Content Menu

● Introduction

● Understanding the PCB SMT Stencil Screen Printer

>> Key Components

>> Function

● Setting Up the PCB SMT Stencil Screen Printer

>> 1. Printer Placement and Leveling

>> 2. Power and Pneumatic Connections

>> 3. Stencil Installation

>> 4. PCB Support Setup

>> 5. Squeegee Preparation

>> 6. Solder Paste Preparation

● Calibrating the PCB SMT Stencil Screen Printer

>> 1. Alignment Calibration

>> 2. Print Gap Adjustment

>> 3. Squeegee Pressure Calibration

>> 4. Print Speed Optimization

>> 5. Separation Speed Adjustment

● Fine-tuning the Printing Process

>> 1. Solder Paste Consistency

>> 2. Stencil Cleaning Frequency

>> 3. Environmental Control

>> 4. Regular Inspection

● Troubleshooting Common Issues

>> 1. Insufficient Solder Paste Deposit

>> 2. Solder Paste Smearing

>> 3. Poor Alignment

>> 4. Incomplete Aperture Filling

>> 5. Bridging Between Pads

● Advanced Techniques for Optimal Performance

>> 1. Stencil Nanocoating

>> 2. Enclosed Print Head

>> 3. Automatic Paste Dispensing

>> 4. Vision-assisted Alignment

>> 5. Data-driven Process Control

● Maintaining Your PCB SMT Stencil Screen Printer

● Conclusion

● FAQ

>> 1. How often should I clean the stencil during a production run?

>> 2. What is the ideal room temperature and humidity for PCB SMT stencil printing?

>> 3. How do I determine the correct stencil thickness for my PCB?

>> 4. What should I do if I notice uneven solder paste deposits across the PCB?

>> 5. How can I improve the printing process for BGAs and other area array packages?

● Citations:

Introduction

In the world of electronics manufacturing, precision and efficiency are paramount. One crucial step in the production of printed circuit boards (PCBs) is the application of solder paste using a stencil screen printer. This process, integral to surface mount technology (SMT), ensures accurate placement of solder paste on PCB pads, facilitating proper component attachment during reflow soldering. This comprehensive guide will walk you through the essential steps of setting up and calibrating a PCB SMT stencil screen printer, helping you achieve optimal results in your PCB assembly process.

Understanding the PCB SMT Stencil Screen Printer

Before diving into the setup and calibration process, it's important to understand the key components and functions of a PCB SMT stencil screen printer.

Key Components

1. Stencil Frame: Holds the metal stencil in place during the printing process.

2. PCB Support System: Provides a stable platform for the PCB during printing.

3. Alignment System: Ensures precise alignment between the stencil and the PCB.

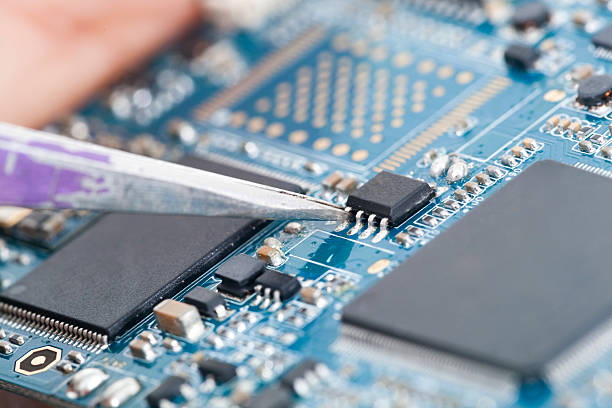

4. Squeegee Assembly: Applies pressure to spread solder paste across the stencil.

5. Paste Dispenser: Delivers solder paste onto the stencil.

6. Control Panel: Allows adjustment of various printing parameters.

Function

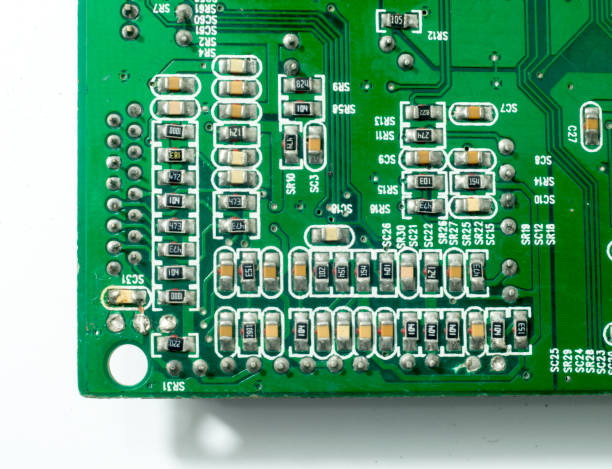

The primary function of a PCB SMT stencil screen printer is to deposit a precise amount of solder paste onto specific areas of a PCB. This is achieved by aligning a metal stencil with pre-cut apertures over the PCB and using a squeegee to force solder paste through these openings onto the board's surface[1].

