Content Menu

● The Importance of Accurate Counting in Manufacturing

● What is a Small Parts Counter?

>> Key Features of Small Parts Counters

● How Small Parts Counters Enhance Manufacturing Efficiency

>> 1. Time Savings

>> 2. Labor Cost Reduction

>> 3. Improved Accuracy

>> 4. Enhanced Data Management

>> 5. Flexibility in Operations

● Applications Across Industries

>> Emerging Technologies in Small Parts Counting

● Challenges Addressed by Small Parts Counters

● Cost-Benefit Analysis of Small Parts Counters

● Conclusion

● FAQ

>> 1. What types of industries benefit from using small parts counters?

>> 2. How do small parts counters improve accuracy?

>> 3. Can small parts counters handle different types of components?

>> 4. What are the cost benefits of using a small parts counter?

>> 5. How do I choose the right small parts counter for my business?

● Citations:

In the modern manufacturing landscape, efficiency is paramount. With increasing competition and the demand for high-quality products, manufacturers are constantly seeking ways to optimize their processes. One often overlooked yet crucial element in achieving this efficiency is the use of small parts counters. These devices not only streamline operations but also enhance accuracy and reduce labor costs. This article explores the significance of small parts counters in manufacturing and how they contribute to overall efficiency.

The Importance of Accurate Counting in Manufacturing

Accurate counting of small parts is essential for various reasons:

- Inventory Management: Maintaining an accurate inventory is critical for production planning and avoiding stockouts or overstock situations.

- Cost Control: Errors in counting can lead to costly mistakes, such as overordering or underordering components.

- Quality Assurance: Ensuring the correct number of parts are used in production helps maintain product quality and consistency.

Manual counting methods are often tedious and prone to human error. As such, many manufacturers are turning to automated solutions like small parts counters to enhance their operations.

What is a Small Parts Counter?

A small parts counter is a specialized device designed to count small components quickly and accurately. These machines utilize advanced technology, including sensors and cameras, to identify and tally items with minimal human intervention. Depending on the model, they can count a wide range of components, from tiny screws to electronic parts.

Key Features of Small Parts Counters

- High Speed: Many small parts counters can count thousands of components per minute, significantly reducing the time required for inventory management.

- Accuracy: With accuracy rates often exceeding 99%, these machines minimize errors associated with manual counting.

- Versatility: They can handle various shapes and sizes of components, making them suitable for multiple industries.

- User-Friendly Interfaces: Most modern counters come equipped with intuitive interfaces that allow operators to set up and manage counting processes easily.

How Small Parts Counters Enhance Manufacturing Efficiency

Integrating small parts counters into manufacturing processes can yield several benefits:

1. Time Savings

By automating the counting process, manufacturers can save significant time that would otherwise be spent on manual counting. This allows employees to focus on more critical tasks, thereby increasing overall productivity.

2. Labor Cost Reduction

With fewer hours needed for manual counting, companies can reduce labor costs. Additionally, fewer errors mean less time spent rectifying mistakes, further enhancing cost efficiency.

3. Improved Accuracy

The precision offered by small parts counters minimizes discrepancies in inventory counts. This accuracy is vital for maintaining production schedules and ensuring that assembly lines are adequately stocked with necessary components.

4. Enhanced Data Management

Many small parts counters come with integrated data management systems that allow for easy tracking and reporting of inventory levels. This capability supports better decision-making regarding purchasing and production planning.

5. Flexibility in Operations

Small parts counters can be easily adjusted to accommodate different types of components or changes in production requirements. This flexibility makes them a valuable asset in dynamic manufacturing environments.

Applications Across Industries

Small parts counters are utilized across various sectors due to their versatility:

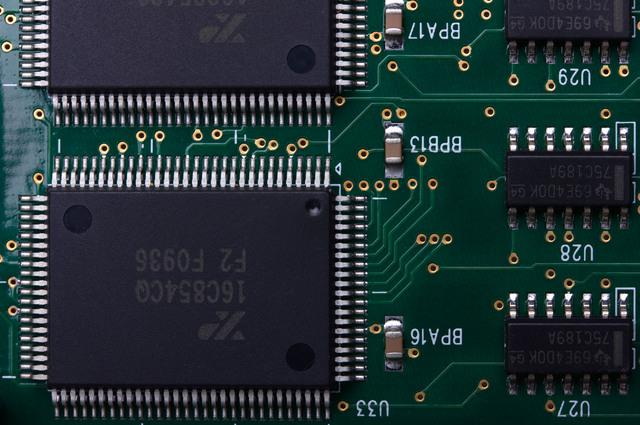

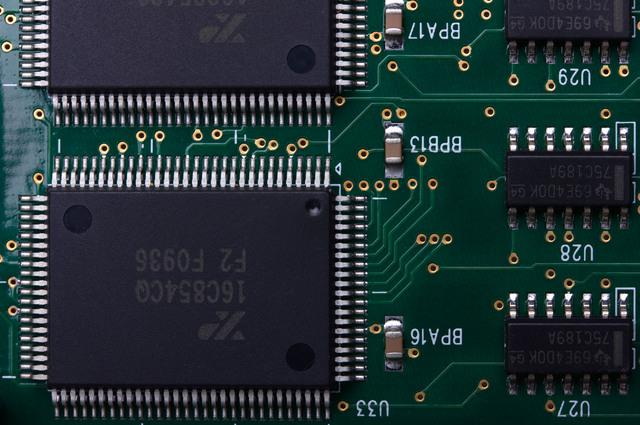

- Electronics Manufacturing: In this sector, accurate counting of components like resistors and capacitors is crucial for quality control.

