Content Menu

● Introduction

● Key Components of an SMT Line

● Steps to Set Up an Efficient SMT Line

● Tips for Optimizing Efficiency

● Common Challenges and Solutions

● Advanced Techniques for Enhanced Efficiency

● Quality Control Measures

● Conclusion

● FAQ

>> 1. What is the role of a pick-and-place machine in an SMT line?

>> 2. How do I choose the right equipment for my SMT line?

>> 3. What are common mistakes to avoid during setup?

>> 4. How can I improve the efficiency of my SMT line?

>> 5. What maintenance is required for SMT equipment?

● Citations:

Introduction

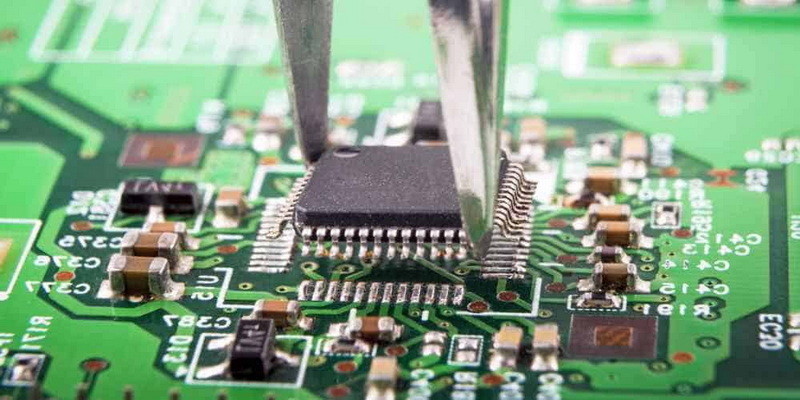

Surface Mount Technology (SMT) pick and place machine lines are the backbone of modern electronics manufacturing. These lines enable the precise and efficient assembly of printed circuit boards (PCBs), which are integral to countless electronic devices. Setting up an efficient SMT line is crucial for achieving high-quality production while minimizing costs and downtime. This article will guide you through the essential components, steps, and best practices for establishing an efficient SMT pick and place machine line.

Key Components of an SMT Line

An efficient SMT line comprises several essential components:

- Pick-and-Place Machines: Automate the placement of components onto PCBs with high precision. These machines are designed to handle various component sizes and shapes, ensuring accurate placement.

- Solder Paste Printers: Apply solder paste to PCBs, preparing them for component placement. The quality of solder paste application is critical for ensuring reliable solder joints.

- Reflow Ovens: Heat PCBs to solder components securely in place. Proper temperature profiles in reflow ovens are essential for achieving optimal soldering results.

- Inspection Systems: Ensure quality control by detecting errors in assembly. Automated Optical Inspection (AOI) systems are commonly used to verify component placement and solder quality.

Steps to Set Up an Efficient SMT Line

Follow these steps to establish a high-performing SMT line:

1. Planning: Assess production requirements, including volume, component types, and assembly complexity. This assessment will guide your decisions regarding equipment selection and layout design.

2. Equipment Selection: Choose machines compatible with your production needs. Consider factors such as speed, accuracy, and flexibility in handling different component types.

3. Layout Design: Arrange equipment to optimize workflow and minimize bottlenecks. A well-designed layout facilitates smooth material flow and reduces unnecessary movement.

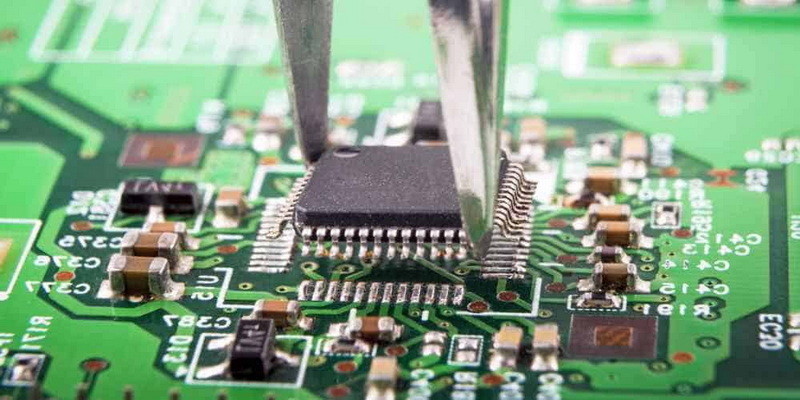

4. Installation: Install and configure equipment according to manufacturer guidelines. Ensure all connections are secure and that machines are properly aligned.

5. Calibration: Regularly calibrate machines to maintain precision and efficiency. Calibration should be performed according to the manufacturer's recommendations.

Tips for Optimizing Efficiency

Implement these best practices to enhance your SMT line's performance:

- Automation: Use automated systems to reduce errors and increase speed. Automation can significantly improve production rates while minimizing labor costs.

- Training: Ensure staff are well-trained to operate and maintain equipment. Continuous training programs can help improve worker efficiency and product quality.

- Lean Production: Minimize waste and streamline workflows by implementing lean manufacturing principles. Identify bottlenecks in the production process and address them promptly.

- Regular Maintenance: Schedule routine maintenance to prevent downtime. Preventive maintenance helps extend the lifespan of your equipment and ensures consistent performance.

Common Challenges and Solutions

While setting up an SMT line, you may encounter challenges such as:

- Improper Calibration: Address this by following manufacturer guidelines for calibration closely. Regular checks can prevent inaccuracies in component placement.

- Poor Layout Design: Optimize equipment arrangement to improve workflow. A logical layout reduces movement time between processes, enhancing overall efficiency.

- Neglecting Maintenance: Implement a regular maintenance schedule to avoid unexpected issues. Maintenance should include cleaning, lubrication, and inspection of critical components.

