Content Menu

● Understanding the Importance of Feeder Loading

● Key Skills Required for SMT Line Operators

● Training Techniques for Effective Feeder Loading

>> 1. Hands-On Training

>> 2. Standard Operating Procedures (SOPs)

>> 3. Visual Aids and Checklists

>> 4. Continuous Assessment and Feedback

>> 5. Cross-Training Opportunities

● Implementing Technology in Training

>> 1. E-Learning Platforms

>> 2. Virtual Reality (VR) Training

● Creating a Supportive Learning Environment

● Conclusion

● FAQ

>> 1. What are the common challenges faced during feeder loading?

>> 2. How often should SMT line operators receive refresher training?

>> 3. What role does teamwork play in effective feeder loading?

>> 4. Can technology replace traditional training methods?

>> 5. How do performance metrics influence operator training?

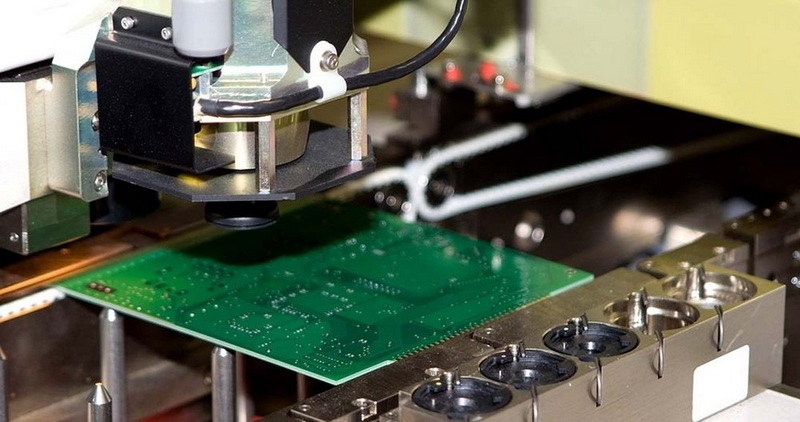

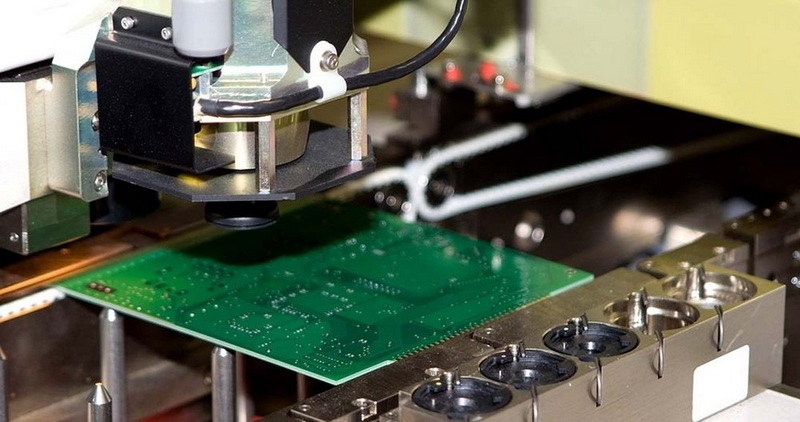

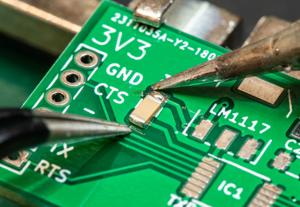

Surface Mount Technology (SMT) is a vital aspect of modern electronics manufacturing. It involves placing electronic components onto printed circuit boards (PCBs) using automated machines. One of the critical components of this process is the feeder loading, which directly influences the efficiency and quality of production. Training SMT line operators effectively in feeder loading is essential for optimizing production processes, reducing waste, and ensuring high-quality output. This article will explore various strategies and techniques to train SMT line operators for effective feeder loading.

Understanding the Importance of Feeder Loading

Feeder loading refers to the process of loading component reels into feeders on an SMT machine. Proper feeder loading ensures that the machine can pick components accurately and efficiently during the assembly process. The significance of effective feeder loading includes:

- Minimizing Downtime: Properly loaded feeders reduce the time spent on reloading during production runs.

- Enhancing Accuracy: Accurate feeder loading ensures that the right components are picked at the right time, minimizing errors.

- Increasing Production Efficiency: Efficient feeder loading allows for smoother operations, leading to higher throughput.

Key Skills Required for SMT Line Operators

To train SMT line operators effectively, it is essential to focus on developing specific skills that contribute to successful feeder loading:

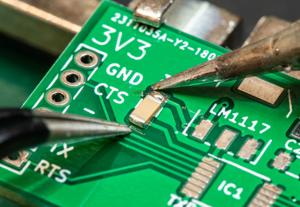

- Attention to Detail: Operators must be meticulous in checking component specifications and ensuring proper alignment.