Setting Up the PCB SMT Stencil Screen Printer

1. Printer Placement and Leveling

Begin by placing the printer on a stable, level surface. Use a spirit level to ensure the printer is perfectly horizontal. Adjust the printer's feet if necessary to achieve proper leveling.

2. Power and Pneumatic Connections

Connect the printer to a suitable power source and compressed air supply. Ensure that the air pressure meets the manufacturer's specifications, typically between 5-7 kg/cm²[2].

3. Stencil Installation

Carefully mount the stencil onto the stencil frame. Ensure it's taut and free from wrinkles or deformations. Proper tension in the stencil is crucial for achieving consistent print quality.

4. PCB Support Setup

Configure the PCB support system according to your board's dimensions. Many printers use adjustable pins or a dedicated tooling plate. Ensure that the support provides adequate stability to prevent board flexing during printing[1].

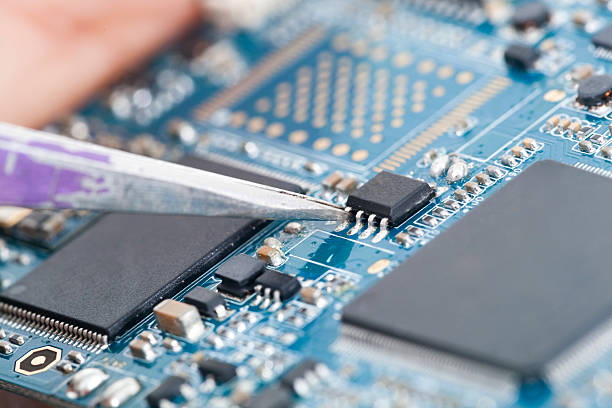

5. Squeegee Preparation

Install the squeegee blades, ensuring they're clean and undamaged. Set the initial squeegee pressure based on the manufacturer's recommendations or your previous experience with similar boards.

6. Solder Paste Preparation

Prepare the solder paste according to the manufacturer's instructions. This typically involves allowing it to reach room temperature and mixing it thoroughly to ensure consistent viscosity.

Calibrating the PCB SMT Stencil Screen Printer

Proper calibration is crucial for achieving high-quality prints. Follow these steps to calibrate your printer:

1. Alignment Calibration

1. Load a test PCB onto the support system.

2. Lower the stencil to the printing position.

3. Use the printer's alignment controls to adjust the X, Y, and θ (rotation) axes.

4. Aim for perfect alignment between the stencil apertures and PCB pads[1].

2. Print Gap Adjustment

1. Set the initial print gap (distance between stencil and PCB) to the manufacturer's recommended value.

2. Perform a test print and inspect the results.

3. Adjust the gap as needed. A smaller gap generally results in better paste transfer but may increase the risk of smearing.

3. Squeegee Pressure Calibration

1. Start with the manufacturer's recommended pressure setting.

2. Perform test prints, gradually adjusting the pressure.

3. Aim for complete clearing of paste from the stencil surface without excessive force that could damage the stencil or PCB.

