Content Menu

● Introduction

● Understanding SMT Production Lines

>> What is an SMT Production Line?

>> Key Components of an SMT Line

● Planning and Preparation

>> Assessing Production Requirements

>> Selecting the Right Equipment

● Setting Up the SMT Line

>> Designing the Layout

>> Installation and Configuration

● Operating the SMT Line

>> Step-by-Step Process

>> Quality Control Measures

● Advanced Techniques in SMT Production

>> Lean Manufacturing Principles

>> Automation Integration

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. What are the main advantages of using an SMT production line?

>> 3. How do I choose the right pick-and-place machine?

>> 4. What role does inspection play in an SMT line?

>> 5. How can I improve efficiency in my SMT production line?

Introduction

Setting up and operating a full automatic Surface Mount Technology (SMT) production line is a complex yet rewarding endeavor in the electronics manufacturing industry. This article will guide you through the essential steps required to establish an efficient SMT line, from planning and equipment selection to operational best practices. By understanding the intricacies involved, manufacturers can optimize their production processes, improve product quality, and enhance overall efficiency.

Understanding SMT Production Lines

What is an SMT Production Line?

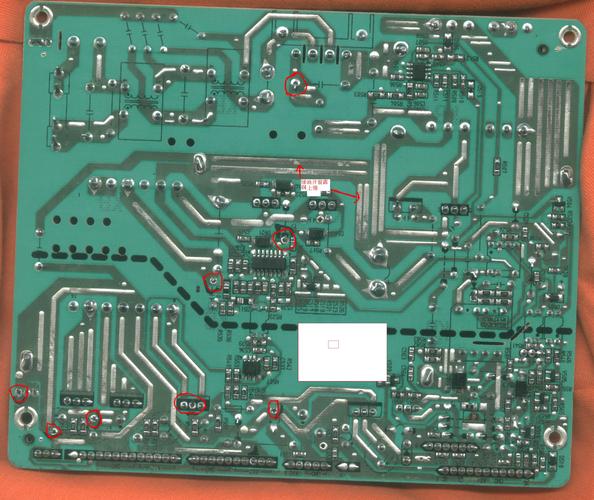

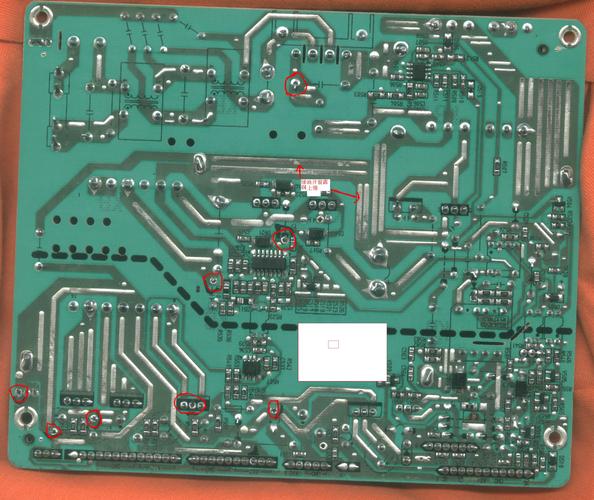

An SMT production line is a fully automated system designed to assemble surface mount devices (SMDs) onto printed circuit boards (PCBs). This method of assembly has become the standard in modern electronics manufacturing due to its efficiency and ability to accommodate high-density designs. The SMT process allows for greater flexibility in design, enabling manufacturers to create smaller, lighter, and more complex electronic devices.

Key Components of an SMT Line

1. Solder Paste Printer: Applies solder paste onto the PCB pads with precision. This step is crucial as it determines the quality of solder joints.

2. Pick-and-Place Machine: Accurately places electronic components onto the soldered pads. These machines are equipped with advanced vision systems that ensure correct placement.

3. Reflow Oven: Melts solder paste to create permanent connections between components and PCBs. The reflow process must be carefully controlled to prevent defects such as cold solder joints.

4. Conveyor System: Moves PCBs through various stages of production, ensuring a smooth workflow and minimizing handling.

5. Inspection Systems: Ensures quality control at different stages of assembly, including Automated Optical Inspection (AOI) and X-ray inspection for hidden solder joints.

Planning and Preparation

Assessing Production Requirements

Before setting up an SMT line, it is crucial to assess your production needs. Consider factors such as:

- Production Volume: Determine how many units you need to produce within a specific timeframe. High-volume production may necessitate more advanced machinery capable of faster processing speeds.

- Component Types: Identify the types of SMDs you will be using, as different components may require specialized handling or specific placement techniques.

- Assembly Complexity: Analyze the complexity of your assemblies, which will influence equipment selection and layout design. Complex assemblies may require additional inspection processes or specialized placement machines.

Selecting the Right Equipment

Choosing appropriate equipment is vital for optimizing production efficiency. Key equipment includes:

- Stencil Printer: For applying solder paste accurately. The printer should be compatible with various stencil designs to accommodate different PCB layouts.

