Content Menu

● Understanding Rigid Flex PCBs and SMT Assembly

● The Importance of SMT Fixtures for Rigid Flex PCBs

● Factors to Consider When Selecting SMT Fixtures in China

>> Material Selection

>> Design Complexity

>> Production Volume

>> Compatibility with Assembly Equipment

● Types of SMT Fixtures for Rigid Flex PCBs

>> 1. Vacuum Fixtures

>> 2. Mechanical Clamping Fixtures

>> 3. Magnetic Fixtures

>> 4. Custom-Designed Fixtures

● Working with Chinese SMT Fixture Manufacturers

>> Manufacturer Expertise

>> Communication and Collaboration

>> Prototyping and Testing

>> Quality Control

>> Cost Considerations

● Best Practices for Using SMT Fixtures with Rigid Flex PCBs

● Conclusion

● FAQ

>> 1. What are the main challenges in assembling rigid flex PCBs?

>> 2. How do SMT fixtures for rigid flex PCBs differ from those for standard rigid PCBs?

>> 3. What are the key factors to consider when choosing an SMT fixture manufacturer in China?

>> 4. How can I ensure that the SMT fixture will not damage the flexible areas of my rigid flex PCB?

>> 5. What are the advantages of using custom-designed SMT fixtures for rigid flex PCBs?

● Citations:

Selecting the right SMT (Surface Mount Technology) fixture for rigid flex PCBs in China is a critical process that can significantly impact the quality and efficiency of your electronic manufacturing. As the demand for compact and flexible electronic devices continues to grow, rigid flex PCBs have become increasingly popular due to their ability to combine the benefits of both rigid and flexible circuit boards[1]. However, the unique characteristics of rigid flex PCBs present challenges during the assembly process, making the selection of appropriate SMT fixtures crucial.

Understanding Rigid Flex PCBs and SMT Assembly

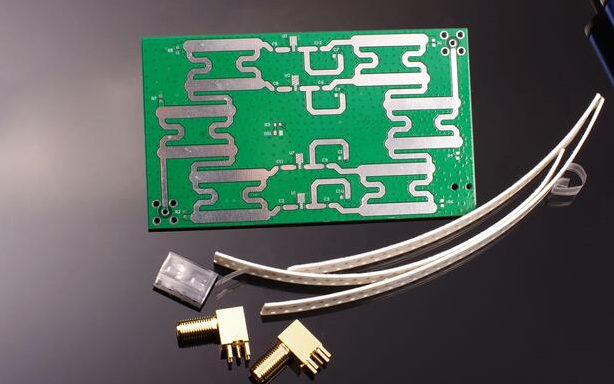

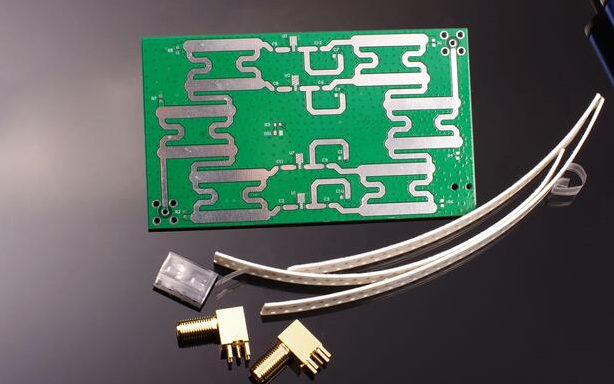

Rigid flex PCBs are a hybrid of rigid and flexible circuit boards, offering the stability of rigid boards and the flexibility of flex circuits in a single package[4]. These boards are widely used in industries where space is at a premium, such as aerospace, medical devices, and consumer electronics. The assembly of rigid flex PCBs requires special considerations due to their unique structure and properties.