Advanced Techniques for Enhanced Efficiency

To further enhance the efficiency of your SMT line, consider these advanced techniques:

- Load Balancing: Distribute the workload evenly among machines to ensure that no single machine becomes a bottleneck in the production process[2]. This can be achieved by analyzing the time each machine takes to complete its tasks and adjusting the number of components assigned accordingly.

- Component Grouping: Organize similar components together on feeders to minimize changeover times during production runs[2]. This strategy allows the pick-and-place machine to pick multiple components in one cycle, reducing idle time.

- Real-Time Monitoring Systems: Implement systems that provide real-time data on machine performance[20]. These systems can alert operators to potential issues before they escalate into significant problems, thus maintaining continuous operation.

- Simulation Tools for Layout Design: Utilize simulation software during the layout design phase[1]. This technology allows manufacturers to visualize workflows, identify potential bottlenecks, and optimize equipment placement before physical installation occurs.

Quality Control Measures

Quality control is paramount in SMT assembly; therefore, integrating robust inspection systems is crucial:

- Automated Optical Inspection (AOI): Deploy AOI systems at various points along the production line to catch defects early[20]. These systems use cameras to inspect PCBs for misaligned components or insufficient solder joints before they proceed further down the line.

- X-ray Inspection Systems: For more complex assemblies with hidden solder joints (e.g., BGAs), X-ray inspection provides critical insights into internal connections[28]. This technology helps ensure that all solder joints meet quality standards before final assembly.

Conclusion

Setting up an efficient SMT pick-and-place machine line is a complex but rewarding process that requires careful planning, precise execution, and ongoing maintenance. By carefully planning, selecting the right equipment, optimizing layout design, implementing advanced techniques, and maintaining rigorous quality control measures, you can achieve a high-performing production line that meets your manufacturing goals. Continuous improvement through regular monitoring and maintenance is key to long-term success in electronics manufacturing.

FAQ

1. What is the role of a pick-and-place machine in an SMT line?

It automates the placement of components onto PCBs, ensuring precision and efficiency.

2. How do I choose the right equipment for my SMT line?

Consider production volume, component types, and assembly complexity when selecting equipment.

3. What are common mistakes to avoid during setup?

Common mistakes include improper calibration, poor layout design, and neglecting maintenance.

4. How can I improve the efficiency of my SMT line?

Implement automation, train staff effectively, and regularly monitor processes for continuous improvement.

5. What maintenance is required for SMT equipment?

Regular cleaning, lubrication, and calibration as per manufacturer guidelines are necessary for maintaining SMT equipment.

Citations:

[1] https://www.smtfactory.com/Strategic-SMT-Production-Line-Layout-Design-id40117676.html

[2] https://www.neodensmt.com/news/improve-smt-production-efficiency-48868013.html

[3] https://www.pcb-hero.com/blogs/lisas-column/surface-mount-technology-common-problems-and-solutions-for-efficient-smt-assembly

[4] https://www.itechsmt.com/blogs/news/10-hot-topics-about-smt-pick-and-place-machine

[5] https://wellerpcb.com/pcb-layout-guidelines-for-smt-assembly-process-limits

[6] https://www.smtfactory.com/Essential-Steps-for-SMT-Production-Line-Setup-id49117676.html

[7] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[8] https://jhdpcb.com/blog/efficient-smt-assembly/

[9] https://www.raypcb.com/surface-mount-technology/

[10] https://www.smtneoden.com/news/how-to-effectively-improve-the-production-efficiency-of-pcb-smt-machine/

[11] https://www.viasion.com/blog/common-challenges-in-smt-assembly-and-solutions/

[12] https://core-emt.com/pick-place

[13] https://forum.core-electronics.com.au/t/pcb-layout-for-surface-mount/12429

[14] https://www.rayprasad.com/selection-criteria-for-smt-placement-equipment

[15] https://www.tronstol.com/how-to-optimize-smt-mounter-machine-equipment.html

[16] https://www.vse.com/blog/2022/03/15/8-common-smt-placement-issues-and-solutions/

[17] https://www.nextpcb.com/blog/top-10-smt-machines-worldwide

[18] https://www.qhsmt.com/2023/08/16/smt-pick-and-place-how-to-design-a-pcb-layout-a-comprehensive-guide/

[19] https://core-emt.com/blog/smt-news-1/identifying-addressing-smt-line-bottlenecks-to-plan-line-upgrades-smartly-119

[20] https://www.smtfactory.com/Perfecting-Your-SMT-Line-Layout-for-Efficiency-id47017676.html

[21] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[22] https://smt.fuji.co.jp/en/topics/2858

[23] https://www.linkedin.com/pulse/perfect-layout-analysis-design-smt-electronics-factory-mia-feng-vxw6c

[24] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[25] https://www.raypcb.com/line-efficiency/

[26] https://www.macdermidalpha.com/sites/default/files/2021-09/ALPHA%20SMT%20Troubleshooting%20Guide%20EN%2001Jun20%20BR_0.pdf

[27] https://www.zjyingxing.com/info/what-is-the-future-of-smt-machine-82208106.html

[28] https://faroads.com/start-smt-line-guide-2024/

[29] https://quality-line.com/smt-quality/

[30] https://fctassembly.wordpress.com/technical-resources/technical-papers/smt-assembly-challenges-and-proven-solutions-for-improving-yields/

[31] https://asquared.uk.com/surface-mount-technology-pick-and-place/

[32] https://www.smthelp.com/methods-and-measures-to-improve-the-production-efficiency-of-smt-production-line

[33] https://resources.altium.com/p/complete-guide-diy-smt-assembly-your-office

[34] https://www.tronstol.com/how-to-configure-the-pick-and-place-machine-correctly.html