Content Menu

● Understanding Surface Mount Technology in PCB Assembly Production

● Key Strategies to Optimize Your SMT Line for High-Speed PCB Assembly

>> 1. Optimize PCB Design for SMT Assembly

>> 2. Balance Load Distribution Across SMT Machines

>> 3. Optimize Equipment and Program Settings

>> 4. Minimize Component Changeovers and Nozzle Swaps

>> 5. Employ Advanced Automation and Inline Inspection

>> 6. Streamline the SMT Process Flow

>> 7. Invest in Skilled Workforce Training

>> 8. Utilize Design for Manufacturing (DFM) Guidelines

>> 9. Maintain Rigorous Preventive Maintenance Programs

>> 10. Implement Real-Time Production Monitoring and Analytics

● Benefits of an Optimized SMT Line in PCB Assembly Production

● Conclusion

● FAQ

>> 1. What is the role of PCB design in optimizing SMT assembly?

>> 2. How does balancing load distribution affect SMT line speed?

>> 3. Why is minimizing component changeovers important in SMT production?

>> 4. What automation technologies enhance SMT line optimization?

>> 5. How does operator training influence SMT line performance?

Surface Mount Technology (SMT) has revolutionized the way printed circuit boards (PCBs) are assembled, enabling faster production, higher component density, and improved reliability. To fully leverage the benefits of SMT in PCB assembly production, optimizing your SMT line is essential. This article explores comprehensive strategies and best practices to optimize your SMT line for high-speed PCB assembly, ensuring efficiency, quality, and cost-effectiveness.

