Content Menu

● Understanding SMT PCBA Production

● Key Strategies for Streamlining SMT Workflow

>> 1. Optimize Production Line Layout

>> 2. Invest in Advanced Technology

>> 3. Standardize Processes

>> 4. Lean Manufacturing Principles

>> 5. Effective Quality Control Measures

● Additional Techniques for Enhanced Efficiency

>> Component Sequencing

>> Feeder Management

>> Continuous Monitoring

>> Maintenance Practices

● Training for Excellence

● Embracing Automation

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How can automation improve SMT production efficiency?

>> 3. What role does training play in optimizing SMT workflows?

>> 4. What are lean manufacturing principles?

>> 5. Why is quality control important in SMT production?

● Citations:

In the fast-paced world of electronics manufacturing, optimizing the workflow in Surface Mount Technology (SMT) Printed Circuit Board Assembly (PCBA) production lines is crucial for enhancing efficiency, reducing costs, and maintaining high-quality standards. This article explores various strategies and best practices to streamline workflows in SMT production, ensuring that manufacturers can meet the increasing demands of the market while minimizing waste and maximizing productivity.

Understanding SMT PCBA Production

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). The SMT process involves several key stages:

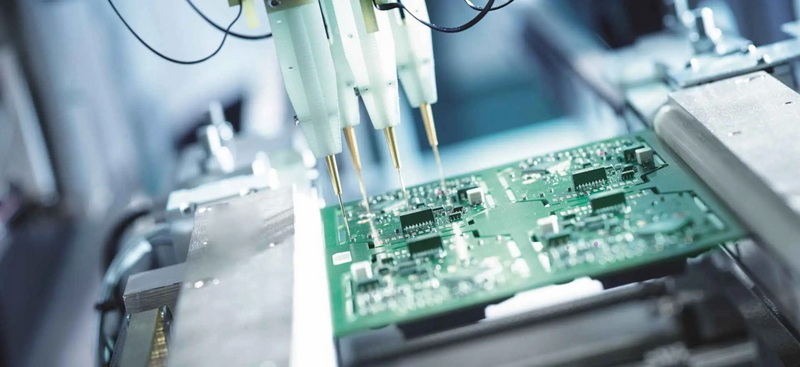

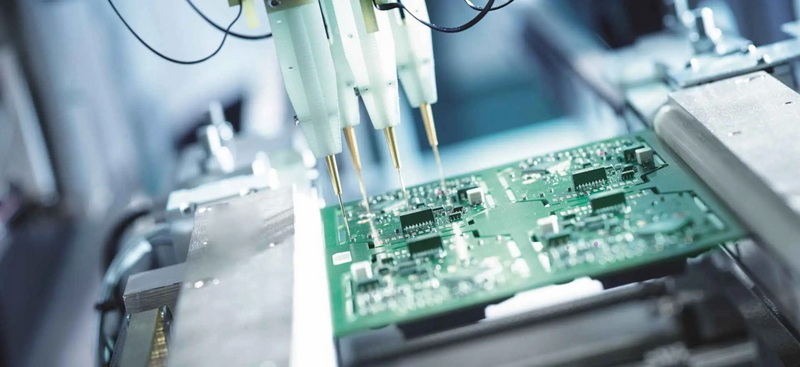

- Solder Paste Printing: Applying solder paste to the PCB using a stencil.

