Content Menu

● Introduction

● Understanding Wholesale SMT Manufacturing

● Key Strategies for Optimization

>> 1. Invest in Advanced Machinery

>> 2. Implement Lean Manufacturing Principles

>> 3. Utilize Data Analytics

>> 4. Embrace Industry 4.0 Technologies

>> 5. Focus on Employee Training and Engagement

● Streamlining the Production Process

>> 1. Optimize Layout and Workflow

>> 2. Enhance Quality Control Measures

>> 3. Reduce Changeover Times

>> 4. Foster Supplier Relationships

>> 5. Monitor Industry Trends

● Conclusion

● FAQ

>> 1. What is wholesale SMT manufacturing?

>> 2. How can I reduce waste in my SMT manufacturing line?

>> 3. What role does data analytics play in optimizing SMT production?

>> 4. How can employee training impact SMT manufacturing efficiency?

>> 5. What technologies are essential for Industry 4.0 in SMT manufacturing?

Introduction

In the fast-paced world of electronics manufacturing, optimizing your wholesale SMT (Surface Mount Technology) manufacturing line is crucial for enhancing productivity and ensuring high-quality output. This article delves into various strategies and best practices that can help manufacturers streamline their processes, reduce waste, and ultimately improve their bottom line. As the demand for electronic devices continues to rise, the need for efficient and effective manufacturing processes becomes even more critical.