- Technical Knowledge: Understanding how feeders work and their settings is crucial for troubleshooting issues.

- Problem-Solving Skills: Operators should be trained to identify and resolve common problems that may arise during feeder loading.

- Time Management: Efficiently managing time during feeder loading can significantly impact overall production schedules.

Training Techniques for Effective Feeder Loading

1. Hands-On Training

One of the most effective methods for training SMT line operators is through hands-on experience. This approach allows operators to practice loading feeders under supervision, enabling them to learn from mistakes in real-time. Key aspects include:

- Simulation Exercises: Use simulated environments where operators can practice without affecting actual production lines.

- Shadowing Experienced Operators: New operators can learn by observing skilled operators, gaining insights into best practices.

2. Standard Operating Procedures (SOPs)

Creating clear SOPs for feeder loading is essential for consistency and quality control. These documents should outline:

- Step-by-Step Instructions: Detailed procedures for each type of component and feeder.

- Safety Guidelines: Instructions on handling components safely to prevent damage or injury.

- Troubleshooting Tips: Common issues and their solutions to empower operators to act independently when problems arise.

3. Visual Aids and Checklists

Visual aids can enhance understanding and retention of training materials. Consider incorporating:

- Diagrams and Flowcharts: Visual representations of the feeder loading process can help clarify complex steps.

- Checklists: Providing checklists ensures that operators do not overlook critical steps during the loading process.

4. Continuous Assessment and Feedback

Regular assessments help gauge operator proficiency in feeder loading. Implementing feedback mechanisms allows trainers to identify areas needing improvement. Techniques include:

- Performance Metrics: Track key performance indicators such as loading time, error rates, and downtime associated with feeder issues.

- Feedback Sessions: Conduct regular meetings where operators can discuss challenges faced during feeding operations and share solutions.

5. Cross-Training Opportunities

Cross-training operators in various roles within the SMT line can enhance their overall understanding of the production process. Benefits include:

- Broader Skill Set: Operators become more versatile, allowing them to fill in for colleagues when necessary.

- Improved Teamwork: Understanding different roles fosters collaboration among team members, leading to a more cohesive work environment.

Implementing Technology in Training

Incorporating technology into training programs can enhance learning experiences for SMT line operators. Consider these technological tools:

1. E-Learning Platforms

Using e-learning platforms allows operators to access training materials anytime, anywhere. Benefits include:

- Flexible Learning Pace: Operators can learn at their own speed, revisiting complex topics as needed.

- Interactive Content: Incorporating quizzes and interactive modules keeps learners engaged and reinforces knowledge retention.

2. Virtual Reality (VR) Training

VR technology offers immersive training experiences that simulate real-world scenarios without risk. Advantages include:

- Realistic Practice Environment: Operators can practice feeder loading in a controlled setting that mimics actual conditions.

- Safe Learning Space: Mistakes made in VR do not have real-world consequences, encouraging experimentation and learning from errors.

Creating a Supportive Learning Environment

A supportive learning environment is crucial for effective training outcomes. Strategies include:

- Encouraging Open Communication: Foster an atmosphere where operators feel comfortable asking questions and sharing concerns about their training.

- Recognizing Achievements: Acknowledge progress and accomplishments in training, motivating operators to continue improving their skills.

Conclusion

Training SMT line operators for effective feeder loading is a multifaceted process requiring attention to detail, technical knowledge, and hands-on experience. By implementing various training techniques such as hands-on practice, SOPs, visual aids, continuous assessment, cross-training opportunities, and leveraging technology like e-learning platforms and VR training, organizations can enhance operator proficiency significantly.

Creating a supportive learning environment encourages open communication and recognizes achievements, ultimately leading to improved efficiency in SMT operations. As manufacturers strive for excellence in production processes, investing in comprehensive training programs will yield long-term benefits in quality output and operational efficiency.

FAQ

1. What are the common challenges faced during feeder loading?

Operators may encounter issues such as misalignment of components, incorrect reel placement, or mechanical failures within feeders. Regular training helps mitigate these challenges by equipping operators with troubleshooting skills.

2. How often should SMT line operators receive refresher training?

It is recommended that operators undergo refresher training at least once a year or whenever new equipment or procedures are introduced to ensure they remain updated on best practices.

3. What role does teamwork play in effective feeder loading?

Teamwork enhances communication among operators, allowing them to share insights on best practices and troubleshoot issues collaboratively, leading to improved overall efficiency on the production line.

4. Can technology replace traditional training methods?

While technology enhances training effectiveness through interactive learning experiences, it should complement traditional methods rather than replace them entirely; hands-on practice remains essential for skill development.

5. How do performance metrics influence operator training?

Performance metrics provide measurable data on operator efficiency and accuracy during feeder loading, allowing trainers to identify areas needing improvement and tailor training programs accordingly.