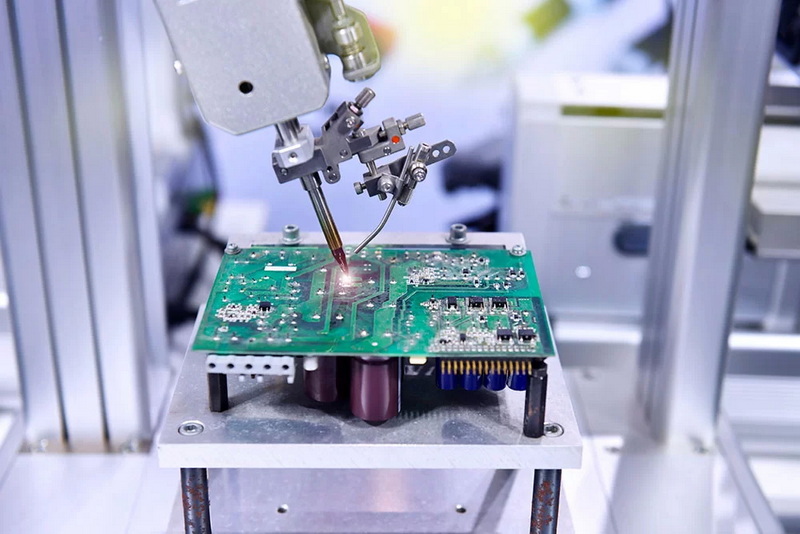

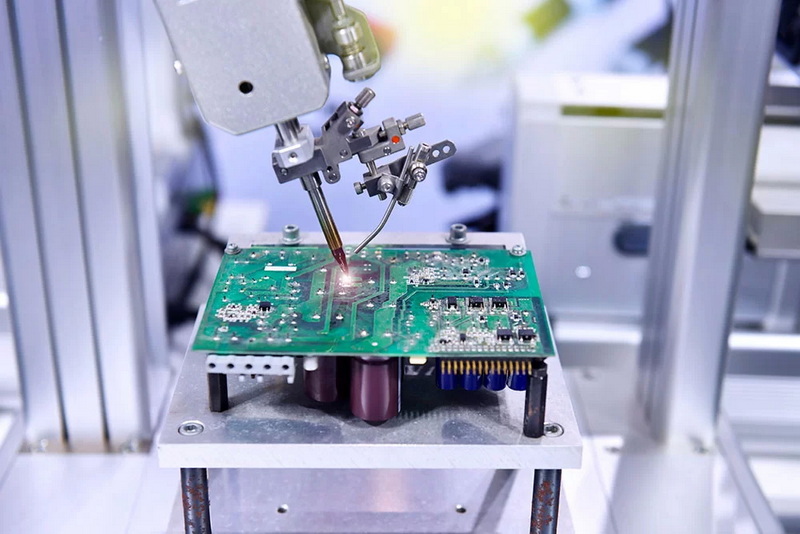

- Component Placement: Using pick-and-place machines to position components accurately on the PCB.

- Reflow Soldering: Heating the PCB to melt the solder paste, creating electrical connections.

- Inspection: Conducting quality checks to ensure components are correctly placed and soldered.

The efficiency of each stage directly impacts the overall productivity of the SMT production line. Therefore, streamlining these processes is essential.

Key Strategies for Streamlining SMT Workflow

1. Optimize Production Line Layout

A well-organized production line layout minimizes unnecessary movements and reduces cycle times. Key considerations include:

- Flow Design: Arrange equipment in a linear flow from solder paste application to inspection. This reduces backtracking and material handling.

- Workstation Design: Ensure that each workstation is equipped with necessary tools and materials to minimize downtime during transitions between tasks.

- Material Handling Systems: Implement automated guided vehicles (AGVs) or conveyor systems to transport materials efficiently between workstations.

2. Invest in Advanced Technology

Upgrading machinery and utilizing advanced technologies can significantly enhance production efficiency:

- High-Speed Placement Machines: Invest in state-of-the-art pick-and-place machines that can handle multiple component types at high speeds, reducing placement time.

- Automated Inspection Systems: Implement inline inspection systems such as Automated Optical Inspection (AOI) to detect defects early in the process, minimizing rework costs.

- Data Analytics Tools: Use software solutions that provide real-time data on production metrics, enabling quick adjustments and informed decision-making.

3. Standardize Processes

Standardizing operating procedures ensures consistency across production lines:

- Develop Standard Operating Procedures (SOPs): Create detailed documentation for each stage of the SMT process, including setup instructions, quality checkpoints, and troubleshooting guides.

- Training Programs: Regularly train operators on SOPs and best practices to ensure everyone is aligned with production goals and quality standards.

4. Lean Manufacturing Principles

Implementing lean manufacturing principles can help eliminate waste and improve efficiency:

- Value Stream Mapping: Analyze each step of the production process to identify bottlenecks and areas for improvement.

- Continuous Improvement (Kaizen): Foster a culture where employees are encouraged to suggest improvements regularly, leading to incremental enhancements over time.

- Just-In-Time (JIT) Inventory: Reduce excess inventory by synchronizing material delivery with production schedules, minimizing storage costs and waste.

5. Effective Quality Control Measures

Quality control is integral to maintaining high standards in SMT production:

- Inline Quality Checks: Conduct inspections at various stages of production rather than only at the end. This helps catch defects early when they are easier and cheaper to fix.

- Statistical Process Control (SPC): Utilize statistical methods to monitor and control processes, ensuring consistent quality output.

Additional Techniques for Enhanced Efficiency

Component Sequencing

Proper sequencing of components can lead to significant improvements in efficiency. By arranging components in the order they will be placed on the PCB, manufacturers can reduce machine setup time and improve overall throughput. This approach minimizes idle time during component placement and enhances workflow continuity[1].

