Content Menu

● Introduction

● Understanding Production Requirements

● Choosing the Right Equipment

● Designing the Line Layout

● Installation and Calibration

● Ensuring Environmental and Safety Standards

● Testing and Maintenance

● Conclusion

● FAQ

>> 1. What is an SMT production line?

>> 2. How do I choose the right equipment for my SMT line?

>> 3. What are the environmental requirements for an SMT workshop?

>> 4. Why is calibration important in SMT production?

>> 5. How can I maintain my SMT production line?

● Citations:

Introduction

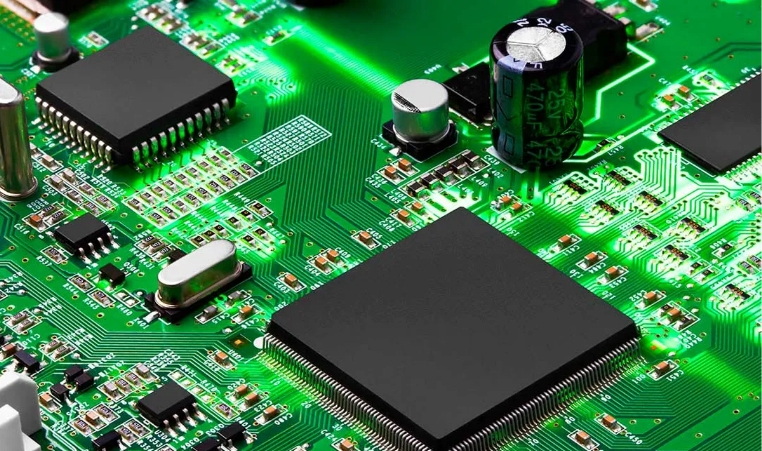

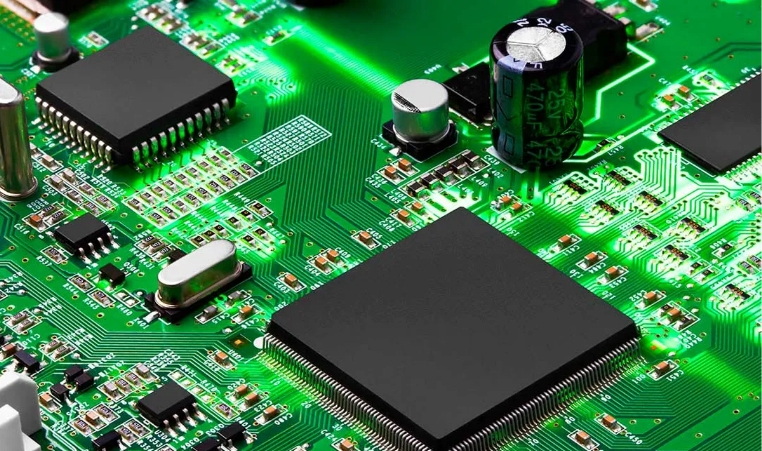

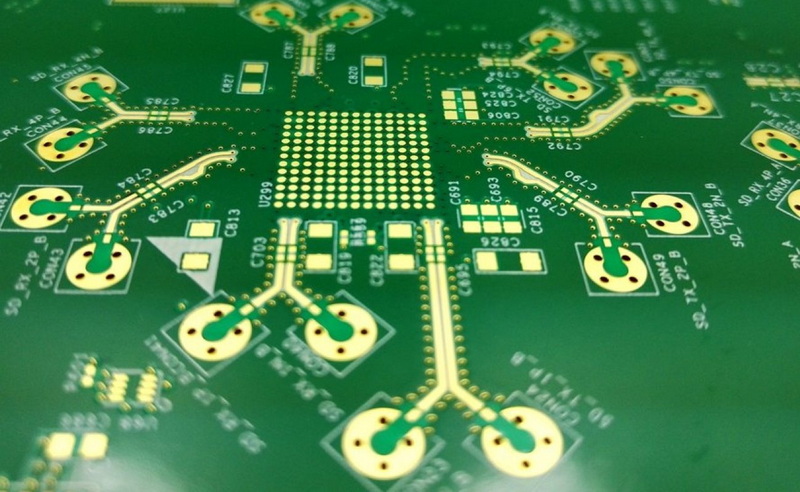

Surface Mount Technology (SMT) production lines are integral to the electronics manufacturing industry, enabling the efficient assembly of printed circuit boards (PCBs). The complexity and precision required in SMT processes necessitate careful planning to ensure a smooth installation. This article outlines the key steps involved in planning and executing an effective SMT production line installation, emphasizing the importance of each stage in achieving optimal performance and minimizing downtime.

Understanding Production Requirements

Before embarking on the installation of an SMT production line, it is vital to assess your specific production requirements. This involves:

- Determining Production Volume: Understand the scale of production needed, which will influence equipment choice and layout.

- Identifying Component Types: Different components require different handling and placement techniques. Knowing whether you will be working with standard or specialized components is crucial.