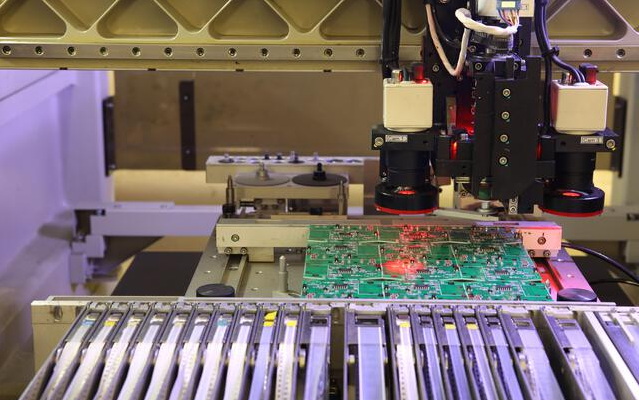

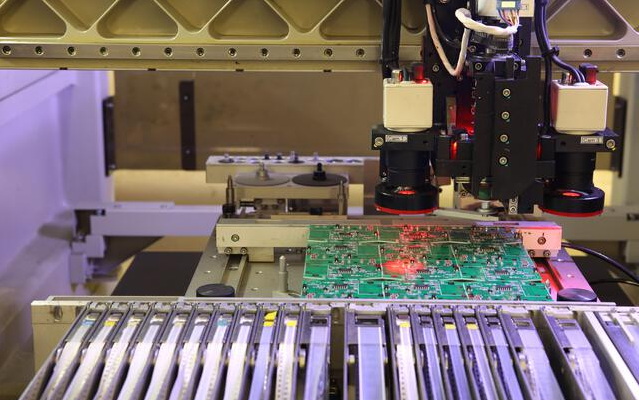

Surface Mount Technology (SMT) is the preferred method for assembling components on PCBs, including rigid flex boards. SMT involves placing and soldering components directly onto the surface of the PCB, rather than through holes[2]. This technique allows for higher component density, improved performance, and more efficient production.

The Importance of SMT Fixtures for Rigid Flex PCBs

SMT fixtures play a crucial role in the assembly process of rigid flex PCBs. These fixtures serve several important functions:

1. Board Support: Rigid flex PCBs are prone to deformation due to their flexible nature. SMT fixtures provide the necessary support to keep the board flat and stable during component placement and soldering[1].

2. Alignment: Precise alignment is critical for successful SMT assembly. Fixtures ensure that the PCB is correctly positioned relative to the pick-and-place machine and other assembly equipment[2].

3. Protection: The flexible areas of rigid flex PCBs are particularly vulnerable to damage. Properly designed fixtures can protect these sensitive areas during the assembly process[3].

4. Consistency: By maintaining consistent positioning and support, SMT fixtures help ensure repeatable results across multiple boards, which is essential for high-volume production[5].

Factors to Consider When Selecting SMT Fixtures in China

When choosing SMT fixtures for rigid flex PCBs in China, several factors should be taken into account:

Material Selection

The material used for the SMT fixture is crucial. Common materials include:

- Aluminum: Lightweight and cost-effective, suitable for most applications.

- Steel: Offers higher durability and stability, ideal for high-volume production.

- Composite materials: Provide a balance between weight and durability.

Consider the thermal properties of the material, as it should withstand the temperatures involved in the reflow soldering process without warping or degrading[6].

Design Complexity

The complexity of your rigid flex PCB design will influence the fixture requirements. Factors to consider include:

- Board shape and size: Irregular shapes or large boards may require custom fixture designs.

- Component density: High-density designs may need more precise fixturing to ensure accurate placement.

- Flexible areas: The fixture should adequately support flexible sections without restricting necessary movement[1].

Production Volume

The expected production volume will impact your fixture choice:

- Low-volume production: Simple, cost-effective fixtures may suffice.

- High-volume production: More durable, precision-engineered fixtures are often necessary to withstand repeated use and maintain consistency[7].

Compatibility with Assembly Equipment

Ensure that the SMT fixture is compatible with your assembly equipment, including:

- Pick-and-place machines: The fixture should allow for proper component placement without interference.

- Reflow ovens: The fixture material should withstand reflow temperatures without warping or outgassing.

- Automated optical inspection (AOI) systems: The fixture design should not obstruct inspection processes[2].

Types of SMT Fixtures for Rigid Flex PCBs

Several types of SMT fixtures are commonly used for rigid flex PCB assembly in China:

1. Vacuum Fixtures

Vacuum fixtures use suction to hold the PCB in place. They are particularly useful for thin or flexible boards that may warp easily. Benefits include:

- Excellent flatness control

- Minimal contact with the PCB surface

- Adaptability to various board shapes and sizes

However, vacuum fixtures may not be suitable for boards with many cutouts or holes, as these can compromise the vacuum seal[3].

2. Mechanical Clamping Fixtures

These fixtures use mechanical means to secure the PCB. They are versatile and can accommodate a wide range of board sizes and shapes. Advantages include:

- Strong holding force

- No reliance on external power sources

- Ability to handle boards with cutouts or irregular shapes

Care must be taken to ensure that the clamping mechanism does not damage or stress the flexible areas of the PCB[5].

3. Magnetic Fixtures

Magnetic fixtures use magnetic force to hold ferrous metal plates attached to the PCB. They offer:

- Quick and easy board placement and removal

- Minimal obstruction of the PCB surface

- Good flatness control

However, they require the addition of metal plates to the PCB, which may not be suitable for all designs[6].

4. Custom-Designed Fixtures

For complex or unique rigid flex PCB designs, custom fixtures may be necessary. These can be tailored to the specific requirements of your board, offering:

- Optimal support for both rigid and flexible areas

- Precise alignment for high-density designs

- Integration of additional features such as shielding or heat sinking

Custom fixtures typically have higher upfront costs but can provide significant benefits in terms of assembly quality and efficiency for specialized designs[7].

