Content Menu

● Understanding the Importance of Maintenance

● Daily Maintenance Tasks

>> Cleaning the Stencil Frame

>> Inspecting the Printer

>> Checking Alignment

● Weekly Maintenance Procedures

>> Deep Cleaning

>> Lubricating Moving Parts

● Monthly Maintenance Checks

>> Stencil Inspection

>> Squeegee Blade Replacement

● Quarterly Maintenance Procedures

>> Calibration Check

>> Component Inspection

● Annual Maintenance

>> Comprehensive Overhaul

>> Professional Inspection

● Best Practices for Ongoing Maintenance

>> Proper Storage

>> Training Staff

>> Keeping Detailed Records

>> Using Quality Materials

● Troubleshooting Common Issues

>> Solder Bridging

>> Insufficient Solder

>> Print Misalignment

● Environmental Considerations

>> Temperature and Humidity Control

>> Dust and Contaminant Control

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. How often should I clean my SMT manual stencil printer?

>> 2. What type of lubricant should I use on my SMT manual stencil printer?

>> 3. How can I prevent solder bridging when using my SMT manual stencil printer?

>> 4. When should I replace the squeegee blade on my SMT manual stencil printer?

>> 5. How important is the environment for my SMT manual stencil printer's performance?

● Citations:

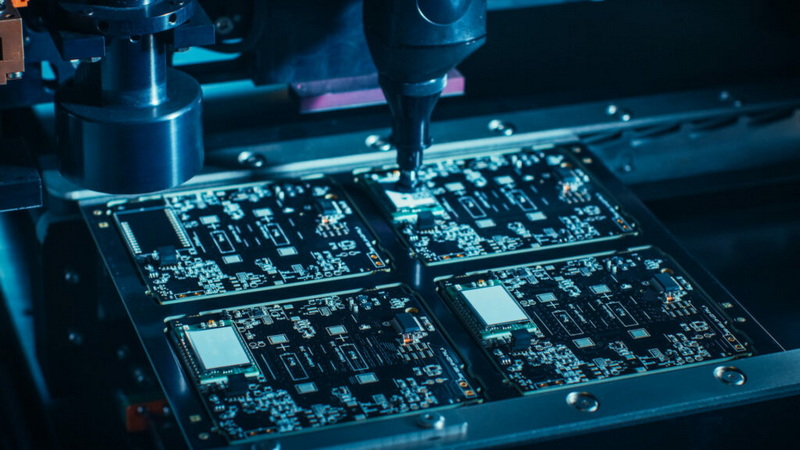

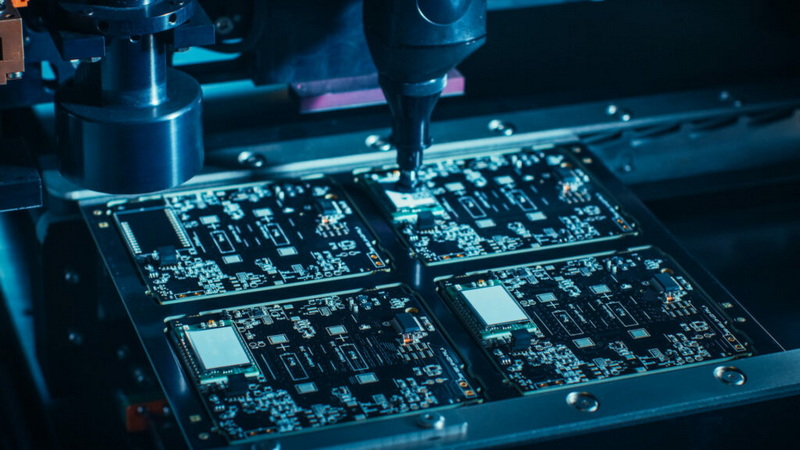

Maintaining an SMT manual stencil printer is crucial for ensuring consistent and high-quality PCB production. Proper maintenance not only extends the life of your equipment but also helps prevent costly errors and downtime. In this comprehensive guide, we'll explore the essential steps and best practices for maintaining your SMT manual stencil printer.

Understanding the Importance of Maintenance

Before diving into the specifics of maintenance, it's essential to understand why it's so critical. SMT manual stencil printers are precision instruments used in the delicate process of applying solder paste to PCBs. Even minor issues with these printers can lead to significant problems in the final product, such as solder bridging, insufficient solder, or misaligned components.

Regular maintenance helps ensure:

1. Consistent print quality

2. Longer equipment lifespan

3. Reduced downtime

4. Cost savings in the long run

5. Improved overall production efficiency

Daily Maintenance Tasks

Cleaning the Stencil Frame

One of the most critical daily maintenance tasks is cleaning the stencil frame. This process helps prevent the buildup of solder paste residue, which can affect print quality[1]. To clean the stencil frame:

1. Turn the top height adjustment knob clockwise until it's easy to access the frame.

2. Use a clean, lint-free cloth and an approved solvent to wipe down the frame.

3. Pay special attention to any areas where solder paste tends to accumulate.

Inspecting the Printer

Before each use, conduct a visual inspection of your SMT manual stencil printer. Look for any signs of wear, damage, or misalignment. Pay particular attention to:

- The squeegee blade

- The stencil itself

- The PCB support system

- Any moving parts

If you notice any issues, address them immediately before proceeding with printing.

