Content Menu

● Understanding SMT Reel Splicing

>> Benefits of SMT Splicing

● Essential Tools for SMT Splicing

● Step-by-Step Guide on Using SMT Reel Splicer

>> 1. Preparation

>> 2. Cutting the Carrier Tape

>> 3. Aligning the Reels

>> 4. Applying Splice Tape

>> 5. Crimping with Splice Tool

>> 6. Finalizing Splice Connection

>> 7. Testing and Verification

● Common Issues and Troubleshooting

● Advanced Techniques in SMT Splicing

>> 1. Automatic Splicing Machines

>> 2. Smart Sensors Integration

>> 3. Data Analytics for Performance Monitoring

● Best Practices for Effective SMT Splicing

● Conclusion

● FAQ

>> 1. What is SMT splicing?

>> 2. What tools are required for SMT splicing?

>> 3. How do I know if my splice is successful?

>> 4. Can I use any type of tape for SMT splicing?

>> 5. What should I do if my splice tape isn't sticking?

● Citations:

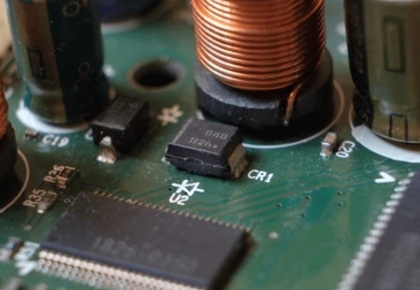

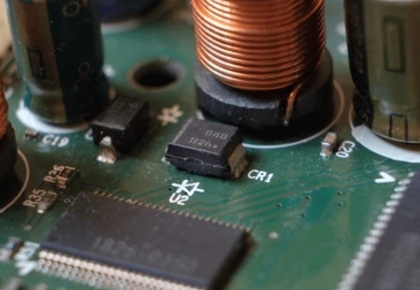

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, allowing for more efficient and precise assembly of electronic components. One essential tool in this process is the SMT reel splicer, which facilitates the seamless connection of component reels, ensuring uninterrupted operation of pick-and-place machines. In this article, we will explore the functionality, benefits, and a comprehensive step-by-step guide on how to effectively use an SMT reel splicer.

Understanding SMT Reel Splicing

SMT reel splicing involves joining two reels of component tape to create a continuous feed for automated assembly processes. This is crucial for maintaining production flow and minimizing downtime. The splicing process typically employs specialized splicing tape and tools designed to securely bond the ends of the tapes while ensuring proper alignment of the components.

Benefits of SMT Splicing

- Increased Efficiency: By reducing the need for frequent reel changes, SMT splicing enhances the throughput of pick-and-place machinery.

- Cost Savings: Utilizing 100% of the components on a reel minimizes waste and lowers overall production costs.

- Improved Quality: Automated splicing ensures precise alignment, reducing errors in component placement and enhancing product quality.

- Reduced Downtime: Continuous operation without interruptions leads to higher productivity levels.

Essential Tools for SMT Splicing

To successfully splice SMT reels, you will need several key tools:

- SMT Splice Tool: This tool is designed to crimp and join the ends of the carrier tapes securely.

- Splice Tape: A specialized adhesive tape used to bond the two ends of the component reels together.

- Cutting Tool: For trimming the carrier tape accurately before splicing.

- Hold Down Units: These help stabilize the carrier tape during the splicing process.

Step-by-Step Guide on Using SMT Reel Splicer

Here is a comprehensive guide on how to use an SMT reel splicer effectively:

1. Preparation

Before beginning the splicing process, ensure that you have all necessary tools at hand. Prepare your workspace by cleaning it to avoid contamination that could affect adhesion.

2. Cutting the Carrier Tape

- Use a cutting tool to trim the leader of the new component reel to your desired length.

- Make sure not to cut through any pockets that contain components; this is crucial for maintaining a continuous feed.

3. Aligning the Reels

- Align the end of the current reel with the beginning of the new reel, ensuring that all components are properly aligned.

- This step is critical as misalignment can lead to defects in component placement during assembly.

4. Applying Splice Tape

- Peel back the backing of the splice tape and position it over the joint where both reels meet.

- Ensure that it covers the entire joint area for maximum adhesion.

5. Crimping with Splice Tool

- Place both ends of the carrier tape into the SMT splice tool.

- Use hold downs to secure them in place, preventing any movement during crimping.