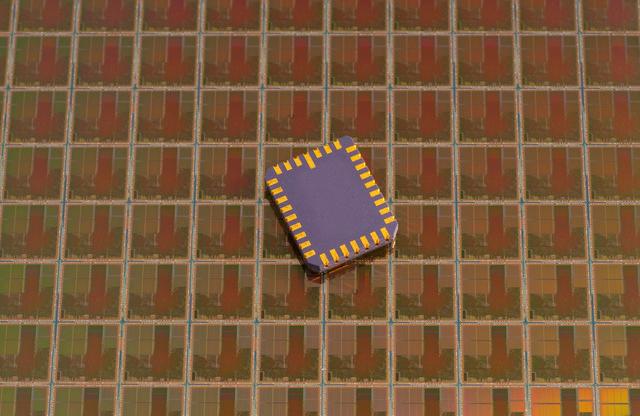

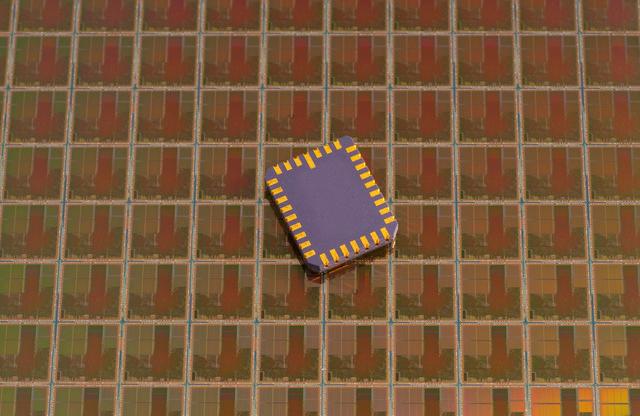

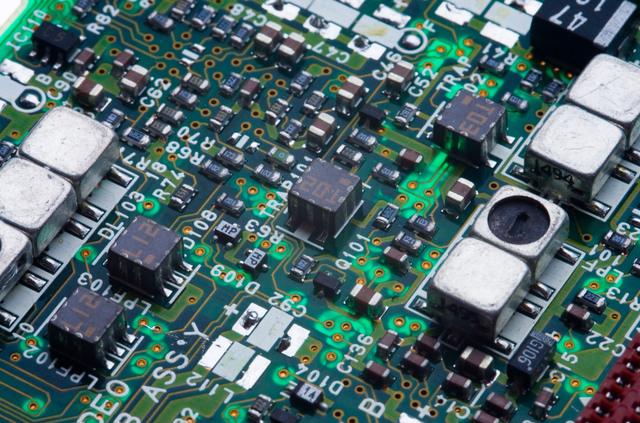

Understanding Wholesale SMT Manufacturing

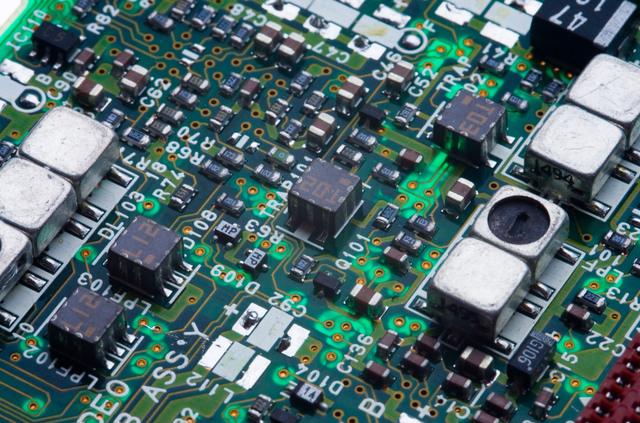

Wholesale SMT manufacturing involves the mass production of electronic components mounted directly onto the surface of printed circuit boards (PCBs). This method is favored for its efficiency and ability to produce compact, high-performance electronic devices. However, to maximize the benefits of wholesale SMT manufacturing, companies must focus on optimizing their production lines. The complexity of modern electronics requires manufacturers to adopt innovative approaches to stay competitive.

Key Strategies for Optimization

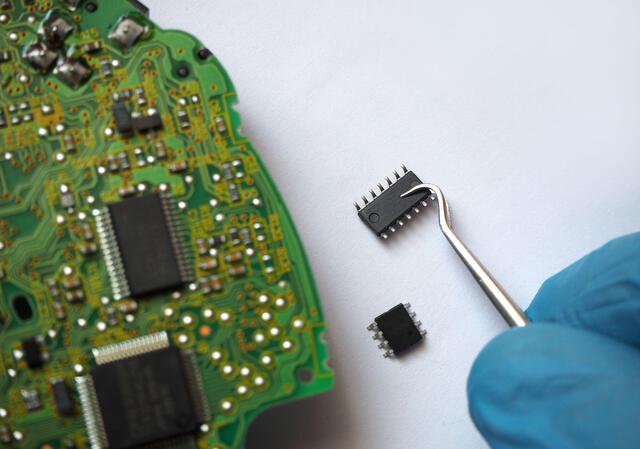

1. Invest in Advanced Machinery

Investing in state-of-the-art machinery is one of the most effective ways to enhance the efficiency of your wholesale SMT manufacturing line. Modern machines come equipped with advanced features such as:

High-speed placement: Machines that can place components at a faster rate reduce cycle times, allowing for higher output.

Automated inspection systems: These systems help identify defects early in the production process, minimizing rework and waste. Automated Optical Inspection (AOI) systems can detect misalignments, soldering issues, and other defects in real-time.

Flexible configurations: Machines that can easily adapt to different product types allow for greater versatility in production. This flexibility is essential in a market where product lifecycles are short and customer demands are constantly changing.

2. Implement Lean Manufacturing Principles

Lean manufacturing focuses on minimizing waste while maximizing productivity. Key principles include:

Value Stream Mapping: Analyze the flow of materials and information to identify bottlenecks and areas for improvement. This visual representation helps teams understand the entire process and pinpoint inefficiencies.

Just-In-Time (JIT) Production: Produce only what is needed, when it is needed, to reduce inventory costs and waste. JIT can significantly lower holding costs and improve cash flow.

Continuous Improvement (Kaizen): Foster a culture of ongoing improvement where employees are encouraged to suggest enhancements to processes. Regularly scheduled Kaizen events can lead to significant improvements over time.