- Pick-and-Place Machines: Automated machines that handle various component sizes and types. Consider machines with multiple heads for higher throughput.

- Reflow Ovens: Essential for soldering components onto boards. Select ovens that provide precise temperature control and have multiple heating zones for optimal results.

- Inspection Systems: Automated Optical Inspection (AOI) machines help identify defects early in the process, while X-ray systems can inspect hidden solder joints.

Setting Up the SMT Line

Designing the Layout

The layout of your SMT line should maximize efficiency while minimizing bottlenecks. Considerations include:

- Flow of Materials: Arrange machines in a logical sequence based on the production process. A linear flow from printing to placement to reflow will streamline operations.

- Space Requirements: Ensure adequate spacing between machines for maintenance and troubleshooting. This will facilitate quick access during repairs or adjustments without disrupting the entire line.

Installation and Configuration

Once the layout is designed, proceed with installing and configuring the equipment:

1. Install Equipment: Follow manufacturer instructions for each piece of equipment, ensuring all connections are secure and properly calibrated.

2. Software Configuration: Most modern SMT machines come with sophisticated software that controls various aspects of production. Configure settings to match your specific requirements, including component libraries, placement coordinates, and reflow profiles.

3. Training Operators: Provide comprehensive training for operators on each machine's functionality and maintenance procedures to ensure smooth operations from day one.

Operating the SMT Line

Step-by-Step Process

The typical operation of an SMT line involves several key steps:

1. Solder Paste Printing:

- The PCB passes through a stencil printer where solder paste is applied to designated pads. The thickness and uniformity of the paste are critical for achieving reliable solder joints.

2. Component Placement:

- The pick-and-place machine picks components from feeders and places them accurately on the PCB. Advanced machines can handle multiple component types simultaneously, increasing throughput.

3. Reflow Soldering:

- The populated board enters a reflow oven where solder paste is melted to form reliable electrical connections. The reflow profile must be carefully monitored to prevent overheating or insufficient melting.

4. Inspection:

- Automated inspection systems check for defects in solder joints and component placement. Early detection of issues can save time and resources by preventing defective boards from moving further down the line.

5. Final Testing:

- After assembly, functional testing ensures that all components operate correctly under specified conditions. This step is crucial for verifying that the assembled product meets quality standards before delivery.

Quality Control Measures

Implementing quality control measures at each stage of production is essential for maintaining high standards:

- Conduct regular inspections using AOI systems at multiple points in the assembly process.

- Perform functional tests on completed assemblies using automated test equipment (ATE) to ensure all components function as intended.

- Keep detailed records of production metrics for continuous improvement initiatives, tracking defect rates, yield percentages, and operator performance.

Advanced Techniques in SMT Production

Lean Manufacturing Principles

Incorporating lean manufacturing principles can significantly enhance efficiency in your SMT production line:

- Value Stream Mapping: Analyze each step in your process to identify wasteful activities that do not add value.

- Just-In-Time (JIT) Production: Implement JIT strategies to reduce inventory costs and improve cash flow by producing only what is needed when it is needed.

- Continuous Improvement (Kaizen): Foster a culture of continuous improvement where employees are encouraged to suggest enhancements in processes or workflows.

Automation Integration

Integrating automation throughout your SMT line can lead to significant productivity gains:

- Utilize robotics for material handling tasks such as loading/unloading PCBs from conveyors or moving components between stations.

- Implement Industry 4.0 technologies like IoT sensors to monitor machine performance in real-time, allowing for predictive maintenance and reducing downtime.

- Use data analytics tools to analyze production data, identifying trends that can inform decision-making and process improvements.

Conclusion

Setting up and operating a full automatic SMT production line requires careful planning, selection of appropriate equipment, and adherence to best practices in manufacturing processes. By understanding each step involved—from assessing production needs to implementing quality control measures—manufacturers can achieve efficient operations that meet market demands while ensuring product reliability.

As technology continues to evolve, staying abreast of advancements in SMT processes will be key in maintaining competitiveness within the industry. Embracing automation, lean principles, and continuous improvement will not only streamline operations but also enhance product quality and customer satisfaction.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used for mounting electronic components directly onto the surface of PCBs, allowing for more compact designs compared to traditional through-hole technology.

2. What are the main advantages of using an SMT production line?

The main advantages include higher assembly speeds, reduced manufacturing costs, smaller PCB sizes, improved performance due to shorter electrical paths, and enhanced design flexibility.

3. How do I choose the right pick-and-place machine?

Consider factors such as component size range, speed (placements per hour), accuracy, flexibility with different component types, ease of programming, and compatibility with your existing equipment when selecting a pick-and-place machine.

4. What role does inspection play in an SMT line?

Inspection ensures that any defects in solder joints or component placements are identified early in the process, minimizing rework costs and improving overall product quality through systematic checks at critical stages.

5. How can I improve efficiency in my SMT production line?

Regular maintenance of equipment, continuous training for operators on best practices, implementing lean manufacturing techniques like value stream mapping or JIT production strategies can significantly enhance efficiency in your SMT production line.