Content Menu

● Understanding SMD Machines and SMT Pick & Place Technology

● Key Components of Effective SMD Machine Training

>> 1. Comprehensive Operator Training

>> 2. Software and Programming Training

>> 3. Maintenance and Calibration Training

>> 4. Process Optimization Training

● Steps to Train Your Team Effectively on SMD Machines

>> Step 1: Assess Skill Levels and Training Needs

>> Step 2: Develop a Structured Training Program

>> Step 3: Use Hands-On Training with Real Machines

>> Step 4: Implement Continuous Learning and Certification

>> Step 5: Monitor Performance and Provide Feedback

● Best Practices for Operating SMT Pick & Place Machines

● Advanced Tips for Training and Operation

>> Emphasize Cross-Functional Knowledge

>> Leverage Simulation and Virtual Training

>> Foster a Culture of Continuous Improvement

>> Utilize Visual Aids and Standard Operating Procedures (SOPs)

>> Invest in Experienced Trainers

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What are the essential skills required to operate an SMT pick and place machine?

>> 2. How often should SMT machines be calibrated?

>> 3. Can software training improve the efficiency of SMT machine operation?

>> 4. What maintenance tasks are critical for SMT pick and place machines?

>> 5. How can process optimization impact SMT machine productivity?

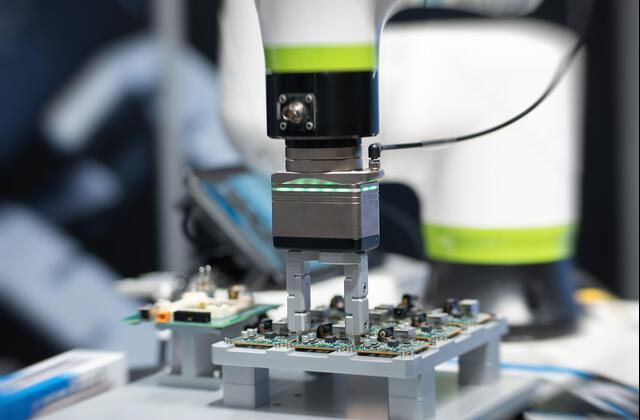

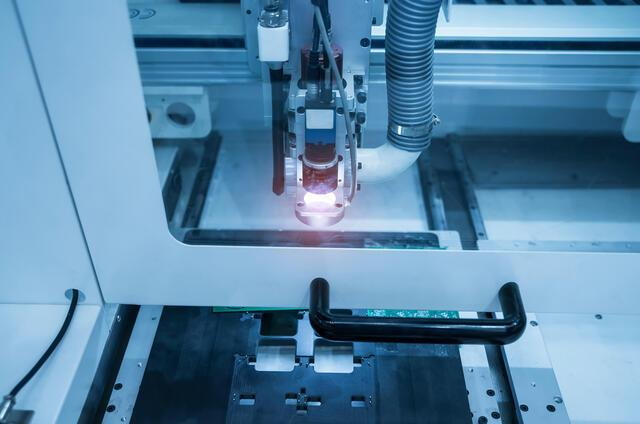

Surface Mount Device (SMD) machines, particularly SMT pick and place machines, are pivotal in modern electronics manufacturing. Efficient operation of these machines directly impacts production speed, quality, and cost-effectiveness. Training your team to operate an SMD machine effectively is essential for maximizing these benefits. This comprehensive guide will walk you through the best practices, training methods, and operational tips to empower your workforce for optimal performance.

Understanding SMD Machines and SMT Pick & Place Technology

Before diving into training strategies, it's crucial to understand what an SMD machine is and the role of SMT pick and place machines in PCB assembly.

- SMD Machine: A machine designed to place surface mount components onto printed circuit boards (PCBs) with high precision and speed.

- SMT Pick & Place Machine: A specialized SMD machine that picks components from feeders and places them accurately on the PCB pads.

The SMT pick and place machine is a cornerstone of surface mount technology (SMT), automating the placement of thousands of tiny components in a fraction of the time manual assembly would take. These machines use advanced vision systems and robotic arms to ensure components are placed with micron-level accuracy. Mastering the operation of these machines requires knowledge of their mechanics, software, and maintenance protocols.

Key Components of Effective SMD Machine Training

Training your team to operate an SMD machine effectively involves multiple facets, from hands-on machine operation to software programming and maintenance. Below are the key components to focus on:

1. Comprehensive Operator Training

Operator skills significantly influence the efficiency and accuracy of SMT pick and place machines. Training should cover:

- Machine Operation: Operators must learn how to load PCBs, set up feeders correctly, and start or stop the machine safely. This includes understanding the machine's user interface and control panel.

- Safety Protocols: Handling sensitive components requires adherence to safety standards such as wearing personal protective equipment (PPE) and following electrostatic discharge (ESD) precautions to prevent component damage.

- Quality Control: Operators should be trained to monitor placement accuracy continuously, identify defects such as misaligned or missing components, and understand how to pause or stop the machine for corrections.

- Troubleshooting: Basic problem-solving skills are essential. Operators should know how to clear jams, replace feeders, and reset machine errors without causing damage or downtime.