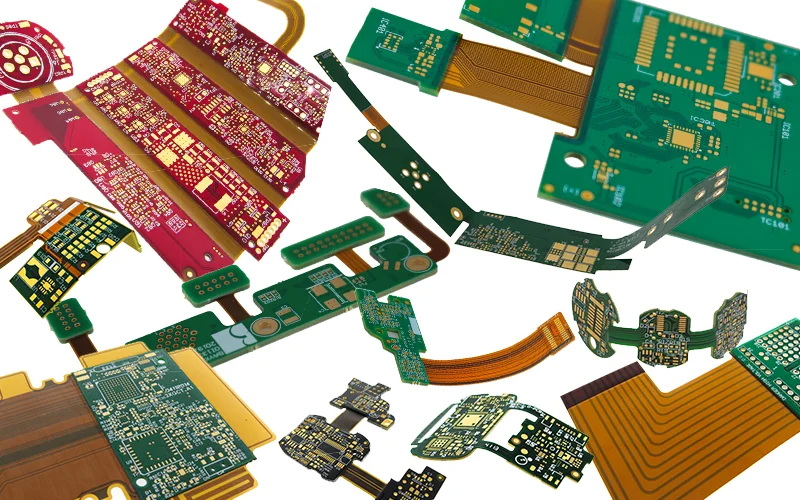

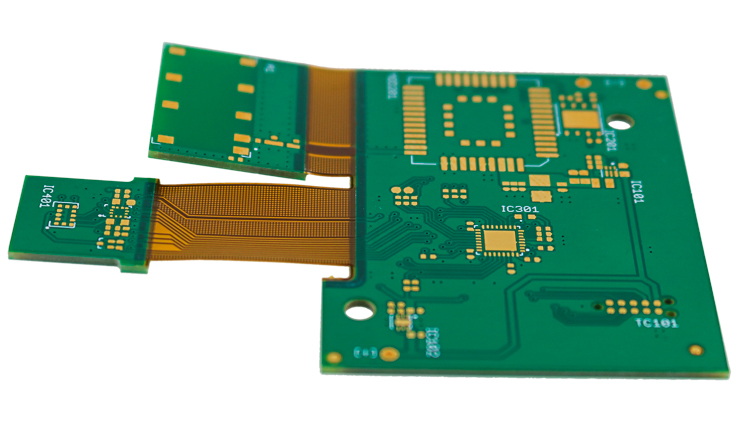

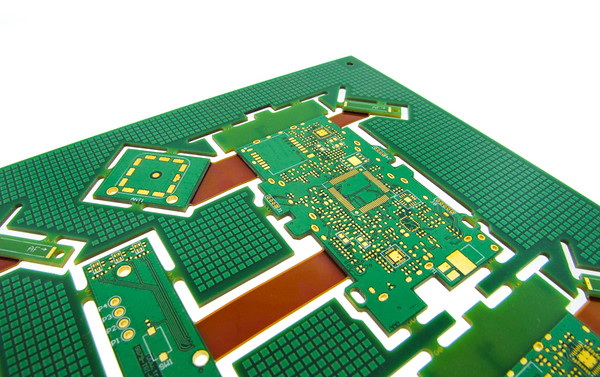

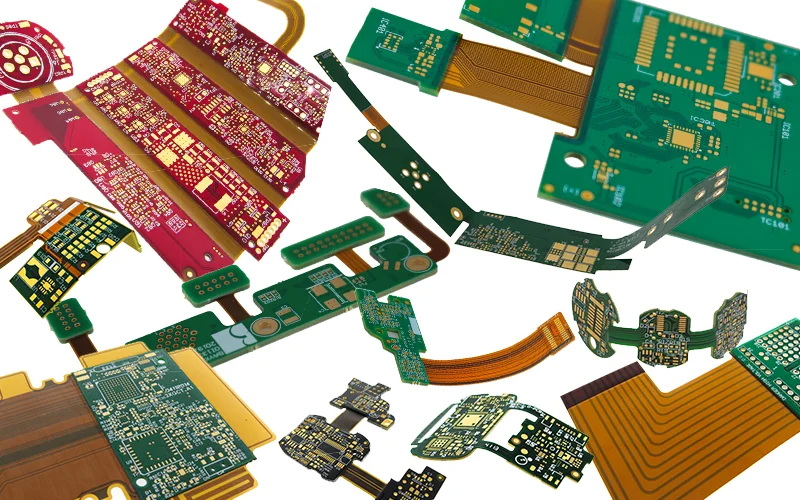

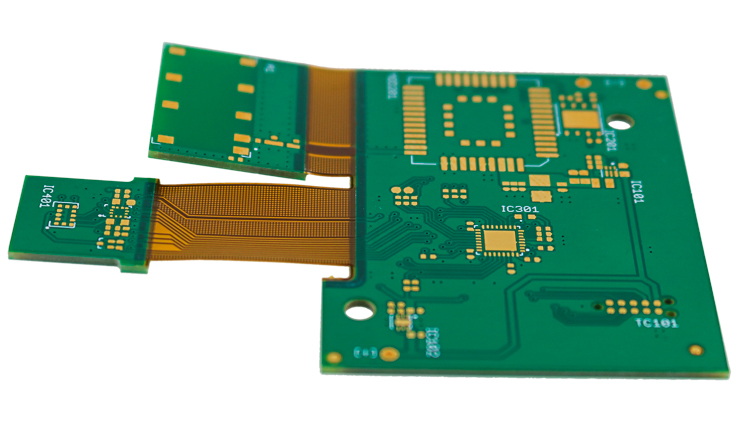

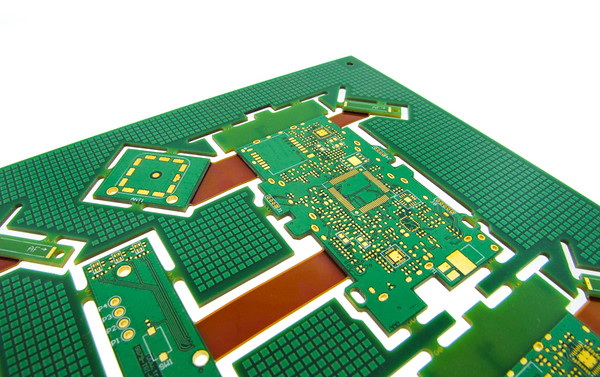

Understanding Surface Mount Technology in PCB Assembly Production

Surface Mount Technology involves mounting electronic components directly onto the surface of a PCB rather than inserting component leads through holes. This method supports miniaturization, higher circuit complexity, and faster manufacturing cycles. The SMT line typically includes equipment such as solder paste printers, pick-and-place machines, reflow ovens, and inspection systems, all orchestrated to achieve streamlined PCB assembly production.