3. Utilize Data Analytics

Data analytics can provide valuable insights into your manufacturing processes. By collecting and analyzing data from your SMT line, you can:

Monitor performance metrics: Track key performance indicators (KPIs) such as cycle time, yield rates, and equipment efficiency. This data can help identify trends and areas needing attention.

Predict maintenance needs: Use predictive analytics to anticipate equipment failures and schedule maintenance before issues arise. This proactive approach can reduce downtime and extend the lifespan of your machinery.

Optimize production schedules: Analyze historical data to improve scheduling and resource allocation. By understanding peak production times and resource availability, manufacturers can better plan their operations.

4. Embrace Industry 4.0 Technologies

The fourth industrial revolution, or Industry 4.0, introduces smart manufacturing technologies that can significantly enhance your wholesale SMT manufacturing line. Key technologies include:

IoT (Internet of Things): Connect machines and devices to the internet to enable real-time monitoring and control. IoT devices can provide insights into machine performance and environmental conditions, allowing for better decision-making.

Artificial Intelligence (AI): Implement AI algorithms to optimize production processes and improve decision-making. AI can analyze vast amounts of data to identify patterns and suggest improvements.

Robotics: Use collaborative robots (cobots) to assist human workers in repetitive tasks, increasing efficiency and reducing fatigue. Cobots can work alongside humans, enhancing productivity without replacing the workforce.

5. Focus on Employee Training and Engagement

A well-trained workforce is essential for optimizing your manufacturing line. Consider the following:

Regular training programs: Provide ongoing training to ensure employees are familiar with the latest technologies and best practices. Training should cover both technical skills and soft skills, such as teamwork and communication.

Cross-training: Encourage employees to learn multiple roles within the manufacturing process to enhance flexibility and adaptability. Cross-trained employees can fill in for one another, reducing downtime during absences.

Employee engagement: Foster a positive work environment where employees feel valued and motivated to contribute to process improvements. Engaged employees are more likely to take ownership of their work and suggest innovative solutions.

Streamlining the Production Process

1. Optimize Layout and Workflow

The physical layout of your manufacturing line can significantly impact efficiency. Consider the following:

Flow optimization: Arrange equipment and workstations to minimize movement and reduce cycle times. A well-organized layout can lead to smoother operations and less wasted time.

Buffer zones: Implement buffer zones between different stages of production to prevent bottlenecks and ensure a smooth flow of materials. Buffer zones can help manage variations in production rates and maintain a steady workflow.

Visual management: Use visual cues such as color-coded labels and signage to enhance communication and organization on the shop floor. Visual management tools can help employees quickly identify issues and understand their tasks.

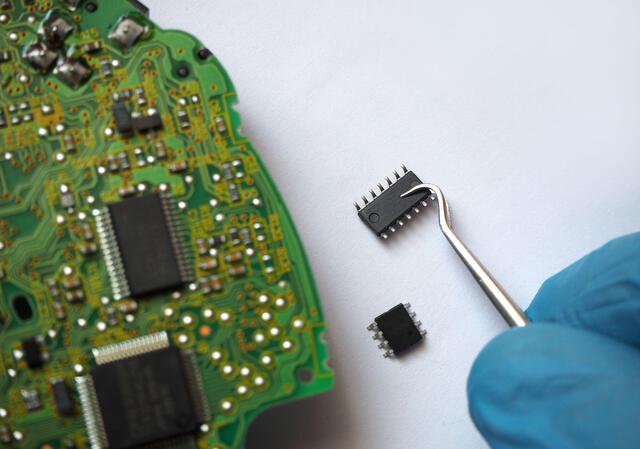

2. Enhance Quality Control Measures

Quality control is critical in wholesale SMT manufacturing. Implement robust quality control measures to ensure consistent output:

Automated inspection: Use automated optical inspection (AOI) systems to detect defects in real-time. These systems can significantly reduce the time spent on manual inspections and improve accuracy.