Hands-on training on the actual machine is highly recommended to build confidence and familiarity. Simulation software can also be used to supplement real-world experience.

2. Software and Programming Training

Modern SMD machines rely heavily on sophisticated software for programming placement sequences and monitoring production. Training should include:

- Program Creation: Operators and programmers must learn how to create, load, and modify placement programs tailored for different PCB designs and component types.

- Software Navigation: Understanding the machine's software interface, including menus, alerts, and diagnostic tools, is critical for smooth operation.

- Real-time Monitoring: Training should cover how to interpret software alerts, monitor production metrics, and respond to warnings or errors promptly.

- Data Analysis: Utilizing software-generated reports to analyze machine performance, placement accuracy, and production throughput helps optimize the assembly process.

Offering both primary and comprehensive software training ensures operators and programmers can fully leverage the machine's capabilities, reducing errors and increasing throughput.

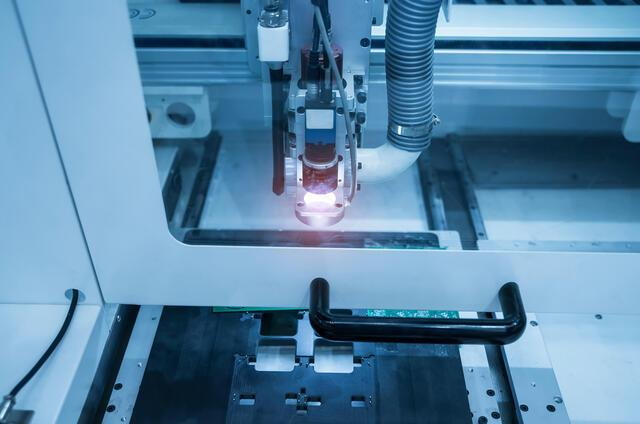

3. Maintenance and Calibration Training

Proper maintenance and calibration are critical to keep SMT pick and place machines running smoothly and accurately. Training should emphasize:

- Routine Maintenance: This includes daily cleaning of nozzles, feeders, and vision systems, lubrication of moving parts, and replacement of worn components.

- Calibration Procedures: Regular calibration ensures that the machine's placement accuracy remains within specified tolerances. Operators should learn how to perform calibration routines using fiducial marks and test PCBs.

- Preventive Measures: Training should include how to identify early signs of wear or malfunction to prevent unexpected breakdowns and production delays.

- Documentation: Keeping detailed maintenance logs helps track machine condition and plan future maintenance activities.

Training maintenance staff alongside operators promotes a culture of proactive machine care, reducing downtime and extending machine lifespan.

4. Process Optimization Training

Training should also include understanding the entire SMT production flow to optimize machine use:

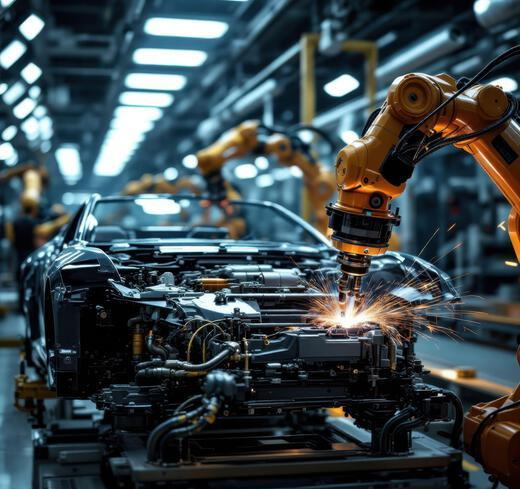

- Process Flow: Operators should understand the sequence of PCB loading, solder paste printing, component placement, reflow soldering, and inspection to appreciate how their role fits into the overall manufacturing process.

- Component Preparation: Proper handling and preparation of components, including correct feeder loading and tape orientation, help prevent placement errors.

- Production Scheduling: Training on scheduling helps minimize machine idle time and maximize throughput by coordinating feeder changes and PCB loading efficiently.

- Error Reduction: Standardizing procedures and checklists reduces operator errors and rework, improving overall yield.

Steps to Train Your Team Effectively on SMD Machines

Step 1: Assess Skill Levels and Training Needs

Begin by evaluating your team's current knowledge of SMT processes and machine operation. This can be done through skills assessments, interviews, or observation. Understanding their baseline helps tailor training content to address specific gaps.

Step 2: Develop a Structured Training Program

Create a curriculum that covers:

- Basic SMT principles and terminology

- Machine operation and safety procedures

- Software programming and troubleshooting

- Maintenance and calibration techniques

- Quality assurance and process optimization

Incorporate both theoretical lessons and practical exercises. Use multimedia resources such as videos, manuals, and interactive software to enhance learning.