- Assessing Assembly Complexity: The complexity of the assemblies being produced will dictate the sophistication of the equipment required.

By thoroughly understanding these factors, manufacturers can make informed decisions that align with their operational goals.

Choosing the Right Equipment

The efficiency of an SMT line heavily relies on selecting appropriate equipment. Key machinery includes:

- Pick-and-Place Machines: These machines are essential for accurately placing components onto PCBs. They should be selected based on their speed, accuracy, and flexibility to handle various component sizes.

- Solder Paste Printers: Consistent application of solder paste is critical for reliable connections. Choose printers that offer precision and adaptability to different PCB designs.

- Reflow Ovens: These ovens are used to solder components onto PCBs by melting solder paste. Selecting a reflow oven with good temperature control and energy efficiency is vital.

- Inspection Systems: Automated Optical Inspection (AOI) and X-ray systems help ensure quality control by identifying defects in component placement and solder joints.

Ensuring that all equipment is compatible with your production needs and allows for future scalability is essential for long-term success.

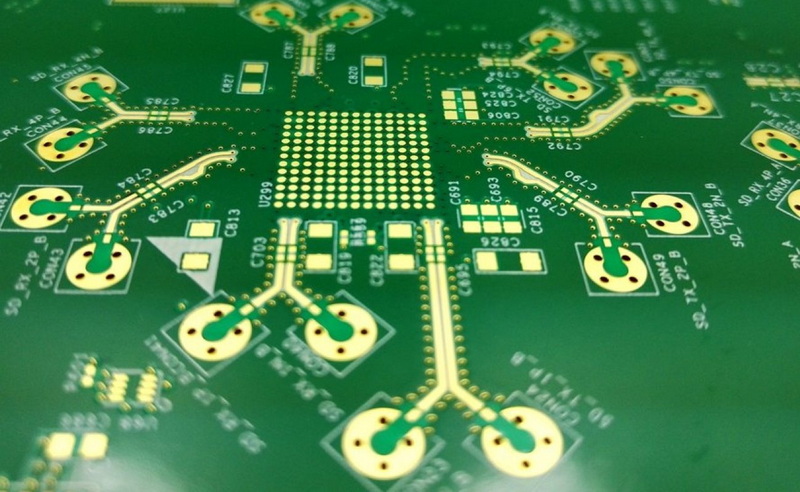

Designing the Line Layout

A well-thought-out layout is crucial for maximizing efficiency in an SMT production line. Considerations include:

- Material Flow: Arrange machines to facilitate a smooth flow of materials, minimizing bottlenecks and delays.

- Spacing: Adequate space between machines is necessary for maintenance activities and ease of access.

- Ergonomics: Workstations should be designed for operator comfort to enhance productivity and reduce fatigue-related errors.

An optimized layout not only improves efficiency but also enhances safety within the workspace.

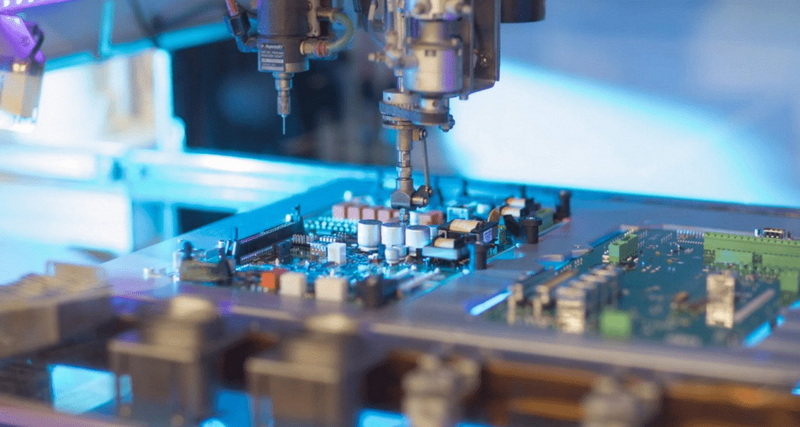

Installation and Calibration

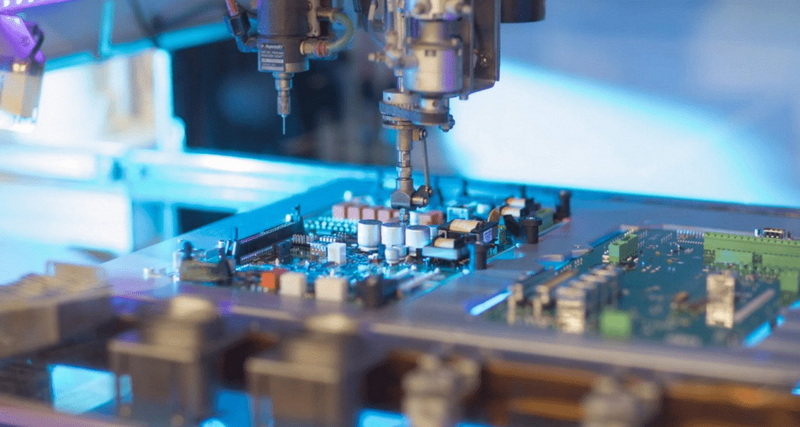

The installation phase must be executed with precision. Steps include:

1. Hiring a Professional Installation Team: Engaging skilled technicians ensures that equipment is installed according to manufacturer specifications, which is vital for optimal performance.