4. Print Speed Optimization

1. Begin with a moderate print speed.

2. Conduct test prints, adjusting the speed incrementally.

3. Find the optimal speed that allows for complete paste transfer without smearing or incomplete filling of apertures.

5. Separation Speed Adjustment

1. Set the initial separation speed (the speed at which the stencil lifts off the PCB after printing).

2. Perform test prints and inspect the solder paste deposits.

3. Adjust the speed to achieve clean separation without disturbing the paste deposits.

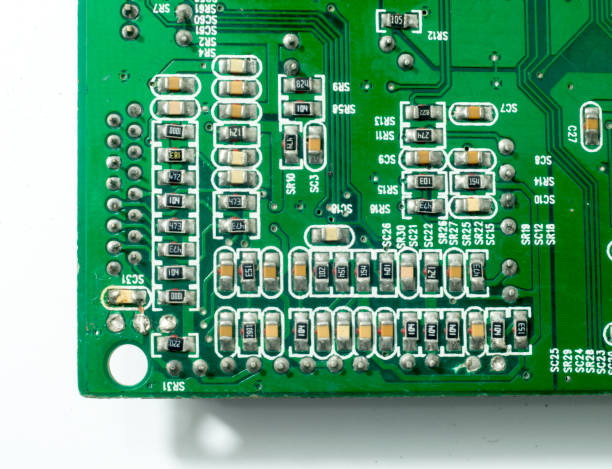

Fine-tuning the Printing Process

After initial calibration, focus on fine-tuning the process for optimal results:

1. Solder Paste Consistency

Monitor the solder paste consistency throughout the printing process. If it becomes too dry or tacky, replace it with fresh paste to maintain print quality.

2. Stencil Cleaning Frequency

Determine the optimal frequency for cleaning the stencil. This will depend on factors such as paste properties, aperture size, and environmental conditions. Regular cleaning helps maintain print quality and prevents defects[3].

3. Environmental Control

Maintain a consistent temperature and humidity in the printing area. Fluctuations can affect solder paste properties and print quality. Consider using a temperature control module if necessary[3].

4. Regular Inspection

Implement a regular inspection routine to catch any issues early. This may include visual inspection of prints, periodic measurement of paste deposits, and checking for any wear or damage to printer components.

Troubleshooting Common Issues

Even with careful setup and calibration, issues may arise. Here are some common problems and their potential solutions:

1. Insufficient Solder Paste Deposit

- Cause: Inadequate squeegee pressure, high print speed, or clogged stencil apertures.

- Solution: Increase squeegee pressure, reduce print speed, or clean the stencil thoroughly[3].

2. Solder Paste Smearing

- Cause: Excessive squeegee pressure, low print speed, or improper separation speed.

- Solution: Reduce squeegee pressure, increase print speed, or adjust separation speed[3].

3. Poor Alignment

- Cause: Improper calibration or PCB warpage.

- Solution: Recalibrate the alignment system or improve PCB support[1].

4. Incomplete Aperture Filling

- Cause: Insufficient paste viscosity, high print speed, or improper squeegee angle.

- Solution: Check paste condition, reduce print speed, or adjust squeegee angle[3].

5. Bridging Between Pads

- Cause: Excessive paste deposit, improper stencil design, or PCB warpage.

- Solution: Adjust print parameters, review stencil design, or improve PCB support[3].

Advanced Techniques for Optimal Performance

To further enhance your PCB SMT stencil screen printing process, consider implementing these advanced techniques:

1. Stencil Nanocoating

Apply a nanocoating to the stencil surface to improve paste release and reduce the need for frequent cleaning. This can lead to more consistent print quality and increased productivity.

2. Enclosed Print Head

Use an enclosed print head system to maintain consistent paste properties throughout the printing process. This can help prevent premature drying of the paste and ensure uniform deposition.

3. Automatic Paste Dispensing

Implement an automatic paste dispensing system to ensure consistent paste volume on the stencil. This can help maintain print quality over long production runs.

4. Vision-assisted Alignment

Utilize a vision system for precise alignment of the stencil and PCB. This can significantly improve accuracy, especially for high-density boards with fine-pitch components.

5. Data-driven Process Control

Implement a system for collecting and analyzing print data. This can help identify trends, optimize parameters, and predict maintenance needs before issues arise.

Maintaining Your PCB SMT Stencil Screen Printer

Regular maintenance is crucial for ensuring consistent performance and longevity of your printer. Develop a maintenance schedule that includes:

1. Daily cleaning of stencils, squeegees, and paste dispensing components.

2. Weekly inspection of alignment systems and PCB support mechanisms.

3. Monthly lubrication of moving parts and calibration checks.

4. Quarterly thorough cleaning and inspection of all printer components.

Keep detailed maintenance logs and track any issues or adjustments made. This information can be invaluable for troubleshooting and process optimization.

Conclusion

Setting up and calibrating a PCB SMT stencil screen printer is a critical process that requires attention to detail and a systematic approach. By following the steps outlined in this guide, you can achieve optimal print quality, minimize defects, and improve the overall efficiency of your PCB assembly process. Remember that calibration is an ongoing process, and regular fine-tuning based on print results and changing conditions is key to maintaining high-quality output.