Statistical process control (SPC): Monitor production processes using statistical methods to identify variations and implement corrective actions. SPC can help maintain consistent quality and reduce variability in production.

Feedback loops: Establish feedback mechanisms to quickly address quality issues and prevent recurrence. Regularly review quality data and involve employees in problem-solving discussions.

3. Reduce Changeover Times

Minimizing changeover times between production runs can significantly enhance efficiency. Strategies include:

Standardized procedures: Develop standardized work instructions for changeovers to streamline the process. Clear instructions can reduce confusion and errors during transitions.

Pre-setup: Prepare tools and materials in advance to reduce downtime during changeovers. Having everything ready before a changeover can significantly speed up the process.

Quick-change tooling: Invest in tooling that allows for rapid changes between different product types. Quick-change tooling can minimize the time spent on setup and increase overall production capacity.

4. Foster Supplier Relationships

Strong relationships with suppliers can enhance the efficiency of your wholesale SMT manufacturing line. Consider the following:

Collaborative planning: Work closely with suppliers to align production schedules and ensure timely delivery of materials. Collaborative planning can help prevent delays and improve overall supply chain efficiency.

Quality assurance: Establish quality standards for suppliers and conduct regular audits to ensure compliance. Maintaining high-quality standards throughout the supply chain is essential for consistent output.

Feedback and communication: Maintain open lines of communication with suppliers to address issues quickly and collaboratively. Regular feedback can help suppliers improve their processes and better meet your needs.

5. Monitor Industry Trends

Staying informed about industry trends and advancements can help you maintain a competitive edge in wholesale SMT manufacturing. Key trends to watch include:

Sustainability: Increasingly, manufacturers are focusing on sustainable practices, such as reducing waste and energy consumption. Implementing eco-friendly practices can enhance your brand reputation and appeal to environmentally conscious customers.

Customization: The demand for customized electronic products is on the rise. Being able to quickly adapt your manufacturing processes to accommodate custom orders can set you apart from competitors.

Globalization: As the market becomes more globalized, manufacturers must be prepared to navigate international regulations and supply chain challenges. Understanding global trends can help you make informed decisions about sourcing and production.

Conclusion

Optimizing your wholesale SMT manufacturing line is a multifaceted endeavor that requires a combination of advanced technology, lean principles, data analytics, and employee engagement. By implementing these strategies, manufacturers can enhance productivity, reduce waste, and improve the overall quality of their output. As the electronics industry continues to evolve, staying ahead of the curve through continuous improvement and innovation will be key to success. The journey toward optimization is ongoing, and manufacturers must remain adaptable to thrive in a competitive landscape.

FAQ

1. What is wholesale SMT manufacturing?

Wholesale SMT manufacturing refers to the mass production of electronic components that are mounted directly onto the surface of printed circuit boards (PCBs). This method is known for its efficiency and ability to produce compact electronic devices.

2. How can I reduce waste in my SMT manufacturing line?

To reduce waste, implement lean manufacturing principles, such as Just-In-Time (JIT) production, value stream mapping, and continuous.

3. What role does data analytics play in optimizing SMT production?

Data analytics allows manufacturers to monitor performance metrics, predict maintenance needs, and optimize production schedules. By analyzing data, companies can identify areas for improvement and make informed decisions to enhance efficiency.

4. How can employee training impact SMT manufacturing efficiency?

Well-trained employees are essential for optimizing manufacturing processes. Regular training programs, cross-training, and fostering employee engagement can lead to a more skilled workforce that is better equipped to identify and implement improvements.

5. What technologies are essential for Industry 4.0 in SMT manufacturing?

Key technologies for Industry 4.0 in SMT manufacturing include the Internet of Things (IoT), artificial intelligence (AI), and robotics. These technologies enable real-time monitoring, data-driven decision-making, and increased automation, leading to enhanced efficiency.