Feeder Management

Maintaining well-organized feeders is vital for minimizing changeover time and preventing component shortages. Regularly checking feeder status ensures that components are readily available when needed, reducing delays during production runs[1][2].

Continuous Monitoring

Implementing real-time monitoring systems allows manufacturers to identify bottlenecks as they occur. Data analytics can provide insights into process performance, enabling quick adjustments that enhance overall efficiency[2][3].

Maintenance Practices

Regular maintenance of machinery is critical for ensuring high availability and reliability on the production line. Establishing a preventive maintenance schedule can minimize unexpected breakdowns and downtime, ultimately boosting productivity[4][6].

Training for Excellence

A well-trained workforce is essential for optimizing SMT workflows. Continuous training programs should focus on:

- Equipment operation

- Troubleshooting techniques

- Quality assurance practices

By investing in employee development, manufacturers can enhance operational efficiency and reduce error rates[2][5].

Embracing Automation

Automation plays a pivotal role in streamlining SMT processes. Key areas where automation can be beneficial include:

- Solder Paste Application: Automated solder paste printers ensure consistent application thickness, reducing defects during reflow soldering.

- Component Placement: Automated pick-and-place machines increase speed and accuracy compared to manual operations.

- Inspection Systems: Automated optical inspection systems can quickly identify defects without slowing down production lines[4][8].

Conclusion

Streamlining workflow in an SMT PCBA production line requires a multifaceted approach that encompasses optimizing layout, investing in advanced technology, standardizing processes, applying lean manufacturing principles, implementing effective quality control measures, managing feeders efficiently, maintaining equipment rigorously, training employees thoroughly, and embracing automation wherever possible. By focusing on these strategies, manufacturers can enhance productivity, reduce costs, and maintain high-quality standards in their electronic assembly processes. As technology continues to evolve, staying adaptable and open to new methodologies will be key for success in this competitive industry.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs and higher assembly speeds compared to traditional through-hole methods.

2. How can automation improve SMT production efficiency?

Automation improves SMT production efficiency by reducing manual labor, minimizing human error, increasing speed through high-speed machines, and providing consistent quality through automated inspection systems.

3. What role does training play in optimizing SMT workflows?

Training ensures that operators are skilled in using equipment correctly, following standardized procedures, and identifying potential issues early in the process, which collectively enhances overall productivity and quality.

4. What are lean manufacturing principles?

Lean manufacturing principles focus on eliminating waste within manufacturing processes while maximizing productivity. This includes techniques such as value stream mapping, continuous improvement (Kaizen), and just-in-time inventory management.

5. Why is quality control important in SMT production?

Quality control is crucial in SMT production because it ensures that defects are identified and corrected early in the process, reducing rework costs and ensuring that final products meet required specifications for reliability and performance.

Citations:

[1] https://txjpcb.com/the-best-practices-for-smt-line-balancing-and-optimization/

[2] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[3] https://blogs.sw.siemens.com/valor/2021/08/02/is-new-infrastructure-the-only-way-to-improve-shop-floor-productivity/

[4] https://www.smtneoden.com/news/how-to-effectively-improve-the-production-efficiency-of-pcb-smt-machine/

[5] https://www.electronicspecifier.com/news/surface-mount-technology-best-practice-guide

[6] https://www.neodensmt.com/news/improve-smt-production-efficiency-48868013.html

[7] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[8] https://jhdpcb.com/blog/efficient-smt-assembly/

[9] https://www.raypcb.com/line-efficiency/

[10] https://www.raypcb.com/smt-assembly-process-optimization-by-multi-head-gantry-type-chip-mounter/

[11] https://pcbtrace.com/techniques-to-streamline-and-optimize-pcb-assembly/

[12] https://asselems.com/en/best-practices-in-smt-assembly

[13] https://www.smthelp.com/methods-and-measures-to-improve-the-production-efficiency-of-smt-production-line

[14] https://cogiscan.com/cycle-time-optimization-pcba-manufacturing

[15] https://www.linkedin.com/pulse/rapid-smt-assembly-improving-efficiency-surface-oerzc

[16] https://smtnet.com/news/index.cfm?fuseaction=view_news&company_id=58069&news_id=30605

[17] https://www.andwinpcb.com/efficient-strategies-for-smt-board-assembly-in-electronics-production/

[18] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[19] https://www.linkedin.com/pulse/how-improve-smt-production-efficiency-