Working with Chinese SMT Fixture Manufacturers

When sourcing SMT fixtures for rigid flex PCBs in China, consider the following:

Manufacturer Expertise

Look for manufacturers with specific experience in rigid flex PCB assembly. They should understand the unique challenges posed by these boards and have a track record of developing effective fixture solutions[1].

Communication and Collaboration

Clear communication is essential when working with Chinese manufacturers. Ensure that you can effectively convey your design requirements and that the manufacturer can provide detailed feedback and suggestions[2].

Prototyping and Testing

Request prototypes of the SMT fixture before committing to full production. This allows you to verify the fixture's performance with your specific rigid flex PCB design and assembly process[5].

Quality Control

Implement rigorous quality control measures to ensure that the fixtures meet your specifications. This may include dimensional checks, material verification, and performance testing under simulated production conditions[6].

Cost Considerations

While cost is an important factor, it should not be the sole determining factor. Consider the total cost of ownership, including the fixture's durability, its impact on assembly yield, and any potential need for replacements or modifications[7].

Best Practices for Using SMT Fixtures with Rigid Flex PCBs

To maximize the benefits of your SMT fixtures for rigid flex PCB assembly in China, follow these best practices:

1. Proper Handling: Train operators on the correct handling of both the fixtures and the rigid flex PCBs to prevent damage.

2. Regular Maintenance: Implement a regular maintenance schedule for the fixtures to ensure they remain in optimal condition.

3. Temperature Management: Monitor and control the temperature of the fixtures during the assembly process to prevent warping or thermal expansion issues.

4. Cleanliness: Keep fixtures clean and free from debris to maintain precision and prevent contamination of the PCBs.

5. Documentation: Maintain detailed documentation of fixture designs and usage to facilitate future improvements and troubleshooting.

Conclusion

Selecting the right SMT fixture for rigid flex PCBs in China is a critical step in ensuring high-quality, efficient assembly of these complex boards. By considering factors such as material selection, design complexity, production volume, and compatibility with assembly equipment, you can choose fixtures that optimize your manufacturing process. Working closely with experienced Chinese manufacturers and following best practices for fixture use will help you achieve consistent, high-quality results in your rigid flex PCB assembly operations.

FAQ

1. What are the main challenges in assembling rigid flex PCBs?

The main challenges in assembling rigid flex PCBs include maintaining board flatness during assembly, protecting flexible areas from damage, ensuring precise component placement across both rigid and flexible sections, and managing the different thermal properties of rigid and flexible materials during soldering.

2. How do SMT fixtures for rigid flex PCBs differ from those for standard rigid PCBs?

SMT fixtures for rigid flex PCBs are designed to provide support for both rigid and flexible areas, often incorporating features to prevent bending or stress on flexible sections. They may also include specialized clamping or support mechanisms to maintain overall board flatness while accommodating the unique properties of the flexible areas.

3. What are the key factors to consider when choosing an SMT fixture manufacturer in China?

Key factors include the manufacturer's experience with rigid flex PCB assembly, their ability to provide custom solutions, communication capabilities, prototyping and testing services, quality control processes, and overall cost-effectiveness. It's also important to consider their understanding of international quality standards and their ability to meet your specific production requirements.

4. How can I ensure that the SMT fixture will not damage the flexible areas of my rigid flex PCB?

To protect flexible areas, choose fixtures with smooth, rounded edges where they contact the PCB. Consider using materials like soft silicone or foam padding in areas that interface with flexible sections. Design the fixture to provide adequate support without applying excessive pressure to flexible areas. Always test the fixture with sample boards before full production to verify that it does not cause damage.

5. What are the advantages of using custom-designed SMT fixtures for rigid flex PCBs?

Custom-designed SMT fixtures offer several advantages for rigid flex PCBs, including optimal support tailored to the specific board layout, precise alignment for high-density designs, accommodation of unique board shapes or flexible section arrangements, integration of features like shielding or heat management, and potentially improved assembly efficiency and yield for complex or unusual designs.

Citations:

[1] https://rushpcb.com/assembling-rigid-flex-pcbs/

[2] https://www.fs-pcba.com/smt-pcba/

[3] https://www.venture-mfg.com/flex-pcb-assembly/

[4] https://www.allflexinc.com/blog/pcb-design-guidelines/

[5] https://www.protoexpress.com/kb/flex-pcb-assembly/

[6] https://www.protoexpress.com/blog/dfm-flex-rigid-flex-pcbs-utilizing-smt/

[7] https://www.viasion.com/blog/rigid-flex-pcb-fabrication/

[8] https://www.ourpcb.com/sitemap