role of Stencils in SMT

An integral part of using SMT line icons effectively is understanding how stencils contribute to precision and efficiency in PCB assembly. Stencils are thin sheets with precise openings that allow solder paste to be applied accurately onto PCBs before component placement occurs[7][14].

- Accuracy: High-quality stencils ensure that solder paste is applied where needed without excess or deficiency.

- Efficiency: Stencils can be reused across multiple runs, significantly speeding up production while maintaining quality standards[12].

- Quality Control: The right stencil design minimizes defects such as bridging or insufficient solder joints[27].

The Importance of PCB Design for Assembly

Optimizing PCB design for SMT assembly is crucial for ensuring that products are functional and reliable[18]. Here are some key considerations:

- Proper Footprints: Ensuring that component footprints match manufacturer specifications is essential for accurate placement.

- Component Placement: Grouping related components together reduces trace lengths and improves electrical performance.

- Design for Manufacturing (DFM): Following DFM guidelines helps streamline assembly processes and reduce costs[8].

Trends Influencing SMT Production Lines

The landscape of SMT production lines is constantly evolving due to technological advancements and market demands:

1. Automation Integration

Automation continues to play a significant role in enhancing production efficiency by reducing human error and increasing throughput[20]. Automated systems can monitor processes in real-time, allowing for quick adjustments when issues arise[22].

2. Environmental Considerations

Manufacturers are increasingly focusing on eco-friendly practices within their SMT lines by minimizing waste and adopting sustainable materials[6]. This trend not only helps protect the environment but also meets consumer demand for sustainable products.

3. Advanced Inspection Technologies

With higher component densities on PCBs, advanced inspection technologies such as Automated Optical Inspection (AOI) systems have become essential for maintaining quality control throughout the assembly process[10]. These systems detect defects early on, reducing waste and improving overall product reliability.

Conclusion

In conclusion, SMT line icons play an essential role in modern electronics manufacturing by enhancing communication and understanding among personnel involved in the assembly process. Their use promotes efficiency, reduces errors, and serves as an effective training tool for new employees. By adhering to best practices in icon design and addressing potential challenges while also considering critical aspects like stencil use and PCB design optimization, manufacturers can maximize the benefits of these visual symbols in their operations.

FAQ

1. What is the primary purpose of SMT line icons?

The primary purpose of SMT line icons is to provide a standardized visual representation of components, processes, and equipment within an SMT production line to enhance communication and understanding among personnel.

2. How do component icons differ from equipment icons?

Component icons represent individual electronic components like resistors or capacitors, while equipment icons depict machinery used in the assembly process such as pick-and-place machines or soldering stations.

3. Why is consistency important in designing SMT line icons?

Consistency is crucial because it reinforces understanding among operators by ensuring that all icons maintain uniform colors, shapes, and sizes for easier recognition across different contexts.

4. What challenges might arise from using SMT line icons?

Challenges include cultural differences in interpreting symbols, keeping up with technological changes that may require icon updates, and ensuring adequate training for operators unfamiliar with iconography.

5. How can manufacturers improve their use of SMT line icons?

Manufacturers can improve their use of SMT line icons by focusing on simplicity in design, gathering user feedback during development, ensuring intuitive representations of meanings, and maintaining consistency across all symbols.

Citations:

[1] https://www.ourpcb.com/smt-line.html

[2] https://www.pivotint.com/blog/3-benefits-of-choosing-a-manufacturing-partner-with-mirrored-smt-lines/

[3] https://designmodo.com/line-icons/

[4] https://www.macrofab.com/blog/smt-assembly-vs-through-hole/

[5] https://www.alamy.com/stock-photo/smt-line.html

[6] https://www.quick-pcba.com/the-main-equipment-in-an-smt-line/

[7] https://www.oem-pcb.com/news/the-role-of-stencils-in-smt-precision-effici-80830062.html

[8] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[9] https://en.wikipedia.org/wiki/Surface-mount_technology

[10] https://www.pcbasic.com/blog/smt_machines.html

[11] https://www.nuvation.com/resources/article/pcb-layout-creating-perfect-smt-footprints

[12] https://blog.intraratio.com/revolutionizing-smt-manufacturing-amidst-economic-challenges

[13] https://www.freepik.com/vectors/smt-components

[14] https://www.twistedtraces.com/blog/understanding-smt-stencils-the-backbone-of-electronics-manufacturing

[15] https://resources.pcb.cadence.com/blog/2019-surface-mount-technologies-and-devices-pesky-enclosures-and-smart-layouts

[16] https://www.criticalmanufacturing.com/blog/material-optimization-in-the-smt-and-electronics-assembly-industries/

[17] https://www.fermionx.com/blog/day-in-the-life-of-surface-mount-line-smt/

[18] https://www.protoexpress.com/blog/tips-pcb-design-for-assembly/

[19] https://www.ipc.org/system/files/technical_resource/E8&S24_03.pdf

[20] https://www.pcbonline.com/blog/smt-manufacturing-process.html

[21] https://www.pcbtok.com/pcb-schematic-design/

[22] https://cogiscan.com/solve-factory-real-time-dashboard-smt-assembly

[23] https://www.qhsmt.com/2023/07/06/smt-line-equipment-electrical-symbols-for-electronic-components/

[24] https://www.electronicdesign.com/technologies/eda/printed-circuit-boards/article/55041417/viasion-technology-top-5-miniaturization-challenges-in-pcb-assembly-and-their-solutions

[25] https://stock.adobe.com/search?k=smt+line

[26] https://iconnect007.com/index.php/article/118186/cavity-board-smt-assembly-challenges-part-2/118189?skin=smt

[27] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[28] https://www.freepik.com/free-photos-vectors/smt-production-line/2