Content Menu

● Understanding SMT Technology

● Planning and Preparation

● Selecting Equipment

● Designing the Layout

● Setting Up the SMT Line

● Testing and Calibration

● Maintenance and Continuous Improvement

● Quality Control Measures

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. What are the key pieces of equipment needed for an SMT line?

>> 3. How do I determine my production requirements before setting up an SMT line?

>> 4. What factors should I consider when designing my SMT line layout?

>> 5. How can I maintain quality in my SMT assembly process?

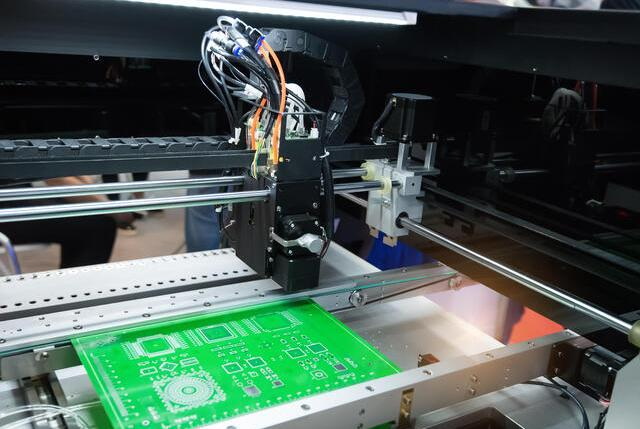

Setting up a Surface Mount Technology (SMT) line is a fundamental process in modern electronics manufacturing. This technology allows for the efficient assembly of electronic components onto printed circuit boards (PCBs), significantly enhancing production speed, cost-effectiveness, and reliability. This article will guide you through the essential steps involved in establishing an SMT line, covering everything from planning and equipment selection to layout design and maintenance.

Understanding SMT Technology

SMT involves mounting electronic components directly onto the surface of PCBs. Unlike traditional through-hole technology, which requires drilling holes in the board, SMT allows for a more compact design and higher component density. This method is widely used in various applications, including consumer electronics, automotive systems, and industrial equipment.

The key advantages of SMT include:

- Higher Component Density: SMT allows for smaller components that can be placed closer together, leading to more compact PCB designs.

- Improved Performance: Shorter electrical paths reduce signal delays and improve performance, especially in high-frequency applications.

- Cost Efficiency: The reduction in board size and weight can lead to lower material costs and shipping expenses.

Planning and Preparation

Before setting up an SMT line, thorough planning is crucial. This phase involves several key steps:

- Assessing Production Requirements: Determine the volume of production needed, types of components to be used, and complexity of assemblies. This assessment will guide your decisions regarding equipment and resources.

- Defining Goals: Establish clear objectives for your SMT line. Are you aiming for high-volume production, flexibility in product types, or a balance of both? Understanding your priorities will help streamline decision-making throughout the setup process.

- Budgeting: Develop a comprehensive budget that covers initial investments in equipment, facility setup costs, and ongoing operational expenses. Research different suppliers to compare prices and ensure you get the best value for your investment.

- Regulatory Compliance: Familiarize yourself with industry regulations that may impact your production process. Compliance with standards such as IPC-A-610 for acceptability of electronic assemblies is crucial for maintaining quality and reliability.