- Firmly crimp the tool to secure both ends together, creating a strong bond between them.

6. Finalizing Splice Connection

Once you have completed the splicing process, it's vital to test it:

- Run a few cycles through your pick-and-place machine to verify that everything operates smoothly without any jams or misalignments.

7. Testing and Verification

After completing your splice:

- Check for any visible defects or misalignments in your splice area.

- Conduct a test run with your pick-and-place machine to ensure that there are no blockages or issues during operation.

Common Issues and Troubleshooting

While using an SMT reel splicer can significantly enhance efficiency, certain issues may arise:

- Tape Not Sticking: If you find that your splice tape isn't adhering properly, ensure that both surfaces are clean and dry before application.

- Misalignment: If components aren't aligning correctly after splicing, double-check your initial alignment before applying splice tape.

Advanced Techniques in SMT Splicing

As technology evolves, so do methods and tools associated with SMT splicing. Here are some advanced techniques that can further enhance efficiency:

1. Automatic Splicing Machines

Modern facilities often utilize automatic splicing machines that streamline the process. These machines cut and join component tapes with precision, significantly increasing efficiency and reducing labor costs. They can be programmed to detect when a reel is running low on components and prepare for splicing automatically.

2. Smart Sensors Integration

Newer machines incorporate smart sensors that detect when a reel is running low on components and automatically prepare for splicing. This feature minimizes human intervention and ensures seamless transitions between reels without interrupting production flow.

3. Data Analytics for Performance Monitoring

Advanced data analytics tools help manufacturers track performance metrics related to splicing operations, allowing for informed decision-making and continuous improvement in processes.

Best Practices for Effective SMT Splicing

To maximize efficiency when using an SMT reel splicer, consider implementing these best practices:

- Quality Assurance: Invest in high-quality splice tapes to minimize risks associated with blockages and misfeeds.

- Proper Training: Ensure that personnel are well-trained in splicing techniques to maintain consistency and accuracy.

- Regular Maintenance: Keep splicing tools and machines well-maintained to ensure optimal performance.

- Monitoring Systems: Implement monitoring systems that provide real-time feedback on splicing effectiveness and component flow.

Conclusion

Using an SMT reel splicer is an integral part of modern electronics manufacturing that can significantly improve productivity and reduce costs. By following proper procedures for preparation, cutting, aligning, applying splice tape, crimping, testing, and verification, manufacturers can ensure seamless operation in their assembly lines. Understanding advanced techniques such as automatic machines and smart sensor integration will further enhance reliability in production processes. As technology continues to advance, staying informed about innovations will be crucial for maintaining competitive advantages in an ever-evolving market.

FAQ

1. What is SMT splicing?

SMT splicing refers to joining two reels of component tapes together using specialized tools and adhesive tapes to create a continuous feed for automated assembly processes.

2. What tools are required for SMT splicing?

Essential tools include an SMT splice tool, splice tape, cutting tool, and hold down units for stabilizing carrier tapes during splicing.

3. How do I know if my splice is successful?

A successful splice should allow smooth operation through pick-and-place machines without jams or misalignments; testing with a few cycles can verify this.

4. Can I use any type of tape for SMT splicing?

No, it's important to use specialized SMT splice tape designed for strong adhesion and flexibility suitable for automated assembly processes.

5. What should I do if my splice tape isn't sticking?

Ensure that both surfaces are clean and dry before applying splice tape; if issues persist, check if your tape is expired or damaged.

Citations:

[1] https://www.youtube.com/watch?v=UAaee_ybiEg

[2] https://www.khj.com.cn/news/the-ultimate-guide-to-smt-splicing-tape-everything-you-need-to-know-143816.html

[3] https://www.sucatec.com/products/indirect/SMT_splicing/

[4] https://smtnet.com/news/index.cfm?fuseaction=view_news&company_id=55778&news_id=20242

[5] https://www.gssmt-parts.com/what-is-smt-splice-and-why-is-it-crucial-for-electronics-manufacturing.html

[6] https://www.somersetsolders.com/smt-component-reel-splicing-tool-single-shim

[7] https://www.youtube.com/watch?v=CMoQ-RQWKkQ

[8] https://www.allsmt.com/SMT-splicing-tapes-and-Extenders-a-valuable-aid-in-electronics-production

[9] https://www.youtube.com/watch?v=r2E1JU3xXGs

[10] https://www.youtube.com/watch?v=71TTsoWhiHA