Optimizing the SMT line means enhancing each step of this process-from design to final inspection-to maximize throughput, minimize defects, and reduce production costs.

Key Strategies to Optimize Your SMT Line for High-Speed PCB Assembly

1. Optimize PCB Design for SMT Assembly

The foundation of a high-speed SMT line is a PCB design tailored for surface mount assembly. Key design considerations include:

- Use Proper Footprints: Accurate footprints that comply with manufacturer and IPC standards ensure components fit precisely and solder joints form correctly.

- Logical Component Placement: Group related components closely and maintain consistent orientation to simplify placement and reduce errors.

- Single-Sided SMT Components: Whenever possible, place all SMT components on one side of the PCB to streamline assembly and reduce handling time.

- Adequate Spacing and Test Points: Maintain proper spacing to facilitate soldering and inspection, and include test points for easy troubleshooting post-assembly.

These design optimizations reduce assembly complexity and improve the reliability of the SMT process, enabling faster and more consistent production cycles.

2. Balance Load Distribution Across SMT Machines

In multi-machine SMT lines, balancing the component mounting workload evenly across all pick-and-place machines prevents bottlenecks. Assign components so that each machine's mounting time is approximately equal, which maximizes line throughput and avoids idle equipment time.

Balancing also involves strategic feeder setup and intelligent programming to ensure that no machine is overwhelmed with complex or high-volume components, which could slow down the entire line.

3. Optimize Equipment and Program Settings

Each SMT machine has a maximum speed capability, but real-world performance depends on optimized numerical control programs and machine parameters. Fine-tuning these settings ensures the pick-and-place heads operate at peak efficiency, reducing cycle times without compromising placement accuracy.

Key parameters to optimize include:

- Placement Speed: Adjusting the speed of the pick-and-place head movement.

- Acceleration and Deceleration: Smooth motion profiles prevent mechanical stress and improve accuracy.

- Nozzle Change Timing: Minimizing the time required to swap nozzles for different component sizes.

- Vision System Settings: Enhancing component recognition and alignment precision.

Regularly updating machine software and firmware also helps maintain optimal performance.

4. Minimize Component Changeovers and Nozzle Swaps

Component changeovers and nozzle swaps slow down the SMT line. Strategies to reduce these include:

- Grouping similar components together on feeders.

- Using standardized component brands and models where possible.

- Positioning high-frequency pick components close to the PCB placement area to minimize head travel distance.

- Ensuring each pick-and-place cycle fully loads the mounting heads with components.

Additionally, planning production runs to minimize the number of unique components per batch can significantly reduce changeover frequency.

5. Employ Advanced Automation and Inline Inspection

Modern SMT lines benefit greatly from automation and real-time quality control, such as:

- Automated Optical Inspection (AOI): Pre- and post-reflow AOI detects missing, misaligned, or defective components early.

- Inline Component Verification: Confirms part numbers and orientation before placement, preventing common defects.

- Force Sensors and Vision Alignment: Enhance placement precision by adjusting force and position dynamically.

Incorporating machine learning and artificial intelligence into inspection systems can further improve defect detection rates and reduce false positives, enabling faster throughput without sacrificing quality.

6. Streamline the SMT Process Flow

A smooth SMT line requires well-defined, standardized procedures for each stage, including:

- Solder Paste Application: Using precise stencils and automated printers to ensure consistent paste volume and placement.

- Efficient Pick-and-Place Operations: Optimizing component feeders and placement sequences to reduce cycle time.

- Controlled Reflow Soldering: Developing and maintaining optimized thermal profiles tailored to the PCB and component specifications.

- Post-Reflow Cleaning and Inspection: Removing flux residues and verifying solder joint quality.