As technology continues to advance and component sizes decrease, the importance of precise solder paste application becomes even more critical. Stay informed about new developments in stencil technology, printing techniques, and solder paste formulations to ensure your process remains at the cutting edge of PCB assembly.

FAQ

1. How often should I clean the stencil during a production run?

The frequency of stencil cleaning depends on several factors, including the type of solder paste used, the size of the apertures, and the environmental conditions. As a general rule, you should clean the stencil:

- Every 5-10 prints for fine-pitch components

- Every 15-20 prints for standard components

- Whenever you notice a decline in print quality or incomplete aperture filling

Always follow the recommendations provided by your stencil and solder paste manufacturers for best results.

2. What is the ideal room temperature and humidity for PCB SMT stencil printing?

Maintaining proper environmental conditions is crucial for consistent print quality. The ideal conditions are:

- Temperature: 20-25°C (68-77°F)

- Relative Humidity: 40-60%

These conditions help maintain the proper viscosity of the solder paste and prevent issues like premature drying or excessive moisture absorption. Consider using environmental control systems in your production area to maintain these conditions consistently.

3. How do I determine the correct stencil thickness for my PCB?

Selecting the appropriate stencil thickness is critical for achieving the right amount of solder paste deposit. The general guidelines are:

- For components with a pitch of 0.5mm or larger: Use a stencil thickness of 0.127mm (5 mil)

- For components with a pitch between 0.4mm and 0.5mm: Use a stencil thickness of 0.1mm (4 mil)

- For ultra-fine pitch components (less than 0.4mm pitch): Consider using a step stencil with reduced thickness in fine-pitch areas

Always consider the specific requirements of your components and consult with your stencil manufacturer for optimal thickness recommendations.

4. What should I do if I notice uneven solder paste deposits across the PCB?

Uneven solder paste deposits can be caused by several factors. Here are some troubleshooting steps:

1. Check the levelness of the printer and PCB support system

2. Inspect the stencil for damage or warping

3. Verify that the squeegee pressure is uniform across the entire print stroke

4. Ensure that the PCB is properly supported and not flexing during printing

5. Check for any obstructions or debris on the stencil or PCB surface

If the issue persists, you may need to adjust your print parameters or consider using a tensioned stencil system for improved uniformity.

5. How can I improve the printing process for BGAs and other area array packages?

Printing solder paste for BGAs and other area array packages can be challenging. Here are some tips to improve the process:

1. Use a nano-coated stencil to improve paste release for small apertures

2. Consider using a step stencil with reduced thickness in the BGA area

3. Implement slow print speed and higher squeegee pressure for better aperture filling

4. Use an enclosed print head to maintain consistent paste properties

5. Implement vision-assisted alignment for precise stencil-to-board registration

Additionally, consider using solder paste with fine particle size (Type 4 or Type 5) for improved printing performance with small apertures.

Citations:

[1] https://tecan.co.uk/printing-parameters-and-smt-stencils/

[2] https://www.smtmax.com/pdf/AE-3090D.pdf

[3] https://www.youtube.com/watch?v=sH7_QCVIJzI

[4] https://www.elecrow.com/blog/what-is-a-pcb-stencil-and-how-to-use-it.html

[5] https://www.aimsolder.com/technical-center/solder-paste-print-setting-recommendations/

[6] https://www.youtube.com/watch?v=_sDVc2kfX9M

[7] https://www.macdermidalpha.com/sites/default/files/2021-09/ALPHA%20SMT%20Troubleshooting%20Guide%20EN%2001Jun20%20BR_0.pdf

[8] https://jlcpcb.com/blog/guide-to-smt-stencils-in-pcb-assembly

[9] https://community.element14.com/technologies/open-source-hardware/f/forum/7173/pcb-stencil-printer---alignment-discussion/169476

[10] https://www.surfacemountprocess.com/surface-mount-troubleshooting-guide.html

[11] https://resources.altium.com/p/stencil-for-pcb

[12] https://community.element14.com/technologies/open-source-hardware/f/forum/7173/pcb-stencil-printer---alignment-discussion

[13] https://www.instructables.com/SMT-Solder-Paste-Stencil-Production-Jig-using-a-/