Checking Alignment

Due to the precise nature of SMT work, it's crucial to check the alignment of your printer regularly. Before each print:

1. Place a PCB on the placeholders and close the printer.

2. Verify that the PCB pads exactly match the stencil holes[1].

3. Make any necessary adjustments using the X- and Y-axis controls.

Weekly Maintenance Procedures

Deep Cleaning

While daily cleaning is essential, a more thorough cleaning should be performed weekly. This involves:

1. Removing the stencil and cleaning it thoroughly with an appropriate solvent.

2. Cleaning all surfaces of the printer, including hard-to-reach areas.

3. Inspecting and cleaning the squeegee blade.

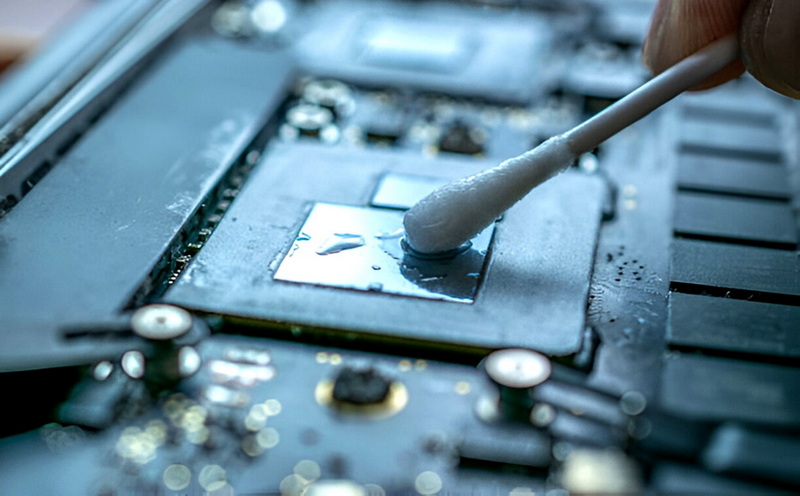

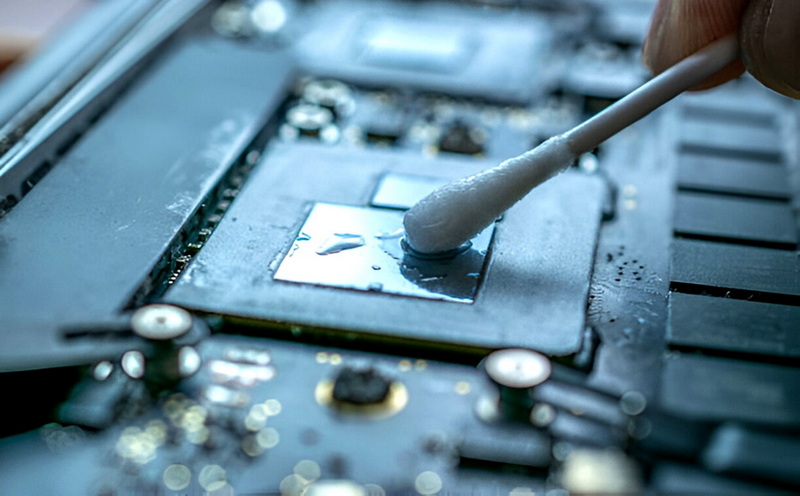

Lubricating Moving Parts

To prevent corrosion and ensure smooth operation, lightly oil all metal surfaces with resin and acid-free machine oil[1]. Be careful not to over-lubricate, as this can lead to other issues.

Monthly Maintenance Checks

Stencil Inspection

On a monthly basis, perform a detailed inspection of your stencils:

1. Check for any signs of wear or damage.

2. Verify that all apertures are clear and properly sized.

3. Ensure the stencil is still properly tensioned.

Squeegee Blade Replacement

Squeegee blades wear out over time, affecting print quality. Inspect your squeegee blades monthly and replace them if you notice:

- Uneven wear

- Nicks or damage

- Inconsistent print quality

Quarterly Maintenance Procedures

Calibration Check

Every three months, perform a thorough calibration check of your SMT manual stencil printer. This may involve:

1. Verifying the accuracy of the X, Y, and Z-axis movements.

2. Checking the alignment of the stencil frame.

3. Ensuring the PCB support system is level and properly adjusted.

Component Inspection

Conduct a detailed inspection of all printer components, including:

- Bearings and guide rails

- Adjustment knobs and levers

- PCB support system

- Stencil tensioning mechanism

Replace any components showing signs of excessive wear or damage.

Annual Maintenance

Comprehensive Overhaul

Once a year, consider performing a comprehensive overhaul of your SMT manual stencil printer. This might include:

1. Disassembling and cleaning all components.

2. Replacing worn parts, even if they're still functional.

3. Updating any software or firmware if applicable.

4. Performing a complete recalibration.

Professional Inspection

While regular in-house maintenance is crucial, it's also beneficial to have a professional technician inspect your printer annually. They can identify potential issues that might be missed and provide expert advice on maintaining your specific model.

