Content Menu

● What Is an SMD Hot Air Machine?

● Key Features of High-End SMD Hot Air Machines

● Comparing SMD Hot Air Machine Price Ranges

● Advantages of Investing in a High-End SMD Hot Air Machine

>> 1. Improved Precision and Quality

>> 2. Enhanced Efficiency and Productivity

>> 3. Versatility and Adaptability

>> 4. Durability and Long-Term Cost Savings

>> 5. Safety Features

● Potential Drawbacks of High-End SMD Hot Air Machines

● When Should You Consider a High-End SMD Hot Air Machine?

● How to Choose the Right SMD Hot Air Machine

>> 1. Application Requirements

>> 2. Frequency of Use

>> 3. Budget Constraints

>> 4. Brand and Support

>> 5. Additional Features

● Maintenance Tips for High-End SMD Hot Air Machines

● Conclusion

● FAQ

>> 1. What factors influence the smd hot air machine price?

>> 2. Can a high-end SMD hot air machine be used for all types of SMD components?

>> 3. How does a vacuum pickup system benefit SMD rework?

>> 4. Are high-end SMD hot air machines suitable for beginners?

>> 5. How long do high-end SMD hot air machines typically last?

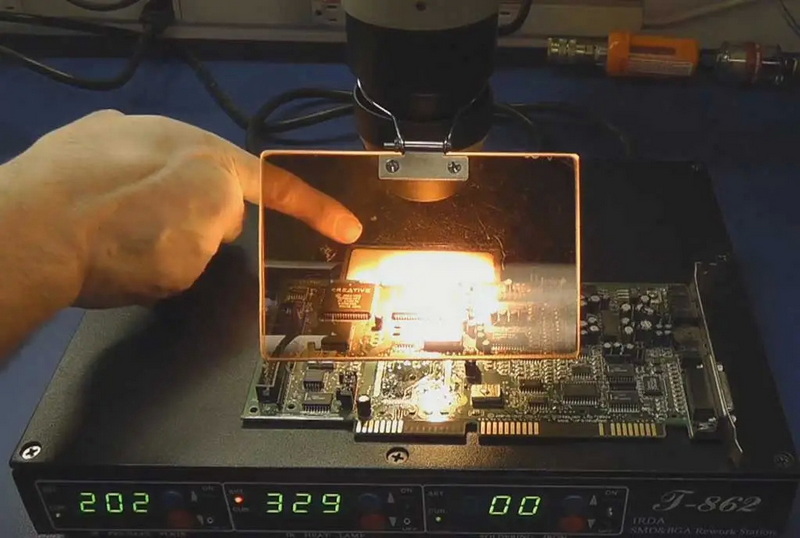

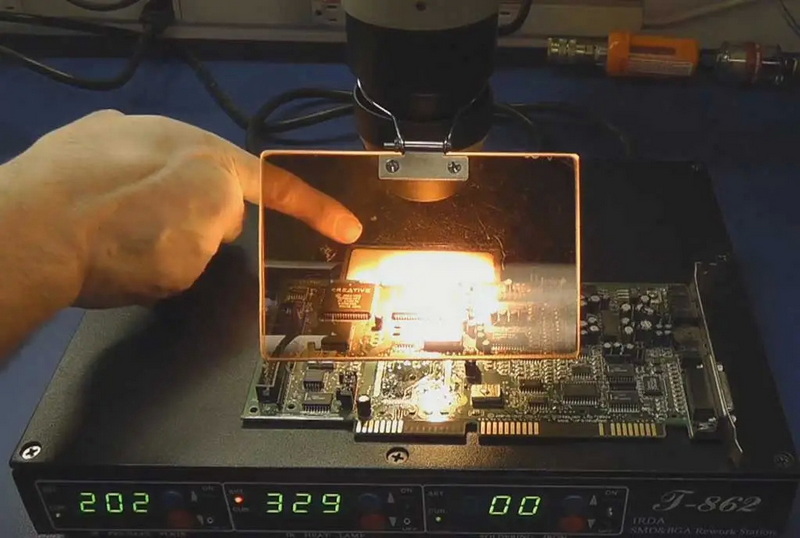

Surface Mount Device (SMD) hot air machines have become indispensable tools in modern electronics manufacturing and repair. These machines use hot air to solder, desolder, and rework surface-mounted components on printed circuit boards (PCBs). With a wide range of options available, from budget models to high-end professional stations, many technicians and manufacturers face the question: Is it worth investing in a high-end SMD hot air machine? This article explores the features, benefits, costs, and overall value of high-end SMD hot air machines, focusing on the keyword smd hot air machine price to help you make an informed decision.