Implementing lean manufacturing principles, such as value stream mapping and continuous improvement cycles, can identify and eliminate process inefficiencies.

7. Invest in Skilled Workforce Training

Operator expertise directly impacts SMT line performance. Training programs should cover equipment operation, troubleshooting, maintenance, and quality control techniques. Skilled operators can quickly identify and resolve issues, keeping the line running at high speed and quality.

Cross-training employees to handle multiple roles increases flexibility and reduces downtime caused by absenteeism or shift changes. Regular refresher courses and certification programs help maintain a high skill level across the workforce.

8. Utilize Design for Manufacturing (DFM) Guidelines

Following DFM guidelines provided by your SMT assembly house helps avoid design pitfalls that slow production or cause defects. These guidelines cover component spacing, orientation, pad design, and other factors critical to smooth assembly.

Collaborating closely with your manufacturing partner during the design phase ensures that the PCB layout is optimized for the specific SMT line capabilities, reducing the need for costly rework or process adjustments.

9. Maintain Rigorous Preventive Maintenance Programs

Regular preventive maintenance of SMT line equipment prevents unexpected breakdowns that can halt production. Scheduled cleaning, calibration, and part replacement keep machines running at peak performance.

Monitoring equipment health through sensors and predictive maintenance software allows early detection of potential issues, minimizing downtime and repair costs.

10. Implement Real-Time Production Monitoring and Analytics

Utilizing Manufacturing Execution Systems (MES) and real-time data analytics provides visibility into SMT line performance. Tracking key performance indicators such as cycle time, yield, and downtime enables quick identification of bottlenecks and quality issues.

Data-driven decision-making supports continuous improvement initiatives and helps optimize resource allocation for maximum efficiency.

Benefits of an Optimized SMT Line in PCB Assembly Production

Optimizing your SMT line yields multiple advantages:

- Increased Throughput: Balanced workloads and minimized changeovers enable faster production cycles.

- Higher First-Pass Yield: Inline inspection and process control reduce defects.

- Cost Reduction: Efficient use of equipment and labor lowers operational costs.

- Improved Product Quality: Precise placement and soldering enhance reliability.

- Flexibility: Optimized lines can adapt quickly to design changes or new product introductions.

- Enhanced Traceability: Integrated data systems improve tracking and accountability throughout production.

These benefits combine to provide a competitive edge in the fast-paced electronics manufacturing industry.

Conclusion

Optimizing your SMT line for high-speed PCB assembly production is a multifaceted endeavor involving design optimization, equipment tuning, process streamlining, automation adoption, workforce training, and data-driven management. By implementing these strategies, manufacturers can achieve faster production rates, higher quality output, and lower costs, meeting the demands of today's competitive electronics market. The synergy between surface mount technology SMT line in PCB assembly production and these optimization practices forms the backbone of modern, efficient electronics manufacturing.

Continuous evaluation and adaptation of your SMT line processes ensure sustained performance improvements and readiness for future technological advancements.

FAQ

1. What is the role of PCB design in optimizing SMT assembly?

PCB design directly impacts SMT assembly efficiency. Proper footprints, logical component placement, consistent orientation, and adherence to DFM guidelines reduce assembly errors and speed up production.

2. How does balancing load distribution affect SMT line speed?

Balancing load distribution ensures that no single pick-and-place machine becomes a bottleneck. Equalizing mounting times across machines maximizes overall line throughput and prevents idle time.

3. Why is minimizing component changeovers important in SMT production?

Component changeovers and nozzle swaps consume valuable time and reduce line speed. Minimizing these by grouping similar components and standardizing parts improves cycle times and efficiency.

4. What automation technologies enhance SMT line optimization?

Automated Optical Inspection (AOI), inline component verification, force sensors, and vision alignment systems improve placement accuracy, detect defects early, and increase first-pass yield.

5. How does operator training influence SMT line performance?

Well-trained operators can efficiently run equipment, troubleshoot issues, and maintain quality control, reducing downtime and ensuring smooth, high-speed SMT production.