Selecting Equipment

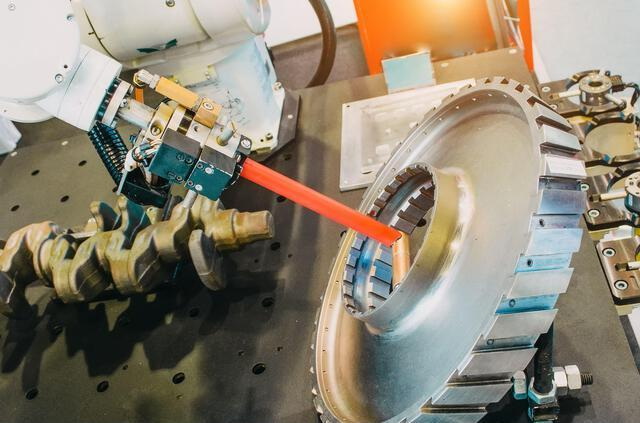

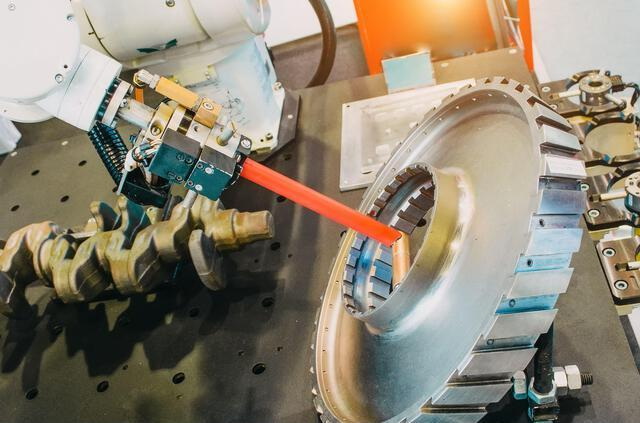

Choosing the right equipment is vital for the efficiency and quality of your SMT line. Key pieces of equipment include:

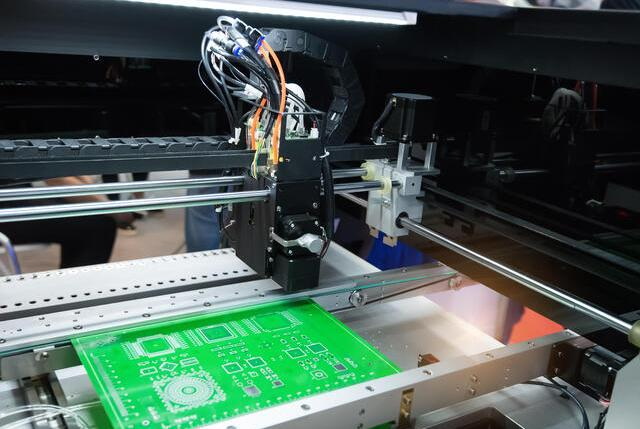

- Pick-and-Place Machines: These machines are responsible for accurately placing components onto PCBs. Consider factors such as speed, accuracy, component size compatibility, and ease of programming when selecting these machines.

- Solder Paste Printers: These apply solder paste to PCBs before component placement. The printer's accuracy is crucial for ensuring high-quality solder joints. Look for printers that offer adjustable squeegee pressure and speed for optimal paste application.

- Reflow Ovens: Used to solder components onto PCBs, these ovens must provide uniform heating to ensure proper soldering. Features such as multiple heating zones and precise temperature control are essential for achieving consistent results.

- Inspection Systems: Automated optical inspection (AOI) systems are essential for detecting defects and verifying the functionality of assembled PCBs. Choose systems with advanced imaging technology that can identify various defects such as misalignment, solder voids, or insufficient solder.

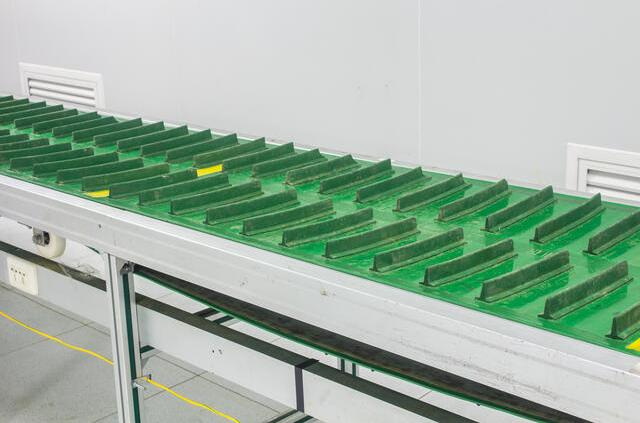

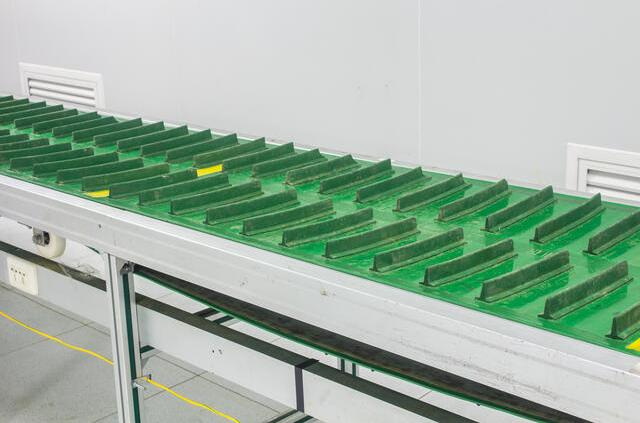

- Conveyor Systems: Conveyor systems facilitate the movement of PCBs between different stages of the assembly process. Ensure that conveyors are compatible with your equipment layout and can handle the required throughput.