Best Practices for Ongoing Maintenance

Proper Storage

When not in use, store your SMT manual stencil printer properly:

1. Cover the printer to protect it from dust and debris.

2. Store it in a clean, dry environment.

3. Ensure it's not exposed to extreme temperatures or humidity.

Training Staff

Ensure that all staff members who use the SMT manual stencil printer are properly trained in its operation and maintenance. This includes:

- Proper cleaning techniques

- How to identify potential issues

- When to seek professional assistance

Keeping Detailed Records

Maintain a log of all maintenance activities performed on your printer. This can help you:

1. Track the frequency of maintenance tasks

2. Identify recurring issues

3. Plan for future maintenance needs

Using Quality Materials

Always use high-quality materials in your SMT manual stencil printer:

1. Use the recommended solder paste for your specific applications.

2. Ensure your stencils are made from quality materials and properly manufactured.

3. Use only approved cleaning solvents and lubricants.

Troubleshooting Common Issues

Even with proper maintenance, issues can still arise. Here are some common problems and their potential solutions:

Solder Bridging

If you're experiencing solder bridging, check:

1. Stencil cleanliness and condition

2. Squeegee pressure and angle

3. Solder paste quality and consistency[3]

Insufficient Solder

For insufficient solder issues:

1. Verify the stencil apertures aren't blocked

2. Check squeegee pressure

3. Ensure the solder paste is at room temperature and properly mixed[3]

Print Misalignment

If prints are misaligned:

1. Check the printer's alignment settings

2. Verify the PCB support is adequate

3. Inspect fiducial marks on both the stencil and PCB[3]

Environmental Considerations

The environment in which your SMT manual stencil printer operates can significantly impact its performance and maintenance needs:

Temperature and Humidity Control

Maintain a consistent temperature and humidity level in your production area. Fluctuations can affect solder paste consistency and print quality.

Dust and Contaminant Control

Implement measures to minimize dust and other contaminants in the printing area:

1. Use air filtration systems

2. Regularly clean the workspace

3. Implement proper clothing and cleanliness protocols for staff

Conclusion

Proper maintenance of an SMT manual stencil printer is essential for ensuring consistent, high-quality PCB production. By implementing a comprehensive maintenance routine that includes daily, weekly, monthly, quarterly, and annual tasks, you can significantly extend the life of your equipment and improve your overall production efficiency.

Remember that maintenance is an ongoing process. Stay vigilant, address issues promptly, and don't hesitate to seek professional assistance when needed. With proper care, your SMT manual stencil printer will continue to be a reliable and valuable asset to your production process for years to come.

Frequently Asked Questions (FAQ)

1. How often should I clean my SMT manual stencil printer?

Daily cleaning is essential for maintaining print quality. Wipe down the stencil frame and other accessible parts daily, and perform a more thorough cleaning weekly. Always clean the printer after each use to prevent solder paste from drying and causing issues.

2. What type of lubricant should I use on my SMT manual stencil printer?

Use only resin and acid-free machine oil for lubricating your SMT manual stencil printer[1]. Avoid over-lubricating, as this can lead to unwanted residue accumulation. Always consult your printer's manual for specific lubrication recommendations.

3. How can I prevent solder bridging when using my SMT manual stencil printer?

To prevent solder bridging, ensure your stencil is clean and in good condition, check that squeegee pressure and angle are correct, and verify that your solder paste is of good quality and consistency[3]. Regular maintenance and proper setup of your printer are key to avoiding this issue.

4. When should I replace the squeegee blade on my SMT manual stencil printer?

Inspect your squeegee blade monthly for signs of wear or damage. Replace it if you notice uneven wear, nicks, or if you're experiencing inconsistent print quality. The frequency of replacement will depend on usage, but many operators find they need to replace squeegee blades every 3-6 months with regular use.

5. How important is the environment for my SMT manual stencil printer's performance?

The environment is crucial for optimal performance of your SMT manual stencil printer. Maintain consistent temperature and humidity levels in your production area, as fluctuations can affect solder paste consistency and print quality. Also, implement measures to control dust and other contaminants, as these can interfere with the precise operation of the printer.

Citations:

[1] https://www.pcbunlimited.com/pdf/SMT-Stencil-Printers-SD300_Manual.pdf

[2] https://www.raypcb.com/smt-stencil-cleaning-operation-content-and-precautions/

[3] https://www.surfacemountprocess.com/surface-mount-troubleshooting-guide.html

[4] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[5] https://neodenusa.com/smt-stencil-printers/

[6] https://islandsmt.com/wp-content/uploads/2017/05/8983_02-1.pdf

[7] https://www.pcbunlimited.com/pdf/SMT-Stencil-Printers-SD-360U_Manual.pdf

[8] https://smtnet.com/library/files/upload/SMT-troubleshooting-guide.pdf

[9] https://www.youtube.com/watch?v=sH7_QCVIJzI

[10] https://neodenusa.com/fp2636-frameless-stencils

[11] https://www.zjyingxing.com/info/what-are-the-cleaning-and-maintenance-methods-82799641.html