Content Menu

● Understanding Turnkey SMT Production Lines

● Key Components of an SMT Production Line

● Steps to Set Up a Successful Turnkey SMT Production Line

>> 1. Assess Production Requirements

>> 2. Select Appropriate Equipment

>> 3. Design the Layout

>> 4. Install and Configure Equipment

>> 5. Testing and Calibration

>> 6. Implement Quality Control Measures

>> 7. Train Your Workforce

● Ongoing Maintenance and Continuous Improvement

● Conclusion

● FAQ

>> 1. What is a turnkey SMT production line?

>> 2. What equipment is essential for an SMT line?

>> 3. How do I choose the right pick-and-place machine?

>> 4. What are common challenges in setting up an SMT line?

>> 5. How often should I perform maintenance on my SMT equipment?

Setting up a successful turnkey Surface Mount Technology (SMT) production line requires meticulous planning, precise execution, and a commitment to quality. This article provides a comprehensive guide on how to establish an efficient SMT production line, covering everything from equipment selection to layout design and ongoing maintenance.

Understanding Turnkey SMT Production Lines

A turnkey SMT production line refers to a complete assembly setup where the supplier manages all aspects of the manufacturing process, from design and component sourcing to assembly and testing. This model allows businesses to focus on their core competencies while ensuring high-quality production without the hassle of managing multiple vendors.

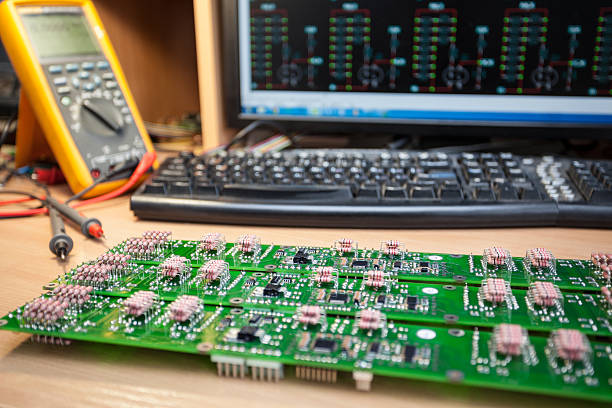

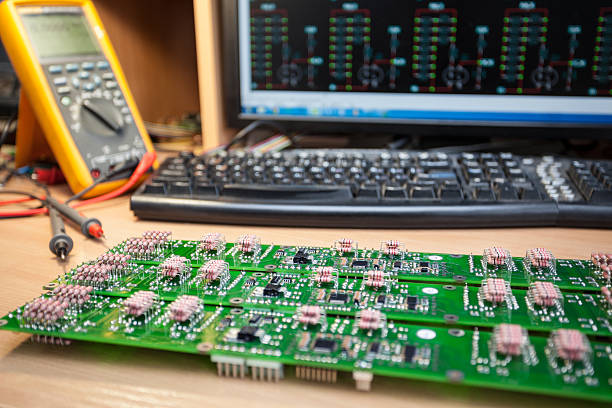

Key Components of an SMT Production Line

Before diving into the setup process, it is essential to understand the critical components involved in an SMT production line:

- Solder Paste Printer: Responsible for applying solder paste onto the PCB.

- Pick-and-Place Machine: Automatically places surface mount components onto the solder paste.

- Reflow Oven: Melts the solder paste to create electrical connections between components and the PCB.

- Inspection Systems: Automated Optical Inspection (AOI) systems check for placement accuracy and solder joint quality.

- Conveyor Systems: Facilitate the movement of PCBs through various stages of the assembly process.

Steps to Set Up a Successful Turnkey SMT Production Line

1. Assess Production Requirements

The first step in setting up an SMT production line is to evaluate your specific production needs. Consider factors such as:

- Production Volume: Determine how many units you plan to produce daily or weekly.

- Component Types: Identify the types of components you will be using, as this will influence equipment selection.

- Complexity of Assemblies: Understand the complexity of your PCB designs, which may require specialized equipment.

Additionally, consider future scalability. As your business grows, you may need to increase production capacity or adapt to new technologies. A flexible setup that can accommodate changes will save time and resources in the long run.

2. Select Appropriate Equipment

Choosing the right equipment is crucial for an efficient SMT line. Key considerations include:

- Solder Paste Printer: Look for a printer that offers precision and speed. Consider options with automatic alignment features. The ability to handle various stencil types will also enhance flexibility.

- Pick-and-Place Machine: Select a machine that can handle various component sizes and types. Ensure it has high placement accuracy and speed. Some machines come with advanced vision systems that enhance their ability to place components accurately.