Designing the Layout

The layout of your SMT line should maximize efficiency and minimize bottlenecks. Consider the following factors:

- Workflow Design: Arrange equipment in a logical sequence that reflects the flow of materials and components through the line. A linear flow minimizes backtracking and reduces cycle times.

- Space Management: Ensure adequate spacing between machines to facilitate maintenance and troubleshooting. Consider incorporating workstations for manual assembly or rework if necessary.

- Environmental Control: Maintain appropriate temperature and humidity levels to prevent damage to sensitive electronic components. Implement air filtration systems to minimize dust contamination during production.

- Safety Considerations: Design your layout with safety in mind by ensuring clear pathways for personnel and emergency exits. Proper labeling of hazardous materials is also essential.

Setting Up the SMT Line

Once planning and equipment selection are complete, it's time to set up the SMT line:

- Installation: Install all equipment according to the designed layout. Follow manufacturer instructions carefully to ensure proper setup.

- Integration: Ensure seamless communication between different systems in your SMT line. This may involve configuring network connections and data exchange protocols to enable real-time monitoring of production metrics.

- Software Configuration: Most modern SMT equipment comes with sophisticated software that controls various aspects of production. Configure software settings to match your production requirements, including component libraries and reflow oven profiles.

Testing and Calibration

After installation, thorough testing and calibration are necessary:

- Initial Tests: Run test boards through the line to verify that all equipment functions as expected. Pay attention to component placement accuracy, solder paste application consistency, reflow profiles, and overall assembly quality.

- Calibration: Regularly calibrate all machines according to manufacturer recommendations to maintain precision and prevent errors. Implement a calibration schedule that aligns with production cycles to minimize disruptions.

Maintenance and Continuous Improvement

Establishing an SMT line is not a one-time task; it requires ongoing maintenance and improvement:

- Regular Maintenance Schedule: Implement a routine maintenance schedule for all equipment to prevent unexpected downtime. Include tasks such as cleaning nozzles on pick-and-place machines, checking solder paste printer alignment, and inspecting reflow oven heating elements.

- Continuous Monitoring: Utilize real-time monitoring tools to identify bottlenecks in production processes and make data-driven decisions for improvements. Analyze key performance indicators (KPIs) such as yield rates, cycle times, and defect rates regularly.

- Employee Training: Invest in training programs for employees operating the SMT line. Well-trained staff can quickly identify issues during production processes and contribute valuable insights into continuous improvement efforts.

Quality Control Measures

Quality control is paramount in an SMT line setup:

- In-Line Inspection: Implement in-line inspection processes at critical stages of assembly to catch defects early on. This includes inspecting solder paste application before component placement as well as post-reflow inspections using AOI systems.

- Final Testing: Conduct functional testing on finished assemblies to ensure they meet performance specifications before shipping them out. This may involve electrical testing or functional testing based on product requirements.

Conclusion

Setting up an SMT line involves careful planning, selecting appropriate equipment, designing an efficient layout, thorough testing, ongoing maintenance, and implementing robust quality control measures. By following these steps diligently, manufacturers can create a highly efficient assembly process that meets modern production demands while ensuring high-quality outputs.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs compared to traditional through-hole technology.

2. What are the key pieces of equipment needed for an SMT line?

Essential equipment includes pick-and-place machines, solder paste printers, reflow ovens, inspection systems (like AOI), conveyor systems for material handling, along with environmental control systems such as air filtration units.

3. How do I determine my production requirements before setting up an SMT line?

Assess your expected production volume by analyzing market demand forecasts; consider types of products you will manufacture based on customer needs; evaluate complexity by determining whether you will work with standard or custom PCBs; also review any specific industry standards or regulations that may apply.

4. What factors should I consider when designing my SMT line layout?

Consider workflow efficiency by arranging machines logically; manage space effectively between machines; maintain environmental controls; ensure safety measures are implemented; plan for future scalability if needed based on anticipated growth or changes in product lines.

5. How can I maintain quality in my SMT assembly process?

Implement regular calibration schedules for all machines; conduct thorough inspections at each stage using automated optical inspection systems (AOI); continuously monitor production data using real-time analytics tools; invest in employee training programs focused on quality assurance practices.