Content Menu

● Introduction

● What is Surface Mount Technology?

● Components of a Surface Mount Technology Kit

● Benefits of Using a Surface Mount Technology Kit for Beginners

● Getting Started with Your Surface Mount Technology Kit

● Common Challenges Faced by Beginners

● Tips for Success

● Conclusion

● FAQ

>> 1. What is the difference between surface mount technology and through-hole technology?

>> 2. Do I need special tools for working with surface mount technology?

>> 3. Can I use a regular soldering iron for SMT projects?

>> 4. Are there any safety precautions I should take when using my SMT kit?

>> 5. Where can I find more resources or tutorials on surface mount technology?

Introduction

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, allowing for more compact and efficient designs. As technology continues to advance, many enthusiasts and beginners are eager to learn about SMT and how to work with it. One of the best ways to get started is by using a Surface Mount Technology kit. This article will explore whether a Surface Mount Technology kit is suitable for beginners, the components typically included in these kits, and tips for getting started with SMT.

What is Surface Mount Technology?

Surface Mount Technology refers to a method of electronic component assembly where components are mounted directly onto the surface of printed circuit boards (PCBs). This technology contrasts with traditional through-hole technology, where components are inserted into holes drilled in the PCB. SMT offers several advantages:

- Compact Design: SMT components are typically smaller than their through-hole counterparts, allowing for more compact circuit designs.

- Increased Performance: SMT can lead to better electrical performance due to shorter connection paths.

- Automated Manufacturing: SMT is well-suited for automated assembly processes, which can reduce manufacturing costs.

Components of a Surface Mount Technology Kit

A typical Surface Mount Technology kit designed for beginners will include several essential components and tools:

- SMT Components: Various surface mount resistors, capacitors, diodes, and integrated circuits (ICs) that you can practice soldering.

- PCB: A printed circuit board specifically designed for practicing SMT techniques.

- Soldering Tools: A soldering iron or hot air rework station, solder wire, and desoldering tools.

- Tweezers: Precision tweezers designed for handling small SMT components.

- Magnifying Glass or Microscope: For inspecting solder joints and component placement.

- Instruction Manual: A guide that provides step-by-step instructions on how to assemble circuits using the kit.

Benefits of Using a Surface Mount Technology Kit for Beginners

Using a Surface Mount Technology kit can be incredibly beneficial for beginners looking to dive into electronics. Here are some reasons why:

- Hands-On Learning: A kit provides practical experience that is essential for understanding SMT concepts.

- Structured Guidance: Many kits come with manuals or online resources that guide you through the assembly process.

- Variety of Components: Beginners can familiarize themselves with different types of SMT components, which is crucial for future projects.

- Error Correction: Practicing on a dedicated PCB allows beginners to make mistakes and learn from them without the fear of damaging expensive equipment.

Getting Started with Your Surface Mount Technology Kit

1. Gather Your Tools: Before starting, ensure you have all necessary tools ready. This includes your soldering iron, solder, tweezers, and magnifying glass.

2. Read the Instructions: Familiarize yourself with the instruction manual provided in your kit. Understanding the layout of your PCB and the components you'll be using is crucial.

3. Practice Soldering Techniques: If you're new to soldering, consider practicing on scrap PCBs before working on your project board. Techniques like drag soldering and using flux can significantly improve your results.

4. Start with Simple Projects: Begin with simple circuits that require only a few components. This will help build your confidence before moving on to more complex assemblies.

5. Inspect Your Work: After soldering each component, inspect your work under magnification to ensure there are no cold joints or bridges between pads.

Common Challenges Faced by Beginners

While working with a Surface Mount Technology kit can be rewarding, beginners may encounter several challenges:

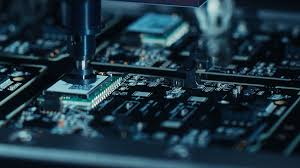

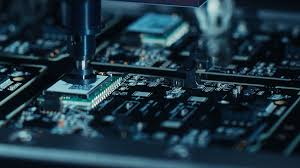

- Small Component Size: SMT components are significantly smaller than through-hole parts, making them difficult to handle without proper tools like tweezers.

- Soldering Skills: Many beginners struggle with soldering techniques specific to SMT due to the precision required.

- Component Placement: Accurately placing tiny components on the PCB can be challenging, particularly without magnification tools.

Tips for Success

To overcome these challenges and succeed in your SMT journey, consider the following tips:

- Use Proper Lighting: Good lighting is essential when working with small components; consider using a bright desk lamp or LED light.

- Stay Organized: Keep your workspace organized to avoid losing small parts and tools. Use trays or containers for different components.

- Watch Tutorials: Online video tutorials can provide visual guidance on techniques such as soldering and component placement.

- Join Online Communities: Engaging with other electronics enthusiasts online can provide support and valuable advice as you learn.

Conclusion

In conclusion, a Surface Mount Technology kit is indeed suitable for beginners who are eager to learn about electronics and soldering techniques. These kits offer hands-on experience and structured guidance that can help novices develop their skills in a supportive environment. By starting with simple projects and gradually increasing complexity, beginners can gain confidence in their abilities while enjoying the fascinating world of surface mount technology.

FAQ

1. What is the difference between surface mount technology and through-hole technology?

Surface mount technology involves mounting components directly onto the surface of PCBs, while through-hole technology requires inserting leads into holes drilled in the PCB. SMT allows for smaller designs and often better performance due to shorter connections.

2. Do I need special tools for working with surface mount technology?

Yes, working with SMT typically requires specific tools such as precision tweezers, a fine-tipped soldering iron or hot air rework station, magnifying glasses or microscopes, and desoldering tools for correcting mistakes.

3. Can I use a regular soldering iron for SMT projects?

While you can use a regular soldering iron for some SMT projects, it's recommended to use a fine-tipped soldering iron or hot air rework station for better precision when working with small components.

4. Are there any safety precautions I should take when using my SMT kit?

Always work in a well-ventilated area when soldering to avoid inhaling fumes. Additionally, be careful when handling hot tools and components to prevent burns or injuries.

5. Where can I find more resources or tutorials on surface mount technology?

Many online platforms offer tutorials on surface mount technology, including YouTube channels dedicated to electronics projects, forums like Reddit's r/electronics community, and educational websites focused on DIY electronics.