What Is an SMD Hot Air Machine?

An SMD hot air machine, also known as a hot air rework station, is a device that blows heated air to melt solder on electronic components for assembly or repair. It is widely used for:

- Removing and replacing SMD components such as QFP, BGA, SOP, and PLCC chips.

- Reflow soldering during prototyping or small batch production.

- Repairing PCBs without damaging sensitive parts.

The hot air is precisely controlled for temperature and airflow, allowing technicians to work on delicate components without overheating or damaging the board. This precision makes SMD hot air machines essential in electronics repair shops, manufacturing lines, and R&D labs.

Key Features of High-End SMD Hot Air Machines

High-end SMD hot air machines distinguish themselves through advanced features that improve precision, durability, and ease of use. Some notable features include:

- Precise Temperature Control: High-end models offer digital temperature settings with fine adjustments, often reaching up to 600°C (1120°F), allowing for accurate soldering without overheating. This precision is crucial when working with heat-sensitive components or multilayer PCBs.

- Integrated Vacuum Pickup: Some models, like the Hakko FR-810B, include vacuum pickup systems for safely lifting components after reflow, reducing the risk of pad or lead damage. This feature is especially valuable when handling small or fragile parts.

- Multiple Nozzle Options: Quick-change nozzles designed for various SMD sizes improve versatility and efficiency. These nozzles focus the hot air flow precisely where needed, minimizing heat spread to surrounding components.

- Quiet and Stable Airflow: Advanced turbine air supplies provide consistent airflow rates (e.g., up to 115 L/min) with minimal noise, enhancing operator comfort during long working hours.

- User-Friendly Interface: Digital displays and intuitive controls make it easier to set and monitor temperature and airflow, reducing operator errors and improving repeatability.

- Durability: High-end machines use robust heating elements and materials designed to withstand frequent use and harsh environments, ensuring long-term reliability.

- Safety Features: Over-temperature protection, airflow alarms, and automatic shut-off functions protect both the operator and the sensitive electronics.

Comparing SMD Hot Air Machine Price Ranges

The smd hot air machine price varies widely depending on brand, features, and performance. Here is a general overview:

| Price Range (USD) | Typical Features | Use Case |

| Under $300 | Basic temperature control, manual airflow | Hobbyists, occasional repairs |

| $300 - $900 | Digital controls, better airflow stability | Small workshops, prototyping |

| $900 - $2,500 | Integrated vacuum, multiple nozzles, high temp | Professional repair shops |

| Above $2,500 | Advanced systems with preheaters, multi-port | Industrial manufacturing, high-volume rework |

For example, the Hakko FR-810B SMD Hot Air Rework Station is priced around $916.77 and offers integrated vacuum pickup and durable heating elements. On the other hand, complete systems with fixtures and preheaters can cost upwards of $5,000, reflecting their industrial-grade capabilities.

Advantages of Investing in a High-End SMD Hot Air Machine

1. Improved Precision and Quality

High-end machines provide precise temperature and airflow control, essential for working with sensitive components. This reduces the risk of thermal damage and improves solder joint quality, leading to more reliable electronics. The ability to maintain stable temperatures during reflow ensures consistent soldering results, which is critical in professional manufacturing environments where quality standards are stringent.

2. Enhanced Efficiency and Productivity

Features like quick-change nozzles, stable airflow, and integrated vacuum pickups speed up the rework process. This results in shorter downtime and higher throughput, which is crucial for professional environments. For example, the vacuum pickup feature eliminates the need for manual handling of tiny components, reducing the chance of errors and speeding up the workflow.

3. Versatility and Adaptability

High-end stations accommodate a wide range of component sizes and types, making them suitable for diverse applications—from small prototypes to complex multi-layer PCBs. The availability of different nozzle sizes and airflow settings allows technicians to tailor the machine's operation to the specific task, whether it's delicate chip removal or heavy solder reflow.