2. Debugging and Calibration: After installation, each machine must undergo debugging to resolve any issues. Calibration involves setting parameters such as placement accuracy, solder paste thickness, and reflow temperature profiles to meet production standards.

3. Conducting Performance Tests: Initial testing should be performed to verify that all equipment operates correctly before full-scale production begins.

Proper installation and calibration are critical for minimizing operational disruptions later on.

Ensuring Environmental and Safety Standards

The environment in which an SMT line operates significantly impacts its effectiveness. Key considerations include:

- Power Supply: Ensure that the facility has a stable power supply capable of meeting the demands of all machinery.

- Air Quality: Use oil-free compressed air systems and maintain proper ventilation to prevent contamination of components.

- Lighting: Adequate lighting levels (800–1200 LUX) are necessary for operators to perform tasks accurately without strain.

- Anti-static Measures: Implement electrostatic discharge (ESD) protection throughout the workspace to safeguard sensitive electronic components from damage.

Adhering to these environmental standards contributes to a safer workplace and enhances overall production quality.

Testing and Maintenance

Once the SMT line is operational, ongoing testing and maintenance are vital for sustaining performance:

- Initial Testing: Conduct thorough tests on initial batches to identify any discrepancies in component placement or soldering quality.

- Regular Maintenance Schedule: Establish a routine maintenance plan that includes cleaning, lubrication, calibration, and replacement of worn parts. Regular maintenance helps prevent unexpected downtimes and extends equipment lifespan.

Continuous monitoring of performance metrics will help identify areas for improvement over time, ensuring sustained efficiency in operations.

Conclusion

Planning a smooth SMT production line installation process involves a comprehensive approach that encompasses understanding production requirements, selecting appropriate equipment, designing an efficient layout, ensuring proper installation and calibration, maintaining environmental standards, and implementing ongoing testing and maintenance protocols. By following these steps meticulously, manufacturers can establish a highly efficient SMT production line that meets their operational goals while minimizing potential disruptions.

FAQ

1. What is an SMT production line?

An SMT production line is a series of machines and processes used to assemble electronic components onto printed circuit boards using surface mount technology.

2. How do I choose the right equipment for my SMT line?

Choosing the right equipment involves assessing your production requirements, understanding component types, and considering scalability options. Essential equipment includes pick-and-place machines, solder paste printers, reflow ovens, and inspection systems.

3. What are the environmental requirements for an SMT workshop?

Key environmental requirements include stable power supply, proper ventilation systems, optimal lighting levels (800–1200 LUX), cleanliness standards, and anti-static measures throughout the workspace.

4. Why is calibration important in SMT production?

Calibration ensures that all machines operate at their specified parameters, which minimizes errors in component placement and soldering quality—critical factors in maintaining high product standards.

5. How can I maintain my SMT production line?

Implementing a regular maintenance schedule that includes cleaning, lubrication, calibration checks, and monitoring performance metrics will help sustain efficiency and prevent unexpected downtimes.

Citations:

[1] https://smtnet.com/news/index.cfm?fuseaction=view_news&company_id=58069&news_id=30605

[2] https://www.smtfactory.com/Essential-Steps-for-SMT-Production-Line-Setup-id49117676.html

[3] https://www.pcbonline.com/blog/smt-manufacturing-process.html

[4] https://www.smtfactory.com/Perfecting-Your-SMT-Line-Layout-for-Efficiency-id47017676.html

[5] https://m.smt11.com/blog/News/SMT-Workshop-Production-Environment-Requirements-5145.html

[6] https://www.viasion.com/blog/what-are-the-steps-in-smt-assembly-process/

[7] https://faroads.com/start-smt-line-guide-2024/

[8] https://alimco.in/WriteReadData/UserFiles/file/Specification3MR3.pdf

[9] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[10] https://www.viasion.com/blog/smt-manufacturing-process-step-by-step-guide/

[11] https://es.hayawin.com/resources/how-to-optimize-pcb-design-for-smt-assembly-process-flow.html

[12] https://www.protoexpress.com/kb/smt-assembly/

[13] https://resources.pcb.cadence.com/blog/2020-how-to-optimize-pcb-design-for-smt-assembly-process-flow

[14] https://asselems.com/en/best-practices-in-smt-assembly

[15] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[16] https://www.linkedin.com/pulse/ins-outs-setting-up-smt-factory-prototype-pcb-assembly-yljdc

[17] https://www.youtube.com/watch?v=xBSndJnQdRw