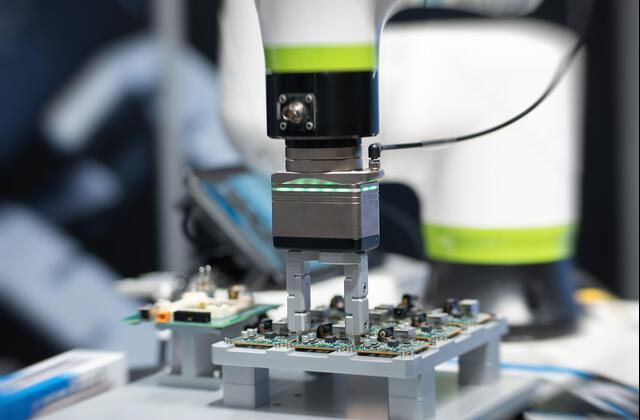

Step 3: Use Hands-On Training with Real Machines

Nothing beats practical experience. Conduct training sessions on actual SMT pick and place machines or high-fidelity simulators. Allow trainees to practice loading feeders, running placement programs, and performing maintenance tasks under supervision. Hands-on training enhances learning retention and operator confidence.

Step 4: Implement Continuous Learning and Certification

Technology and processes evolve rapidly in electronics manufacturing. Offer refresher courses and advanced training modules regularly. Establish certification programs to motivate employees and ensure consistent skill levels across the team. Certified operators are more likely to adhere to best practices and contribute to higher production quality.

Step 5: Monitor Performance and Provide Feedback

Track operator performance through production metrics such as placement accuracy, machine uptime, and defect rates. Use this data to identify skill gaps or recurring issues. Provide constructive feedback and targeted coaching to help operators improve continuously.

Best Practices for Operating SMT Pick & Place Machines

To maximize the efficiency and reliability of your SMT pick and place machines, adhere to the following best practices:

- Regular Calibration: Daily calibration ensures that the machine maintains micron-level placement accuracy, reducing component misplacement and rework.

- Preventive Maintenance: Follow manufacturer-recommended maintenance schedules meticulously. Clean nozzles, feeders, and vision systems regularly to prevent dust and debris buildup.

- Feeder Preparation: Load feeders carefully, ensuring components are correctly oriented and tapes are intact. Check component expiry dates and storage conditions to avoid defects.

- Optimize Placement Sequence: Program machines to place components in an order that minimizes head movement and maximizes speed. Group similar components together to reduce nozzle changes.

- Maintain Clean Work Environment: Dust and contaminants can affect machine vision systems and PCB quality. Keep the production area clean and controlled.

- Use ESD Protection: Operators should always wear ESD wrist straps and work on grounded mats to protect sensitive components from electrostatic damage.

- Document Procedures: Maintain detailed logs of machine settings, maintenance activities, and production runs. This documentation aids troubleshooting and continuous improvement.

Advanced Tips for Training and Operation

Emphasize Cross-Functional Knowledge

Encourage operators to understand related processes such as solder paste printing and reflow soldering. This holistic knowledge helps them appreciate the importance of their role and collaborate better with other teams.

Leverage Simulation and Virtual Training

Use simulation software to allow operators to practice programming and troubleshooting without risking actual production. Virtual training can accelerate learning and reduce errors on the production floor.

Foster a Culture of Continuous Improvement

Promote open communication where operators can share insights and suggest process improvements. Regular team meetings and feedback sessions help identify bottlenecks and innovative solutions.

Utilize Visual Aids and Standard Operating Procedures (SOPs)

Display SOPs, checklists, and troubleshooting guides near the machines. Visual aids help operators follow correct procedures consistently, reducing errors and downtime.

Invest in Experienced Trainers

Experienced trainers who understand both technical and practical aspects of SMT pick and place machines can deliver more effective training. Consider partnering with machine manufacturers or industry experts for specialized sessions.

Conclusion

Training your team to operate SMD machines, especially SMT pick and place machines, effectively requires a comprehensive approach that combines operator skill development, software proficiency, maintenance knowledge, and process optimization. Hands-on training, continuous learning, and adherence to best practices ensure your production line runs efficiently, producing high-quality PCBs with minimal downtime. Investing in robust training programs not only enhances machine performance but also empowers your workforce, driving long-term success in electronics manufacturing.

By focusing on structured training, ongoing skill development, and fostering a culture of quality and continuous improvement, your team will be well-equipped to handle the complexities of SMT assembly. This ultimately leads to increased productivity, reduced costs, and superior product quality.

Frequently Asked Questions (FAQs)

1. What are the essential skills required to operate an SMT pick and place machine?

Operators need to understand machine operation, safety protocols, basic troubleshooting, and quality control measures to ensure efficient and accurate placement of components.

2. How often should SMT machines be calibrated?

Calibration should be performed regularly, ideally daily or as recommended by the manufacturer, to maintain placement precision and reduce errors.

3. Can software training improve the efficiency of SMT machine operation?

Yes, software training enables operators and programmers to create optimized placement programs, monitor production in real-time, and quickly address issues, significantly enhancing efficiency.

4. What maintenance tasks are critical for SMT pick and place machines?

Routine cleaning, lubrication, part replacement, and preventive checks are essential to prevent downtime and maintain machine accuracy.

5. How can process optimization impact SMT machine productivity?

Optimizing the production flow, preparing components in advance, and scheduling production effectively reduce idle time and increase placement speed, improving overall productivity.