Content Menu

● Introduction

● Tools and Materials Needed

● Step-by-Step Soldering Process

>> Step 1: Preparation

>> Step 2: Applying Solder Paste

>> Step 3: Placing Components

>> Step 4: Soldering

>> Step 5: Inspection and Rework

>> Step 6: Cleaning Up

>> Step 7: Testing

● Tips for Successful Soldering

● Conclusion

● FAQ

>> 1. What are SMT components?

>> 2. Why is precision important in soldering SMT components?

>> 3. What tools are essential for soldering SMT components?

>> 4. How can I improve my soldering skills?

>> 5. What are common mistakes to avoid when soldering SMT components?

Introduction

Surface Mount Technology (SMT) components are essential in modern electronics, enabling the production of smaller, lighter, and more efficient devices. The advantages of SMT include reduced size, improved performance, and lower manufacturing costs. However, soldering these small components presents unique challenges due to their tiny dimensions and the dense layouts on printed circuit boards (PCBs). This article serves as a comprehensive guide on how to solder small SMT components with precision, ensuring reliable electronic assemblies.

Tools and Materials Needed

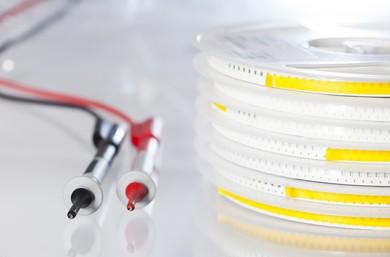

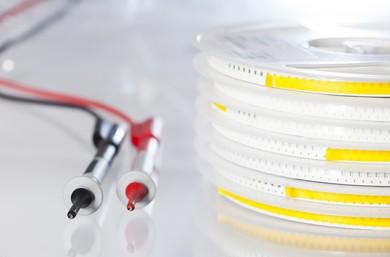

To effectively solder SMT components, it is crucial to have the right tools and materials. Below is a list of essential items for precise soldering:

- Soldering iron with a fine tip: A fine tip allows for precise application of heat to small areas.

- High-quality solder (lead-free): Lead-free solder is commonly used in modern electronics for environmental safety.

- Flux: This substance helps clean and prepare surfaces for soldering, improving adhesion.

- Solder wick or solder vacuum: These tools are useful for removing excess solder or correcting mistakes.

- Tweezers: Essential for handling and positioning small components accurately.

- ESD protection: Electrostatic discharge protection prevents damage to sensitive electronic components.

- Magnification tools: Tools such as magnifying glasses or microscopes aid in seeing small details clearly, enhancing precision.

- PCB holder or vise: A stable holder keeps the PCB secure while you work, allowing for more accurate soldering.

- Cleaning tools: Isopropyl alcohol and lint-free wipes are used to clean the PCB before and after soldering.

Step-by-Step Soldering Process

Step 1: Preparation

Preparation is key to successful soldering. Begin by organizing your workspace and gathering all necessary tools and materials. Ensure that both the PCB and components are clean to prevent contamination that could negatively impact the quality of your solder joints.

Cleaning can be done using isopropyl alcohol on a lint-free cloth. This step removes any oils or residues that may interfere with the soldering process.

Step 2: Applying Solder Paste

Applying solder paste accurately is crucial for creating good solder joints. You can use a stencil or syringe to apply the paste to the PCB pads. Make sure the paste is evenly distributed and adequately covers all necessary areas. This step is vital as it provides a solid foundation for the components.

If using a stencil, align it carefully with the PCB pads before applying the paste. Use a squeegee to spread the paste evenly across the stencil openings. For syringe application, ensure that you apply just enough paste without overfilling.

Step 3: Placing Components

Using tweezers and magnification tools, carefully place the SMT components onto the pads covered with solder paste. Precision is vital; each component must be correctly aligned with its corresponding pads to ensure proper functioning.

For very small components, consider using a vacuum pick-up tool, which can help position them accurately without applying excessive pressure that might damage them.

Step 4: Soldering

With your soldering iron ready, apply heat to both the pads and the component leads. The solder paste will melt and create a bond between the component and the PCB. It's important to avoid overheating, as this can damage sensitive components.

Common mistakes during this step include:

- Using too much solder, which can lead to bridging between pads.

- Applying heat for too long, resulting in cold joints or damaged components.

To achieve optimal results, follow these tips:

- Apply a small amount of solder directly onto the tip of the iron before touching it to the joint.

- Use a gentle motion when applying heat to avoid disturbing the component's position.

Step 5: Inspection and Rework

After soldering, inspect each joint carefully. Good solder joints should appear smooth and shiny. If you notice any issues like cold joints or bridges between connections, rework may be necessary. Use solder wick or a vacuum tool to remove excess solder and reapply heat as needed for correction.

It's also beneficial to use magnification during inspection to ensure every joint meets quality standards. If you find any defects, don't hesitate to rework them immediately; addressing issues early prevents future problems in device performance.

Step 6: Cleaning Up

Once all components are successfully soldered and inspected, it's time to clean up any residual flux from the PCB. Flux residues can attract moisture and dust over time, potentially leading to corrosion or short circuits. Use isopropyl alcohol along with a brush or lint-free wipes to remove any remaining flux from the board surface thoroughly.

Step 7: Testing

After cleaning, it's crucial to test your assembly before deployment. Use a multimeter to check continuity across connections and ensure that there are no short circuits between adjacent pads. If possible, run functional tests on your device to confirm that all components are working correctly.

Tips for Successful Soldering

To further enhance your skills in soldering SMT components with precision, consider these additional tips:

- Practice Regularly: Like any skill, practice makes perfect. Start with simpler projects before moving on to more complex assemblies involving smaller components.

- Use Proper Lighting: Good lighting helps you see details better when working on small parts.

- Stay Patient: Rushing through tasks can lead to mistakes. Take your time with each step.

- Learn from Mistakes: Each error presents an opportunity for learning; analyze what went wrong and adjust your technique accordingly.

- Stay Updated on Techniques: The field of electronics is always evolving; keep learning about new techniques and tools that can improve your work.

Conclusion

Precision in soldering small SMT components is essential for ensuring the reliability and functionality of electronic devices. By following the steps outlined in this guide and utilizing the appropriate tools, you can achieve high-quality solder joints that meet professional standards. Mastery of this skill requires practice and patience; with time, you will become proficient in soldering even the smallest components.

Investing time in learning proper techniques not only enhances your skills but also contributes significantly to producing high-quality electronic products that perform reliably over time.

FAQ

1. What are SMT components?

Surface Mount Technology (SMT) components are electronic parts designed to be mounted directly onto the surface of PCBs. They are smaller than traditional through-hole components, allowing for more compact designs in modern electronics.

2. Why is precision important in soldering SMT components?

Precision is critical because SMT components are tiny and densely packed on PCBs. Accurate soldering ensures that each component functions correctly without interference from adjacent parts, maintaining overall device reliability.

3. What tools are essential for soldering SMT components?

Essential tools include:

- A fine-tipped soldering iron

- High-quality lead-free solder

- Flux

- Tweezers

- ESD protection gear

- Magnification tools

- PCB holder or vise

- Cleaning tools

These tools help achieve precision in your work.

4. How can I improve my soldering skills?

Improving your skills requires practice and patience. Start with larger SMT components before progressing to smaller ones. Utilize online resources like tutorials and practice kits specifically designed for honing your skills.

5. What are common mistakes to avoid when soldering SMT components?

Common pitfalls include:

- Using excessive amounts of solder

- Overheating components

- Misaligning parts during placement

By practicing good techniques and using appropriate tools, you can avoid these mistakes.