4. Durability and Long-Term Cost Savings

Though the initial smd hot air machine price is higher, the durability and reliability of premium models reduce maintenance and replacement costs over time. High-quality heating elements and robust construction mean fewer breakdowns and longer service life, which translates to lower total cost of ownership.

5. Safety Features

Advanced models often include safety mechanisms like temperature limiters and vacuum pickups to prevent damage to components and operators. This not only protects your investment in expensive PCBs but also ensures a safer working environment.

Potential Drawbacks of High-End SMD Hot Air Machines

- High Initial Cost: The upfront investment can be significant, especially for small businesses or hobbyists. The smd hot air machine price for high-end models may be prohibitive for those with limited budgets.

- Learning Curve: Advanced features may require training for optimal use. Without proper knowledge, users might not fully exploit the machine's capabilities or could inadvertently damage components.

- Overkill for Simple Tasks: For basic soldering jobs or infrequent use, a high-end machine might be more than necessary, making lower-cost options more practical.

When Should You Consider a High-End SMD Hot Air Machine?

- If you regularly work with complex or sensitive SMD components.

- When high throughput and productivity are required.

- If you need precise control to avoid damaging expensive PCBs.

- When durability and long-term reliability are priorities.

- If your budget allows for investment in quality tools to enhance your work.

In contrast, hobbyists, students, or occasional repair technicians might find that mid-range or budget models meet their needs adequately.

How to Choose the Right SMD Hot Air Machine

When deciding whether to invest in a high-end SMD hot air machine, consider the following factors:

1. Application Requirements

Evaluate the types of components you will be working with. Large BGAs or fine-pitch QFPs require more precise temperature and airflow control than simple resistors or capacitors.

2. Frequency of Use

If you use the machine daily in a production environment, investing in a high-end model with better durability and features makes sense. For occasional use, a lower-cost model may suffice.

3. Budget Constraints

Set a realistic budget that balances initial cost with long-term benefits. Remember, a higher smd hot air machine price can be offset by improved efficiency and reduced rework costs.

4. Brand and Support

Choose reputable brands known for quality and customer support. Reliable after-sales service and availability of spare parts are critical for minimizing downtime.

5. Additional Features

Consider whether features like integrated vacuum pickup, multiple nozzles, and digital interfaces are necessary for your tasks.

Maintenance Tips for High-End SMD Hot Air Machines

To maximize the lifespan and performance of your investment, follow these maintenance tips:

- Regular Cleaning: Keep nozzles and air filters clean to maintain consistent airflow.

- Calibration: Periodically calibrate temperature sensors to ensure accuracy.

- Proper Storage: Avoid storing the machine in dusty or humid environments.

- Use Recommended Accessories: Use manufacturer-approved nozzles and parts to prevent damage.

- Routine Inspection: Check heating elements and airflow components for wear and replace as needed.

Proper maintenance reduces repair costs and extends the service life of your high-end SMD hot air machine.

Conclusion

Investing in a high-end SMD hot air machine is worthwhile for professionals and manufacturers who demand precision, efficiency, and reliability in their rework processes. While the smd hot air machine price may be higher compared to basic models, the benefits of advanced features, durability, and productivity gains justify the cost. For hobbyists or occasional users, budget-friendly options may suffice, but for industrial or commercial applications, a high-end machine is a smart investment that pays off in quality and time savings. Ultimately, the decision hinges on your specific needs, budget, and the complexity of your work.

FAQ

1. What factors influence the smd hot air machine price?

The price depends on brand reputation, temperature range, airflow control, integrated features like vacuum pickup, and included accessories such as nozzles and preheaters.

2. Can a high-end SMD hot air machine be used for all types of SMD components?

Yes, high-end machines are designed to handle a wide variety of SMD sizes and types, from small resistors to large BGA packages, with adjustable temperature and airflow settings.

3. How does a vacuum pickup system benefit SMD rework?

It allows safe lifting of components after reflow without damaging the PCB pads or leads, improving rework quality and reducing scrap rates.

4. Are high-end SMD hot air machines suitable for beginners?

While they offer advanced features, beginners may find them complex. However, user-friendly interfaces and training can help novices leverage their benefits effectively.

5. How long do high-end SMD hot air machines typically last?

With proper maintenance, these machines can last many years, making them a cost-effective solution despite their higher initial smd hot air machine price.