- Reflow Oven: Choose an oven that provides uniform heating profiles suitable for your specific solder paste requirements. Features such as convection heating and multiple heating zones can improve soldering quality.

- Inspection Equipment: Invest in AOI systems that can detect common issues like misalignment and solder defects before they escalate. Some systems also offer 3D inspection capabilities for more accurate assessments.

3. Design the Layout

An efficient layout minimizes bottlenecks and maximizes workflow. Consider these elements when designing your SMT line layout:

- Flow of Materials: Arrange machines in a logical sequence that allows for smooth transitions from one stage to another. A linear flow is often most effective, but U-shaped layouts can also work well in smaller spaces.

- Space Requirements: Ensure adequate spacing between machines for maintenance access and operator safety. This includes considering emergency exits and pathways for material handling.

- Ergonomics: Design workstations that are comfortable for operators, reducing fatigue and increasing productivity. Adjustable work surfaces can accommodate different operator heights, while proper lighting is essential for detailed tasks.

4. Install and Configure Equipment

Once you have selected your equipment and designed your layout, it's time to install everything:

- Follow manufacturer instructions carefully during installation.

- Ensure all machines are properly calibrated before starting production.

- Integrate software systems for machine control, data collection, and process monitoring. This integration allows real-time tracking of production metrics, which is crucial for identifying inefficiencies or problems quickly.

5. Testing and Calibration

Before commencing full-scale production, conduct thorough testing:

- Run test boards through the entire production line to verify that all machines are functioning correctly.

- Calibrate each machine based on test results, adjusting settings as necessary to achieve optimal performance. Regular calibration ensures consistent quality over time.

- Utilize statistical process control (SPC) techniques during testing to monitor variations in processes and identify areas needing improvement.

6. Implement Quality Control Measures

Quality control is essential for maintaining high standards in SMT assembly:

- Establish inspection checkpoints throughout the production process.

- Utilize AOI systems post-reflow to detect any defects early in the assembly process.

- Perform regular maintenance on all equipment to prevent downtime and ensure consistent quality. A preventive maintenance schedule should include detailed checklists for each piece of equipment.

Additionally, consider implementing a feedback loop where operators can report issues or suggest improvements based on their hands-on experience with the machines and processes.

7. Train Your Workforce

A well-trained workforce is critical for success:

- Provide comprehensive training on operating machinery, quality control procedures, and safety protocols.

- Encourage continuous learning and development to keep staff updated on new technologies and best practices. Online courses or workshops can be beneficial for ongoing education.

Moreover, fostering a culture of collaboration where team members can share insights or challenges can lead to innovative solutions and improvements in processes.

Ongoing Maintenance and Continuous Improvement

Maintaining an efficient SMT production line requires ongoing effort:

- Implement a regular maintenance schedule for all equipment to prevent breakdowns.

- Continuously monitor production metrics to identify areas for improvement. Key performance indicators (KPIs) such as yield rates, cycle times, and defect rates should be tracked regularly.

- Stay updated on industry trends and advancements in technology that can enhance your production capabilities. Consider participating in industry conferences or subscribing to relevant publications for insights into emerging technologies like artificial intelligence (AI) in manufacturing or Industry 4.0 practices.

Conclusion

Setting up a successful turnkey SMT production line involves careful planning, strategic equipment selection, effective layout design, rigorous testing, ongoing maintenance, and workforce training. By following these steps, businesses can ensure high-quality production while minimizing costs and maximizing efficiency in their manufacturing processes. The investment in a well-designed SMT line not only enhances productivity but also positions companies favorably in a competitive market landscape.

FAQ

1. What is a turnkey SMT production line?

A turnkey SMT production line is a complete assembly setup managed by a supplier that handles everything from design to testing, allowing businesses to focus on their core activities without managing multiple vendors.

2. What equipment is essential for an SMT line?

Key equipment includes solder paste printers, pick-and-place machines, reflow ovens, inspection systems (like AOI), and conveyor systems for moving PCBs through various stages of assembly.

3. How do I choose the right pick-and-place machine?

Select a pick-and-place machine based on its ability to handle various component sizes, its speed (measured in components per hour), placement accuracy, ease of programming, and feeder capacity.

4. What are common challenges in setting up an SMT line?

Common challenges include ensuring proper calibration of machines, maintaining consistent quality control throughout the process, managing inventory effectively, and training staff adequately on new technologies.

5. How often should I perform maintenance on my SMT equipment?

Regular maintenance should be scheduled based on manufacturer recommendations but typically includes daily checks for cleanliness and functionality, with more comprehensive inspections performed weekly or monthly depending on usage levels.