- Automotive Industry: Manufacturers rely on these counters to ensure that all necessary parts are available for assembly lines without delays.

- Medical Device Production: Precision is vital in this field; thus, small parts counters help maintain strict inventory controls.

- Pharmaceuticals: Accurate counts are essential for compliance with regulatory standards regarding component quantities in packaging.

Emerging Technologies in Small Parts Counting

Recent advancements in technology have further enhanced the capabilities of small parts counters. For instance:

- Image Counting Inside (ICI) Technology: This innovative technology allows for real-time counting as components fall freely through a detection apparatus, eliminating the need for mechanical separation at fixed intervals. This method significantly increases efficiency by allowing continuous operation without interruptions[8].

- Optical Sensors and High-Resolution Cameras: Modern small parts counters utilize sophisticated imaging technologies that accurately identify and count even similar-looking components, minimizing errors associated with manual counting[4].

These advancements not only improve counting speed but also enhance overall operational efficiency by integrating seamlessly into existing manufacturing processes.

Challenges Addressed by Small Parts Counters

The implementation of small parts counters addresses several challenges faced by manufacturers:

- Human Error: Manual counting is inherently prone to mistakes due to fatigue or distraction. Automated systems eliminate this risk.

- Inefficiency: Traditional counting methods can slow down production lines. Small parts counters enhance speed without sacrificing accuracy.

- Inventory Discrepancies: Inaccurate counts can lead to production delays or excess inventory costs. Automated counters provide real-time data that helps maintain accurate stock levels.

Cost-Benefit Analysis of Small Parts Counters

Investing in small parts counters may involve upfront costs; however, the long-term benefits often outweigh these initial expenses:

- Reduced Labor Costs: By automating the counting process, companies can decrease reliance on manual labor, leading to significant savings over time.

- Minimized Waste: Accurate counts help prevent overproduction or underproduction scenarios, reducing material waste and improving resource allocation[5].

- Improved Customer Satisfaction: Consistent accuracy ensures that customers receive the correct number of products, enhancing trust and loyalty[9].

Conclusion

In conclusion, small parts counters play a pivotal role in enhancing manufacturing efficiency by automating the tedious task of counting components. Their ability to provide high-speed, accurate counts not only saves time but also reduces labor costs and minimizes errors—factors that are crucial in today's competitive manufacturing environment. As industries continue to evolve towards automation, investing in small parts counters will likely become a standard practice for those looking to optimize their operations and improve their bottom line.

FAQ

1. What types of industries benefit from using small parts counters?

Small parts counters are beneficial across various industries including electronics manufacturing, automotive production, medical device manufacturing, and pharmaceuticals due to their ability to accurately count tiny components quickly.

2. How do small parts counters improve accuracy?

Small parts counters utilize advanced technology such as sensors and cameras that significantly reduce human error associated with manual counting methods, ensuring higher accuracy rates often exceeding 99%.

3. Can small parts counters handle different types of components?

Yes, most small parts counters are versatile enough to handle a wide range of component shapes and sizes, making them suitable for diverse manufacturing applications.

4. What are the cost benefits of using a small parts counter?

Investing in a small parts counter can lead to reduced labor costs due to less time spent on manual counting, decreased errors that result in costly mistakes, and improved overall operational efficiency which positively impacts the bottom line.

5. How do I choose the right small parts counter for my business?

When selecting a small parts counter, consider factors such as speed (components counted per minute), accuracy rate, ease of use (user interface), versatility (types of components it can handle), and data management capabilities.

Citations:

[1] https://www.bagmatic.com/en/products-equipment/packaging-machines/input-accessories/small-part-counter-machine/

[2] https://www.seamarkzm.com/benefits-of-using-smt-component-counters-for-assembly-line-efficiency.html

[3] https://acctivate.com/automated-inventory-counting/

[4] https://www.seamarkzm.com/how-component-counter-machines-work.html

[5] https://sciotex.com/how-to-automate-small-part-counting-operations/

[6] https://chemometec.com/advantages-and-disadvantages-automated-cell-counters/

[7] https://www.bagmatic.com/en/piece-counter-parts-counting/

[8] https://data-technologies.com/pressroom/automate-small-parts-counting/

[9] https://www.multi-fill.com/counting-machine-in-filling-machine-industries

[10] https://sciotex.com/perfectcount-solves-the-bottleneck-of-counting-products-in-manufacturing-companies/